Superalloy Powder

Shanghai Truer Industrial Development Co., Ltd

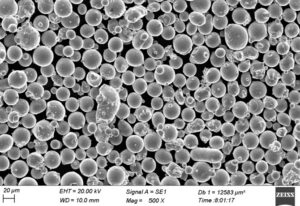

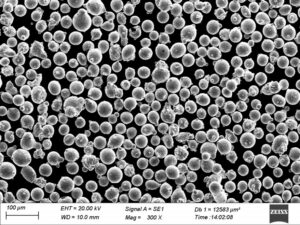

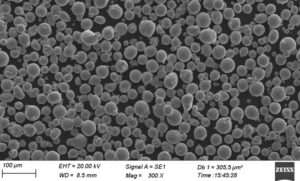

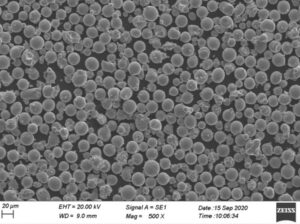

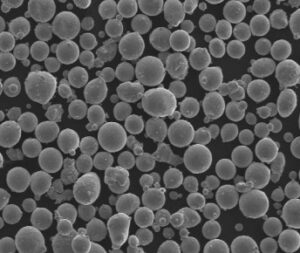

Metal Powder Produced by Gas Atomizing :Superalloy Powder

Contact to get free solution!

13 superalloy Powders Produced by Gas Atomizing | |||||

Superalloy Powder | |||||

| Alloy grades | Chemistry | Particle Size | ASTM | AMS | |

Hastelloy X | Ni Bal. | Co 0.5 – 2.5 | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm 53-150μm | B572 | 5754 |

| Cr 20.5 – 23.0 | Al 0.5max | ||||

| Fe 17.0 – 20.0 | W 0.2 – 1.0 | ||||

| C 0.05 – 0.15 | B 0.01max | ||||

| Mn 1.0max | P 0.04max | ||||

| Si 1.0max | S 0.03max | ||||

| Mo 8.0 – 10.0 | Ti 0.15max | ||||

| Cu 0.5max | |||||

Inconel 625 | Ni Bal. | Nb+Ta: 3.15-4.15 | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm 53-150μm | B446 | 5666 |

| C 0.10max | Co 1.0max | ||||

| Mn 0.50max | Mo 8.0-10.0 | ||||

| Si 0.50max | Fe 5.0 max | ||||

| P 0.015 max | Al 0.40max | ||||

| S 0.015 max | Ti 0.40max | ||||

| Cr 20.0-23.0 | |||||

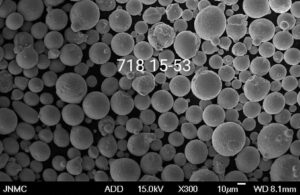

Inconel 718 | Ni 50.0-55.0 | Co 1.0max | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm 53-150μm | B637 | 5664 |

| C 0.08max | Mo 2.80-3.30 | ||||

| Mn 0.35max | Nb+Ta: 4.75-5.50 | ||||

| Si 0.35max | Ti 0.65-1.15 | ||||

| P 0.015 max | Al 0.20-0.80 | ||||

| S 0.015 max | B 0.006max | ||||

| Cu 0.30max | Fe Bal. | ||||

| Cr 17.0-21.0 | |||||

Haynes alloy 188 | C 0.05-0.15 | Cr 20.0-24.0 | 15-53μm 15-45μm 53-150μm | – | 5772 |

| Mn 1.25max | W 13.0-16.0 | ||||

| Si 0.20-0.50 | La 0.02-0.12 | ||||

| P 0.020max | B 0.015max | ||||

| S 0.015 max | Fe 3.0max | ||||

| Ni 20.0-24.0 | Co Bal. | ||||

K403 | C 0.11-0.20 | Al 5.3-5.9 | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm | – | – |

| Cr 10.0-12.0 | Ti 2.3-2.9 | ||||

| Co 4.5-6.0 | Zr 0.03-0.08 | ||||

| Mo 3.8-4.5 | Fe 2.0max | ||||

| W 4.8-5.5 | Ni Bal. | ||||

GH1131 | C 0.10max | W 4.8-6.0 | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm | – | – |

| Si 0.8max | Nb 0.7-1.3 | ||||

| Mn 1.2max | P 0.02max | ||||

| Ni 25.0-30.0 | S 0.02max | ||||

| Cr 19.0-22.0 | Fe Bal. | ||||

| Mo 2.8-3.5 | |||||

Inconel 738LC | Ni Bal. | Nb 0.6-1.1 | 15-53μm 53-150μm | – | – |

| C 0.1-0.2 | Ta 1.5-2.0 | ||||

| Cr 15.7-16.3 | B 0.005-0.015 | ||||

| Co 8.0-9.0 | Fe 0.5max | ||||

| W 2.4-2.8 | Si 0.3max | ||||

| Mo 1.5-2.0 | Mn 0.2max | ||||

| Al 3.2-3.7 | P 0.015max | ||||

| Ti 3.0-3.5 | S 0.015max | ||||

| Zr 0.05-0.15 | |||||

GH4099 | Ni Bal. | Mn 0.4max | 15-53μm 53-150μm | – | – |

| Cr 17.0-20.0 | Si 0.5max | ||||

| W 5.0-7.0 | Mg 0.01max | ||||

| Co 5.0-8.0 | Ce 0.02max | ||||

| Mo 3.5-4.5 | B 0.005max | ||||

| Al 1.7-2.4 | Fe 2.0max | ||||

| Ti 1.0-1.5 | P 0.015max | ||||

| C 0.08max | S 0.015max | ||||

GH3230 | Ni Bal. | W 13.0-15.0 | 15-53μm 53-150μm | – | – |

| C 0.05-0.15 | Ti 0.10max | ||||

| Si 0.25-0.75 | Co 5.0max | ||||

| Mn 0.3-1.0 | Cu 0.5max | ||||

| Cr 20.0-24.0 | Fe 3.0max | ||||

| Mo 1.0-3.0 | B 0.015max | ||||

| La 0.005-0.050 | P 0.030max | ||||

| Al 0.2-0.5 | S 0.015max | ||||

GH3128 | Ni Bal. | B 0.005max | 15-53μm 53-150μm | – | – |

| Cr 19.0-22.0 | Zr 0.06max | ||||

| W 7.5-9.0 | Ce 0.05max | ||||

| Mo 7.5-9.0 | Mn 0.50max | ||||

| Al 0.4-0.8 | Si 0.80max | ||||

| Ti 0.4-0.8 | P 0.015max | ||||

| C 0.05max | S 0.015max | ||||

| Fe 0.20max | |||||

K447A | Ni Bal. | Ta 2.8-3.3 | 15-53μm 53-150μm | – | – |

| C 0.13-0.17 | Al 5.3-5.7 | ||||

| Cr 8.0-8.8 | Ti 0.9-1.2 | ||||

| Co 9.0-11.0 | Hf 1.2-1.6 | ||||

| W 9.5-10.5 | B 0.01-0.02 | ||||

| Mo 0.5-0.8 | Zr 0.03-0.08 | ||||

CoCrW | Co Bal. | Mn 0.30max | 15-53μm 53-106μm 53-150μm | ||

| Cr 26.0-30.0 | C 0.10max | ||||

| W 8.0-10.0 | P 0.03max | ||||

| Si 0.80-1.50 | O 0.08max | ||||

| Ni 0.30max | N 0.15max | ||||

| Fe 0.50max | |||||

CoCrMo | Co Bal. | Fe 0.75max | 15-53μm 53-106μm 53-150μm | ||

| Cr 26.0-30.0 | Mn 0.30max | ||||

| W 0.20max | C 0.40max | ||||

| Mo 4.0-7.0 | P 0.03max | ||||

| Si 1.20max | O 0.08max | ||||

| Ni 0.50max | N 0.15max | ||||

| Customized: IN738, IN939, Incoloy 800, Nimonic 80A, Hastelloy C-276, Rene125, CMSX4, Haynes282, K418, CoCrMoW, Monel400, etc | |||||

Superalloy Powder Applications

3D Printing

Mechanical Industry

Metallurgical Industry

Medical Industry

about us

Truer Industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Send Us A Message

Contact us

sales

Cassiel Ding

+86 – 13611869448

[email protected]

Sales Manager

Lucy Wen

+86 – 15250232891

[email protected]

Quality Control

Mike Wu

+86 – 13862291355

[email protected]

sales

Joan Zhou

+86 – 17316565943

[email protected]

Customer Service

Luke Zhang

+86 – 15250014048

[email protected]