Introduction of spherical titanium powder

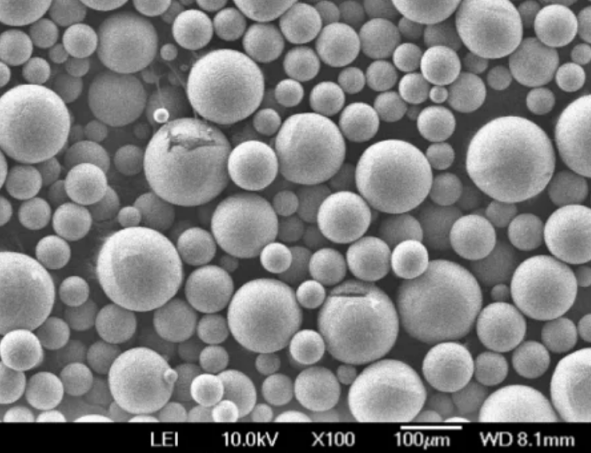

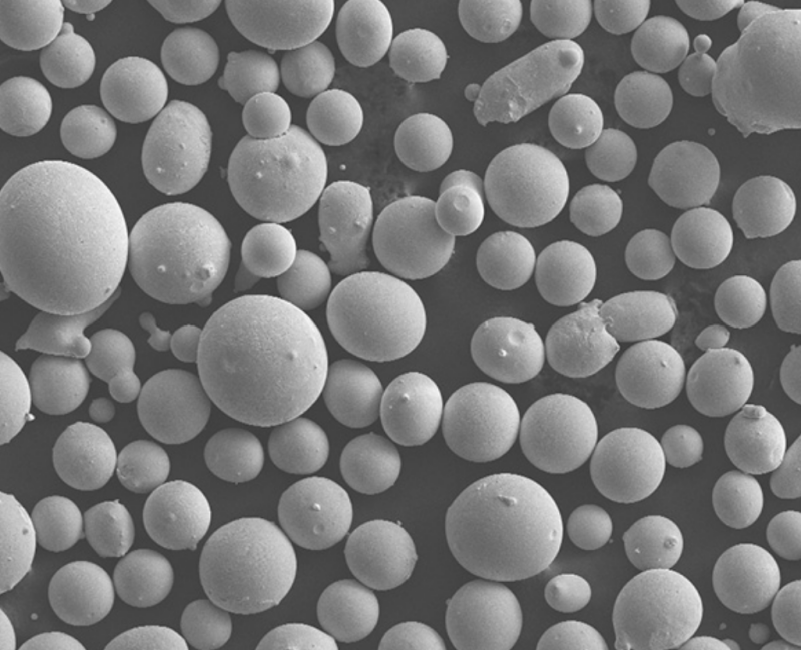

Spherical titanium powder is a form of pure titanium powder with a spherical morphology and controlled particle size distribution. It offers excellent flowability, mixability, and consistency which makes it suitable for advanced metal manufacturing processes across industries.

Composition and Characteristics

Table 1: Composition and Key Characteristics of Spherical Titanium Powder

| Parameter | Details |

|---|---|

| Chemical Composition | >99% Titanium. Remaining trace elements like Nitrogen, Oxygen, Carbon, Hydrogen. |

| Particle Shape | Highly spherical morphology |

| Particle Size Range | Typically 15-45 microns |

| Flowability | Excellent due to spherical shape |

| Apparent Density | Around 2.7 g/cm3 |

| Tap Density | Up to 73% solid titanium density i.e. ~4 g/cm3 |

The precise particle size distribution, oxygen and nitrogen content, flow rates and tap density can be customized as per application requirements.

Manufacturing Process

Spherical titanium powder is manufactured through advanced methods that involve melting titanium feedstock, atomizing and rapidly solidifying droplets into highly spherical powder particles:

- Plasma Atomization uses high energy plasma torches and inert gas jets

- Electrode Induction Gas Atomization (EIGA) relies on induction melted electrodes

- Rotating Electrode Process (REP) generates molten metal streams from tips of spinning titanium electrodes

The key is rapid solidification in an inert atmosphere which results in purity and spherical morphology. Post-production sieving and classification leads to strict fractions.

spherical titanium powder Applications and Uses

The unique properties of spherical titanium powder make it suitable for:

Table 2: Major Applications of Spherical Titanium Powder

| Area | Applications |

|---|---|

| Additive Manufacturing | 3D printing implants, aerospace components via DMLS, SLM, EBM |

| Powder Metallurgy | Pressing and sintering to make titanium automotive and aircraft parts |

| Investment Casting | Injection molds and tooling manufacture |

| Biomedical | Porous structures for bone grafts |

| Pigments and Catalysts | Chemical and plastics industry |

The high purity, flowability, mixability and consistency of particle size distribution allows reliable high-performance use across powder-based manufacturing processes like metal 3D printing.

Specifications

Spherical titanium conforms to specifications like ASTM B988 and ASTM F3049. Typical values are:

Table 3: Typical Specifications of Spherical Titanium Powder

| Parameter | Specification |

|---|---|

| Particle Size | 15-45 microns |

| Oxygen Content | <0.20% |

| Nitrogen Content | <0.05% |

| Hydrogen Content | <0.015% |

| Tap Density | Up to 4 g/cm3 |

| Flow Rate | >25 s/50 g |

| Particle Size Distribution | D10 > 20 microns; D90 < 63 microns |

Customization of properties like tap density, flow rates, oxygen and nitrogen content is possible based on application requirements.

Price of spherical titanium powder

Table 4: Spherical Titanium Powder Price Ranges of Key Suppliers

| Supplier | Price Per Kg |

|---|---|

| Advanced Powders & Coatings | $100–$200 |

| AP&C | $90–$180 |

| TLS Technik GmbH & Co | $120–$250 |

| Sandvik Osprey | $80–$220 |

Prices depend on order volumes, grades, and customization needs. High purity grades for medical uses are premium priced. Recycled powder can cost 50% less but has lower and inconsistent quality.

Comparison With Alternatives

Table 5: Pros and Cons of Spherical Titanium Powder

| Pros | Cons |

|---|---|

| Excellent flowability and spreadability | Higher cost than alloy variants |

| Mixes without segregation | Limited global suppliers, scarce supply |

| Allows high density AM printed parts | Reactive, requires inert handling |

| Isotropic properties | Post-processing like HIP is a must |

| Highest strength-to-weight ratio | Lacks niche alloy properties |

Despite higher costs, spherical titanium powder enables lighter and stronger titanium components across aerospace, automotive, medical, and general engineering domains – applications where properties like corrosion resistance and biocompatibility are vital.

FAQs

What role does particle shape play in metal AM processes?

Spherical shape leads to uniform and dense powder layers during additive manufacturing methods like SLM and DMLS to minimize porosity in printed titanium parts. This results in higher mechanical strength.

How is full density achieved for sintered titanium parts?

Hot Isostatic Pressing (HIP) post-treatment on sintered titanium compacts is vital to eliminate internal pores and voids and achieve full theoretical density. This maximizes strength.

Are there health hazards associated with handling titanium powder?

Like most fine metal powders, handling precautions are vital as titanium powder can be reactive, explosive or cause skin/respiratory sensitization. Use of argon gloves boxes, protective equipment is recommended.

know more 3D printing processes

Frequently Asked Questions (FAQ)

1) What particle size distribution is best for Spherical Titanium Powder in AM vs. PM?

- AM (LPBF/SLM/EBM): typically 15–45 μm (sometimes 20–63 μm depending on OEM). PM press-and-sinter often prefers finer cuts (5–25 μm) to improve green density.

2) How do oxygen and nitrogen contents impact mechanical properties?

- Higher O/N increase strength/hardness but reduce ductility and fatigue life. For Ti-6Al-4V AM powders, many specs target O ≤0.15–0.20 wt% and N ≤0.05 wt% to balance elongation and toughness.

3) Gas atomization vs. plasma atomization vs. EIGA: which yields better Spherical Titanium Powder?

- Plasma atomization and EIGA typically deliver the highest sphericity and lowest satellite content, ideal for LPBF spreadability. Close-coupled gas atomization can be cost-effective but may require additional spheroidization/sieving.

4) Can Spherical Titanium Powder be reused in AM without compromising quality?

- Yes, with controlled sieving, oxygen monitoring (ASTM E1409/E1447), and blend-back rules. Many workflows achieve 5–10 cycles before blending with virgin powder; track PSD shift and flow (ASTM B213) to maintain consistency.

5) What post-processing is common for AM parts made from Spherical Titanium Powder?

- Stress relief, HIP to close porosity, and heat treatments per alloy (e.g., Ti‑6Al‑4V). Surface finishing (machining, shot peen, electropolish) and NDT (CT, dye penetrant) are used for critical components.

2025 Industry Trends: Spherical Titanium Powder

- Digital powder passports: Lot-level traceability for PSD (D10/D50/D90), O/N/H, flow, tap density, and reuse count accelerating cross-site qualifications.

- Sustainability gains: Inert gas recovery (Ar) and higher recycled feed content disclosures (5–20%) without compromising O/N specs.

- Higher throughput AM: Multi-laser systems and path optimization improving LPBF build rates by 20–50% for Ti‑6Al‑4V.

- Medical and aerospace focus: Tighter bioburden/EO sterilization workflows for medical-grade powders and stricter inclusion control for flight hardware.

- Coarse-cut growth: Expanded 45–106 μm cuts for EBM and cold spray, improving application reach beyond LPBF.

2025 KPI Snapshot for Spherical Titanium Powder (indicative ranges)

| Metric | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| Sphericity (AM grade) | 0.92–0.95 | 0.94–0.97 | Plasma/EIGA improvements |

| Oxygen (wt%, Ti‑6Al‑4V AM grade) | 0.10–0.20 | 0.08–0.18 | Better inert handling |

| Hall flow (spherical 15–45 μm) | 25–32 s/50 g | 22–28 s/50 g | ASTM B213 |

| Tap density (g/cm³, 15–45 μm) | 3.6–4.0 | 3.8–4.2 | Depends on PSD |

| LPBF build rate (cm³/h per laser) | 25–40 | 35–60 | OEM notes, multi‑laser |

| Reuse cycles before blend | 3–6 | 5–10 | With digital passports |

References: ASTM B213/B212/B703; ASTM E1409 (O/N), E1447 (H); ISO/ASTM 52907; OEM application notes (EOS, SLM Solutions, GE Additive); NIST AM‑Bench

Latest Research Cases

Case Study 1: Improving LPBF Yield with Low‑Oxygen Spherical Titanium Powder (2025)

Background: An orthopedic OEM experienced variable elongation in Ti‑6Al‑4V ELI acetabular cups due to powder reuse.

Solution: Implemented digital powder passports, tightened O spec from 0.18 to 0.13 wt% max, added inline oxygen monitoring and tighter sieving (20–63 μm). Post‑HIP and surface finishing standardized.

Results: Elongation Cpk improved 0.9 → 1.5; CT‑detected porosity reduced by 35%; first‑pass yield +12%; no change in build rate.

Case Study 2: EIGA Spherical Titanium Powder for Thin‑Wall Aerospace Brackets (2024)

Background: An aero supplier needed consistent layer spread for 0.8–1.2 mm walls in Ti‑6Al‑4V.

Solution: Switched to EIGA powder (D50 ≈ 35 μm, sphericity >0.96), optimized recoater speed and stripe rotation, applied HIP and machining.

Results: Lack‑of‑fusion defects −42%; as‑built density +0.4% absolute; bracket mass −9% via topology optimization; lead time −30% vs prior workflow.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “For Spherical Titanium Powder, oxygen and hydrogen control verified by standardized methods is pivotal to predictable fatigue life in AM parts.” https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “In 2025 we see parameter portability and digital material passports making titanium AM scalable for serial aerospace and medical production.” - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Closer alignment with ISO/ASTM 52907 and harmonized COAs is shortening qualification cycles for Ti‑6Al‑4V and related medical/aerospace grades.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: General principles for metal powder feedstock characterization

https://www.iso.org/standard/78974.html - ASTM E1409/E1447: Determination of O/N and H in titanium

https://www.astm.org/ - ASTM F2924/F3301/F3571: AM process and material standards for titanium alloys

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets for AM process validation

https://www.nist.gov/ambench - Senvol Database: Machine/material data for Spherical Titanium Powder applications

https://senvol.com/database - HSE ATEX/DSEAR: Guidance on combustible metal powders and inert gas handling

https://www.hse.gov.uk/fireandexplosion/atex.htm

Last updated: 2025-08-27

Changelog: Added five focused FAQs, 2025 KPI/trend table, two case studies (medical and aerospace), expert viewpoints, and curated standards/resources for Spherical Titanium Powder.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, OEMs release new Ti AM parameter sets, or significant changes occur in oxygen control/reuse best practices.