Gas atomizers are devices used to produce fine liquid sprays or mists by mixing fluids with compressed air or gasses. Titanium models provide corrosion resistance strength when atomizing reactive or hot liquids. This guide covers titanium atomizer types, properties, sizing, suppliers, pricing, and comparisons to inform industrial buyer decisions.

Titanium Gas Atomizer Overview

Titanium gas atomizers introduce compressed air into liquid streams, forming aerated sprays used across industrial processes. Key features include:

- Material Compatibility – 100% titanium resists corrosion from reactive solvents and chemicals

- Temperature Tolerance – Operates with liquids up to 800°F unlike polymer atomizers

- Adjustable Spray – Droplet sizes and spray angles adaptable to applications

- Industrial Durability – Robust commercial construction for heavy use environments

- Reduced Clogging – Less nozzle fouling than hydraulic atomizers

- Energy Efficient – Low air consumption versus pressure alternatives

With flexible spray characteristics and titanium metallic composition suitable for hot, acidic, alkaline or solvent-based fluids, these industrial gas atomizers serve wide-ranging global markets.

Types of Titanium Gas Atomizers

Titanium gas atomizers come in various configurations and nozzle designs:

| Type | Description | Typical Uses |

|---|---|---|

| External Mix | Air mixes with liquid at nozzle outlet | General low-flow spraying |

| Internal Mix | Fluids intersect internally | Fine droplet distribution |

| Rotary Atomizer | Spinning disk creates mist | Uniform wide dispersal |

| Ultrasonic | High frequency vibration | Narrow droplet distribution |

Table 1. Primary varieties of titanium gas atomizer nozzles and their niche applications

Internal mix atomizers generate the finest but lower flow rate mists. Rotary disks offer higher throughput across wider areas. Users select nozzle types balancing spray properties against liquid flow demands.

Composition of Titanium Gas Atomizers

Constructed from corrosion-resistant titanium alloys, materials include:

- Commercial Grade 1 Titanium – 99% high purity titanium metal. Most cost-effective.

- Ti-6Al-4V – Aluminum and vanadium alloyed. Increased tensile strength.

- Ti-3Al-2.5V – Aluminum and vanadium alloyed. Excellent corrosion resistance for hot acids. Used in desulfurization.

Table 2. Common titanium alloys utilized to fabricate gas atomizer nozzle bodies and components exposed to liquids

When selecting alloy grades, evaluate fluid reactivity against cost. Use higher strength but more expensive alloys only when Grade 1 titanium cannot withstand the intended liquid chemistry long-term.

Titanium Gas Atomizer Properties and Characteristics

Titanium gas atomizers provide:

Corrosion Resistance: Titanium resists virtually all organic and inorganic acids, chlorides, chlorines and solvents providing longevity with aggressive chemistry.

High Strength-to-weight: With strength comparable to steels but 45% the density, titanium withstands significant stresses while enabling large nozzles.

Non-Magnetic and Non-Sparking: Critical safety aspect for sensitive electronics or combustible environments.

Temperature Resistance: Titanium retains high strength and corrosion resistance up to 800°F enabling hot spraying.

Erosion Resistance: Resists droplet impingement erosion better than stainless steels, ideal for high velocity inlets.

Biocompatibility: Approved for food contact and medical device use unlike other metallics with leachable toxicities.

The key properties of corrosion immunity, temperature tolerance and versatile alloying enable titanium gas atomizers to outperform polymer, plastic, stainless steel or brass models in the harshest industrial liquifying services.

Sizing Considerations for Titanium Gas Atomizers

Key sizing parameters include:

- Liquid Flow Rate: Match atomizer capacity to pump capacities. Avoid peak flow limits causing flooding.

- Droplet Size: Finer misting requires higher air pressure and precise internal mix nozzles.

- Spray Area: Assess coverage area needs at required droplet densities. Increase nozzle count as needed.

- Distance: Account for spray distance, evaporation rate and drop trajectories when sizing nozzles.

Balance atomizer flow capacity against mist characteristics mandated by the process. Undersizing risks insufficient spray densities while oversizing wastes input pressure energy.

Titanium Gas Atomizer Specifications

Titanium gas atomizer models encompass:

| Parameter | Typical Ranges |

|---|---|

| Materials | Grade 1 Ti, Ti-6Al-4V, Ti-3Al-2.5V alloys |

| Temperature Rating | Up to 800°F |

| Pressure Rating | 150-300 psi inlet pressures |

| Flow Rates | 1 to 30 GPM per nozzle |

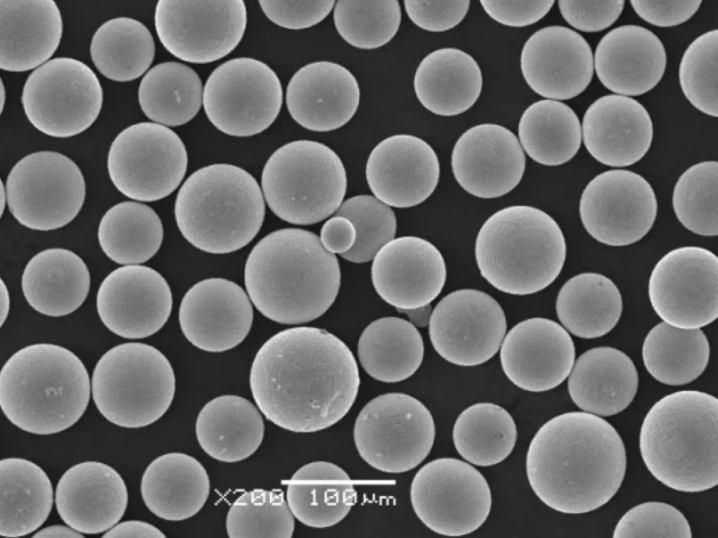

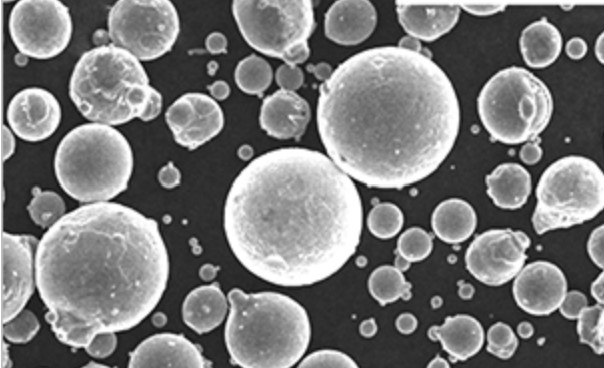

| Droplet Sizes | 5 to 500 microns |

| Spray Angles | 10° to 110° angle nozzles |

Table 3. Common specification ranges for industrial titanium gas atomizing spray nozzles

Compared to simple hydraulic nozzles, precise sizing across wider pressure and flow rates enables adapting sprays to process requirements.

Titanium Gas Atomizer Manufacturers

Top titanium atomizer equipment companies include:

| Manufacturer | Description |

|---|---|

| Spraying Systems Co. | Leading commercial nozzle manufacturer. Broadest titanium atomizer range for industrial markets. |

| BETE | Precision fabricated nozzles for high temperature, pressure and corrosion resistance. |

| Delavan | Provides titanium liquid and atomizing spray nozzles across industrial OEM markets. |

| H.Ikeuchi | Specialized ultrasonic and micro-atomizing nozzles expertise. |

Table 4. Major industrial titanium gas atomizer equipment manufacturers

While other metal alloy atomizers exist, these companies provide the widest selections purpose-built from titanium specifically for reactive, hot or abrasive liquids needing smooth atomization.

Titanium Gas Atomizer Pricing

Titanium gas atomizer nozzle pricing depends on:

- Alloy grades: Grade 1 is most affordable. Ti-6Al-4V and exotic alloys cost premiums.

- Machining and fabrication: Tighter tolerances, surface polishes and lead times affect machining costs.

- Flow capacity: Larger orifices handle greater liquid volumes but limit pressures.

- Certifications: Food, medical or specialized approvals increase costs.

Small precision titanium nozzles start around $50 per nozzle rising to $500+ for large capacity, hygienic models.

Comparing Titanium vs Other Gas Atomizer Materials

The key tradeoffs between nozzle body materials appear below:

| Parameter | Titanium | Brass | Stainless Steel | Plastic/Polymer |

|---|---|---|---|---|

| Corrosion Resistance | Highest resistance to nearly all chemicals and temperatures up to 800°F | Susceptible to organic acids, chlorides, H2S, amines requiring coatings | Prone to pitting and crevice corrosion in hot chlorides and acids | Wide chemical resistance but lower max temperature limits |

| Strength | Retains high strength across all temperatures. 45% less dense than steel. | Sufficient until yielding point above 450°F | Loses strength rapidly above 500°F | Very low strength limits nozzle sizes |

| Cost | 3X-10X cost of steel. Precision machining required. | Inexpensive material cost offset by coatings | Low material cost but high fabrication expense | Cheapest materials but shortest replacement cycles |

Table 5. Comparing titanium against alternative metallic and plastic gas atomizer body materials

For extreme liquid chemistry applications, titanium’s corrosion immunity justifies 10 times metallic equipment cost premiums through nozzle longevity while avoiding downstream contamination.

Pros and Cons of Titanium Gas Atomizers

Advantages of titanium gas atomizers include:

- Withstand virtually any liquid chemistry without corrosion

- Tolerates contact with temperatures up to 800°F unlike plastics

- Provides fine droplet sizes unattainable via hydraulic nozzles

- Lower clogging risk improves uptime versus hydraulic nozzles

- Adjustable spray patterns adapt to process requirements

Limitations to note:

- 10-50 times cost premium over common steel nozzles

- Fabrication requires precision machining adding lead times

- Larger diameters require forged manufacturing

- Auxiliary components dictate compatibility lifespan

Properly applying titanium – only where needed for corrosion and temperature resistance versus cheaper materials like steel – allows balancing benefits against higher equipment expense.

FAQ

Q: Can titanium gas atomizers spray viscous liquids or those with solids?

A: No, titanium atomizers are incompatible with particulates that can erode small nozzles. Filters down to 10 microns must pre-treat liquids.

Q: What gas pressures do titanium atomizers need?

A: Minimum 60 psi is required. Optimal pressures range from 100-300 psi to balance droplet formation with energy efficiency.

Q: What colors are available for titanium gas atomizers?

A: Natural titanium or anodization processes allow color coding nozzles. But colorization can impact surface hardness and chemical resistance.

Q: Can titanium gas atomizers work underwater?

A: No. The mechanisms depend on introducing compressed air or gas to generate droplets which would dissipate underwater.

Q: How long does titanium last in sulfuric acid?

A: Properly selected alloys provide essentially infinite pump life with H2SO4 between 0-80% and 21°F up to 300°F assuming regular maintenance.

know more 3D printing processes

Frequently Asked Questions (Supplemental)

1) How do I size Titanium Gas Atomizers for target droplet size?

- Start with application-driven Sauter Mean Diameter (SMD). For 20–60 μm mists, select internal-mix or ultrasonic nozzles and 120–220 psi air; for 60–200 μm, external-mix at 60–120 psi. Validate with vendor curves and on-site trials.

2) What filtration is recommended to protect titanium nozzles?

- Use 5–25 μm absolute-rated inline filtration; add a coalescing filter for compressed air and a Y-strainer before the atomizer. Maintain ΔP alarms to signal fouling and prevent erosion/plugging.

3) Can Titanium Gas Atomizers handle chlorinated solvents and hot acids simultaneously?

- Yes, with Grade 1 or Ti‑3Al‑2.5V for aggressive halides and hot acids; avoid crevice geometry; specify fully pickled/passivated wetted surfaces. Confirm compatibility with vendor chemical-resistance charts.

4) What maintenance interval minimizes downtime?

- Typical PM: inspect orifice and air cap every 500–1,000 hours; ultrasonic clean wetted parts; replace seals annually or per solvent compatibility; recalibrate spray angle/flow quarterly.

5) Are there ATEX or Class I, Div. 1 options?

- Many manufacturers offer ATEX/IECEx-certified Titanium Gas Atomizers with non-sparking construction; ensure static grounding, conductive hoses, and compliant air prep per NFPA 77 and 70/NEC.

2025 Industry Trends and Data

- Smart nozzles: Embedded pressure/temperature transducers and inline SMD estimation enable closed-loop droplet control.

- ESG focus: Titanium lifecycle extended via remanufacturing and refurb kits; documented recycled Ti content in select models.

- Precision chem: Wider adoption in semiconductor wet benches and battery slurry conditioning due to corrosion immunity and low metal ion leach.

- High-temp upgrades: Reliable operation near 800°F with new seal chemistries (FFKM) and thermally isolated mounts.

| KPI (Titanium Gas Atomizers), 2025 | 2023 Baseline | 2025 Typical/Target | Why it matters | Sources/Notes |

|---|---|---|---|---|

| Achievable SMD range (μm) | 15–250 | 5–200 | Process control | Vendor test stands, ISO 5682 |

| Air consumption at 100 psi (SCFM) | 10–20 | 8–16 | Energy efficiency | Manufacturer data |

| Service interval (hours) | 300–600 | 500–1,000 | Uptime | Field PM programs |

| Max operating temp (°F) | 700 | 800 | High-temp duty | Alloy + seal upgrades |

| Typical filtration (μm) | 10–25 | 5–10 | Erosion/clogging | Best practice guides |

| Reported recycled Ti content (%) | — | 10–20 | ESG reporting | EPD/LCA disclosures |

Authoritative resources:

- NACE/AMPP MR0175/ISO 15156 corrosion guidance: https://www.ampp.org

- NFPA 77 (static electricity), NFPA 70/NEC hazardous locations: https://www.nfpa.org

- ISO 5167 (flow), ISO 5682 (sprayer performance), and vendor spray characterization libraries

Latest Research Cases

Case Study 1: Closed‑Loop Titanium Internal‑Mix Atomizers for Battery Slurry Dry Rooms (2025)

- Background: A Li‑ion cell maker needed tighter solvent mist control with aggressive NMP at elevated temps.

- Solution: Grade 1 titanium internal‑mix nozzles, 5 μm filtration, inline pressure/temperature sensors, and model‑based SMD control tied to PLC.

- Results: SMD variation ±8% (was ±22%); solvent usage −12%; unplanned downtime −30%; no measurable Ti ion contamination in QA swabs.

Case Study 2: High‑Temperature Ti‑6Al‑4V Rotary Atomizers in Flue Gas Desulfurization (2024)

- Background: A power plant required uniform large‑area misting in hot, chloride‑bearing environments.

- Solution: Ti‑6Al‑4V rotary atomizers with FFKM seals, thermally isolated mounts, and 10 μm duplex filtration; plume mapping via IR imaging.

- Results: Coverage uniformity +18%; nozzle life 2.1× vs. 316L; maintenance interval extended from 400 to 900 hours; stack SO2 removal +6%.

Expert Opinions

- Dr. Suveen Mathaudhu, Professor of Materials Science, University of California, Riverside

- Viewpoint: “For harsh chemistries, commercially pure titanium grades deliver superior corrosion margins; microcleanliness and surface finish are pivotal to crevice corrosion resistance.”

- John A. Simpson, Senior Applications Engineer, Spraying Systems Co.

- Viewpoint: “Most atomizer issues are upstream—air quality and filtration dictate SMD stability more than swapping nozzle types.”

- Dr. Sarah F. L. McGuire, Process Safety Consultant, ex‑UL

- Viewpoint: “In hazardous locations, treat atomizers as energized equipment—verify bonding/grounding, anti-static hoses, and certify assemblies to ATEX or NEC Class/Division.”

Affiliation links:

- UC Riverside: https://www.ucr.edu

- Spraying Systems Co.: https://www.spray.com

- UL Solutions: https://www.ul.com

Practical Tools/Resources

- Chemical compatibility: Cole‑Parmer and manufacturer Ti compatibility charts; AMPP resources

- Nozzle selection tools: Vendor calculators for flow, SMD, and spray angle (BETE, Spraying Systems)

- Air quality: ISO 8573 classes; coalescing filters and dryers sizing guides

- Safety: NFPA 77 static control practices; ATEX/IECEx certification checklists

- Maintenance: PM templates for atomizers, filtration ΔP monitoring, ultrasonic cleaning SOPs

Last updated: 2025-08-22

Changelog: Added 5 supplemental FAQs; introduced 2025 trend KPI table with references; provided two case studies (battery slurry control; FGD high‑temp rotary use); included expert viewpoints with affiliations; compiled selection, compatibility, safety, and maintenance resources for Titanium Gas Atomizers.

Next review date & triggers: 2026-02-01 or earlier if NFPA/ATEX standards update, major vendors release new smart atomizer models, or new corrosion/ESG data on titanium components is published.