Aluminum Alloy Powders

Shanghai Truer Industrial Development Co., Ltd

What Is Aluminum Alloy Powder?

Aluminum alloy powder is a number of aluminum compounds that are mixed together, melted and then made into a paste or dried to form a powder. There are many different types of aluminum alloys, which have been used for hundreds of years in the aerospace industry for their strength, light weight and corrosion-resistance properties.

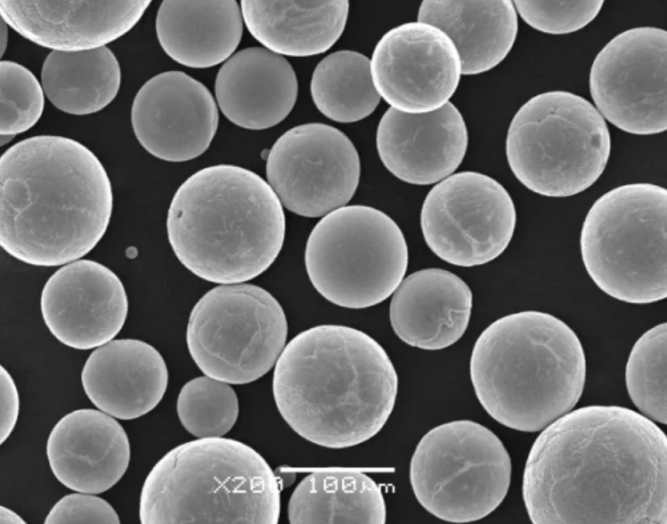

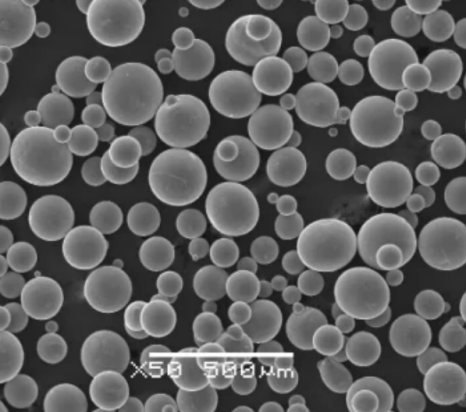

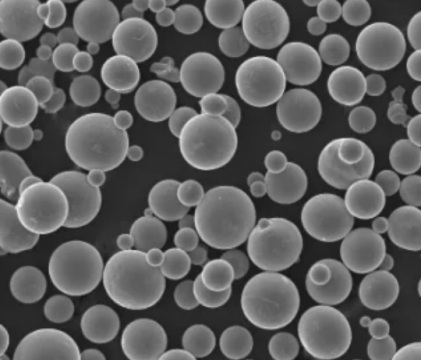

3 PREP Aluminum Alloy Powders:

Aluminum alloy powders chemical composition:

Aluminum alloy powders are a mixture of aluminum and other metals that are processed to create a durable powder form. These powders can be used in various applications, including construction, transportation, and aerospace.

Some common uses for aluminum alloy powders include automotive components, aircraft parts, and armor plating. Aluminum alloy powders are also used in energy production and the manufacturing of consumer goods.

The composition of an aluminum alloy powder is important for determining its properties. The most common aluminum alloys are made from six elements: aluminum, magnesium, silicon, sulfur, copper, and zinc. Aluminium is the most common element in an alloy and is often combined with other metals to create a specific powder. The amount of each metal in an alloy affects the properties of the powder and how it performs in different applications. For example, an alloy with more magnesium will be harder than an alloy with more aluminium.

| Additive Manufacturing | |||||

| Aluminum Alloy Powder | |||||

| Grades | Chemical Composition, wt% | Particle Size Grades | ASTM | AMS | |

| AlSi7Mg | Al Bal. | Mn 0.35max | 15-53μm 53-106μm 53-150μm | B26 | 4289 |

| Si 6.5-7.5 | Mg 0.20-0.45 | ||||

| Fe 0.6max | Zn 0.35max | ||||

| Ti 0.25max | Other 0.15max | ||||

| Cu 0.25max | |||||

| AlSi10Mg | Al Bal. | Pb 0.05max | 15-53μm 53-106μm 53-150μm | – | – |

| Si 9.0-11.0 | Mg 0.20-0.45 | ||||

| Mn 0.45max | Cu 0.10max | ||||

| Ni 0.05max | Ti 0.15max | ||||

| Zn 0.10max | Fe 0.55max | ||||

| Sn 0.05max | |||||

| 2048 | Al Bal. | Mn 0.20-0.60 | 15-53μm 53-106μm 53-150μm | – | – |

| Si 0.15max | Ti 0.10max | ||||

| Fe 0.20max | Zn 0.25max | ||||

| Mg 1.2-1.8 | Other 0.15max | ||||

| Cu 2.8-3.8 | |||||

| Customized: AlSi12, AlMgScZr,etc | |||||

Aluminum alloy Powders uses

Aluminum alloy powders are widely used in a variety of industries, including aerospace, automotive, and construction. They’re also commonly used as fillers and additives in products such as paint and plastics.

Some of the common uses for aluminum alloy powders include:

-As a filler in products such as paint and plastic

-As an additive in products such as aviation fuel and fireworks

-As an alloying agent in other metals to create new alloys

Aluminum Alloy Powder Applications

Aluminum alloy powder is a fine, white, odorless powder used in a variety of applications across many industries. It is frequently used in manufacturing processes where heat and pressure are applied to metal powders. Aluminum alloy powder is also used as an additive to other materials to improve their strength, ductility, and resistance to corrosion.

3D Printing

Mechanical Industry

Metallurgical Industry

Medical Industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Send Us A Message

Contact us

sales

Cassiel Ding

+86 – 13611869448

[email protected]

Sales Manager

Lucy Wen

+86 – 15250232891

[email protected]

Quality Control

Mike Wu

+86 – 13862291355

[email protected]

sales

Joan Zhou

+86 – 17316565943

[email protected]

Customer Service

Luke Zhang

+86 – 15250014048

[email protected]