Tungsten metal powder is a fine particulate form of tungsten used as a raw material in various industrial applications. Its unique properties like high density, strength, corrosion resistance and high melting point make it an important engineering material.

Composition and Manufacturing

| Parameter | Details |

|---|---|

| Elemental Composition | Pure tungsten (W) or an alloy with other metals |

| Production Process | Milled from tungsten rods or reduced from tungsten oxides |

| Particle Sizes | Ranging from 1 micron to 150 microns typically |

| Purity Grades | From 99% to 99.995% pure tungsten |

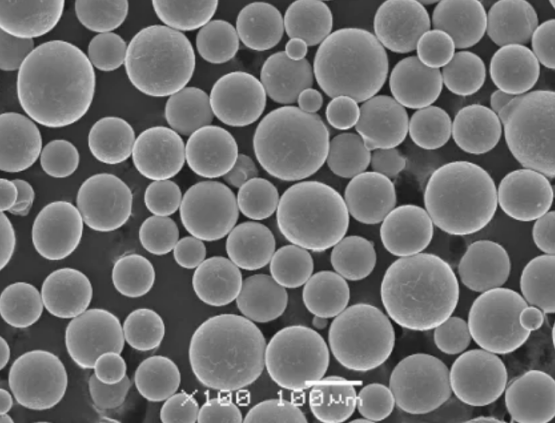

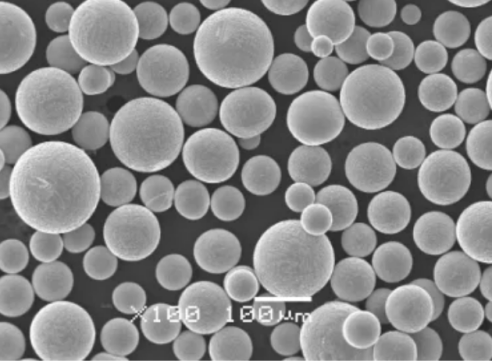

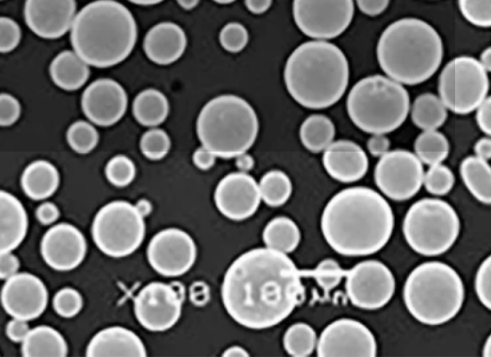

Tungsten powder is produced through various processes like hydrogen reduction, milling, or thermal plasma spheroidization to achieve desired shape and purity.

Properties and Characteristics

| Property | Value |

|---|---|

| Density | 19.3 g/cm3, almost twice that of steel |

| Melting Point | 3422 °C, highest of all metals |

| Strength | Very high hardness and strength, especially when sintered |

| Conductivity | Low electrical resistivity, high thermal conductivity |

| Stability | Excellent chemical stability and corrosion resistance |

These unique properties lend tungsten metal powder to various specialty applications.

Applications and Uses of tungsten metal powder

| Application | Usage |

|---|---|

| cemented carbide tools | binded in cobalt matrix for cutting tools |

| Counterweights | High density ideal for weights and ballast |

| Radiation Shielding | Effective shield from X-ray/gamma sources |

| Thermionic Emitters | Filaments due to high melting point |

| 3D Printing Powders | For printing high-strength tungsten parts |

Tungsten powder supports mission-critical needs across defense, medical, aerospace, and other industries.

Specifications and Standard Grades

Tungsten powder is available under various international standards that define particle size distribution, purity levels, manufacturing method etc. Some common specifications include:

- ASTM B772 – Pure tungsten powder types

- ISO 5453 – Chemical analysis and size classification

- ICDD 00-001-1202 – Crystalline structure reference

Suppliers and Pricing

| Supplier | Price per kg |

|---|---|

| Midwest Tungsten | $70 – $500 |

| Buffalo Tungsten | $100 – $600 |

| Tungsten Heavy Powder | $150 – $800 |

| Global Tungsten Powders | $250 – $1500 |

Pricing depends heavily on purity grade, particle shape/size consistency, quantity ordered, and value-added processing.

Pros vs Cons

| Pros | Cons |

|---|---|

| Exceptional hardness and density | Expensive compared to alternatives |

| Withstands high temps | Heavy – adds weight if used in products |

| Corrosion and wear resistant | Brittle if not properly processed |

| Environmentally stable | Difficult to machine in certain forms |

| Uniform particle distribution | May require protective atmospheres |

FAQs

What is tungsten metal powder used for?

It has applications in tools, weights, radiation shielding, electronics, 3D printing, and other high-performance domains due to its specialized properties.

What purity grades are available?

Common purity levels range from 99% to 99.995%. Higher purity commands much higher pricing.

What is the typical particle size?

Particle size can range from 1 micron to 150 microns. Desired size depends on application method and end-use requirements.

Is tungsten environmentally hazardous?

No. Tungsten metal powder is generally non-toxic and eco-friendly. Certain processing may use hazardous compounds requiring care.

know more 3D printing processes

Additional FAQs: Tungsten Metal Powder

1) What particle morphology is best for different processes?

- Press-and-sinter: irregular/sponge for better green strength. Thermal spray and AM (LPBF): spherical for high flowability and packing. DED/wire-DED: coarser spherical or crushed granules.

2) How do oxygen and carbon impurities affect tungsten metal powder?

- Elevated O and C form WOx and carbides during sintering, increasing brittleness and porosity. For critical applications, target O ≤ 0.05 wt% and C ≤ 0.01 wt% unless intentionally alloyed.

3) Can tungsten metal powder be used in laser powder bed fusion?

- Yes, but it requires preheating and optimized parameters to mitigate cracking due to high stiffness and thermal gradients. Typical LPBF PSD: 15–45 µm spherical, with low O/N and tight PSD.

4) What are common tungsten composites and why use them?

- W-Ni-Fe/W-Ni-Cu heavy alloys for radiation shielding and kinetic energy components; W-Cu for thermal management and EDM electrodes; WC-Co for cutting tools. Composites balance density, ductility, and conductivity.

5) How should tungsten powder be stored and handled safely?

- Keep sealed and dry, under inert gas if possible; use local exhaust ventilation, antistatic grounding, and explosion-rated dust controls. Although tungsten is not highly reactive, fine powders can pose a dust explosion hazard.

2025 Industry Trends: Tungsten Metal Powder

- Semiconductor and medical growth: Demand up for W-Cu heat spreaders and high-density shielding components.

- Advanced manufacturing: More spherical, plasma-atomized W powders available for LPBF/DED; crack-mitigation strategies mature.

- Sustainability: Increased closed-loop recycling and take-back programs for W scrap/powders with certified impurity control.

- Standards tightening: Stricter impurity and PSD specs for AM-grade W and W-heavy alloys; wider adoption of in-line O/N/H analysis.

- Defense/aerospace: Continued shift from lead to tungsten-based shielding/ballast and kinetic components.

2025 Tungsten Powder Market Snapshot (Indicative)

| Metric | 2023 | 2024 | 2025 YTD (Aug) | Notes |

|---|---|---|---|---|

| Global W powder demand (kt) | ~18.5 | ~19.3 | ~20.1 | Semiconductor + defense |

| Spherical W (15–45 µm) price (USD/kg) | 180–320 | 190–340 | 200–360 | PA/spheroidized, low O/N |

| Irregular W (-325 mesh) price (USD/kg) | 70–140 | 75–150 | 80–160 | Hydrogen-reduced |

| Typical O spec (AM-grade W) | ≤0.06 wt% | ≤0.05 wt% | ≤0.04 wt% | Tighter QC, in-line analyzers |

| AM adoption (W/W-alloys programs) | Emerging | Early pilots | Pilot-to-production | LPBF + DED parameter maturity |

| W-Cu demand growth (YoY) | +6% | +8% | +9–11% | Power electronics, EDM |

Sources:

- USGS Mineral Commodity Summaries (Tungsten): https://pubs.usgs.gov/periodicals/mcs

- ASTM/ISO powder standards: https://www.astm.org, https://www.iso.org

- Supplier technical notes (Global Tungsten & Powders, H.C. Starck Solutions, Plansee) and industry trackers

Latest Research Cases

Case Study 1: Crack-Resistant LPBF of Tungsten for Collimators (2025)

Background: A medical device OEM needed dense, fine-featured W collimators with reduced post-machining.

Solution: Used plasma-atomized W powder (D50 ~28 µm, O=0.035 wt%) with build plate preheat >600°C, beam shaping, and contour-remelting; stress-relief + hot isostatic pressing (HIP).

Results: Relative density 99.5–99.8%, microcrack incidence reduced by 70% vs. baseline; dimensional accuracy ±60 µm on 2 mm walls; machining time cut 25%.

Case Study 2: W-Cu Heat Spreaders via PM Infiltration for SiC Power Modules (2024)

Background: An EV inverter supplier sought CTE-matched plates with high thermal conductivity.

Solution: Sintered porous W skeletons from -325 mesh W, followed by capillary Cu infiltration to 15–30 vol% Cu; final surface lapped.

Results: Thermal conductivity 200–230 W/m·K; CTE 7.5–8.5 ppm/K (25–200°C); warpage <8 µm over 50 mm; yield +10% compared to prior route.

Expert Opinions

- Dr. Dirk N. Schwab, Head of R&D, Plansee High Performance Materials

- “For AM-grade tungsten metal powder, controlling interstitials and applying elevated preheat are decisive to suppress solidification cracking and achieve near-wrought density.”

- Prof. Susanne Wurster, Materials Processing, TU Munich

- “W–Cu and W–Ni–Fe heavy alloys continue to expand as lead replacements. Process route selection—PM infiltration vs. AM—should follow CTE and flatness tolerance needs.”

- Dr. Kevin J. Hemker, Professor of Mechanical Engineering, Johns Hopkins University

- “Grain boundary engineering and beam shaping are enabling finer W features with improved toughness, opening opportunities in radiation optics and micro heat exchangers.”

Practical Tools and Resources

- ASTM B777 (tungsten heavy alloys), B772 (tungsten powder), B214/B212 (sieve/flow), E1019 (O/N/H): https://www.astm.org

- ISO 4497 (particle size by sieving), ISO 13320 (laser diffraction), ISO 7637-equivalent PM methods: https://www.iso.org

- USGS Tungsten Statistics and Information: https://www.usgs.gov

- OSHA/NIOSH guidance for metal powder handling and combustible dust: https://www.osha.gov, https://www.cdc.gov/niosh

- MatWeb materials database for W and W-composites: https://www.matweb.com

- Senvol Database for AM machine–material compatibility: https://senvol.com

- Supplier technical libraries: Global Tungsten & Powders, H.C. Starck Solutions, Plansee, Midwest Tungsten

Last updated: 2025-08-25

Changelog: Added 5 FAQs; inserted 2025 market snapshot table; provided two recent case studies; included expert opinions; compiled practical tools/resources with standards and datasets

Next review date & triggers: 2026-02-01 or earlier if USGS data revises demand/pricing >10%, new ASTM/ISO standards for AM-grade tungsten publish, or major LPBF/DED breakthroughs reduce cracking further