1. Introduction: Why Tungsten Carbide Powder Matters in Modern Manufacturing

Tungsten carbide powder (WC) is a key raw material in the production of cutting tools, wear-resistant parts, and other high-performance industrial components. Its exceptional hardness, thermal resistance, and durability make it indispensable in sectors such as aerospace, automotive, mining, and metal fabrication.

For B2B buyers, understanding the sourcing, properties, and applications of tungsten carbide powder is crucial to maintaining product quality and competitiveness. In today’s industrial landscape, choosing the right tungsten carbide powder supplier can drastically affect your cost-efficiency and product performance.

Key Properties of Tungsten Carbide Powder:

| Property | Typical Value | Industrial Benefit |

|---|---|---|

| Hardness (Mohs) | 8.5–9.0 | Superior wear resistance |

| Melting Point | 2,870°C (5,198°F) | Excellent high-temperature performance |

| Density | 15.6 g/cm³ | High mass efficiency in tooling |

| Grain Size | 0.4 – 10 microns | Customizable for various applications |

| Electrical Conductivity | Moderate | Useful in specialized electronic uses |

Common Forms of WC Powder:

- Agglomerated and sintered WC powder

- Spherical tungsten carbide powder

- Nano-tungsten carbide powder

- Spray-dried WC-Co composite powders

2. Key Industrial Applications of Tungsten Carbide Powder

Tungsten carbide powder is widely used in sintering applications and is a base material for cemented carbide production. Its ability to withstand extreme conditions makes it ideal for precision component manufacturing.

Major Use Cases:

- Cutting Tools

- Drills, end mills, and reamers

- Machining non-ferrous and hardened materials

- Mining and Drilling Equipment

- WC buttons and inserts for rock drills and tunnel boring machines

- Aerospace Components

- Engine nozzles and turbine blades

- Metal Forming and Stamping Dies

- Dies for punching, extrusion, and cold heading

- Wear Parts

- Pump seals, valve seats, and bearings

- Thermal Spray Coating

- WC-Co powders for surface protection in corrosion-prone environments

Application Table:

| Industry | Application | Benefit of WC Powder |

|---|---|---|

| Automotive | Engine parts, stamping dies | Enhances durability and lifespan |

| Mining | Drill bits, crusher parts | Withstands impact and abrasion |

| Aerospace | Nozzles, jet engine parts | High heat and wear resistance |

| Metalworking | Cutting inserts, dies | Improves productivity and finish quality |

| Oil & Gas | Valve seats, pump components | Corrosion resistance under harsh conditions |

3. Grades and Types of Tungsten Carbide Powder

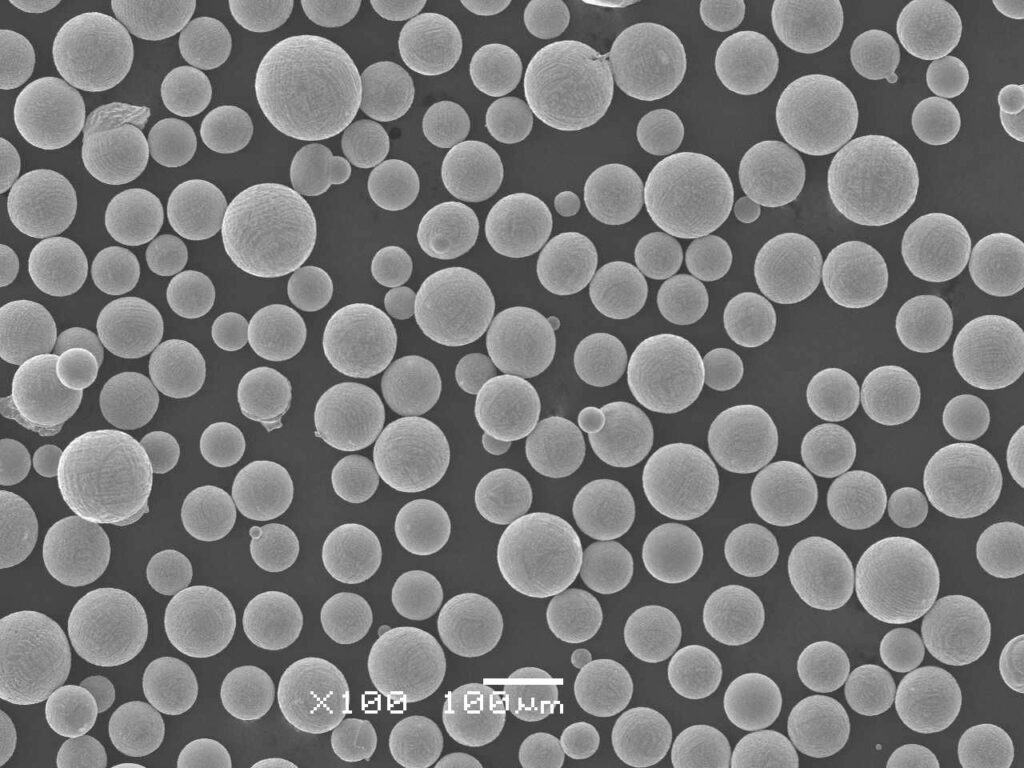

Tungsten carbide comes in several grades and formulations, each tailored for specific uses. The choice of WC powder depends on factors such as grain size, binder content, and sintering process.

Common WC Powder Grades:

| Grade Name | WC Content | Binder (Co/Ni) | Grain Size | Application Area |

|---|---|---|---|---|

| WC-94/6 | 94% WC | 6% Co | 1-3 µm | Cutting tools |

| WC-92/8 | 92% WC | 8% Co | 2-4 µm | Mining inserts, wear parts |

| WC-90/10 | 90% WC | 10% Co | 5-8 µm | Heavy-duty wear applications |

| Nano WC | >97% WC | <3% Co/Ni | <1 µm | Precision micro tools |

Classification by Production Method:

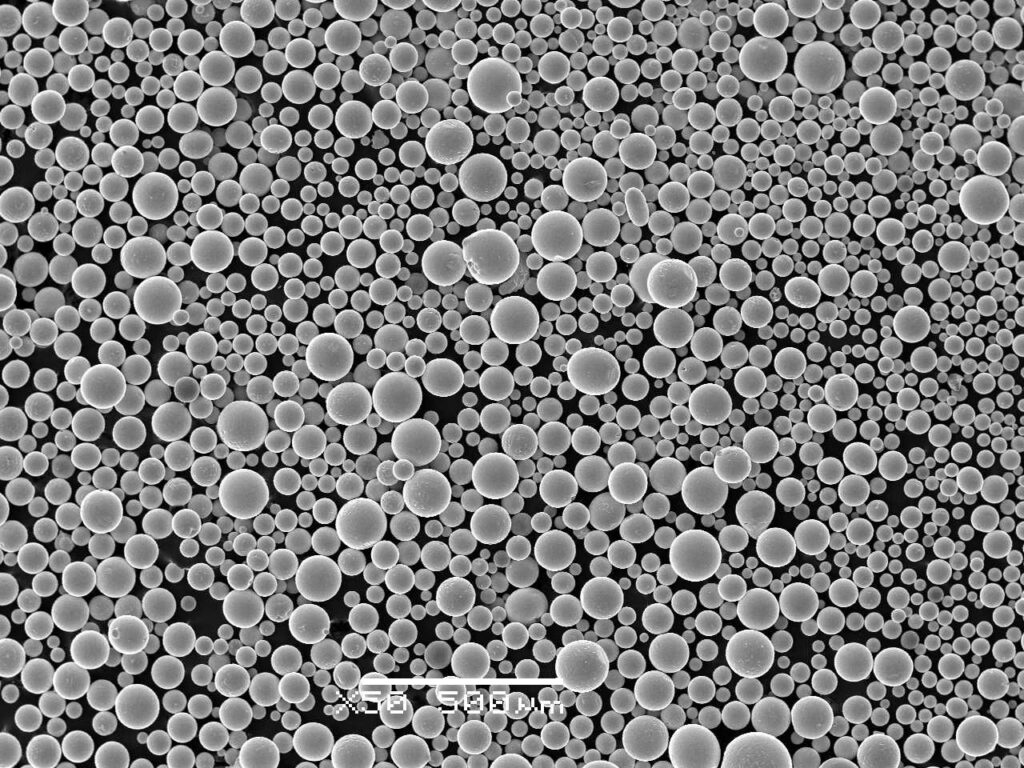

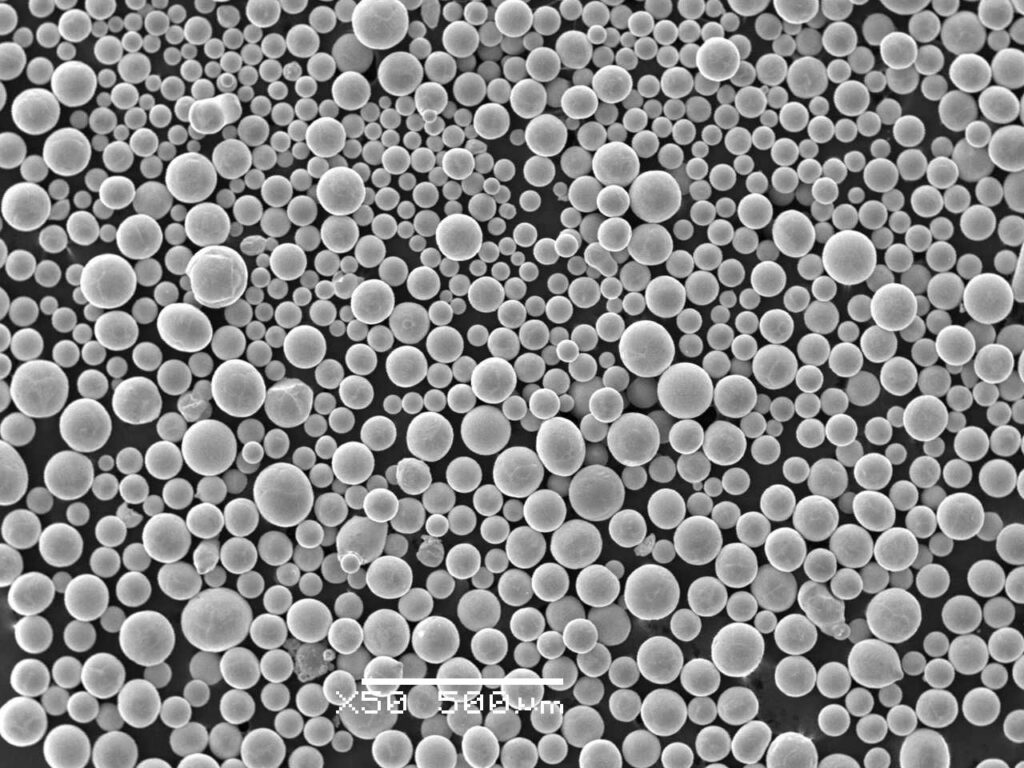

- Agglomerated/Sintered Powder: Enhanced flowability for additive manufacturing.

- Spray-Dried WC-Co: Ideal for thermal spray coatings.

- Nano Tungsten Carbide: High-performance applications requiring extreme precision.

Choosing the Right Grade:

- For cutting tools, opt for fine-grain WC (1–3 µm) with 6–8% Co.

- For mining, use coarse-grain WC (4–8 µm) with higher Co content.

- For thermal spraying, choose spherical or agglomerated spray-grade powders.

Shanghai Truer Technology Co., Ltd offers a wide range of powder metallurgy materials, including high-performance tungsten carbide powders suitable for both sintering and coating applications. Their product portfolio includes advanced materials made via gas and water atomization, ensuring consistent particle size and purity.

4. Market Trends and Global Demand for WC Powder

As industrial demand for high-performance materials rises, tungsten carbide powder has seen a substantial increase in global consumption. From 2020 to 2024, the tungsten carbide market has grown at a CAGR of over 5.7%, driven by factors such as increasing precision machining, automation, and global infrastructure development.

Global Market Insights:

| Region | Market Share (2023) | Key Drivers |

|---|---|---|

| Asia-Pacific | 45% | Automotive, mining, and manufacturing growth |

| North America | 25% | Aerospace and oil & gas expansion |

| Europe | 20% | Focus on electric vehicle (EV) manufacturing |

| Rest of World | 10% | Emerging industries and defense sectors |

Key Trends in the WC Powder Industry:

- 📈 Shift Toward Nano-WC Powders: For micro tools and precision applications.

- 🌱 Sustainable Manufacturing: Demand for powders produced with eco-friendly processes.

- 🛠️ Additive Manufacturing Integration: WC-Co powders utilized in 3D printing technologies.

- 🧪 Advanced Coatings: WC used in thermal spray coatings for extended product life.

Manufacturers and distributors that can deliver consistent quality, supply assurance, and technical support are seeing increased B2B demand.

5. How to Choose a Reliable Tungsten Carbide Powder Supplier

For wholesale buyers, selecting the right tungsten carbide powder supplier is critical to ensuring supply chain reliability, material consistency, and cost-effectiveness.

Key Factors to Evaluate:

- Purity and Quality Standards

- ISO 9001 certified production

- Consistency in grain size and composition

- Production Methods

- Gas atomization for spherical powders

- Water atomization for cost-effective volume production

- Customizability

- Ability to meet specific Co/Ni binder ratios

- Custom particle size distribution for different sintering processes

- Technical Support

- Pre-sales consultation and application-specific advice

- Post-sales metallurgical analysis and optimization

- Global Logistics and Packaging

- Bulk packaging options (500kg, 1 ton)

- Export-ready documentation and REACH compliance

Supplier Evaluation Checklist:

| Criteria | Description | Importance |

|---|---|---|

| Production Capability | Can they produce WC powder in bulk? | High |

| Technical Expertise | Do they have R&D and metallurgy support? | High |

| Customization Flexibility | Can they adjust grades per your request? | Medium |

| Logistics and Lead Time | Fast shipping, global delivery | High |

| Price Competitiveness | Are rates aligned with market standards? | High |

Shanghai Truer Technology Co., Ltd checks all the boxes above and is known for its robust technical team, advanced powder production methods, and reliable international shipping. They offer tailored solutions to meet the needs of B2B tungsten carbide applications.

6. Top 5 Tungsten Carbide Powder Suppliers in Asia

Asia is currently the largest producer and exporter of tungsten carbide powder, with China, Japan, and South Korea leading the region’s output. Here are the top 5 suppliers known for quality and scale:

1. Shanghai Truer Technology Co., Ltd (China)

- ✅ Founded in 2009, with AM division established in 2019

- ✅ Offers WC powder, PM bronze, PM nickel silver, and more

- ✅ Full range of powder metallurgy solutions

- ✅ ISO-certified with custom alloying capability

2. Sumitomo Electric Hardmetal Corp. (Japan)

- Specializes in carbide tool materials

- High research investment in nano-carbides

3. Zhuzhou Cemented Carbide Group (China)

- One of China’s largest carbide manufacturers

- Supplies powder for internal and external use

4. Kennametal India Ltd.

- US-based operations with manufacturing in India

- Well-known for wear-resistant materials

5. Inframat Advanced Materials (South Korea)

- Focus on nano-powders and spray-grade WC

- Supplies to thermal spray industries globally

| Supplier Name | Country | Specialty | Customization | B2B Focus |

|---|---|---|---|---|

| Shanghai Truer Technology | China | PM powders, WC, AM materials | ✅ | ✅ |

| Sumitomo Electric | Japan | Nano-carbides, tool blanks | ✅ | ✅ |

| Zhuzhou Cemented Carbide | China | Cemented carbide, WC powder | ✅ | ✅ |

| Kennametal India | India | Wear parts and coating materials | ✅ | ✅ |

| Inframat | South Korea | Nano WC, thermal spray powders | ✅ | ✅ |

7. Why More Buyers Are Choosing Chinese WC Powder Manufacturers

Chinese suppliers have gained significant traction in the global tungsten carbide powder market due to their ability to deliver:

- 🔄 High Volume Production: Capable of producing tons of WC powder monthly

- ⚙️ Process Flexibility: Gas atomized, water atomized, and hybrid methods

- 💰 Cost Efficiency: Competitive pricing without compromising quality

- 🌐 Global Logistics: Export-ready documentation and international delivery

- 🧪 Integrated R&D: In-house labs for material testing and formulation

Shanghai Truer Technology Co., Ltd is a standout example, offering competitive pricing and a full suite of tungsten carbide and PM powders. Their contact page provides fast inquiries, custom quotes, and technical consultations.

What Sets Chinese Manufacturers Apart:

- Bulk order capabilities (≥1 ton per month)

- Flexible binder compositions (Co/Ni)

- WC-Co spray powders for coating systems

- Multi-grade options for wear, cutting, and sintering applications

- Strong domestic tungsten reserves for raw material stability

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Supplier

Shanghai Truer Technology Co., Ltd is one of the most trusted and technically advanced providers of tungsten carbide powder and powder metallurgy materials in China. Since its inception in 2009, with a dedicated additive manufacturing division launched in 2019, Truer has positioned itself as a reliable B2B partner for distributors, manufacturers, and e-commerce resellers across the globe.

Core Strengths of Truer as a WC Powder Supplier:

| Strength | Description |

|---|---|

| Extensive Product Portfolio | Offers a wide range of PM powders including WC, PM bronze, PM steel, etc. |

| Advanced Manufacturing Technology | Uses gas atomization, water atomization, and combined methods |

| Customization Capability | Tailored Co/Ni binder content and particle size distribution |

| R&D and Metallurgical Expertise | In-house lab for quality control and custom formulation |

| Global Logistics and Export | Ready for international bulk shipments with full documentation |

Tungsten Carbide Powder Solutions from Truer:

- Custom WC-Co Grades: Tailored for wear parts, cutting tools, and coatings

- Nano Tungsten Carbide: For high-precision micro-cutting and aerospace tools

- Spray-Grade WC Powders: For thermal spray and HVOF applications

- Spherical WC Powders: Ideal for 3D printing and AM applications

Truer’s WC powders are produced using high-purity tungsten and cobalt, ensuring excellent sinterability, mechanical strength, and wear resistance.

🔗 Visit Truer’s product library to explore their full range of powder metallurgy products including WC powder, PM bronze, and additive manufacturing materials.

9. How to Order Wholesale Tungsten Carbide Powder from Truer

Ordering from Shanghai Truer is straightforward, with dedicated B2B support, fast response times, and global shipping options tailored for industrial clients.

Step-by-Step Ordering Process:

- Inquiry Submission

- Visit the Contact Us page

- Fill out the inquiry form with your volume and grade requirements

- Technical Consultation

- A Truer representative will get in touch within 24 hours

- Discuss custom formulations, grain size, binder ratios, and packaging

- Quotation and Sample

- Receive a formal quotation with lead times and pricing

- Optional: request a 1–5 kg sample for quality testing

- Bulk Order Confirmation

- Confirm your order (MOQ: typically 100 kg–1 ton)

- Finalize payment terms and logistics preferences

- Production and Delivery

- Lead time: 7–21 days depending on volume and customization

- Truer handles export documentation, packaging, and freight

Available Packaging Options:

| Volume | Packaging Type | Notes |

|---|---|---|

| 1–5 kg | Vacuum-sealed aluminum bags | For samples/testing |

| 25–50 kg | Sealed metal drums | Standard bulk packaging |

| 500–1000 kg | Industrial-grade super sacks | For large-scale industrial use |

Truer’s team also supports OEM/ODM packaging for distributors and e-commerce resellers looking to rebrand WC powders under their own labels.

10. FAQs: Buying Tungsten Carbide Powder in Bulk

Q1. What is the minimum order quantity (MOQ) for WC powder?

A: At Shanghai Truer, the MOQ is typically 100 kg. However, samples between 1–5 kg can be provided for quality testing and evaluation.

Q2. Can I customize the cobalt or nickel content in my WC powder?

A: Yes. Truer supports custom formulations, including WC-Co, WC-Ni, and WC-CoCr with adjustable binder content from 3% to 12%.

Q3. Do you offer spherical tungsten carbide powder for 3D printing?

A: Absolutely. Truer produces spherical WC powder through gas atomization, suitable for additive manufacturing and thermal spraying.

Q4. What certifications are available for your WC powders?

A: Truer is ISO 9001 certified and provides COA, MSDS, and third-party testing reports upon request.

Q5. How long does shipping take for international orders?

A: Shipping times vary by region. Typically, orders are shipped within 7–21 days after confirmation. Truer partners with DHL, FedEx, and major freight carriers globally.

Internal Anchor Text Links Embedded in This Blog:

- Tungsten carbide powder supplier — Mentioned in Introduction

- Powder metallurgy solutions — In Top Suppliers section

- Contact Us — In How to Order section

- Truer’s product library — In Why Choose Truer section

- Contact page — In Why More Buyers Are Choosing Chinese Manufacturers section

📞 For quotes, technical consultation, or to place an order, visit the official Shanghai Truer Contact Page today. Whether you’re a distributor, OEM manufacturer, or industrial buyer, Truer provides the consistency, customization, and quality you need to scale your tungsten carbide applications.