Introduction to Metal Binder Jet Solutions

The world of manufacturing has undergone seismic shifts with the advent of additive manufacturing, commonly known as 3D printing. Within this realm, metal binder jetting stands out as one of the most promising and versatile technologies. But what exactly is a metal binder jet solution, and why is it making waves in industries ranging from aerospace to jewelry?

Metal binder jetting is a type of additive manufacturing where a binding agent is selectively deposited onto a bed of metal powder, layer by layer, to form a solid part. Unlike other 3D printing methods, it doesn’t require high temperatures or laser beams to fuse the material. Instead, it relies on the binder and subsequent sintering to create robust metal parts. This process opens up a world of possibilities in terms of speed, cost-effectiveness, and material flexibility.

In this comprehensive guide, we’ll explore the nuances of metal binder jet solutions, from the types of metal powders available to the intricacies of their composition, characteristics, and applications. We’ll also dive into specific models of metal powders, their specifications, suppliers, and a thorough comparison of their advantages and limitations. By the end of this article, you’ll have a solid grasp of why metal binder jet solutions are becoming a game-changer in modern manufacturing.

Overview of Metal Binder Jet Solutions

In simple terms, metal binder jetting is a form of 3D printing that uses metal powder and a binding agent to create complex metal parts. The process involves spreading a thin layer of metal powder over a build platform, after which a print head selectively deposits a binder that glues the powder particles together. This process is repeated layer by layer until the part is fully formed. After printing, the part undergoes a curing process to harden the binder, followed by sintering to fuse the metal particles together, producing a fully dense metal component.

This technology has several key advantages over traditional manufacturing methods, including the ability to produce intricate geometries that would be impossible or extremely costly to create using conventional techniques. Additionally, metal binder jetting is faster and more cost-effective for producing small to medium-sized batches of parts.

Composition of Metal Binder Jet Solutions

The composition of a metal binder jet solution is crucial for determining the quality, strength, and durability of the final product. Different types of metal powders are used, each with specific properties that make them suitable for various applications. Below is a detailed look at the common metal powders used in binder jetting, their compositions, and their characteristics.

| Metal Powder | Composition | Characteristics | Applications |

|---|---|---|---|

| Stainless Steel 316L | Iron, Chromium, Nickel, Molybdenum | Corrosion-resistant, good strength, ductility | Aerospace, medical devices, automotive components |

| Inconel 625 | Nickel, Chromium, Molybdenum, Niobium | High-temperature resistance, corrosion-resistant | Aerospace, chemical processing, marine industries |

| Copper | Copper | Excellent electrical and thermal conductivity | Electrical components, heat exchangers, decorative items |

| Titanium Ti6Al4V | Titanium, Aluminum, Vanadium | High strength-to-weight ratio, corrosion-resistant | Aerospace, medical implants, automotive racing parts |

| Tool Steel M2 | Iron, Tungsten, Molybdenum, Chromium, Vanadium | High hardness, wear resistance, toughness | Cutting tools, molds, dies |

| Cobalt-Chrome | Cobalt, Chromium, Molybdenum | Biocompatibility, corrosion-resistant, wear-resistant | Medical implants, dental devices, turbine blades |

| Nickel Alloy 718 | Nickel, Chromium, Iron, Molybdenum | High strength, oxidation-resistant, weldability | Jet engines, power generation turbines, nuclear reactors |

| Aluminum AlSi10Mg | Aluminum, Silicon, Magnesium | Lightweight, good strength, machinability | Automotive parts, aerospace components, consumer electronics |

| Bronze | Copper, Tin | Good wear resistance, machinability, aesthetic appeal | Bearings, bushings, sculptures, musical instruments |

| Iron | Iron | High strength, magnetic properties, cost-effective | Structural components, automotive parts, magnetic devices |

Each of these powders brings something unique to the table, whether it’s the corrosion resistance of stainless steel or the lightweight nature of aluminum. The choice of metal powder largely depends on the specific requirements of the application, such as the need for high strength, thermal stability, or biocompatibility.

Characteristics of Metal Binder Jet Solutions

Understanding the characteristics of metal binder jetting is key to leveraging its full potential. The process involves several steps, each of which can be fine-tuned to produce parts with specific properties. Let’s break down these characteristics.

Layer Thickness

In metal binder jetting, the layer thickness plays a crucial role in determining the surface finish and accuracy of the final part. Typically, layer thickness ranges from 50 to 200 microns. Thinner layers lead to smoother surfaces and more precise details but can increase print time.

Print Speed

Metal binder jetting is known for its high print speed compared to other additive manufacturing techniques. This is because it doesn’t involve melting or fusing the metal powder during the printing process, allowing for faster layer deposition.

Surface Finish

The surface finish of parts produced by metal binder jetting is generally good but may require post-processing, such as polishing or machining, to achieve a mirror-like finish. The binder and powder type, along with layer thickness, all influence the surface quality.

Material Properties

The material properties of binder jetted parts are comparable to those of traditionally manufactured parts, especially after sintering. Properties such as tensile strength, hardness, and thermal conductivity are largely determined by the metal powder used and the sintering process.

Complex Geometries

One of the standout features of metal binder jetting is its ability to produce highly complex geometries that would be impossible or too costly to create using conventional manufacturing methods. This includes intricate internal channels, lattice structures, and overhangs without the need for support structures.

Cost Efficiency

Metal binder jetting is more cost-effective for small to medium-sized production runs compared to traditional methods like CNC machining or casting. The lack of tooling and the ability to produce multiple parts in a single print job further drive down costs.

| Characteristic | Details |

|---|---|

| Layer Thickness | 50-200 microns |

| Print Speed | High, no melting required |

| Surface Finish | Good, may require post-processing |

| Material Properties | Comparable to traditional manufacturing, depends on powder and sintering |

| Complex Geometries | Excellent capability, no support structures needed |

| Cost Efficiency | High, especially for small to medium-sized production runs |

Advantages of Metal Binder Jet Solutions

Metal binder jetting brings several advantages to the table, making it an attractive option for a variety of industries. Let’s explore these benefits in more detail.

Speed and Efficiency

One of the main advantages of metal binder jetting is its speed. Unlike other metal 3D printing methods that require melting and solidifying each layer, binder jetting can print entire layers at once. This significantly reduces print times, allowing for quicker turnaround of parts.

Material Flexibility

Metal binder jetting is compatible with a wide range of metal powders, giving manufacturers the flexibility to choose the best material for their specific needs. Whether it’s stainless steel for corrosion resistance or copper for electrical conductivity, there’s a metal powder that fits the bill.

Cost-Effective Production

For small to medium production runs, metal binder jetting is more cost-effective than traditional manufacturing methods. The ability to print multiple parts in a single batch without the need for expensive tooling or molds further reduces costs.

High Detail and Accuracy

Metal binder jetting excels at producing parts with intricate details and high accuracy. This is particularly useful for applications where precision is critical, such as in aerospace components or medical devices.

Environmentally Friendly

Compared to subtractive manufacturing methods, metal binder jetting produces less waste. Since it’s an additive process, material is only used where it’s needed, reducing the overall consumption of resources.

| Advantage | Explanation |

|---|---|

| Speed and Efficiency | Prints entire layers at once, reducing print time |

| Material Flexibility | Compatible with various metal powders |

| Cost-Effective Production | No need for expensive tooling or molds |

| High Detail and Accuracy | Produces intricate parts with high precision |

| Environmentally Friendly | Less waste produced compared to subtractive methods |

Applications of Metal Binder Jet Solutions

The versatility of metal binder jetting makes it suitable for a wide range of applications across various industries. Below is an overview of some of the key sectors where this technology is making a significant impact.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Lightweight structural components, complex engine parts | High strength-to-weight ratio, complex geometries |

| Automotive | Prototypes, custom parts, small production runs | Cost-effective, quick turnaround, material versatility |

| Medical | Implants, surgical instruments, custom prosthetics | Biocompatibility, high precision, patient-specific solutions |

| Jewelry | Intricate designs, custom pieces, small batches | High detail, cost-effective, material options like gold and silver |

| Energy | Turbine blades, fuel nozzles, heat exchangers | High-temperature resistance, complex geometries |

| Industrial | Tooling, molds, jigs, fixtures | Durability, wear resistance, cost savings |

The applications of metal binder jet solutions are vast, ranging from creating lightweight components for aircraft to producing custom jewelry with intricate designs. The ability to create complex parts with high precision makes this technology indispensable in modern manufacturing.

Specifications and Standards for Metal Binder Jet Solutions

When selecting a metal binder jet solution, it’s crucial to understand the specifications and standards that govern the quality and performance of the materials and processes. Below is a table outlining some of the key specifications, sizes, grades, and standards associated with metal binder jetting.

| Specification/Standard | Details |

|---|---|

| ASTM F2924 | Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion |

| ASTM F3055 | Standard Specification for Additive Manufacturing Nickel Alloy with Powder Bed Fusion |

| ISO/ASTM 52900 | Standard Terminology for Additive Manufacturing |

| Layer Thickness | 50-200 microns, depending on material and application |

| Part Density | Typically 95-99% of wrought materials after sintering |

| Surface Roughness | Typically 5-15 µm, depending on post-processing |

| Dimensional Accuracy | ±0.1-0.3 mm, depending on part size and geometry |

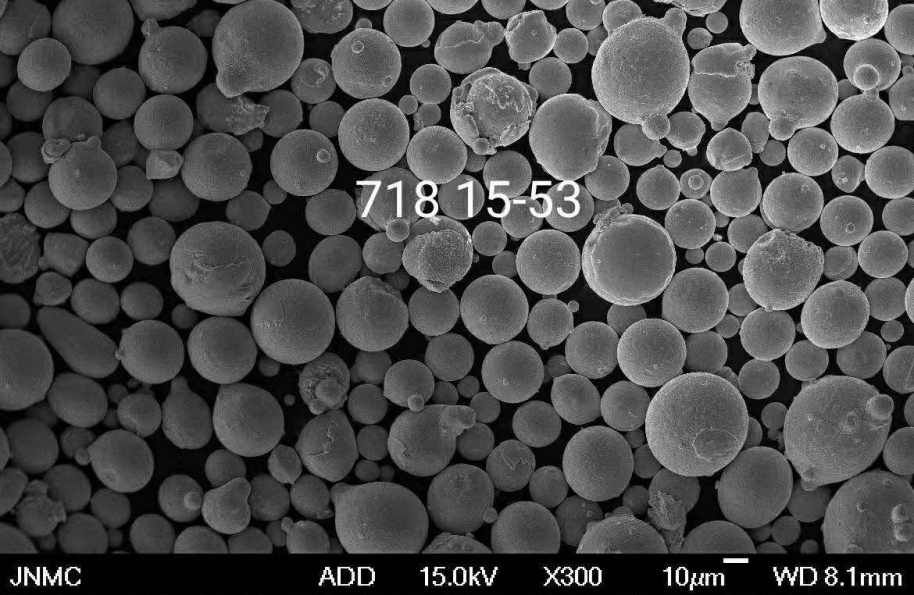

| Powder Particle Size | Typically 15-45 µm, affects flowability and packing density |

These specifications and standards ensure that the metal binder jetting process produces parts that meet the necessary quality and performance requirements. It’s important to choose a solution that aligns with these standards to guarantee the reliability and durability of the final product.

Comparison of Metal Binder Jet Solutions

When considering metal binder jetting for your manufacturing needs, it’s essential to compare the different solutions available. Below is a comparative analysis of the various metal powders and their suitability for different applications.

| Metal Powder | Advantages | Limitations | Best Suited For |

|---|---|---|---|

| Stainless Steel 316L | Corrosion resistance, good mechanical properties | More expensive than some alternatives | Aerospace, medical devices, marine environments |

| Inconel 625 | High-temperature resistance, excellent corrosion resistance | High cost, difficult to machine | Jet engines, chemical processing, nuclear reactors |

| Copper | Excellent electrical and thermal conductivity, malleability | Lower strength compared to steels, prone to oxidation | Electrical components, heat exchangers, plumbing |

| Titanium Ti6Al4V | High strength-to-weight ratio, biocompatibility | Expensive, requires careful handling | Medical implants, aerospace components, racing parts |

| Tool Steel M2 | High hardness and wear resistance, toughness | Requires post-processing like heat treatment | Cutting tools, molds, dies |

| Cobalt-Chrome | Biocompatibility, wear resistance, high strength | High cost, difficult to machine | Medical implants, dental prosthetics, turbine blades |

| Nickel Alloy 718 | High strength, oxidation resistance, weldability | Expensive, challenging to process | Jet engines, power generation, oil and gas |

| Aluminum AlSi10Mg | Lightweight, good strength, ease of machining | Lower strength compared to steels, requires anodizing for corrosion resistance | Automotive parts, consumer electronics, lightweight structures |

| Bronze | Good wear resistance, machinability, aesthetic appeal | Prone to tarnishing, lower mechanical properties compared to steel | Bearings, bushings, decorative items |

| Iron | High strength, magnetic properties, low cost | Susceptible to corrosion, lower fatigue strength compared to alloys | Structural components, automotive parts, magnetic devices |

This comparison helps identify the best metal powder for specific applications, balancing factors like cost, material properties, and ease of processing.

Suppliers and Pricing Details for Metal Binder Jet Solutions

Finding the right supplier is essential for securing high-quality metal powders and reliable binder jetting equipment. Below is a table listing some of the leading suppliers in the industry, along with pricing details for their products.

| Supplier | Metal Powders Available | Price Range (per kg) | Location | Website |

|---|---|---|---|---|

| Höganäs AB | Stainless Steel, Copper, Bronze, Iron | $50-$200 | Sweden | hoganas.com |

| GKN Additive | Inconel, Aluminum, Titanium, Tool Steel | $100-$400 | Germany | gknpm.com |

| Carpenter Technology | Nickel Alloys, Cobalt-Chrome, Tool Steel | $150-$500 | USA | cartech.com |

| Sandvik Additive Manufacturing | Stainless Steel, Titanium, Copper, Iron | $70-$300 | Sweden | additive.sandvik.com |

| Epson Atmix | Aluminum, Bronze, Stainless Steel | $60-$250 | Japan | epson.jp |

| AP&C (a GE Additive company) | Titanium, Aluminum, Nickel Alloys | $200-$600 | Canada | advancedpowders.com |

Pricing can vary based on factors such as the type of metal powder, the required quantity, and the supplier’s location. It’s advisable to request quotes from multiple suppliers to ensure competitive pricing and availability.

Pros and Cons of Metal Binder Jet Solutions

Like any manufacturing technology, metal binder jetting has its pros and cons. Understanding these can help you make an informed decision on whether this method is suitable for your production needs.

| Pros | Cons |

|---|---|

| High Print Speed | Prints layers quickly without needing melting or fusing |

| Material Versatility | Compatible with a wide range of metal powders |

| Cost Efficiency | More affordable for small to medium-sized production runs |

| Complex Geometries | Capable of producing intricate designs and internal structures |

| Environmentally Friendly | Less waste produced, material is only used where needed |

| Lower Strength Compared to Traditional Methods | May require post-processing to achieve desired mechanical properties |

| Surface Finish May Require Post-Processing | Additional steps like polishing or machining may be needed |

| Limited Material Availability | Not all metals are suitable for binder jetting |

By weighing these pros and cons, manufacturers can determine if metal binder jetting aligns with their production goals, whether it’s speed, cost, or the ability to produce complex parts.

FAQs

Here are some frequently asked questions about metal binder jet solutions, along with their answers to help clarify any remaining doubts.

| Question | Answer |

|---|---|

| What is metal binder jetting? | Metal binder jetting is an additive manufacturing process that uses a binding agent to fuse metal powder into solid parts. |

| How does metal binder jetting differ from other 3D printing methods? | Unlike other methods, metal binder jetting does not require melting the powder. Instead, it uses a binder and sintering process, which allows for faster printing and more material options. |

| What metals can be used in binder jetting? | Common metals include stainless steel, titanium, Inconel, copper, and aluminum. The choice of metal depends on the desired properties of the final part. |

| Is post-processing required in metal binder jetting? | Yes, post-processing steps like sintering, polishing, or machining are often required to achieve the desired mechanical properties and surface finish. |

| How strong are parts made with metal binder jetting? | The strength of binder jetted parts is comparable to traditionally manufactured parts, especially after sintering. However, they may require additional heat treatment to reach optimal strength. |

| What industries benefit the most from metal binder jetting? | Industries such as aerospace, automotive, medical, and jewelry benefit from the technology due to its ability to produce complex, high-precision parts. |

| Is metal binder jetting environmentally friendly? | Yes, it’s considered more environmentally friendly than traditional subtractive manufacturing because it produces less waste. |

| How does the cost of metal binder jetting compare to other manufacturing methods? | Metal binder jetting is generally more cost-effective for small to medium-sized production runs, particularly when compared to methods like CNC machining or casting. |

| Can metal binder jetting produce large parts? | While metal binder jetting is typically used for small to medium-sized parts, advances in technology are expanding the potential for larger builds. |

Conclusion

Metal binder jetting represents a significant leap forward in additive manufacturing, offering a blend of speed, material flexibility, and the ability to produce complex geometries. As industries continue to explore its potential, this technology is poised to become a cornerstone of modern manufacturing, driving innovation and efficiency across various sectors.