1. Introduction: Why Silicon Nitride Powder Matters in Advanced Manufacturing

Silicon nitride (Si₃N₄) powder has emerged as a critical material in high-performance industrial sectors due to its superior mechanical, thermal, and chemical properties. As industries pursue stronger, lighter, and more heat-resistant materials for demanding applications, silicon nitride continues to gain traction across multiple sectors — from automotive to aerospace and semiconductor manufacturing.

For B2B buyers, including manufacturers, suppliers, and distributors in these industries, silicon nitride powder represents a vital input material that offers:

- High-temperature resistance

- Superior wear resistance

- Low thermal expansion

- Excellent electrical insulation properties

These qualities make it a go-to material for advanced engineering components such as bearings, cutting tools, engine parts, and electronic substrates.

| Feature | Benefit to Industrial Users |

|---|---|

| High strength at high temperatures | Ideal for engine and turbine components |

| Low thermal expansion | Maintains dimensional stability in thermal cycling |

| Exceptional hardness | Enhances wear resistance and longevity |

| Chemical inertness | Suitable for corrosive environments |

| Electrical insulation | Used in electronic and semiconductor devices |

For businesses sourcing materials for high-performance applications, silicon nitride powder is not just a specialty product — it’s a strategic material for innovation.

2. Key Industrial Applications of Silicon Nitride Powder

Silicon nitride powder’s versatility enables its use across a diverse range of industrial sectors. Below are the primary industries and applications that benefit from its unique combination of properties:

Automotive Industry

- Turbocharger Rotors: Withstand high heat and stress

- Engine Components: Valves, pistons, rocker arm pads

- Ignition Systems: High dielectric strength makes it ideal for spark plugs

Aerospace and Defense

- Jet Engine Parts: Lightweight yet strong at high temperatures

- Thermal Shields: For high-speed aircraft and space vehicles

Electronics and Semiconductors

- Substrates for Power Electronics: Silicon nitride provides electrical insulation and thermal conductivity

- Wafer Processing Components: High purity and heat resistance

Industrial Machinery

- Bearings and Seals: Exceptional wear resistance in harsh environments

- Cutting Tools: Hardness and thermal resistance extend tool life

Energy and Power Generation

- Gas Turbine Components

- Fuel Cells: Used as structural materials and insulators

| Industry | Application | Benefit |

|---|---|---|

| Automotive | Engine parts, turbochargers | High strength and thermal resistance |

| Aerospace | Jet engine components | Lightweight and heat-tolerant |

| Semiconductors | Wafer transport and substrates | Chemical stability and insulation |

| Tools & Machinery | Bearings, cutting tools | Wear resistance and durability |

By understanding these applications, B2B buyers — particularly OEMs, engineers, and material procurement managers — can align their material sourcing with performance and innovation goals.

3. Properties and Types of Silicon Nitride Powder

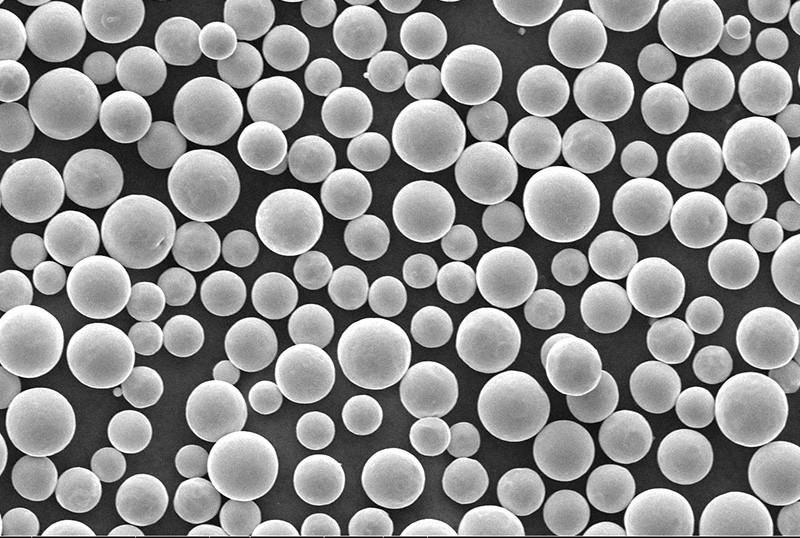

Silicon nitride exists in various crystalline forms and can be tailored to different industrial requirements. The two main types of silicon nitride used in powder metallurgy and ceramics are:

- Alpha-phase Si₃N₄ (α-Si₃N₄): Metastable, finer particle size, and higher sintering activity

- Beta-phase Si₃N₄ (β-Si₃N₄): Thermodynamically stable, elongated grains, stronger mechanical properties after sintering

Key Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 3.2 g/cm³ |

| Hardness | ~15 GPa |

| Flexural Strength | Up to 1000 MPa |

| Thermal Conductivity | 20–30 W/m·K |

| Maximum Use Temperature | Up to 1400°C in air |

| Coefficient of Thermal Expansion | 3.2 × 10⁻⁶/K |

Types of Silicon Nitride Powder Available

| Type | Description | Use Case |

|---|---|---|

| α-Si₃N₄ powder | High surface area, high sinterability | Electronic substrates, fine ceramics |

| β-Si₃N₄ powder | Larger grains, strength in final product | Structural ceramics, bearings |

| Composite Si₃N₄ | Blended for custom properties | Specialized industrial applications |

Shanghai Truer Technology offers advanced powder solutions that can be customized to various applications. To learn more about their silicon nitride and other PM powders, visit their product page.

In addition to pure silicon nitride powders, Shanghai Truer also provides composite and additive-enhanced formulations, enabling manufacturers to tailor material performance for demanding applications.

4. Current Market Trends and Global Demand Forecast

The global silicon nitride powder market is experiencing robust growth, driven by increasing demand across high-performance manufacturing sectors like automotive, aerospace, and semiconductors. For B2B buyers, staying on top of these trends is vital for strategic sourcing and long-term supply chain planning.

Key Market Drivers

- Electrification of Vehicles: Electric vehicles (EVs) require high-performance ceramics in battery modules and power control units.

- Miniaturization in Electronics: Compact, high-efficiency devices demand materials with excellent thermal and electrical insulation.

- Renewable Energy Expansion: Silicon nitride is used in solar and wind turbine components due to its thermal and mechanical stability.

Global Market Forecast (2023–2030)

| Region | CAGR | Key Industries |

|---|---|---|

| Asia-Pacific | 7.8% | Automotive, electronics, renewable energy |

| North America | 6.3% | Aerospace, semiconductor, defense |

| Europe | 5.9% | Precision tools, energy, automotive |

Product Trends

- Rise in demand for α-Si₃N₄ for advanced ceramic substrates

- Increased use of β-Si₃N₄ in structural applications due to its toughness

- Growth in additive-enhanced silicon nitride for customized performance

For B2B procurement teams, the implication is clear: selecting a supplier that can deliver consistent quality, flexible customization, and global delivery capabilities is now more critical than ever. Companies like Shanghai Truer Technology are strategically positioned to meet these demands through their integrated manufacturing and powder customization capabilities.

5. How to Evaluate a Reliable Silicon Nitride Powder Supplier

Sourcing silicon nitride powder in bulk is a strategic decision for manufacturers and distributors. The right supplier not only ensures consistent quality but also contributes to product performance, compliance, and downstream reliability.

Key Criteria for Supplier Evaluation

| Evaluation Factor | Why It Matters |

|---|---|

| Powder Purity & Consistency | Impacts sintering behavior, reliability, and final part performance |

| Customization Ability | B2B buyers often need tailored grades or composites |

| Production Method | Affects cost, particle morphology, and application suitability |

| Technical Support | Crucial for integration into existing processes |

| Delivery & Logistics | Lead times, packaging, and international compliance are critical |

Checklist for B2B Buyers

- ✅ Does the supplier provide both α and β phase silicon nitride?

- ✅ Are the powders available in different particle sizes and morphologies?

- ✅ Is there technical support for application-specific customization?

- ✅ Are the powders compatible with your sintering/fabrication process (e.g., hot pressing, HIP, etc.)?

- ✅ Does the supplier meet ISO or other quality certifications?

Shanghai Truer Technology addresses these needs by offering a wide portfolio of powder metallurgy solutions, including high-purity Si₃N₄ powders customized for structural ceramics, electronics, and precision components. Their technical team is ready to assist B2B clients with formulation, processing, and application guidance. Learn more about their company background.

6. Top Global Suppliers of Silicon Nitride Powder

When it comes to sourcing silicon nitride powder, several global players dominate the market due to their production capabilities, quality control, and global distribution. Here’s a look at the top suppliers that B2B buyers often consider.

Leading Suppliers of Silicon Nitride Powder

| Supplier | Country | Strengths |

|---|---|---|

| UBE Industries | Japan | Pioneer in high-purity Si₃N₄ ceramics |

| Denka Company | Japan | Offers fine-grain powders for electronics |

| Saint-Gobain | USA/France | Broad ceramic material portfolio |

| Shanghai Truer Technology Co., Ltd | China | Cost-effective, customizable, integrated PM solutions |

| AlzChem Group | Germany | Known for high-performance nitrides and additives |

Why Shanghai Truer is Gaining Market Share

- Competitive pricing for bulk orders

- Custom powder formulations for complex B2B applications

- In-house powder production using water, gas, and combined atomization

- Deep expertise in powder metallurgy additives and supporting materials

Shanghai Truer is not just a powder supplier but a complete solution provider for additive manufacturing and powder metallurgy. Their cross-functional capabilities in supplying both structural powders and performance-enhancing additives uniquely position them to serve a wide range of B2B customers.

If you’re a wholesaler, OEM, or distributor looking to expand your sourcing network, contact Shanghai Truer for pricing, samples, and technical consultation.

7. Why More Buyers Are Turning to Chinese Manufacturers

In recent years, China has become a preferred sourcing hub for advanced ceramic powders, including silicon nitride. This shift is driven by several key factors that appeal to B2B procurement teams:

Key Advantages of Chinese Suppliers

- Cost Efficiency: Competitive pricing without compromising material performance

- Scalable Production: Modernized facilities with large-scale capacity

- Material Innovation: Increasing investment in R&D and powder customization

- Shorter Lead Times: Geographic proximity to Asia-Pacific markets reduces shipping delays

Case in Point: Shanghai Truer Technology

Shanghai Truer exemplifies the new generation of Chinese manufacturing excellence. Established in 2009 and expanding into additive manufacturing in 2019, they offer:

- A full range of PM powders including PM copper, PM iron, PM steel, and PM stainless steel

- Advanced atomization technology: water, gas, and combined methods

- Proprietary additives and lubricants for performance tuning

- Custom silicon nitride powders using advanced reduction and nitridation techniques

For international buyers seeking certified, dependable suppliers, Shanghai Truer offers a compelling value proposition. Their tailored approach and B2B focus make them an industry partner—not just a vendor.

You can explore their full range of powder metallurgy solutions for your next procurement project.

8. How to Order Wholesale Silicon Nitride Powder from Shanghai Truer

For B2B buyers — whether you’re a component manufacturer, distributor, or OEM — ordering high-quality silicon nitride powder in bulk requires a streamlined, transparent process. Shanghai Truer Technology Co., Ltd has built a procurement-friendly system that ensures product consistency, technical support, and global delivery.

Step-by-Step Wholesale Ordering Process

| Step | Description | Details |

|---|---|---|

| 1 | Inquiry & Consultation | Contact Truer’s sales team to discuss your application, specs, volumes, and delivery needs. |

| 2 | Sample Request (Optional) | You may request sample quantities for lab testing and pilot runs. |

| 3 | Quotation & Lead Time | Receive a detailed quote including product specifications, packaging, lead time, and logistics. |

| 4 | Custom Formulation (If Required) | For specialized uses, Truer can adjust grain size, purity, phase ratio, or additives. |

| 5 | Order Confirmation | Finalize PO and payment terms. |

| 6 | Production & Quality Control | Batch production with full traceability and quality documentation. |

| 7 | Shipping & Logistics | International delivery support with MSDS, COA, and customs documents. |

Minimum Order Quantities (MOQ)

- Standard Grades: MOQ starts at 25 kg

- Custom Formulations: MOQ may range from 50–100 kg depending on complexity

Packaging Options

- Poly-lined steel drums (25kg, 50kg)

- Vacuum-sealed aluminum foil bags (for sensitive materials)

- Palletized for international freight

Logistics and Export Capabilities

- Global shipping support (air, sea, and express)

- Compliance with REACH, RoHS, and ISO standards

- Export licenses for restricted materials where applicable

Shanghai Truer’s contact page provides a simple form to start your inquiry. Their B2B sales team typically responds within 24 hours with tailored advice and quotations.

9. FAQs: Common Questions About Buying Silicon Nitride Powder Wholesale

To help buyers make informed decisions, here are some of the most frequently asked questions from B2B customers who source silicon nitride powder from Shanghai Truer Technology:

Q1: What’s the difference between α-Si₃N₄ and β-Si₃N₄ powders?

- α-Si₃N₄: Higher sintering activity, preferred for ceramic substrates and fine components.

- β-Si₃N₄: Offers better mechanical properties after sintering, suitable for structural applications like bearings and turbine parts.

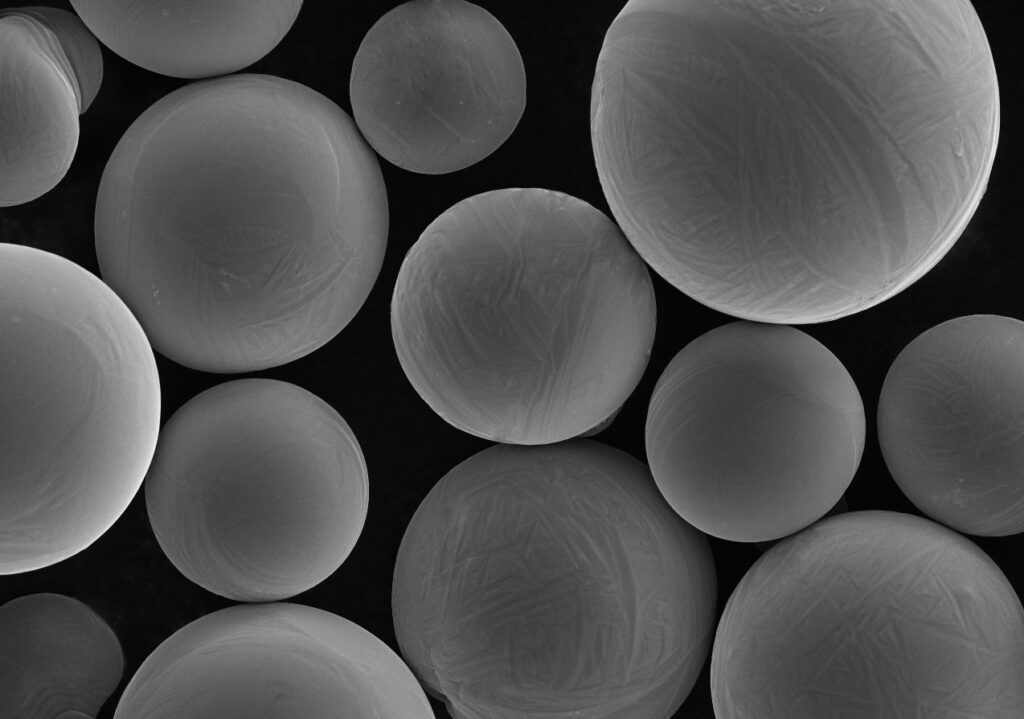

Q2: Can I customize the powder properties for my application?

Yes. Truer offers custom solutions including:

- Particle size control (D50, D90)

- Phase ratio (α/β)

- Morphology (spherical, irregular)

- Additives (e.g., Y₂O₃, Al₂O₃ for sintering aids)

Q3: What quality certifications does Truer have?

- ISO 9001: Quality Management System

- Product-level compliance with REACH and RoHS

- Internal quality control systems with full traceability

Q4: What industries does Truer currently serve?

- Automotive component manufacturers

- Aerospace parts suppliers

- Electronics and semiconductor OEMs

- Precision ceramics producers

- Tooling and industrial equipment manufacturers

Q5: Are there other powder types available?

Absolutely. In addition to silicon nitride, Truer provides a wide range of metal powders including:

- PM stainless steel

- PM iron-copper and nickel steels

- PM bronze, brass, and copper-steel

- Cutting and sintering additives like QH-150, TD-8, SUW-5000B

Call to Action: Partner with Shanghai Truer for Reliable Silicon Nitride Powder Supply

Whether you’re a manufacturer of high-performance ceramics, a supplier of industrial materials, or an OEM in need of advanced powders, Shanghai Truer Technology is your trusted B2B supplier for:

✅ High-purity silicon nitride powders (α, β, or blended)

✅ Custom formulations and technical support

✅ Full export capabilities and international compliance

✅ Integrated additive solutions for powder metallurgy and AM

With over a decade of expertise and a commitment to innovation, Truer is one of China’s most trusted partners for advanced ceramics and metal powders. Visit their company overview to learn more about their capabilities and engineering support.

📞 Ready to get started? Contact Shanghai Truer to request a quote, technical consultation, or sample for your next project.