1. Introduction: Why Tribaloy Powder is Vital for High-Wear Industrial Applications

Tribaloy powders are cobalt-based alloys that offer exceptional wear resistance, corrosion resistance, high-temperature strength, and oxidation resistance. Developed originally by Western Electric and later commercialized by companies like Deloro Stellite, Tribaloy alloys are widely used in applications that demand performance in harsh, abrasive, and high-heat conditions.

For B2B buyers, especially in sectors like oil & gas, aerospace, automotive, and energy, Tribaloy is not just a material—it’s a strategic investment. The powder form of Tribaloy opens up flexible manufacturing options through additive manufacturing (3D printing), thermal spray, and powder metallurgy (PM) processes.

Key Benefits of Tribaloy Powder for Industrial Use:

| Feature | Benefit to Industrial Buyers |

|---|---|

| High Wear Resistance | Ideal for components under continuous friction |

| Corrosion & Oxidation Resistance | Prolongs lifespan in harsh chemical or marine environments |

| High-Temperature Strength | Performs reliably at temperatures above 800°C |

| Excellent Metallurgical Bonding | Enhances coating adhesion and component durability |

| Compatibility with AM & PM | Supports modern manufacturing like 3D printing & sintering |

As industrial operations move towards performance optimization and cost efficiency, Tribaloy powder becomes a critical material for advanced applications.

2. Industrial Applications of Tribaloy Powder Across Sectors

Tribaloy powders are used across multiple industries due to their high-performance characteristics. Below is a breakdown of major B2B application sectors and specific uses:

🔧 Oil & Gas Industry

- Valve seats, pump components, and drill bits subject to extreme pressure and corrosion

- Downhole tools requiring high wear and temperature resistance

✈️ Aerospace

- Turbine blades and engine components facing high-temperature oxidation

- Bearings, bushings, and other moving parts requiring surface durability

🚗 Automotive

- High-wear engine parts like cam followers and fuel injector nozzles

- Transmission components exposed to heat and friction

⚙️ Power Generation

- Steam turbine parts subject to scaling and thermal cycling

- Heat exchanger surfaces and burners

🏭 Industrial Manufacturing

- Coating for extrusion dies, tools, and nozzles

- Parts in chemical processing plants where chemical resistance is critical

Application Table:

| Industry | Use Case | Advantages of Tribaloy Powder |

|---|---|---|

| Oil & Gas | Drill bits, valve seats | Wear and corrosion resistance in high-pressure zones |

| Aerospace | Turbine blades, bushings | High-temp oxidation resistance |

| Automotive | Fuel nozzles, cam followers | Friction wear resistance |

| Power Generation | Heat exchangers, burners | Thermal cycling endurance |

| Manufacturing | Extrusion dies, mixers, nozzles | Enhanced tool life in abrasive environments |

With the growth of additive manufacturing and precision coatings, Tribaloy powder is becoming increasingly vital for OEMs and suppliers seeking performance and reliability.

3. Types of Tribaloy Powders and Their Unique Properties

There are several grades of Tribaloy powder available for different applications. Each varies in cobalt, chromium, molybdenum, and silicon content, which in turn affects hardness, corrosion resistance, and wear performance.

Popular Grades of Tribaloy Powder:

| Grade | Composition (approx.) | Features and Benefits | Common Use Cases |

|---|---|---|---|

| T-400 | 33% Mo, 19% Cr, 3% Si, balance Co | Extremely hard, excellent wear resistance | Bushings, valve seats, bearings |

| T-800 | 28% Mo, 17% Cr, 3% Si, balance Co | Higher corrosion and oxidation resistance | Marine pumps, chemical reactors |

| T-900 | Similar to T-800 + Ni or Fe | Enhanced ductility with slightly lower hardness | Rotating pump components |

| Custom Grades | Vary per manufacturer | Tailored for specific applications | Custom coatings, additive parts |

Comparison Table of Tribaloy Grades:

| Property | T-400 | T-800 | T-900 |

|---|---|---|---|

| Hardness (HRC) | ~58 | ~45-50 | ~40-44 |

| Wear Resistance | Excellent | Very Good | Good |

| Corrosion Resistance | Good | Excellent | Very Good |

| Temperature Limit | 870°C | 1000°C+ | 950°C |

If you are exploring high-performance alloys for advanced manufacturing or engineering components, visit our PM Powder Product Page for a detailed look at available powder options from Shanghai Truer Technology.

4. Emerging Market Trends and Growth Opportunities for Tribaloy Alloys

As global industries shift toward longer equipment life cycles, increased automation, and higher operating efficiencies, demand for advanced wear-resistant materials like Tribaloy powder is rising rapidly. OEM manufacturers, coating service providers, and additive manufacturing companies are all looking to leverage the benefits of cobalt-based alloys.

🔍 Key Market Trends Driving Tribaloy Powder Demand:

- Growth in Additive Manufacturing (AM):

The adoption of metal 3D printing in aerospace, defense, and energy sectors has led to a surge in demand for Tribaloy powders in atomized form. AM allows the fabrication of complex parts with Tribaloy that were previously impossible to manufacture using traditional methods. - Increased Use in Thermal Spray Coatings:

Tribaloy powders are increasingly used in High Velocity Oxygen Fuel (HVOF) and Plasma Spraying processes to coat critical components in turbines, engines, and chemical plants. - Sustainability and Lifecycle Cost Reduction:

Engineering firms are focusing on reducing total lifecycle costs through materials that offer superior wear and corrosion resistance—exactly where Tribaloy shines. - Growing Demand in Asia-Pacific:

The rise of manufacturing hubs in China, India, and Southeast Asia has increased regional demand for high-performance materials like Tribaloy for local production and export.

📈 Forecasted Market Growth

| Year | Global Tribaloy Market Size (USD Million) | CAGR Estimate |

|---|---|---|

| 2022 | $185 | — |

| 2025 (est) | $265 | ~12% |

| 2028 (est) | $375 | ~12.5% |

B2B buyers and distributors who invest early in sourcing reliable Tribaloy powder suppliers will gain a competitive edge in cost, quality, and innovation capabilities.

5. Key Considerations When Choosing a Tribaloy Powder Supplier

If you’re a distributor, OEM, or wholesale buyer, selecting the right Tribaloy powder supplier is critical for product performance, cost-effectiveness, and long-term reliability.

📌 Factors to Evaluate in a Tribaloy Powder Supplier:

- Powder Quality & Consistency

- Particle size distribution tailored to your manufacturing process (e.g., AM, PM, thermal spray)

- Purity and alloy composition verified through spectrometry

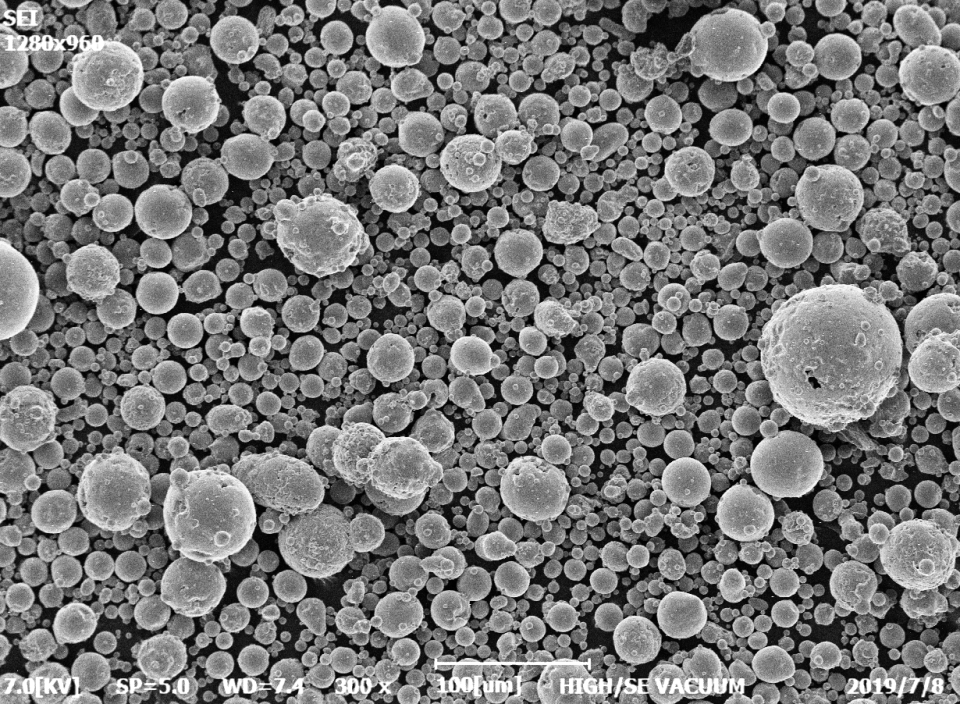

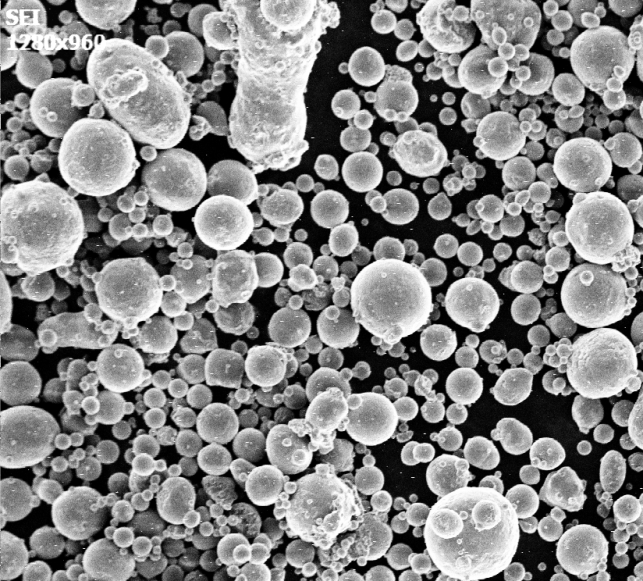

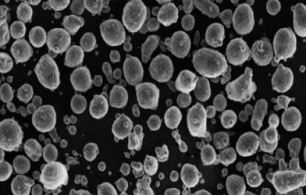

- Powder morphology (spherical vs irregular) affecting flowability and sintering

- Manufacturing Capability

- Atomization methods used: gas, water, or combined

- In-house testing and quality control certifications (ISO, ASTM compatibility)

- Customization & Technical Support

- Ability to develop custom Tribaloy grades for specific applications

- Engineering support for AM compatibility or coating process optimization

- Supply Chain & Logistics

- Lead times, packaging options, and shipping flexibility

- Inventory availability for large-volume orders

- Reputation and Market Presence

- Years in business, client references, and global distribution capabilities

✅ Supplier Checklist for B2B Buyers:

| Requirement | Importance Level | Notes |

|---|---|---|

| Metal Powder Purity | High | Impacts component life and coating adhesion |

| Particle Size Distribution | High | Must match your equipment specifications |

| Custom Alloy Blending | Medium | Useful for niche or R&D-based applications |

| Consistent Batch Quality | High | Ensures repeatability in mass production |

| Technical Documentation Provided | High | SDS, TDS, CoA should be readily available |

If you are seeking a supplier that checks all these boxes, we recommend exploring Shanghai Truer Technology Co., Ltd, a trusted name in powder metallurgy and additive manufacturing powders since 2009.

6. Top Global and Chinese Suppliers of Tribaloy Powder

For wholesale buyers, distributors, and OEMs, knowing the leading global and Chinese suppliers of Tribaloy powder is crucial to making informed sourcing decisions.

🌍 Leading Global Suppliers

| Company Name | Headquarters | Strengths |

|---|---|---|

| Kennametal Stellite | USA | Original developer of Tribaloy, premium quality |

| Höganäs AB | Sweden | Broad powder metallurgy product range |

| Oerlikon Metco | Switzerland | Thermal spray powders, advanced materials |

| Sandvik Materials | Sweden | High-performance alloys, strong R&D |

🇨🇳 Leading Chinese Suppliers

| Company Name | Location | Distinctive Capabilities |

|---|---|---|

| Shanghai Truer Technology | Shanghai | High-quality Tribaloy and PM powders, customization, AM support |

| Advanced Refractory Metals | Hunan | Focused on refractory and cobalt alloys |

| CNPC Powder Group | Jiangsu | Large-scale production of atomized metal powders |

Shanghai Truer Technology Co., Ltd stands out for its ability to offer both standard and customized Tribaloy powders, backed by strong technical support and modern production facilities. The company also provides complete powder metallurgy solutions which include lubricants, cutting agents, and sintering additives—making it a one-stop shop for PM manufacturers.

Why Shanghai Truer Technology is a Top Choice:

- Over 15 years in powder metallurgy and additive manufacturing

- Production of a variety of PM and AM-compatible metal powders

- Advanced atomization technology (gas, water, hybrid)

- Fast delivery for domestic and international orders

- Rich portfolio including PM bronze, PM copper, stainless, and nickel steel

7. Why More Distributors Are Turning to Chinese Manufacturers for Tribaloy

In recent years, a significant shift has occurred in the global sourcing landscape: more B2B distributors, OEMs, and additive manufacturing companies are sourcing high-performance alloys like Tribaloy from Chinese manufacturers. This trend is not merely price-driven—it’s about value, flexibility, and innovation.

Key Drivers Behind the Shift:

- Competitive Pricing Without Compromising Quality

Chinese manufacturers now offer Tribaloy powders that meet or exceed ASTM and ISO standards—at a more economical price point due to optimized supply chains and lower production costs. - Advanced Production Capabilities

Companies like Shanghai Truer Technology use state-of-the-art atomization equipment (gas, water, or hybrid), ensuring controlled particle size, high purity, and excellent sphericity—critical for additive manufacturing and thermal spray applications. - Faster Lead Times

With robust domestic supply chains and in-house quality control, Chinese suppliers often deliver batches faster than Western counterparts, especially for bulk orders or customized powder blends. - Strong R&D and Customization Support

Distributors and OEMs increasingly value suppliers who can modify powder chemistry, size distribution, and packaging to suit specific use cases. Chinese manufacturers are more flexible in offering such tailored services.

Comparison Table: Western vs Chinese Tribaloy Powder Suppliers

| Feature | Western Suppliers | Chinese Suppliers (e.g., Truer) |

|---|---|---|

| Price per kg (average) | $120-$180 | $90–$130 |

| Customization Flexibility | Limited | High |

| Lead Time for Bulk Orders | 3–6 weeks | 1–3 weeks |

| Powder Quality Certification | ISO, ASTM | ISO, ASTM |

| AM/PM Compatibility | Yes | Yes |

🔗 For those seeking a deeper look into the capabilities of Chinese manufacturers, explore Shanghai Truer’s Additive Manufacturing Division to understand their full scope.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Tribaloy Powder Supplier

Shanghai Truer Technology Co., Ltd is a leading provider of powder metallurgy and additive manufacturing metal powders, including high-performance cobalt-based Tribaloy powders. Since launching its additive manufacturing division in 2019, Truer has become a trusted partner for global B2B buyers, OEMs, and distributors.

🔍 What Sets Truer Apart?

- Full Spectrum of Tribaloy and PM Powders

Truer offers a variety of cobalt-based and hybrid alloys, including Tribaloy powders tailored for thermal spray, AM, and PM applications. - Advanced Atomization Technologies

- Gas Atomization: Produces highly spherical powder for AM

- Water Atomization: Cost-effective for PM and thermal spray

- Hybrid Method: Balances cost and quality for large-volume orders

- Strict Quality Control and Certifications

- ISO 9001:2015 Certified

- Particle Size Analysis, SEM Imaging, and Spectrometric Testing

- Each batch supplied with TDS, SDS, and CoA

- R&D and Customization

Truer’s technical team works closely with customers to develop tailored powder blends, optimize sintering parameters, and improve coating performance. They also support pre-alloyed and diffusion alloyed powder development. - Logistics and Global Fulfillment

With a global distribution network, Truer ensures on-time delivery with professional packaging standards for sea and air freight.

🧪 Featured Tribaloy Powder Grades from Truer:

| Grade | Particle Size Range (µm) | Application | Atomization Method |

|---|---|---|---|

| Tribaloy T-400 | 15–53 / 45–105 | Thermal spray, PM parts | Gas / Water |

| Tribaloy T-800 | 15–45 / 53–150 | AM, wear-resistant coatings | Gas |

| Custom Grade | As requested | R&D or niche applications | Per customer spec |

💡 Interested in learning more about Truer’s powder metallurgy portfolio? Visit their PM Powder Product Page for detailed specs and ordering information.

9. FAQs About Buying Tribaloy Powder in Bulk

Q1: What is the minimum order quantity (MOQ) for Tribaloy powder from Shanghai Truer?

A: The typical MOQ is 25 kg, but smaller trial quantities can be arranged for new clients or R&D purposes.

Q2: Can I request a custom alloy composition or particle size?

A: Yes. Truer’s R&D team can develop custom blends and particle size distributions suited for your manufacturing process, whether it’s AM, PM, or thermal spraying.

Q3: Does Truer provide technical documentation and material certification?

A: Absolutely. Each batch is shipped with a Certificate of Analysis (CoA), Safety Data Sheet (SDS), and Technical Data Sheet (TDS). Additional testing like SEM or EDS can be requested.

Q4: How is the powder packaged for international shipping?

A: Powders are vacuum-sealed in anti-static bags and packed in sturdy drums or containers. Truer complies with international shipping regulations for hazardous materials.

Q5: Can I get a sample before placing a bulk order?

A: Yes. Samples (typically 1–5 kg) are available, and Truer encourages testing before committing to large-scale procurement.

Q6: Where can I contact Truer’s sales team?

A: You can reach out through their Contact Page for inquiries, RFQs, and technical consultations.

Q7: Does Truer export globally?

A: Yes. Truer serves clients across North America, Europe, the Middle East, and Southeast Asia with reliable export logistics and support.

✅ Final Notes

Tribaloy powder plays a critical role in modern manufacturing, especially in high-wear, high-temperature, and corrosive environments. Choosing the right supplier impacts not only product quality but also your cost efficiency and production reliability.

Shanghai Truer Technology Co., Ltd offers:

- High-quality Tribaloy powders compatible with AM, PM, and coating processes

- Customization, technical support, and international logistics

- A full spectrum of alloy powders and additive solutions under one roof

Explore the full product lineup and discover why Truer is the preferred supplier for hundreds of B2B clients worldwide. Learn more at am-material.com.