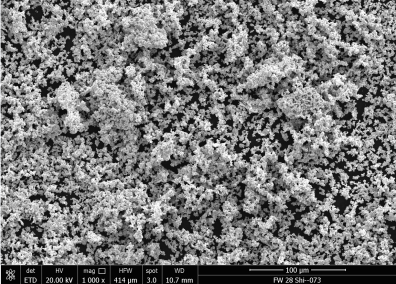

Cobalt-chromium powders, often referred to as CoCr powders, are pivotal materials in a variety of advanced manufacturing processes, particularly in industries such as aerospace, medical implants, and automotive. But what makes these powders so special? Why are they so commonly used in high-performance applications? Let’s dive deep into the fascinating world of cobalt-chromium powders, exploring their properties, applications, and everything in between.

Overview of Cobalt-Chromium Powders

Cobalt-chromium powders are alloys composed primarily of cobalt (Co) and chromium (Cr), often with small additions of other elements like molybdenum, tungsten, or carbon. These powders are revered for their exceptional wear resistance, corrosion resistance, and high-temperature strength. Such properties make them ideal for environments where materials are subjected to extreme conditions, such as in the mouth (dental implants), in the engine (turbine blades), or even in the human body (hip replacements).

Composition of Cobalt-Chromium Powders

The composition of cobalt-chromium powders can vary depending on the specific requirements of the application. The typical composition includes:

| Element | Content (%) |

|---|---|

| Cobalt (Co) | 50-70% |

| Chromium (Cr) | 20-30% |

| Molybdenum (Mo) | 5-10% |

| Tungsten (W) | 0-5% |

| Carbon (C) | 0.5-2% |

| Others (Ni, Fe, etc.) | 0-5% |

Properties and Characteristics of Cobalt-Chromium Powders

Cobalt-chromium powders boast a unique combination of properties that make them indispensable in high-performance applications. Some of the key characteristics include:

- High Strength at Elevated Temperatures: These powders maintain their mechanical strength even at high temperatures, making them ideal for use in turbines and engines.

- Excellent Wear and Corrosion Resistance: The presence of chromium provides exceptional corrosion resistance, while the hardness of the cobalt matrix ensures wear resistance, perfect for dental and orthopedic implants.

- Biocompatibility: CoCr alloys are biocompatible, which means they are not rejected by the human body. This is particularly important for medical implants.

- Fatigue Resistance: Cobalt-chromium alloys can withstand repeated stress without fracturing, making them suitable for parts subjected to cyclic loads.

Key Models of Cobalt-Chromium Powders

There are several specific grades and models of cobalt-chromium powders available in the market, each tailored for different applications. Here’s a closer look at ten prominent models:

- CoCrMo (ASTM F75)

- Description: This is the most commonly used cobalt-chromium-molybdenum alloy for medical implants, particularly for orthopedic and dental applications.

- Properties: High biocompatibility, corrosion resistance, and excellent wear resistance.

- CoCrW (Stellite 21)

- Description: Known for its exceptional wear resistance, this alloy is used in valve seats, bearings, and cutting tools.

- Properties: High hardness, excellent high-temperature strength, and good corrosion resistance.

- CoCrNiMo (ASTM F562)

- Description: Used primarily in surgical instruments and high-strength components.

- Properties: High strength, good ductility, and corrosion resistance.

- CoCrMoC (ASTM F90)

- Description: A variant with carbon additions to improve hardness.

- Properties: Increased wear resistance, suitable for high-stress applications.

- CoCrAlY (AMS 5894)

- Description: Used in aerospace applications, particularly in turbine blades.

- Properties: High oxidation resistance at elevated temperatures, good mechanical properties.

- CoCrFeMnNi (High Entropy Alloy)

- Description: A newer alloy used in advanced research applications for its unique properties.

- Properties: Good ductility, strength, and corrosion resistance.

- CoCrMoTi

- Description: Titanium addition improves biocompatibility and reduces density.

- Properties: Lightweight, high corrosion resistance, suitable for medical implants.

- CoCrSiW

- Description: This alloy is used in wear-resistant coatings for industrial applications.

- Properties: High hardness, excellent wear resistance, and good high-temperature stability.

- CoCrMoNb

- Description: Niobium addition enhances strength and fatigue resistance.

- Properties: Improved mechanical properties, suitable for aerospace components.

- CoCrZr

- Description: Zirconium addition improves biocompatibility and corrosion resistance.

- Properties: High corrosion resistance, suitable for dental and orthopedic implants.

Applications of Cobalt-Chromium Powders

Cobalt-chromium powders are versatile materials used across various industries. Here’s a look at some of their most common applications:

| Application | Industry | Details |

|---|---|---|

| Dental Implants | Medical | CoCr alloys are used in crowns, bridges, and dental frameworks. |

| Hip and Knee Implants | Medical | Due to their biocompatibility and wear resistance, CoCr alloys are used in joint replacements. |

| Turbine Blades | Aerospace | CoCr powders are used in jet engines due to their high-temperature strength. |

| Valve Seats and Bearings | Automotive | High wear resistance makes them ideal for these components. |

| Cutting Tools | Industrial | CoCr alloys are used in tools for their hardness and durability. |

| Aerospace Components | Aerospace | Used in critical high-stress components due to their fatigue resistance. |

| Prosthetics | Medical | CoCr alloys are used in the production of durable and biocompatible prosthetics. |

| Wear-Resistant Coatings | Industrial | Used in coatings to extend the life of equipment exposed to harsh conditions. |

Specifications, Sizes, Grades, and Standards

Cobalt-chromium powders come in various specifications, sizes, and grades, each tailored for specific applications. The table below summarizes the key specifications:

| Specification | Grade | Particle Size (µm) | Standard |

|---|---|---|---|

| ASTM F75 | Medical | 15-45 | ASTM F75 |

| AMS 5894 | Aerospace | 10-53 | AMS 5894 |

| ASTM F90 | Medical | 20-50 | ASTM F90 |

| Stellite 21 | Industrial | 15-63 | ASME BPVC |

| ASTM F562 | Medical | 25-45 | ASTM F562 |

| CoCrAlY | Aerospace | 10-50 | AMS 5894 |

| CoCrFeMnNi | Research | 10-45 | Custom |

| CoCrMoTi | Medical | 20-45 | ISO 5832-4 |

| CoCrSiW | Industrial | 15-63 | ASME BPVC |

| CoCrMoNb | Aerospace | 10-50 | AMS 5894 |

Suppliers and Pricing

The cost of cobalt-chromium powders varies depending on the grade, particle size, and supplier. Here’s a breakdown of some suppliers and their pricing:

| Supplier | Grade | Price (USD/kg) | Country |

|---|---|---|---|

| Carpenter Technology | ASTM F75 | $250 – $300 | USA |

| Sandvik | Stellite 21 | $200 – $250 | Sweden |

| Arcam AB (GE Additive) | CoCrMoTi | $300 – $350 | Sweden |

| HC Starck | CoCrAlY | $400 – $450 | Germany |

| ATI Metals | ASTM F90 | $280 – $320 | USA |

| LPW Technology | CoCrFeMnNi | $350 – $400 | UK |

| EOS GmbH | ASTM F562 | $270 – $320 | Germany |

| Praxair Surface Technologies | CoCrSiW | $200 – $260 | USA |

| Hoganas | CoCrMoNb | $320 – $380 | Sweden |

| Kennametal | CoCrZr | $250 – $310 | USA |

Advantages and Limitations of Cobalt-Chromium Powders

Like any material, cobalt-chromium powders have their strengths and weaknesses. Let’s explore these:

| Advantages | Limitations |

|---|---|

| High Corrosion Resistance | Cost: Cobalt and chromium are expensive materials. |

| Excellent Wear Resistance | Density: Heavier than some alternatives like titanium alloys. |

| High-Temperature Strength | Machinability: CoCr alloys can be challenging to machine. |

| Biocompatibility | Availability: Limited supply compared to more common alloys. |

| Fatigue Resistance | Processing Complexity: Requires precise control during manufacturing. |

| Versatility Across Industries | Environmental Impact: Mining and refining cobalt can have significant environmental consequences. |

FAQs

Q1: What are cobalt-chromium powders primarily used for?

A1: Cobalt-chromium powders are mainly used in high-performance applications requiring materials with high strength, wear resistance, and corrosion resistance. They are widely used in the medical, aerospace, and industrial sectors.

Q2: Are cobalt-chromium alloys safe for medical implants?

A2: Yes, cobalt-chromium alloys are biocompatible, making them safe for use in medical implants like dental crowns, hip, and knee replacements.

Q3: How do cobalt-chromium powders compare to titanium alloys?

A3: Cobalt-chromium powders offer better wear resistance and higher strength at elevated temperatures compared to titanium alloys. However, titanium is lighter and often easier to machine.

Q4: What is the typical cost of cobalt-chromium powders?

A4: The cost varies depending on the grade and supplier but generally ranges from $200 to $450 per kilogram.

Q5: What are the challenges in processing cobalt-chromium powders?

A5: Processing challenges include the high cost of raw materials, the complexity of machining, and the need for precise control during manufacturing to avoid defects.

Q6: Which industries benefit the most from cobalt-chromium powders?

A6: The medical and aerospace industries benefit significantly from the use of cobalt-chromium powders due to their demanding requirements for material performance.

Q7: Are there environmental concerns associated with cobalt-chromium powders?

A7: Yes, the extraction and processing of cobalt and chromium can have environmental impacts, particularly in mining regions where these metals are sourced.

Q8: Can cobalt-chromium powders be used in 3D printing?

A8: Absolutely! CoCr powders are commonly used in additive manufacturing for producing complex, high-performance components.

Q9: How do cobalt-chromium powders improve the performance of cutting tools?

A9: The high wear resistance and hardness of CoCr alloys make them ideal for cutting tools, allowing for longer tool life and more precise cuts.

Q10: What is the future of cobalt-chromium powders in manufacturing?

A10: With ongoing advancements in material science, cobalt-chromium powders are expected to remain crucial in cutting-edge applications, particularly in additive manufacturing and biomedical engineering.

Conclusion

Cobalt-chromium powders are more than just a blend of metals; they are a cornerstone of modern engineering and medical advancements. Whether it’s in the engine of a jet plane or inside a patient’s body, the unique properties of these powders ensure that they meet the stringent demands of high-performance applications.