Overview of titanium silicon powder

Titanium silicon powder is an alloy powder composed of titanium and silicon. It offers a unique combination of properties that make it suitable for a wide range of applications.

Some key advantages of titanium silicon powder include:

- High strength-to-weight ratio

- Good corrosion and oxidation resistance

- Ability to withstand high temperatures

- Low thermal expansion coefficient

- Non-toxic and biocompatible

Titanium silicon powder can be produced through various methods such as gas atomization, mechanical alloying, and thermal plasma synthesis. The composition and properties can be tailored by adjusting the Ti/Si ratio as well as production parameters.

Titanium Silicon Powder Types

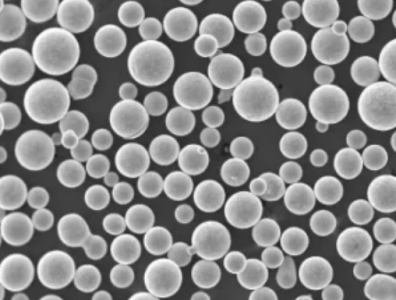

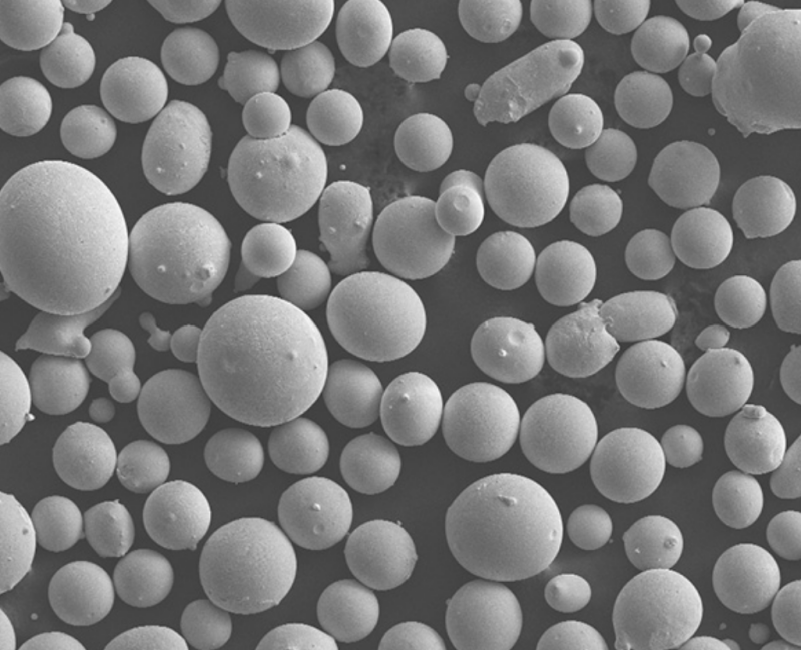

Titanium silicon powder is available in various compositions, particle sizes, and morphologies depending on the production method and intended application:

| Type | Typical Composition | Particle Size | Morphology |

|---|---|---|---|

| Ti-6Si | 6% Si, balance Ti | 15-45 μm | Spherical |

| Ti-10Si | 10% Si, balance Ti | 106-250 μm | Irregular |

| Ti-15Si | 15% Si, balance Ti | 45-106 μm | Flaky |

Ti-6Si powder with small, spherical particles offers good flowability for additive manufacturing. Ti-10Si irregular powder is suitable for thermal spraying. Ti-15Si flaky morphology provides increased surface area for sintering applications.

Titanium Silicon Powder Composition

The silicon content in titanium silicon powder can range from 6% to 15%. Silicon improves the strength, elastic modulus, and high-temperature properties of titanium. It also refines the microstructure leading to better ductility and fracture toughness.

With higher silicon additions, issues like difficult workability and increased brittleness start to emerge. So optimal Si additions are application dependent – around 6% for additive manufacturing, 10% for thermal spraying, and 15% for sintering.

Trace impurities in titanium silicon powder from the production process can include:

| Impurity | Typical Composition |

|---|---|

| Oxygen (O) | 0.15% |

| Nitrogen (N) | 0.05% |

| Carbon (C) | 0.08% |

| Iron (Fe) | 0.30% |

Controlling impurity levels is crucial for powder quality as they can negatively impact mechanical properties.

Titanium Silicon Powder Properties

Key properties of titanium silicon powder include:

| Property | Typical Values |

|---|---|

| Density | 4.1-4.5 g/cm3 |

| Melting Point | 1600-1700°C |

| Thermal Conductivity | 6.7-10.5 W/mK |

| Electrical Resistivity | 1.7-1.75 μΩ.m |

| Young’s Modulus | 110-160 GPa |

| Poisson’s Ratio | 0.32-0.34 |

| Oxidation Resistance | Up to 700°C in air |

With higher silicon content, density, elastic modulus and resistivity increase, while thermal conductivity decreases. Optimizing these properties expands the applicability of titanium silicon powders.

Titanium Silicon Powder Applications

Some major application areas of titanium silicon powder include:

| Industry | Applications | Benefits |

|---|---|---|

| Aerospace | Turbine blades, landing gear | High strength, temperature resistance |

| Automotive | Engine parts, valves | Wear and corrosion resistance |

| Biomedical | Implants, devices | Biocompatible, non-toxic |

| Additive Manufacturing | 3D printed components | Low density, good printability |

| Thermal Spray | Coatings | High hardness and wear resistance |

The tailored composition and properties of titanium silicon powders make them suitable for these critical applications across industries.

Titanium Silicon Powder Specifications

Titanium silicon powders are available under various international and industrial specifications:

| Standard | Grades | Particle Size | Impurities |

|---|---|---|---|

| ASTM B981 | Grade 5, 23 | 63-150 μm | Fe, C, N limits |

| AMS 4995 | Type A, B, C | 45-125 μm | O, N, C limits |

| AP&C | TSi6, TSi10 | 20-63 μm | Custom composition |

Specifications dictate particle size distribution, morphology, flow characteristics, apparent density as well as stringent limits on impurities. Meeting certification standards is essential for quality control assurance.

Titanium Silicon Powder Market Suppliers

Some of the major global suppliers of titanium silicon powder include:

| Company | Production Capacity | Prices |

|---|---|---|

| AP&C | 1500 tons per year | $55-75 per kg |

| TLS Technik | 1000 tons per year | $45-90 per kg |

| AMETEK | 500 tons per year | $60-120 per kg |

| Sandvik | 250 tons per year | $75-150 per kg |

Pricing is driven by order volume, powder composition, particle characteristics and level of quality control as per specifications. Larger customized orders tend to have more negotiation room on pricing terms compared to small standard lot purchases.

Pros and Cons of Titanium Silicon Powder

| Pros | Cons |

|---|---|

| High strength-to-weight ratio | Expensive compared to steel |

| Excellent corrosion resistance | Reactivity with oxygen at high temperatures |

| Good high temperature properties | Lower ductility than pure titanium |

| Low toxicity | Difficult to machine in some compositions |

| Customizable properties | Limited suppliers and production capacity |

By optimizing composition and production methods, titanium silicon powders provide unmatched performance despite some limitations.

Comparison With Alternatives

Vs Stainless Steel: More expensive but much higher strength-to-weight ratio, can withstand higher temperatures

Vs Aluminum Alloys: Higher density but better environmental stability and mechanical properties

Vs Titanium Alloys: More brittle but superior high temperature creep resistance and modulus

Vs Tungsten Alloys: Lower density and easier processability but inferior radiation shielding behavior

Among competing advanced alloys, titanium silicon powders stand out based on the tailored property mix enabled by alloying silicon with titanium.

FAQ

Here are some common FAQs about titanium silicon powder:

Q: What is titanium silicon powder used for?

A: Titanium silicon powder is used to manufacture high-performance components for aerospace, automotive, biomedical devices, additive manufacturing, thermal spray coatings, etc. due to its excellent strength, temperature resistance, and biocompatibility.

Q: Does titanium silicon powder contain titanium and silicon?

A: Yes, it is an alloy powder composed of both titanium and silicon in varying ratios such as Ti-6Si, Ti-10Si based on the designated composition.

Q: What processing methods can use titanium silicon powder?

A: Key processing routes include additive manufacturing (3D printing), powder injection molding, thermal spraying, powder metallurgy including pressing & sintering, hot isostatic pressing (HIP), and heat treatment.

Q: What are the mechanical properties of titanium silicon powder?

A: Its density ranges from 4.1-4.5 g/cm3, elastic modulus 110-160 GPa, strength 500-1100 MPa, elongation 5-15%, and max use temperature up to 700°C in air. Properties depend on composition and processing.

Q: Does titanium silicon powder require special storage or handling?

A: It rapidly oxidizes above 500°C forming brittle surface oxides. So inert gas sealing and limited moisture is necessary during storage and handling to control contamination.

Q: What are the alternatives to using titanium silicon powder?

A: Alternatives include stainless steels, titanium alloys, aluminum alloys, and tungsten alloys. But titanium silicon provides the best balanced property mix of strength, density, stiffness, biocompatibility and high-temperature stability.