Overview of Powder for Multi-Laser Printing

In the ever-evolving world of manufacturing, multi-laser printing has emerged as a cutting-edge technology, pushing the boundaries of what’s possible in additive manufacturing. But what powers this technology? The answer lies in the metal powders used in these sophisticated machines. These powders, meticulously engineered and crafted, are the foundation upon which complex, durable, and high-precision components are built.

Multi-laser printing, particularly in the realm of metal additive manufacturing, relies heavily on the quality and characteristics of the powders used. This article delves deep into the various aspects of metal powders for multi-laser printing, exploring different types, compositions, properties, and applications. We’ll guide you through the technical intricacies and offer comparisons to help you make informed decisions whether you’re a seasoned professional or a curious novice.

Composition of Powder for Multi-Laser Printing

When discussing metal powders for multi-laser printing, composition is crucial. The elemental makeup of the powder determines its suitability for specific applications, its melting behavior, and ultimately, the quality of the printed part. Here’s a breakdown of common metal powder compositions used in multi-laser printing:

| Powder Type | Primary Composition | Secondary Elements | Notable Characteristics |

|---|---|---|---|

| Stainless Steel 316L | Fe, Cr, Ni, Mo | C, Si, Mn | High corrosion resistance, excellent ductility |

| Aluminum Alloy AlSi10Mg | Al, Si, Mg | Fe, Cu, Mn | Lightweight, good thermal properties, high strength-to-weight ratio |

| Titanium Alloy Ti-6Al-4V | Ti, Al, V | O, Fe | High strength, biocompatibility, corrosion resistance |

| Inconel 718 | Ni, Cr, Fe, Nb | Mo, Ti, Al, Co | High temperature resistance, strength, and toughness |

| Cobalt-Chrome (CoCr) | Co, Cr, Mo | W, Si | Excellent wear resistance, biocompatibility |

| Maraging Steel (18Ni300) | Fe, Ni, Co, Mo | Ti, Al | High strength, good toughness, easily machinable |

| Copper Alloy (CuCrZr) | Cu, Cr, Zr | Fe, Pb | High thermal and electrical conductivity |

| Hastelloy X | Ni, Cr, Fe, Mo | Co, W, Si | Oxidation and creep resistance at high temperatures |

| Tool Steel (H13) | Fe, Cr, Mo, V | C, Si, Mn | High wear resistance, excellent toughness |

| Nickel Alloy (Ni625) | Ni, Cr, Mo, Nb | Fe, Al, Ti | High corrosion and oxidation resistance |

These compositions are finely tuned to provide specific properties necessary for diverse applications, from aerospace to biomedical implants.

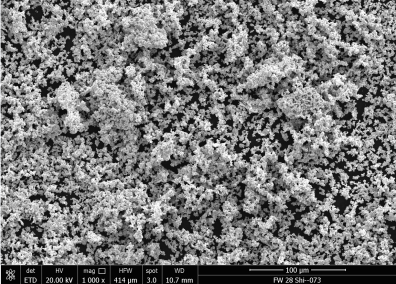

Characteristics of Powder for Multi-Laser Printing

The characteristics of metal powders are just as critical as their compositions. These characteristics impact the printing process, the mechanical properties of the printed parts, and the overall success of the multi-laser printing operation.

| Characteristic | Description |

|---|---|

| Particle Size Distribution | Uniform particle size distribution ensures consistent flowability and packing density, crucial for layer-by-layer printing. |

| Sphericity | Spherical particles promote better flowability and packing, reducing the likelihood of defects in the printed part. |

| Purity | High purity minimizes contamination, which can lead to defects or reduced performance in the final part. |

| Apparent Density | Higher apparent density can improve the mechanical properties of the final part, as it leads to fewer voids and defects. |

| Flowability | Good flowability is essential for consistent powder distribution during the printing process, affecting build quality and reliability. |

| Moisture Content | Low moisture content is critical to prevent oxidation or other reactions that could compromise the powder’s performance. |

| Oxygen Content | Control of oxygen levels is vital, especially in reactive materials like titanium, where high oxygen can lead to embrittlement. |

| Chemical Homogeneity | Ensures uniform mechanical properties throughout the printed part, preventing weak spots or inconsistencies. |

| Surface Texture | Smooth surface texture reduces friction between particles, enhancing flowability and layer cohesion during printing. |

Understanding these characteristics is key to selecting the right powder for your specific application, ensuring optimal performance and quality.

Types of Metal Powders for Multi-Laser Printing

Different applications require different types of metal powders. Here’s a detailed look at some of the most commonly used metal powders in multi-laser printing:

| Metal Powder Type | Applications | Advantages | Disadvantages |

|---|---|---|---|

| Stainless Steel 316L | Medical devices, food processing equipment | High corrosion resistance, biocompatible | Lower strength compared to other alloys |

| Aluminum Alloy AlSi10Mg | Aerospace, automotive parts | Lightweight, high strength-to-weight ratio | Limited fatigue strength |

| Titanium Alloy Ti-6Al-4V | Aerospace, medical implants | High strength, biocompatibility | Expensive, challenging to process |

| Inconel 718 | Turbine blades, high-temperature components | Excellent heat resistance, strength | Difficult to machine |

| Cobalt-Chrome (CoCr) | Dental implants, orthopedic implants | Wear resistance, corrosion resistance, biocompatibility | High cost |

| Maraging Steel (18Ni300) | Tooling, high-strength components | High strength, toughness, easy to machine | Expensive |

| Copper Alloy (CuCrZr) | Heat exchangers, electrical components | Excellent thermal and electrical conductivity | Prone to oxidation |

| Hastelloy X | Chemical processing, aerospace | High-temperature strength, oxidation resistance | Very expensive, difficult to weld |

| Tool Steel (H13) | Injection molds, die-casting | High wear resistance, toughness | Prone to cracking during heat treatment |

| Nickel Alloy (Ni625) | Marine, chemical processing | Corrosion resistance, good weldability | High cost, limited availability |

Each of these powders has unique strengths and weaknesses, making them suitable for specific applications but potentially problematic for others. For example, while Titanium Alloy Ti-6Al-4V offers unmatched strength and biocompatibility, it’s more expensive and harder to process compared to Stainless Steel 316L.

Applications of Powder for Multi-Laser Printing

Multi-laser printing is used across various industries, each requiring specific metal powders that meet their unique demands. Here’s a detailed look at some applications:

| Industry | Applications | Preferred Metal Powders |

|---|---|---|

| Aerospace | Turbine blades, structural components | Inconel 718, Titanium Alloy Ti-6Al-4V, Aluminum Alloy AlSi10Mg |

| Medical | Implants, surgical instruments | Stainless Steel 316L, Cobalt-Chrome (CoCr), Titanium Alloy Ti-6Al-4V |

| Automotive | Lightweight components, engine parts | Aluminum Alloy AlSi10Mg, Maraging Steel (18Ni300), Stainless Steel 316L |

| Tooling | Molds, dies, and high-strength components | Tool Steel (H13), Maraging Steel (18Ni300), Inconel 718 |

| Energy | Heat exchangers, power generation components | Copper Alloy (CuCrZr), Nickel Alloy (Ni625), Hastelloy X |

| Marine | Corrosion-resistant components, structural parts | Nickel Alloy (Ni625), Stainless Steel 316L, Inconel 718 |

Each industry has distinct requirements, making the selection of the right metal powder crucial for ensuring optimal performance and cost-effectiveness.

Specifications, Sizes, Grades, and Standards

When selecting metal powders for multi-laser printing, it’s important to consider the specifications, sizes, grades, and standards required for your specific application. Here’s a detailed table summarizing these aspects:

| Metal Powder Type | Particle Size Range (µm) | Grade | Standards | Purity |

|---|---|---|---|---|

| Stainless Steel 316L | 15-45 | AM Series | ASTM F3184, ISO 5832-1 | 99.9% |

| Aluminum Alloy AlSi10Mg | 20-63 | AM Series | ISO 9001, ASTM F3318 | 99.8% |

| Titanium Alloy Ti-6Al-4V | 15-45 | AM Series | ASTM F2924, ISO 5832-3 | 99.5% |

| Inconel 718 | 15-53 | AM Series | ASTM B637, ISO 6362 | 99.8% |

Cobalt-Chrome (CoCr) | 20-45 | AM Series | ASTM F75, ISO 5832-12 | 99.5% |

| Maraging Steel (18Ni300) | 15-53 | AM Series | ASTM A709, ISO 683-17 | 99.9% |

| Copper Alloy (CuCrZr) | 10-45 | AM Series | ASTM B192, ISO 5414 | 99.9% |

| Hastelloy X | 15-53 | AM Series | ASTM B333, ISO 18286 | 99.8% |

| Tool Steel (H13) | 15-45 | AM Series | ASTM A681, ISO 4957 | 99.7% |

| Nickel Alloy (Ni625) | 15-53 | AM Series | ASTM B443, ISO 6206 | 99.8% |

These specifications ensure that the powders meet industry standards for performance and quality, providing consistency in the final printed components.

Suppliers and Pricing Details

Choosing the right supplier is as important as selecting the right powder. Below is a summary of reputable suppliers and general pricing details for various metal powders:

| Supplier | Metal Powder Type | Approximate Price (per kg) | Location | Website |

|---|---|---|---|---|

| Sandvik Additive Manufacturing | Stainless Steel 316L | $150 – $250 | Sweden | sandvik.com |

| EOS | Aluminum Alloy AlSi10Mg | $200 – $300 | Germany | eos.info |

| Arcam (GE Additive) | Titanium Alloy Ti-6Al-4V | $400 – $600 | Sweden | arcam.com |

| Kennametal | Inconel 718 | $350 – $500 | USA | kennametal.com |

| Desktop Metal | Cobalt-Chrome (CoCr) | $500 – $700 | USA | desktopmetal.com |

| LPW Technology | Maraging Steel (18Ni300) | $300 – $450 | UK | lpwtechnology.com |

| GKN Additive | Copper Alloy (CuCrZr) | $250 – $350 | Germany | gknpowder.com |

| Hastelloy® by Haynes | Hastelloy X | $600 – $800 | USA | haynesintl.com |

| Sisma | Tool Steel (H13) | $220 – $320 | Italy | sisma.com |

| Velo3D | Nickel Alloy (Ni625) | $500 – $700 | USA | velo3d.com |

Prices may vary based on order quantity, shipping costs, and market fluctuations. Always consult with suppliers for the most current pricing and availability.

Advantages and Limitations of Metal Powders for Multi-Laser Printing

Selecting the right metal powder involves weighing its advantages and limitations. Here’s a comparative overview:

| Powder Type | Advantages | Limitations |

|---|---|---|

| Stainless Steel 316L | Corrosion-resistant, good mechanical properties | Less strength compared to some alloys |

| Aluminum Alloy AlSi10Mg | Lightweight, high strength-to-weight ratio | Lower fatigue strength, higher cost of processing |

| Titanium Alloy Ti-6Al-4V | High strength, excellent corrosion resistance, biocompatible | Expensive, challenging to process |

| Inconel 718 | Excellent heat resistance, high strength | Difficult to machine, higher cost |

| Cobalt-Chrome (CoCr) | Wear resistance, biocompatibility | High cost, complex processing requirements |

| Maraging Steel (18Ni300) | High strength, good toughness | Expensive, requires precise heat treatment |

| Copper Alloy (CuCrZr) | Excellent thermal and electrical conductivity | Prone to oxidation, complex to process |

| Hastelloy X | High-temperature strength, oxidation resistance | Very expensive, difficult to weld |

| Tool Steel (H13) | High wear resistance, excellent toughness | Prone to cracking during heat treatment |

| Nickel Alloy (Ni625) | Corrosion resistance, good weldability | High cost, limited availability |

Each type of powder offers a unique set of benefits suited for specific applications but also comes with its own set of challenges. For instance, while Titanium Alloy Ti-6Al-4V is highly desirable for its strength and biocompatibility, its high cost and complex processing needs might not make it suitable for every project.

FAQ

| Question | Answer |

|---|---|

| What is the role of metal powders in multi-laser printing? | Metal powders serve as the material feedstock for multi-laser printing, enabling the creation of complex parts layer by layer. |

| How do different metal powders affect the final product? | The choice of powder impacts the mechanical properties, appearance, and performance of the final printed part, including strength, durability, and resistance to various conditions. |

| Why is particle size important in metal powders? | Particle size affects the powder’s flowability and packing density, which in turn influences the consistency and quality of the printed layers. |

| Can metal powders be recycled? | Yes, many metal powders can be recycled, though the process and efficiency can vary depending on the powder and recycling technology used. |

| What are the typical costs of metal powders for multi-laser printing? | Costs vary widely depending on the type of powder, its purity, and supplier. Prices generally range from $150 to $800 per kilogram. |

| How does purity affect metal powders? | Higher purity powders result in fewer contaminants, leading to better mechanical properties and reliability of the final printed part. |

| Are there any environmental concerns with metal powders? | Metal powders can pose environmental concerns if not handled properly, including dust hazards and contamination. Proper safety measures and disposal practices are crucial. |

| What standards should metal powders for multi-laser printing meet? | Common standards include ASTM and ISO specifications, which ensure quality and consistency in the powders used for additive manufacturing. |