Table of Contents

Add a header to begin generating the table of contents

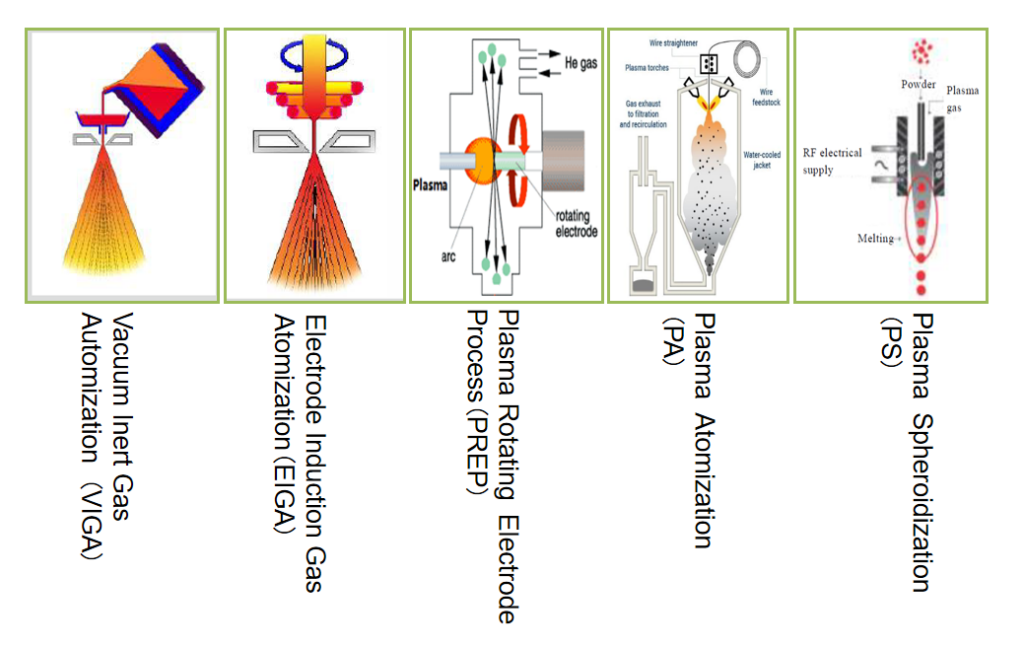

We all know that there are few typical technologies to preparation the spherical metallic powder, they are Gas Automization (GA), Plasma Rotating Electrode Process(prep),Plasma Atomization(PA), Plasma Spheroidization (PS).

4 best spherical metallic powder preparation techniques:

Gas Automization(GA)

Aerosolised powder production is the use of high speed airflow to break up liquid metal streams into small droplets, which are then rapidly condensed to produce a shaped powder.

Aerosolisation has become the most important method for the preparation of fine spherical metal and alloy powders, and according to statistics, the production of metal powders by atomisation has reached 80% of the world’s total powder production. There are many different types of metal powders that can be industrially produced by atomisation, including almost all common metal and alloy systems, except for refractory metals such as tungsten and molybdenum and very reactive metals.

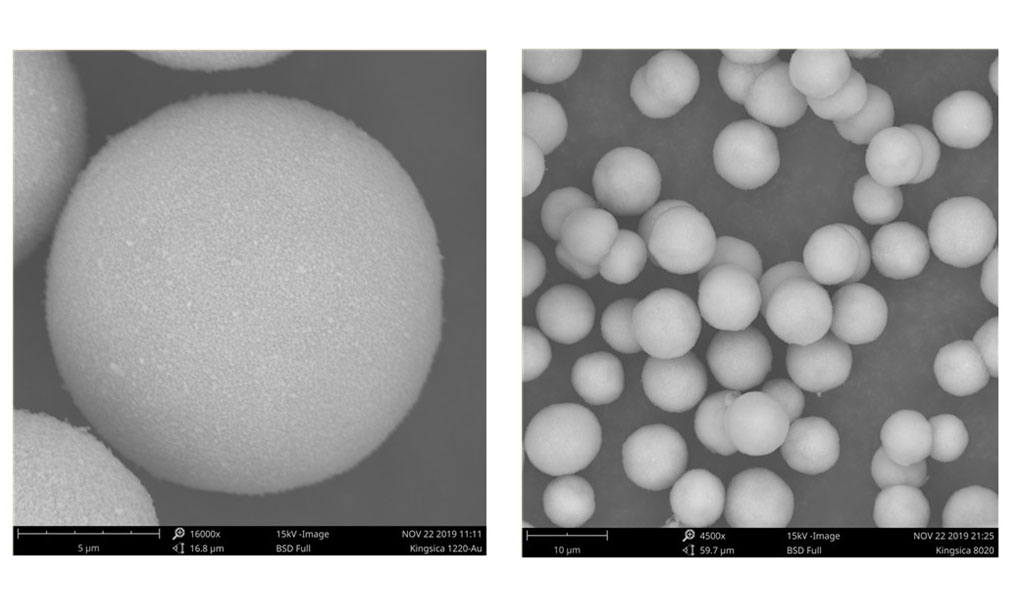

This method produces metal powders with fine particle size (<150μm), good sphericity, high purity, low oxygen content, fast forming speed and low environmental pollution, and is the mainstream method for the preparation of metal powders for powder metallurgy, metal injection moulding and metal additive manufacturing.

Plasma Atomization(PA)

Plasma Atomization (PA) is the process of feeding metal raw materials (generally wire) at a certain rate through a special feeding mechanism. The raw materials are rapidly dispersed into ultra-fine droplets or aerosols by focused plasma jets generated by multiple symmetrically mounted plasma torches at the top of the furnace, and heat exchange with inert gases for cooling during the deposition process, resulting in a near spherical powder.

Using plasma atomisation technology, titanium alloy powders with small particle size, high purity and good flowability can be obtained. In contrast to conventional powder making techniques, plasma atomisation does not use the commonly used water or gaseous media streams to crush the liquid stream, but rather a hot plasma, which avoids the problem of poor sphericity of the molten droplets due to rapid cooling. In addition, this method does not require the use of conventional ceramic crucibles and is suitable for the powdering of all metallic materials that can be melted, especially highly reactive metallic materials containing titanium that cause contamination of the crucible.

Plasma Rotating Electrode Process(PREP)

The plasma rotating electrode atomisation method is one of the more ideal ways to prepare highly pure and dense spherical powder materials. The mechanism can be simply described as follows: the plasma beam is the heat source, the metal or alloy is the self-consuming electrode, the electrode ends are melted into a liquid film by the coaxial plasma, and the spherical powder is obtained under the action of its own high-speed centrifugal force and surface tension.

Plasma rotary atomisation powder making characteristics: (1) powder particle size distribution narrow, particle size more controllable, high sphericity gas atomisation method prepared alloy powder particle size is mainly concentrated in the range of 0-150μm; plasma rotary electrode atomisation method prepared alloy powder particle size is mainly concentrated in 20-200μm.(2) powder basically does not exist hollow powder, satellite powder (3) powder ceramic inclusions less, higher cleanliness (4 ) powder oxygen increment less without alloy melting process; no high-speed inert airflow to break the liquid stream; aerosolized powder oxygen increment in more than 100ppm, plasma rotary atomization powder oxygen increment can be controlled in less than 50ppm. The advantages of plasma rotary atomization powder manufacturing technology in additive manufacturing 1) powder solid, the printing process will not exist in the hollow ball brought about by air gaps, involvement and precipitation pores, cracks and other defects; 2) powder particle size, narrow particle size distribution, printing process less/no spherification, agglomeration phenomenon, higher surface finish, and the consistency and uniformity of printing can be fully guaranteed.

Plasma Spheroidization (PS)

The plasma spheroidisation technique uses the high temperature characteristics of the plasma to rapidly heat and melt irregularly shaped powder particles fed into the plasma, which rapidly solidify under the combined effect of surface tension and extremely high temperature gradients to form spherical powders. Plasma has the advantages of high temperature (~104 K), large plasma torch volume, high energy density, no electrode contamination, fast heat transfer and cooling, etc. It is a good way to produce high quality spherical powders with uniform components, high sphericity and good flowability, especially in the preparation of rare refractory metals, oxides, nitrides, carbides and other spherical powders.

The above is a brief introduction to the principles and characteristics of several types of 3D printing powder making equipment. In summary, atomised powder making technology, especially VIGA and EIGA, is currently the most used powder making technology, but it is still limited by the purity and sphericity of the powder compared to several other technologies.

When PREP, PA and PS technologies are compared, PA has more satellite powder, PS is limited by the raw material, and PREP has a relatively low fines yield compared to the other two.

Additional FAQs on Spherical Metallic Powder

1) Which method yields the highest sphericity and cleanliness for reactive alloys like Ti or Ni superalloys?

PREP generally delivers the highest sphericity and lowest inclusion/oxygen pickup because there is no crucible and minimal melt exposure; EIGA/PA are also strong for reactivity control.

2) How do I choose between Gas Atomization (GA) and Plasma Atomization (PA) for AM powders?

Choose GA for broad alloy coverage and cost efficiency, especially steels and Ni alloys; choose PA for finer PSD, higher sphericity, and lower oxygen in Ti/CoCr, where flowability and purity are critical.

3) When is Plasma Spheroidization (PS) preferable?

PS is ideal for converting irregular feedstocks (e.g., milled, hydride–dehydride Ti, refractory/ceramic powders) to high-sphericity particles, improving flowability without fully remelting large ingots.

4) What PSD ranges are typical for LPBF vs. L-DED from each method?

LPBF: D10–D90 ≈ 15–45 μm (PA, PREP, fine GA, PS-refined). L-DED: 45–150 μm (coarser GA/PREP cuts). Binder jetting often prefers 5–25 μm with tight tails.

5) How does satellite powder formation impact print quality and how can it be minimized?

Satellites reduce flowability and increase porosity risk. Mitigate via optimized atomization pressure/temperature, nozzle design, post-process classification/sieving, and PS reconditioning for GA/PA lots.

2025 Industry Trends in Spherical Metallic Powder

- Multi-laser AM drives tighter PSD control and lower oxygen specs for GA and PA powders.

- Blue/green laser compatibility pushes demand for high-reflectivity Cu/Al spherical metallic powder with enhanced sphericity and oxide control (e.g., EIGA + PS).

- Sustainability: Powder genealogy, higher recycle blend-back with inline O2/H2O monitoring, and EPDs requested by aerospace/medical OEMs.

- Hybrid routes: GA base powder reconditioned by PS to reduce satellites and narrow PSD; PREP used for premium lots where defect tolerance is minimal.

- Cost-down focus: Improved yield in PREP (adaptive electrode control) and PA (torch optimization) narrowing price gap with GA for Ti-6Al-4V.

| 2025 Metric (Spherical Metallic Powder) | Typical Range/Value | Relevance | Source |

|---|---|---|---|

| LPBF PSD target (D10–D90) | 15–45 μm | Flowability and layer quality | ISO/ASTM 52907 |

| Tap density of premium Ti-6Al-4V PA/PREP powders | 2.5–2.9 g/cm³ | Packing, density | OEM datasheets |

| Oxygen spec (Ti AM-grade) | ≤0.13 wt% (ELI), ≤0.20 wt% (Grade 5) | Ductility, fatigue | ASTM F136/F3001 |

| Satellite content (post-PS reconditioning) | <3–5% by count | Flow/defect control | Supplier QC notes |

| Indicative lot yield in PREP (20–200 μm) | 55–70% after classification | Cost and availability | Vendor application notes |

| Market price band (Ti-6Al-4V powder) | ~$80–$200/kg (GA) vs. ~$120–$300/kg (PA/PREP) | Budgeting | Market trackers/suppliers |

Authoritative references and further reading:

- ISO/ASTM 52907 (Additive manufacturing feedstock): https://www.iso.org

- ASTM F2924, F3001 (Ti alloys for AM): https://www.astm.org

- NIST AM Bench datasets: https://www.nist.gov

- ASM Handbook: Powder Metallurgy and Additive Manufacturing: https://www.asminternational.org

Latest Research Cases

Case Study 1: PS Reconditioning of GA Inconel 718 to Reduce Satellites (2025)

Background: An aerospace supplier experienced recoater streaks and variable density from GA IN718 due to satellite-rich lots.

Solution: Applied plasma spheroidization to re-melt particle surfaces, followed by tight classification; implemented inline O2/H2O monitoring and argon recirculation.

Results: Satellite count reduced from ~12% to <3%; Hall flow improved by 18%; LPBF porosity fell from 0.45% to 0.12% without parameter change.

Case Study 2: PREP Titanium Alloy Powder for Thin‑Wall LPBF Lattice Structures (2024)

Background: A medical OEM required high ductility and fatigue life in Ti‑6Al‑4V ELI lattices.

Solution: Switched to PREP powder with narrow PSD (20–40 μm) and O ≤0.12 wt%; applied low‑energy contour scans and stress relief.

Results: 10–15% higher elongation, 25% improvement in HCF endurance at 10⁷ cycles; surface defect incidence reduced, enabling lower CT sampling.

Expert Opinions

- Prof. John Campbell, Casting and Atomization Specialist (Emeritus), University of Birmingham

Key viewpoint: “Control of melt cleanliness and turbulence during atomization is as decisive as gas velocity for minimizing satellites and inclusions.” - Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

Key viewpoint: “PS as a secondary step is proving cost‑effective to lift GA powder quality to PA/PREP performance for many aerospace parts.” - Dr. Brent Stucker, AM standards contributor and industry executive

Key viewpoint: “Powder passports tying PSD, O/N/H, and in‑process monitoring to acceptance are accelerating serial qualification of spherical metallic powder.”

Citations for expert profiles:

- University of Birmingham: https://www.birmingham.ac.uk

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

- ASTM AM CoE: https://amcoe.org

Practical Tools and Resources

- Standards and QC

- ISO/ASTM 52907 (feedstock), ASTM B214/B822 (PSD), ASTM B212/B329 (apparent/tap density)

- NFPA 484 (combustible metals safety): https://www.nfpa.org

- Characterization labs and equipment

- LECO O/N/H analyzers: https://www.leco.com

- Laser diffraction and SEM services at accredited labs

- Process and design tools

- Ansys Additive, Simufact Additive for parameter optimization and distortion control

- nTopology for lattice design tailored to powder PSD

- Market/data

- Senvol Database (machines/materials): https://senvol.com/database

- NIST AM Bench datasets: https://www.nist.gov

Last updated: 2025-08-21

Changelog: Added 5 targeted FAQs, 2025 trends with metrics table and sources, two recent case studies on PS and PREP routes, expert viewpoints with citations, and practical tools/resources relevant to spherical metallic powder.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM feedstock standards update, major OEMs publish new PSD/oxygen specs, or significant price/yield shifts occur in GA/PA/PREP/PS routes.