Ti-48Al-2Cr-2Nb is an advanced intermetallic alloy with excellent properties for high temperature applications. This article provides a comprehensive overview of Ti-48Al-2Cr-2Nb, including its composition, properties, applications, specifications, pricing, handling, inspection, comparisons with other alloys, and more.

Ti-48Al-2Cr-2Nb Composition

Ti-48Al-2Cr-2Nb has the following typical composition:

| Element | Weight % |

|---|---|

| Titanium (Ti) | 48% |

| Aluminum (Al) | 48% |

| Chromium (Cr) | 2% |

| Niobium (Nb) | 2% |

This titanium aluminide alloy has roughly equal parts titanium and aluminum, with small additions of chromium and niobium.

The high aluminum content results in a lightweight intermetallic material. Chromium improves oxidation resistance at high temperatures. Niobium strengthens the alloy through solid solution strengthening and generates fine precipitates.

Ti-48Al-2Cr-2Nb Properties

Ti-48Al-2Cr-2Nb possesses a desirable combination of properties:

| Property | Details |

|---|---|

| Density | 3.7 g/cm3, very low compared to nickel superalloys |

| Melting point | Over 1400°C |

| Strength | Excellent at room temp and high temp |

| Oxidation resistance | Good up to 700°C |

| Corrosion resistance | Resistant to many chemicals |

| Thermal conductivity | Low, about 16 W/m-K |

| Thermal expansion | Reasonably low |

| Damage tolerance | Superior to other intermetallics |

| Creep resistance | Good |

| Fatigue strength | 110 MPa at 10^7 cycles |

| Fracture toughness | Around 20 MPa-m^1/2 |

The properties of Ti-48Al-2Cr-2Nb make it suitable for many high temperature structural applications up to 700°C. The low density results in a high specific strength.

Ti-48Al-2Cr-2Nb Applications

Ti-48Al-2Cr-2Nb is used in:

- Gas turbine engine components

- Turbocharger wheels

- Automotive valves

- Airframe and aerospace structures

- High temperature fasteners

- Components for chemical processing

The alloy is widely used in aircraft engines for its high strength-to-weight ratio at elevated temperatures. It also sees use in automotive turbocharger components.

Ti-48Al-2Cr-2Nb Specifications

Ti-48Al-2Cr-2Nb is covered by the following standards:

| Standard | Details |

|---|---|

| AMS 4988 | Chemical composition and properties |

| AMS 4989 | Sheet, strip, and plate |

| AMS 4990 | Bar, billet, wire |

| AMS 4991 | Forgings |

| AMS 4992 | Castings |

The alloy is available in various product forms like plate, sheet, bar, billet, wire, forgings, and castings.

Common sizes range from 0.010 to 4.0 inches thick for sheet/plate, and 0.25 to 16 inches diameter for round bar.

Ti-48Al-2Cr-2Nb Suppliers

Some leading global suppliers of Ti-48Al-2Cr-2Nb include:

| Supplier |

|---|

| VSMPO |

| Allegheny Technologies |

| Special Metals Corporation |

| Supra Alloys |

| Western Australian Specialty Alloys |

Ti-48Al-2Cr-2Nb is a specialty alloy with higher cost than standard titanium grades. Pricing can vary from $50/lb to over $200/lb depending on product size, form, quality, and order volume.

Handling and Storage of Ti-48Al-2Cr-2Nb

Ti-48Al-2Cr-2Nb should be handled with care to avoid damage, contamination, or deformation:

- Use clean tools and wear gloves when handling

- Avoid scratching or galling finished surfaces

- Store in a cool, dry place and keep sealed in bags or boxes

- Protect from chemical exposure during storage

- Allow parts to fully cool after processing before storing

The alloy can be prone to cracking if mishandled. Care should be taken to prevent dropping, impact, or excessive bending stresses.

Inspection and Testing of Ti-48Al-2Cr-2Nb

Ti-48Al-2Cr-2Nb parts and materials can be tested and inspected by:

| Method | Purpose |

|---|---|

| Visual inspection | Check for defects and imperfections |

| Liquid penetrant testing | Detect surface cracks and pores |

| Ultrasonic inspection | Internal defect detection |

| Eddy current testing | Detect surface and near-surface flaws |

| Proof testing | Verify strength and reveal cracks |

| Tensile testing | Measure tensile properties |

| Metallography | Microstructure and defect analysis |

| Density measurement | Check composition and quality |

| Hardness testing | Determine mechanical properties |

Both nondestructive and destructive methods are used to verify the quality of Ti-48Al-2Cr-2Nb parts before release to high temperature service.

Ti-48Al-2Cr-2Nb vs. Ti-47Al-2Cr-2Nb

Ti-48Al-2Cr-2Nb differs slightly from the Ti-47Al-2Cr-2Nb alloy in aluminum content:

| Alloy | Al Content | Properties and Applications |

|---|---|---|

| Ti-48Al-2Cr-2Nb | 48 wt% | Higher strength, used in turbochargers and airframes |

| Ti-47Al-2Cr-2Nb | 47 wt% | Better ductility, used in fasteners and engines |

The 1% higher aluminum in Ti-48Al-2Cr-2Nb gives it marginally better high temperature strength but slightly lower room temperature ductility than Ti-47Al-2Cr-2Nb. The two alloys are otherwise very similar.

Ti-48Al-2Cr-2Nb vs. Ti-46Al-2Cr-2Nb

Ti-48Al-2Cr-2Nb can be compared to Ti-46Al-2Cr-2Nb as follows:

| Alloy | Al Content | Properties and Uses |

|---|---|---|

| Ti-48Al-2Cr-2Nb | 48 wt% | Higher strength for turbines and structures |

| Ti-46Al-2Cr-2Nb | 46 wt% | Better ductility, used in sheet and forgings |

Ti-48Al-2Cr-2Nb has higher aluminum than Ti-46Al-2Cr-2Nb, giving it greater strength but lower room temperature formability. Ti-46Al-2Cr-2Nb sees more use in sheet and forged components.

Ti-48Al-2Cr-2Nb vs. Ti-48Al-2Cr

Key differences between Ti-48Al-2Cr-2Nb and Ti-48Al-2Cr:

| Alloy | Nb Content | Effect on Properties |

|---|---|---|

| Ti-48Al-2Cr-2Nb | 2% | Higher strength and creep resistance |

| Ti-48Al-2Cr | – | Lower strength, less precipitation hardening |

The 2% niobium addition has a significant strengthening effect in Ti-48Al-2Cr-2Nb compared to the niobium-free Ti-48Al-2Cr alloy. This makes it preferred for critical rotating parts.

Ti-48Al-2Cr-2Nb vs. Ti-47Al-2Mn-2Nb

Ti-48Al-2Cr-2Nb and Ti-47Al-2Mn-2Nb have these differences:

| Alloy | Key Alloying Elements | Properties and Applications |

|---|---|---|

| Ti-48Al-2Cr-2Nb | Chromium | Higher temperature capability |

| Ti-47Al-2Mn-2Nb | Manganese | Greater room temperature ductility |

The chromium in Ti-48Al-2Cr-2Nb improves its oxidation resistance at higher temperatures, while manganese in Ti-47Al-2Mn-2Nb enhances room temperature formability.

Advantages of Ti-48Al-2Cr-2Nb

Key benefits of Ti-48Al-2Cr-2Nb include:

- Excellent strength-to-weight ratio

- Good high temperature strength

- Adequate oxidation resistance up to 700°C

- Lower density than nickel superalloys

- Can be cast, forged, machined

- Better damage tolerance than other intermetallics

Its combination of low density, good strength, and reasonable ductility make it an enabling alloy for aircraft engines and other high performance applications.

Limitations of Ti-48Al-2Cr-2Nb

Some limitations of Ti-48Al-2Cr-2Nb include:

- Lower room temperature ductility than titanium alloys

- Brittle behavior at lower temperatures

- Higher cost than standard titanium alloys

- Difficult to form and machine in some product forms

- Susceptible to cracking if mishandled

- Not suitable for use above 700°C

The inherently lower ductility and fracture toughness of the alloy can restrict its use in some designs and requires careful processing.

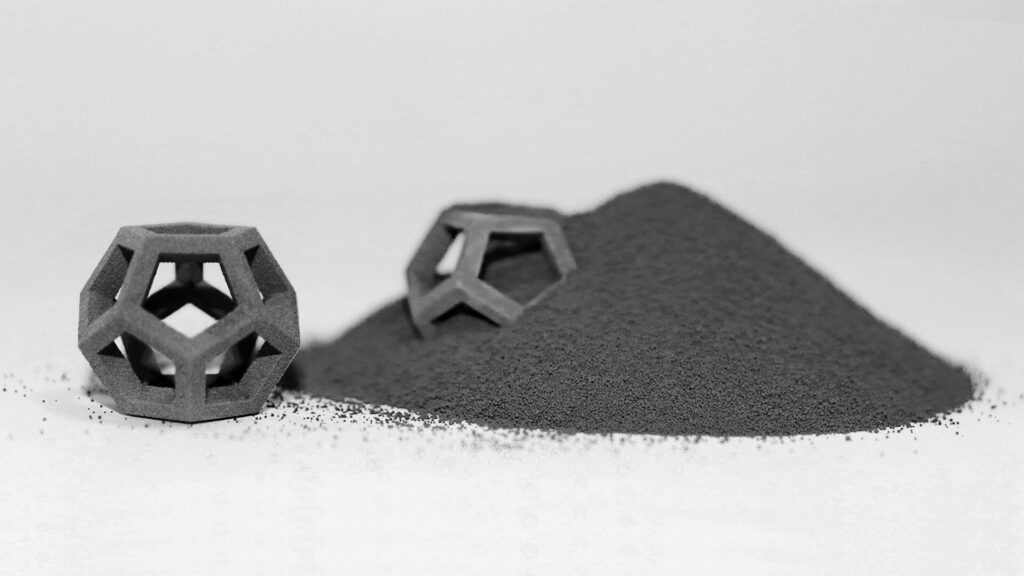

Ti-48Al-2Cr-2Nb Processing

Ti-48Al-2Cr-2Nb can be processed and fabricated by:

- Investment casting

- Forging – closed die or isothermal

- Hot rolling

- Heat treatment – solution and aging

- Machining – turning, milling, drilling

The alloy requires hot working and heat treatment to achieve optimal microstructure and properties. Casting and forging are common production methods.

Ti-48Al-2Cr-2Nb Machining

Ti-48Al-2Cr-2Nb has fair machinability for an intermetallic material:

- Turning, drilling, and milling operations are possible

- Use rigid setups and sharp tools with high positive rake

- Moderate cutting speeds and feeds required

- Use flood coolant or high pressure coolant jet

- Annealed material cuts more easily than aged material

- Carbide tools recommended over high speed steel

The hard and abrasive nature of the alloy means lower speeds and feeds and adequate cooling is needed compared to standard titanium alloys. Annealing can soften the material and improve machinability.

Ti-48Al-2Cr-2Nb Welding

Ti-48Al-2Cr-2Nb has limited weldability:

- Can be welded by gas tungsten arc (GTAW) or plasma arc methods

- Cracking sensitivity requires very strict controls

- Preweld annealing or stress relieving required

- Match compositions of base and filler metals

- Postweld heat treatment generally needed

- Resistance and electron beam welding can also work

The heat affected zone is prone to weld cracking so the joint design, welding parameters, and postweld treatment must be engineered to prevent this.

Ti-48Al-2Cr-2Nb Cost

Ti-48Al-2Cr-2Nb is more expensive than conventional titanium alloys:

- Price ranges from $50/lb to over $200/lb

- High cost limits use to performance-critical applications

- Large quantity orders can lower cost per pound

- Cost also depends on product size, form, quality requirements

- Investment casting grades often cost more than wrought products

The specialized composition, processing, low yield, and aerospace end uses contribute to the higher pricing of Ti-48Al-2Cr-2Nb compared to standard titanium grades.

Ti-48Al-2Cr-2Nb – Frequently Asked Questions

Below are answers to some common questions about Ti-48Al-2Cr-2Nb:

Q: What is Ti-48Al-2Cr-2Nb alloy?

A: Ti-48Al-2Cr-2Nb is an advanced lightweight intermetallic alloy composed of roughly 48% titanium, 48% aluminum, 2% chromium and 2% niobium. It possesses high strength at elevated temperatures up to 700°C and low density.

Q: What are the typical applications of Ti-48Al-2Cr-2Nb?

A: Ti-48Al-2Cr-2Nb is used in aircraft engine components like compressor blades, turbocharger wheels, airframes, fasteners, valves, and other high temperature structures where strength-to-weight ratio is critical.

Q: What are the key properties of Ti-48Al-2Cr-2Nb?

A: Key properties include low density, good elevated temperature strength, adequate oxidation resistance, reasonable room temperature ductility and fracture toughness for an intermetallic. It has specific strengths far exceeding titanium and nickel alloys.

Q: How does Ti-48Al-2Cr-2Nb compare to Ti-6Al-4V?

A: Ti-48Al-2Cr-2Nb has a lower density, higher use temperature, but lower room temperature ductility and fracture toughness than the ubiquitous Ti-6Al-4V titanium alloy. Ti-6Al-4V remains tougher and more formable.

Q: Is Ti-48Al-2Cr-2Nb weldable?

A: Ti-48Al-2Cr-2Nb has only limited weldability owing to its susceptibility to solidification cracking. Special precautions for joint design, preheating, welding parameters, and postweld heat treatment are necessary.

Q: What heat treatment is used for Ti-48Al-2Cr-2Nb?

A: A typical heat treatment is solution treating above the gamma transus followed by aging at 800-850°C to achieve optimal strength and ductility through precipitation hardening.

Q: What is the cost of Ti-48Al-2Cr-2Nb?

A: Ti-48Al-2Cr-2Nb is significantly more expensive than standard titanium alloys, with pricing ranging from $50/lb to over $200/lb depending on quantity, quality, and product size/form.

Q: What are some alternatives to Ti-48Al-2Cr-2Nb?

A: Other gamma titanium aluminides like Ti-45Al-2Mn-2Nb, Ti-47Al-2Cr-2Nb, or Ti-46Al-2Cr-2Nb offer varying combinations of room temperature and high temperature properties. Nickel superalloys also work at higher temperatures.

Q: What precautions are needed when machining Ti-48Al-2Cr-2Nb?

A: Ti-48Al-2Cr-2Nb requires rigid setups, sharp tools, moderate speeds and feeds, abundant cooling, and is preferably annealed first to improve machinability. Careful process engineering is needed to avoid tool wear and damage to the alloy.

Q: Can you summarize the key points about Ti-48Al-2Cr-2Nb?

A: Ti-48Al-2Cr-2Nb is a lightweight high temperature titanium aluminide alloy with good strength up to 700°C, low density, oxidation resistance, and better ductility than other intermetallics. It is enabling for aircraft engines but costs much more than standard titanium alloys. Proper processing and handling is critical to avoid cracking.