GET SEBM SYSTEM

Shanghai Truer Industrial Development Co., Ltd

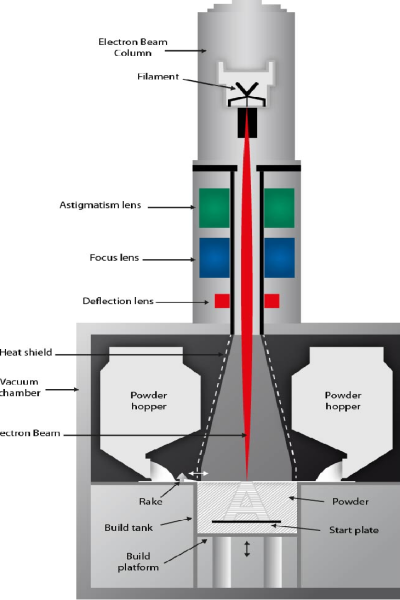

SEBM SYSTEM

SEBM-Y150

SEBM-Y150 designed for the fine manufacturing of orthopedic implants for standardized and personalized prosthetic manufacturing services.

product features:

More detailed electron beam spot and higher forming dimensional accuracy.

Low forming stress, high cleanliness, suitable for high activity, high melting point medical material printing.

High energy efficiency, high speed forming and active cooling, good customized response.

Suitable for AM medical material such as CoCrMo, Ta, Ta-Ti, TC4 alloy.

Main Technical Features:

- The beam spot diameter is finer, the forming precision is higher, and it’s more suitable for the forming of tubercular structure implants;

- The forming parts can be separated directly from the bottom plate without linear cutting, effectively avoiding secondary pollution;

- Increase active cooling, 30% faster cooling speed and quickly improve productivity;

- Especially suitable for high-quality forming of TC4, CoCrMo, Ta and other active medical materials with high melting point;

- Standard TC4 forming process package, CoCrMo and Ta forming process package are optional.

Main Technical Parameters:

- Electron beam gun acceleration voltage: 0 ~ 60kV; Maximum power 3kW; Spot diameter ≤0.2mm;

- Ultimate vacuum degree of forming chamber: 5× 10-3pa;

- Powder coating thickness: Adjustable from 20 to 200 nm;

- The maximum size of forming part: 150×150×180mm;

- Personalized customization and quick response ability;

- Precision of parts: ≤±0.3mm;

- Forming materials: titanium alloy, cobalt chromium, tantalum, titanium tantalum alloy, etc.

Main Parameters of SEBM System( SEBM-Y150)

| External Dimensions | 2000*1200*2150mm³ |

|---|---|

| Build Chamber Dimensions | 200*200*300mm³ |

| Maximum Forming Dimensions | 150*150*200mm³ |

| Layer Thickness | 35-200μm |

| Spot Size of Electron Beam | ≤0.2mm |

| Dimensional accuracy of SEBMed Parts | ±0.2mm |

| Continuous Printing Time | ≥40h |

| Maximum achievable vacuum Pressure | 5.0*10-³ Pa |

Applications

3D Printing

Mechanical Industry

Metallurgical Industry

Medical Industry

about us

Truer Industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Our services

Various metal powders

More than 40 grades of high quality spherical metal powders.

Mature application system

More than 1000 customized orthopedic implant materials to more than 20 hospitals.

No risk of stock outage

Perfect supply chain layout and inventory control make no risk of product stock-out.

3D Printing Equipment

SEBM & PREP technology and equipment.

Support customization

We accept OEM/ODM

Fair prices

High quality products at reasonable prices

FAQ

Most frequent questions and answers

If you have questions or at any point or can’t find the answer you were looking for, call or email us directly at [email protected]. For issues about your orders or our refunds, please refer to our Team. Helping you answer all your questions and solving any problems you may have is our number one priority.

We are the 100% manufacturer specialized in Additive Manufacturing.

Sure. We accept custom orders and OEM/ODM.

You can get a quote by visiting the Request a Quote page, requesting a quote on a product page, phone, email, or from our live chat. Based on a large variance of requirements from project to project, most quotations need to be prepared by a packaging estimator. RFQs can be emailed directly to [email protected].

You will typically receive your quotation within 1-2 business days for most requests. RFQs and complex projects may require more time.

High quantity orders generally net a lower cost-per-unit on all of our orders. For greater savings for your project, you can consult one of our Product Specialists for a customized strategy based on your business requirements and project goals.

We make products easy for our customers. While the steps can differ from project to project, our typical process consists of the following stages:

1. Specification & Project Consultation

2. Quotation

3. Sampling and Prototyping

4. Production

5. Shipping and Fulfillment

We offer a wide range of Additive Manufacturing such as SEBM, PREP and more than 40 different compositions of high-quality spherical metal powders, such as TiNi, TiTa, TiAl, TiNbZr and CoCrMo with fully customizable options.

Most products need to be shipped by sea, but samples used only for testing may be shipped by courier and air to ensure timeliness. All of our products are carefully packaged with care to withstand the potentially harsh elements of travel. You can expect your products to arrive in the same condition they left our facilities.

Production time can range from 5 to 25 business days depending on products type, requirements many other factors. Greater customization with more additional processes generally yields slightly longer production times. For your best estimate in the timeline, consult with your Product Specialist.

While our products technically have no minimum order quantities, recommended MOQs are in place (which will differ based on products type, printing, or processes) to prevent individual unit prices from becoming too costly to recommend.

The minimum order quantity we can usually provide is 1-20kg for samples(based on the detailed products) and 100-200kg for official orders. But it may vary by product, so, please check with your Product Specialist to learn the recommended MOQ of any of our products.

Send Us A Message

Contact us

sales

Cassiel Ding

+86 – 13611869448

[email protected]

Sales Manager

Lucy Wen

+86 – 15250232891

[email protected]

Quality Control

Mike Wu

+86 – 13862291355

[email protected]

sales

Joan Zhou

+86 – 17316565943

[email protected]

Customer Service

Luke Zhang

+86 – 15250014048

[email protected]