Overview of NiAl20 Powder

NiAl20 Powder is an aluminum-based metal powder, specifically composed of nickel and aluminum, which has been gaining popularity in the manufacturing and metallurgical industries. Its unique properties, such as resistance to oxidation, high-temperature performance, and excellent wear resistance, make it an attractive choice for various applications, from aerospace to additive manufacturing. If you’re a manufacturer, engineer, or just someone interested in advanced materials, you’ll want to dig deep into the specifics of NiAl20 powder. Ready? Let’s get started!

In this guide, we’ll explore everything you need to know about NiAl20 Powder, from its composition and characteristics to its applications and pricing. We’ll also compare different metal powder models, discuss their advantages and disadvantages, and help you understand how to choose the right supplier for your needs.

What is NiAl20 Powder?

NiAl20 Powder, also known as Nickel-Aluminum 20, is a specialized intermetallic compound that contains 20% Nickel and 80% Aluminum. This unique combination gives it several enhanced properties such as superior thermal stability and high oxidation resistance. These features make it ideal for use in applications requiring material performance under extreme conditions.

It is widely used in industries such as aerospace, automotive, and manufacturing, where high-temperature materials with excellent structural integrity are required. NiAl20 also offers significant advantages in powder metallurgy and additive manufacturing, making it a flexible and highly valued material in modern engineering.

Composition of NiAl20 Powder

To truly understand NiAl20 powder, we need to break down its elemental composition and how it impacts its properties. The primary components, Nickel (Ni) and Aluminum (Al), play a crucial role in its performance. Here’s a detailed table summarizing the typical composition of NiAl20 Powder:

| Element | Percentage (%) | Function |

|---|---|---|

| Nickel (Ni) | 20 | Enhances corrosion resistance, provides hardness and high-temperature performance |

| Aluminum (Al) | 80 | Contributes to low density, promotes oxidation resistance, enhances thermal conductivity |

Additional Alloying Elements (Traces):

- Titanium (Ti): Increases strength and durability.

- Chromium (Cr): Adds corrosion resistance.

- Molybdenum (Mo): Improves high-temperature strength.

Characteristics of NiAl20 Powder

What makes NiAl20 Powder stand out among other metal powders? Well, it’s the unique blend of physical and mechanical properties that make this alloy highly effective. Below are some of the standout characteristics:

| Characteristic | Description |

|---|---|

| High Oxidation Resistance | NiAl20 forms a protective oxide layer when exposed to high temperatures, preventing further degradation of the material. |

| Thermal Stability | It remains stable under extreme temperatures, making it suitable for applications like gas turbines and heat exchangers. |

| Lightweight | Thanks to its high aluminum content, NiAl20 is significantly lighter than other high-temperature alloys like nickel-based superalloys. |

| Excellent Wear Resistance | It withstands abrasive and adhesive wear, making it ideal for components subjected to high friction, such as engine parts and bearings. |

| Corrosion Resistance | Nickel content contributes to superior corrosion resistance, making it ideal for harsh environments like marine and chemical processing industries. |

| Good Electrical Conductivity | The material exhibits decent electrical conductivity, especially compared to other nickel-based alloys, enabling its use in electrical and electronic components. |

Top Models of Metal Powders Similar to NiAl20 Powder

If you’re considering NiAl20, it might be helpful to compare it against other metal powders with similar applications. Here’s a list of specific models:

- NiAl30 Powder

- Composition: 30% Nickel, 70% Aluminum

- Properties: Higher nickel content for increased corrosion and wear resistance compared to NiAl20.

- Best For: Marine and automotive industries due to its enhanced durability.

- NiAl95 Powder

- Composition: 95% Nickel, 5% Aluminum

- Properties: Significantly higher density, superior electrical and thermal conductivity.

- Best For: Electronics and aerospace applications requiring high nickel content.

- AlSi10Mg Powder

- Composition: 10% Silicon, 90% Aluminum, trace Magnesium

- Properties: Known for high strength and lightweight properties, ideal for 3D printing.

- Best For: Additive manufacturing in automotive and aerospace sectors.

- Ti-6Al-4V Powder

- Composition: 6% Aluminum, 4% Vanadium, balance Titanium

- Properties: Extremely strong and lightweight, excellent corrosion resistance.

- Best For: Medical implants, aerospace components.

- Inconel 625 Powder

- Composition: Nickel-Chromium-Molybdenum alloy

- Properties: High strength, oxidation resistance, and excellent weldability.

- Best For: Aerospace, marine, and chemical processing industries.

- CoCrMo Powder

- Composition: Cobalt, Chromium, Molybdenum

- Properties: High wear resistance and biocompatibility.

- Best For: Medical implants, particularly orthopedic and dental devices.

- 316L Stainless Steel Powder

- Composition: Iron, Nickel, Chromium

- Properties: Good corrosion resistance, weldability, and toughness.

- Best For: Medical devices, automotive, and structural components.

- Al-Mg5 Powder

- Composition: Aluminum-Magnesium alloy

- Properties: High strength, low density, excellent corrosion resistance.

- Best For: Marine applications, thanks to its resistance to saltwater environments.

- Cu-Ni (Copper-Nickel) Powder

- Composition: 90% Copper, 10% Nickel

- Properties: Excellent corrosion resistance, particularly in marine environments.

- Best For: Marine and shipbuilding industries.

- Hastelloy C-276 Powder

- Composition: Nickel-Molybdenum-Chromium alloy

- Properties: Resistance to a wide range of harsh chemicals, acids, and environments.

- Best For: Chemical processing and pollution control industries.

Applications of NiAl20 Powder

NiAl20 is versatile and finds use in many industries. From automotive to aerospace, it performs excellently under conditions where other materials would break down. Here’s a table showing some of the common applications of NiAl20 Powder and similar powders:

| Application | Description |

|---|---|

| Aerospace Components | NiAl20 is used in jet engines, turbine blades, and other high-temperature aerospace components that require resistance to heat and oxidation. |

| Automotive Parts | Used in engines, exhaust systems, and high-performance racing parts due to its wear resistance and ability to withstand extreme temperatures. |

| Additive Manufacturing | NiAl20 Powder is ideal for 3D printing of complex parts where both high strength and low weight are needed, such as aerospace structures and automotive parts. |

| Thermal Spraying Coatings | Applied as a coating material to protect against wear, corrosion, and heat damage in machinery and industrial equipment. |

| Gas Turbines | Its thermal stability and oxidation resistance make it suitable for gas turbines and other energy systems. |

| Chemical Processing | Corrosion-resistant NiAl20 components are used in the chemical processing industry, particularly in harsh, corrosive environments. |

| Marine Components | NiAl20, due to its lightweight properties and corrosion resistance, is used in marine engineering for components like propellers and engine parts. |

Specifications, Sizes, and Standards for NiAl20 Powder

When choosing NiAl20 Powder for your application, it’s crucial to know the exact specifications to ensure proper performance. Below is a table summarizing the common specifications and standards for NiAl20 Powder:

| Specification | Details |

|---|---|

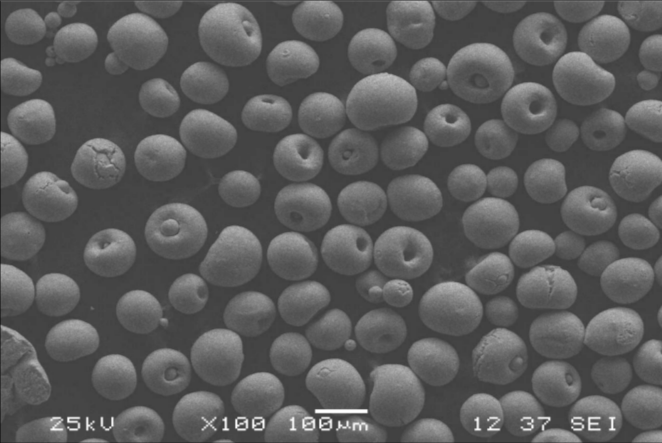

| Particle Size Distribution | Typically available in sizes ranging from 10 to 100 microns, depending on the manufacturing process. |

| Density | Varies from 5.7 g/cm³ to 6.2 g/cm³ depending on alloying elements. |

| Melting Point | 1390°C – 1450°C |

| Powder Shape | Generally spherical or irregularly shaped powders depending on production technique (gas atomization or plasma atomization). |

| Manufacturing Process | Produced via methods such as gas atomization, plasma atomization, or mechanical milling. |

| Standard Compliance | Follows standards like ASTM F3055 for Nickel-Aluminum powder, ensuring consistency in production and quality. |

Suppliers and Pricing of NiAl20 Powder

Getting NiAl20 Powder from reliable suppliers is key to ensuring product quality and performance. Here’s a table showcasing some prominent suppliers and an estimated range of pricing based on different markets:

| Supplier | Location | Pricing (per kg) | Comments |

| Höganäs AB | Sweden | $150 – $200 | Well-known for high-quality metal powders, including NiAl20 for additive manufacturing. |

| Praxair Surface Technologies | USA | $140 – $190 | Provides a wide range of powders, including custom compositions based on customer needs. |

| GKN Hoeganaes | UK/Global | $130 – $170 | Offers extensive technical support for powder metallurgy applications. |

| LPW Technology | UK/USA | $160 – $210 | Specializes in metal powders for 3D printing and other high-tech applications. |

| Sandvik Materials Technology | Sweden | $140 – $195 | Produces consistent, high-quality powders with strict adherence to international standards. |

Advantages of NiAl20 Powder Compared to Other Metal Powders

In comparison to other metal powders, NiAl20 Powder presents several distinct advantages, but it also has limitations. Let’s break it down:

| NiAl20 Powder | Other Metal Powders (e.g., Inconel 625, 316L Stainless Steel, AlSi10Mg) |

|---|---|

| Advantages | |

| High Oxidation Resistance | NiAl20 outperforms other powders like Inconel in oxidation resistance, especially at temperatures above 1000°C. |

| Lightweight | Compared to Inconel 625 or 316L Stainless Steel, NiAl20 is significantly lighter, which can be crucial in aerospace applications. |

| Cost-Effective | NiAl20 is generally more affordable compared to nickel-based superalloys such as Inconel, providing a cost-effective solution for high-temperature environments. |

| Disadvantages | |

| Lower Strength at High Temperatures | NiAl20 may not be as strong as materials like Inconel or Hastelloy when exposed to extreme heat for prolonged periods. |

| Limited Ductility | It can be more brittle compared to alloys with higher nickel or titanium content. |

| Less Wear Resistance | In situations demanding extreme wear resistance (e.g., turbine blades), NiAl20 may fall short compared to titanium-based alloys or cobalt-chrome alloys. |

FAQs

| Question | Answer |

|---|---|

| What are the main uses of NiAl20 Powder? | NiAl20 is primarily used in aerospace, automotive, additive manufacturing, and thermal spray coatings due to its high oxidation resistance and lightweight properties. |

| How is NiAl20 Powder made? | It’s typically produced using atomization techniques, such as gas or plasma atomization, ensuring a fine and consistent powder distribution. |

| Can NiAl20 Powder be used in 3D printing? | Yes, NiAl20 is often used in additive manufacturing (3D printing) to produce lightweight, high-performance components. |

| How does NiAl20 compare to Inconel or Hastelloy? | While NiAl20 is lighter and more cost-effective, Inconel and Hastelloy offer superior strength and wear resistance at high temperatures. |

| What is the cost of NiAl20 Powder? | The price typically ranges from $130 to $210 per kilogram, depending on the supplier, quantity, and additional specifications. |

In conclusion, NiAl20 Powder is a highly versatile and effective material for industries requiring high temperature and corrosion-resistant properties. While it has some limitations, particularly in strength and wear resistance compared to other metal powders, its lightweight nature and affordability make it an excellent choice for applications like aerospace and additive manufacturing. If you’re in the market for high-performance metal powders, understanding the composition, characteristics, and available models can help you make an informed decision.