1. Introduction: Why Carbonyl Iron Powder Matters for Industrial Buyers

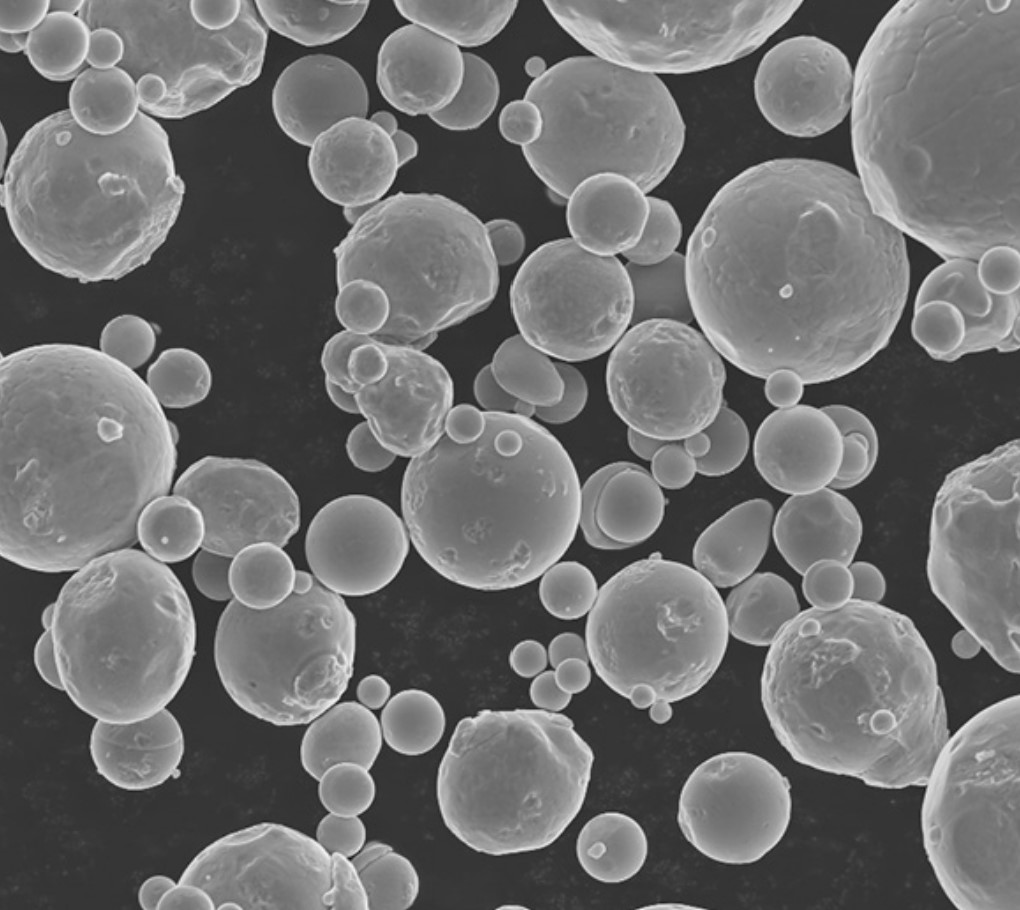

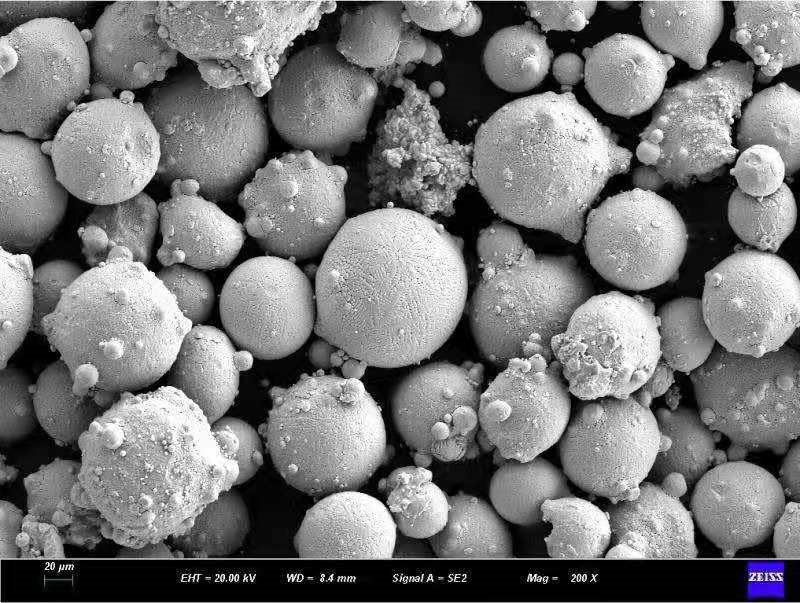

Carbonyl iron powder (CIP) is a highly pure form of elemental iron produced by the decomposition of iron pentacarbonyl. It is characterized by its spherical particles, high surface area, and exceptional purity (typically >99.5%). These traits make it one of the most versatile and in-demand materials across multiple industrial sectors.

For wholesale buyers, e-commerce resellers, and manufacturing procurement managers, understanding the sourcing and application of carbonyl iron powder is critical. Its consistent particle size, high compressibility, and magnetic properties make it essential in powder metallurgy, soft magnetic components, metal injection molding (MIM), and electromagnetic interference (EMI) shielding.

High-Intent B2B Keywords Integrated:

- Carbonyl iron powder supplier

- Wholesale carbonyl iron powder

- Industrial iron powder distributor

- Soft magnetic powder for transformers

- Carbonyl iron for MIM and PM

- High purity iron powder bulk purchase

Benefits of Carbonyl Iron Powder for B2B Buyers:

| Feature | Benefit for Industrial Users |

|---|---|

| High Purity (>99.5%) | Ensures consistent quality and performance |

| Spherical Particle Shape | Enhances flowability and packing density |

| Excellent Compressibility | Suitable for high-density PM parts |

| Soft Magnetic Properties | Ideal for electromagnetic and transformer components |

| Chemical Reactivity | Used in catalyst and chemical reaction processes |

2. Applications of Carbonyl Iron Powder Across Industries

Carbonyl iron powder is not a one-size-fits-all material; its applications span a wide array of sectors due to its unique physical and chemical properties. Below are the primary industries using this advanced material:

a) Powder Metallurgy (PM)

Carbonyl iron powder is a preferred base material for high-density PM parts, where purity and particle morphology significantly impact mechanical properties.

- Gears, cams, and structural components

- Automotive engine parts

- High-performance sintered parts

b) Electronics and Magnetics

Due to its low coercivity and high permeability, carbonyl iron is widely used in:

- Soft magnetic cores

- Transformer cores

- Inductor materials

- EMI shielding components

c) Metal Injection Molding (MIM)

CIP’s fine particle size and high purity make it ideal for MIM applications, enabling the production of:

- Precision components

- Medical devices

- Aerospace fasteners

- Miniaturized mechanical parts

d) Chemical and Pharmaceutical Industry

In the chemical sector, carbonyl iron is utilized for:

- Catalysis and chemical synthesis

- Iron supplements in pharmaceutical products

- Absorbents in environmental applications

e) Defense and Aerospace

Its electromagnetic properties make CIP critical for radar-absorbing materials (RAM), vital in stealth technology and aerospace coatings.

3. Key Properties and Use Cases of Carbonyl Iron Powder

Carbonyl iron powder stands out due to its unique combination of physical, magnetic, and chemical attributes, making it one of the most flexible materials for industrial use.

Physical Properties of Carbonyl Iron Powder:

| Property | Value |

|---|---|

| Purity | >99.5% |

| Particle Size | 1–10 microns |

| Apparent Density | 2.0–3.0 g/cm³ |

| Flow Rate | Excellent |

| Morphology | Spherical |

| Color | Greyish-black |

Magnetic Properties:

| Property | Value |

|---|---|

| Coercivity | <10 A/m |

| Relative Permeability | High (up to 2000) |

| Magnetic Saturation | 215 emu/g |

| Electrical Resistivity | ~10⁻⁵ Ohm·m |

Use Case Scenarios by Industry:

| Industry | Example Applications |

|---|---|

| Automotive | Gears, valve seats, sintered bearings |

| Electronics | Soft magnetic cores and EMI shields |

| Aerospace | Radar-absorbing materials |

| Pharmaceutical | Iron supplements |

| MIM | Micro-precision parts |

| Chemical | Catalysts for reactions |

Specialty Grades Available at Shanghai Truer Technology:

Shanghai Truer Technology Co., Ltd provides a wide range of carbonyl and water atomized powders suitable for powder metallurgy, MIM, and additive manufacturing. Their carbonyl iron powder is engineered for high sinterability, magnetic uniformity, and flow characteristics. For a detailed look at their offerings, visit the PM Powder product page.

4. Global Market Trends and Growth Potential

The global demand for carbonyl iron powder (CIP) is accelerating, driven by its widespread use in powder metallurgy, electronics, and electromagnetic applications. The market is expected to reach USD 300 million by 2028, growing at a CAGR of 6.5%, according to industry research reports.

Key Market Drivers:

- Surge in EV and automotive electronics: The use of CIP in magnetic components such as inductors and EMI shielding is rising rapidly.

- Growth of additive manufacturing: Carbonyl iron powder’s spherical morphology makes it ideal for 3D printing and MIM processes.

- Increased defense spending: Demand for radar-absorbing materials (RAM) is contributing to higher CIP consumption.

- Eco-friendly manufacturing: CIP is recyclable and compatible with green manufacturing initiatives.

Regional Market Insights:

| Region | Market Status | Key Drivers |

|---|---|---|

| Asia-Pacific | Fastest Growing | Rise of PM parts, automotive, and electronics industries |

| North America | Mature Market | Aerospace and defense innovation |

| Europe | Technologically Advanced | Focus on green manufacturing, MIM adoption |

| Middle East & Africa | Emerging | Industrialization and defense projects |

For B2B buyers, these trends reflect a strong opportunity to secure long-term, cost-effective supply contracts with credible manufacturers.

5. Choosing a Reliable Carbonyl Iron Powder Supplier

Selecting the right carbonyl iron powder supplier is critical for manufacturers who need consistent performance, timely delivery, and competitive pricing. Here are the key considerations that every procurement team, distributor, and OEM should evaluate:

Evaluation Checklist for Wholesale Buyers:

| Criteria | Why It’s Important |

|---|---|

| Purity Standards | Impacts end-use product quality and consistency |

| Particle Size Control | Affects flow rate, compressibility, and sintering |

| Production Method | Carbonyl process yields higher purity vs. water atomization |

| Certifications (ISO, REACH, RoHS) | Ensures compliance with international standards |

| MOQ and Pricing | Key for bulk purchases and cost planning |

| Customization Services | Tailored particle sizes or blends for specific applications |

| Delivery and Lead Time | Impacts production schedules and inventory control |

| Technical Support | Crucial for integration into complex manufacturing lines |

Supplier Questions to Ask:

- Do you provide traceability reports and COAs (Certificates of Analysis)?

- Can you support custom particle size distributions?

- What is your monthly production capacity for CIP?

- Are you able to supply both sample and production-scale quantities?

6. Top 5 Carbonyl Iron Powder Manufacturers in Asia

Asia is the leading region for carbonyl iron powder production, offering competitive pricing, high-volume capacity, and technical innovation. Here are five of the top suppliers B2B buyers should consider:

| Company | Country | Key Strengths | Notes |

|---|---|---|---|

| BASF | Germany (with Asia ops) | Inventor of carbonyl iron; pharma grade available | Premium pricing |

| Shanghai Truer Technology Co., Ltd | China | Full range of PM and additive powders; custom services | Ideal for PM and MIM buyers |

| JFE Steel | Japan | High-end magnetic powder; strong in electronics | Limited export |

| Jiangsu Tianyi Ultra-Fine Metal Powder Co. | China | Competitive pricing; large capacity | Focuses on standard grades |

| Sinosteel | China | State-owned; strong in metallurgy | Less flexible with custom orders |

Among these, Shanghai Truer Technology stands out for its commitment to quality control, custom formulations, and full-service support for PM, MIM, and additive manufacturing clients.

7. Why More Buyers Are Sourcing from China

China has emerged as the go-to sourcing hub for carbonyl iron powder, not just because of lower prices, but due to its advancement in powder metallurgy technologies and the maturity of its supply chain network.

Advantages of Sourcing from Chinese Suppliers:

- Economies of Scale: High-volume production lowers per-unit costs

- Shorter Lead Times: Especially for Asian and Pacific region buyers

- Integrated Manufacturing: Suppliers often offer atomization, blending, and packaging in-house

- Innovation Support: Many Chinese suppliers provide R&D collaboration for new product development

What B2B Buyers Say:

“We moved 70% of our CIP procurement to China last year and saw a 20% cost reduction with no compromise in quality.”

— Procurement Manager, European MIM Manufacturer

Risks to Mitigate:

- Ensure proper due diligence on supplier certifications

- Use escrow or trade assurance for large orders

- Request third-party inspection before shipment

To get started with a verified Chinese supplier, you can reach out via the Contact Us page on am-material.com.

8. Why Choose Shanghai Truer Technology as Your Supplier

Shanghai Truer Technology Co., Ltd is a leading supplier of high-quality carbonyl iron powder and other powder metallurgy materials. Established in 2009, and expanding into additive manufacturing in 2019, Truer is recognized as one of China’s most trusted powder supply partners for B2B buyers.

Why B2B Buyers Prefer Truer:

| Feature | Benefit |

|---|---|

| Wide Range of PM Powders | From carbonyl iron to PM stainless steel and hybrid alloys |

| Multiple Production Methods | Carbonyl, water atomized, gas atomized, and dual atomization |

| Custom Blending | Tailored solutions for PM, MIM, and additive manufacturing |

| On-Time Global Delivery | Optimized logistics for Europe, North America, and Asia |

| Technical Expertise | In-house R&D and application engineering support |

Truer’s Carbonyl Iron Powder Advantages:

- High purity >99.5%

- Controlled particle size distribution (1–10μm)

- Excellent flowability and sinterability

- Custom packaging for bulk orders

- Competitive pricing for wholesale and OEM buyers

Additional Offerings:

Besides CIP, Truer offers a full suite of PM additives including:

- Lubricants: Lube-W, SUW-5000B, SUW-8000

- Cutting agents: SME-100, TD-8

- Magnetic additives: QH-150, QHP-330

- Graphite materials: TBC-400, TBC-1000

For a full list of materials, visit the PM Powders page.

Whether you’re a distributor, OEM, or procurement specialist, Shanghai Truer Technology offers the technical support, product reliability, and pricing flexibility you need to stay competitive in today’s market.

9. How to Order Wholesale Carbonyl Iron Powder from Shanghai Truer Technology

Ordering high-purity carbonyl iron powder in bulk from Shanghai Truer Technology is a seamless process designed to support procurement departments, OEMs, and international distributors. Truer offers customizable solutions tailored to your production needs, including flexible MOQ, custom particle sizes, and packaging.

Step-by-Step Procurement Process:

| Step | Action | Notes |

|---|---|---|

| 1 | Submit Inquiry | Use the contact form to provide your specifications (grade, quantity, particle size, application) |

| 2 | Receive Quotation | Truer’s team will respond within 24–48 hours with a detailed quote including lead time and logistics |

| 3 | Sample Request (Optional) | For new buyers, samples (500g–2kg) are available for performance and compatibility testing |

| 4 | Confirm Order | Issue a PO and negotiate payment terms (T/T, L/C, etc.) |

| 5 | Production & QC | Truer will initiate production with full quality control documentation (COA, SDS, ISO certifications) |

| 6 | Shipping & Delivery | Global shipping via air or sea with tracking and customs support |

Packaging Options:

- 25 kg sealed drums

- 500 kg super bags

- Vacuum packaging for moisture-sensitive powders

- Custom branding for resellers or OEM partners

MOQ and Lead Time:

| Order Size | Lead Time | Notes |

|---|---|---|

| <100 kg | 3–5 days | From stock or small-batch production |

| 100–500 kg | 7–14 days | Standard production |

| >500 kg | 15–25 days | Custom formulations or special orders |

Truer also offers long-term supply agreements for clients seeking stable pricing and inventory assurance throughout the year.

Logistics and Export Experience:

Shanghai Truer Technology exports to over 30 countries worldwide, including the US, Germany, India, and Brazil. Their logistics team handles:

- Export documentation

- Dangerous goods classification (if needed)

- Customs clearance support

- Third-party inspections (SGS, BV, etc.)

For more information on how to initiate your first order, visit the About Us page to learn more about Truer’s capabilities and certifications.

10. FAQs: Purchasing Carbonyl Iron Powder in Bulk

Here are the most common questions from wholesale buyers, procurement teams, and resellers when sourcing carbonyl iron powder from Shanghai Truer Technology:

Q1: What is the purity level of your carbonyl iron powder?

A: Our standard carbonyl iron powder exceeds 99.5% purity. We can also supply ultra-high purity grades upon request for critical applications such as electronics and pharmaceutical use.

Q2: What packaging options are available for international shipping?

A: We offer sealed 25 kg drums, 500 kg bulk bags, and vacuum packaging. All packaging complies with international shipping standards and includes moisture barriers.

Q3: Can I request a custom particle size distribution?

A: Yes. Truer can tailor particle size ranges (e.g., 1–5 μm, 3–10 μm) to suit specific applications such as MIM, PM, or EMI shielding.

Q4: Do you supply samples for testing?

A: Absolutely. We provide samples between 500 grams and 2 kilograms for quality validation and process compatibility testing.

Q5: What industries do your current clients belong to?

A: Our clients include manufacturers in automotive, electronics, medical devices (MIM), aerospace, and defense sectors. We also supply to powder metallurgy parts producers and additive manufacturing labs.

Q6: Are your powders suitable for additive manufacturing?

A: Yes, our carbonyl iron powder is spherical and highly flowable, making it well-suited for laser-based additive manufacturing and binder jetting applications.

Q7: Do you offer technical support during material integration?

A: Yes, our engineering team can assist with material selection, process optimization, and troubleshooting during the integration phase.

Q8: How can I ensure consistent quality over multiple orders?

A: Truer provides a Certificate of Analysis (COA) and batch traceability for every order. We also offer sample retention and batch validation services for repeat clients.

Get Started with Shanghai Truer Technology Today

Whether you’re sourcing carbonyl iron powder for powder metallurgy, MIM, additive manufacturing, or electromagnetic shielding, Shanghai Truer Technology offers unmatched product quality, reliability, and customer support. With over a decade of experience and clients across 30+ countries, Truer is your trusted partner for high-performance powders.

Why Choose Truer:

- ISO-certified production and quality control

- Global export capabilities

- Custom formulations and packaging

- Competitive wholesale pricing

- Technical support from R&D to application

To explore our full catalog of PM powders, including carbonyl iron, visit the PM Powder Product Page.

You can also reach out directly through our Contact Us Page to request a quote or sample today.

Let Shanghai Truer Technology be your partner in precision powder solutions.