TiC Powder

TiC powder, or Titanium Carbide powder, is a gray, metallic, extremely hard material known for its exceptional wear resistance, high melting point, excellent corrosion resistance, and good thermal and electrical conductivity. It is used in manufacturing wear-resistant materials, cutting tools, abrasives, high-temperature components, and cermets. It is also used in the coatings and thermal spraying industries to improve the durability of surfaces.

Our Titanium carbide (TiC) powders is produced by Spray Granulation or plasma spheroidization process with spherical shape which is beneficial for applications like additive manufacturing and plasma spraying.

Spray granulation TiC powder is to convert a liquid suspension or slurry into a dried, free-flowing powder with controlled particle size and shape. The liquid feedstock is sprayed through an atomizer into a hot drying chamber, where it breaks into fine droplets, then solid particles agglomerate to form powder.

Plasma spheroidization TiC powder is to melt irregular Titanium Carbide (TiC) powder particles into spherical shapes using the high temperatures of a thermal plasma. This process significantly improves powder characteristics like sphericity, flowability, and density, making them more suitable for applications such as additive manufacturing (AM) processes like Laser Powder Bed Fusion (L-PBF).

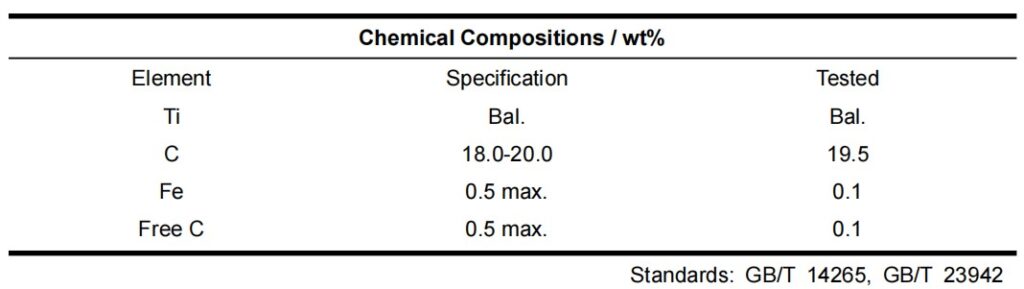

Chemical Composition:

Powder Morphology:

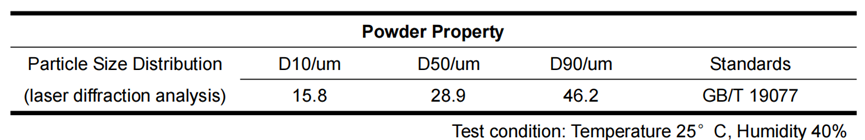

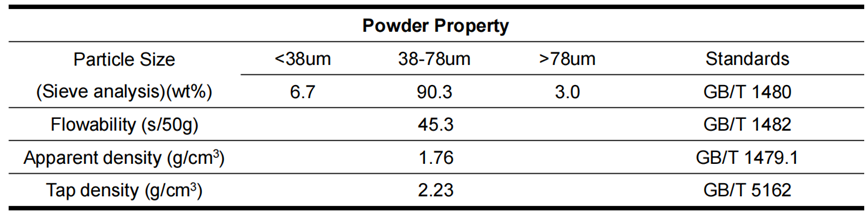

Particle Size Distribution:

15-53um, 45-150um, or Customized

Type 15-53um by plasma spheroidization:

Type 38-78um by Spray granulation:

Packaging:

5kg, 10kg, 25kg or as required; plastic bottle/can.

Documents:

An inspection reports (COA) will be supplied with each order.