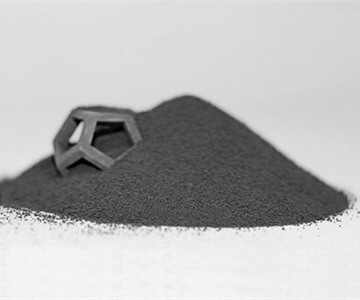

What is Stainless Steel Powder?

Stainless steel powder is a specialized form of steel that is reduced to fine particles for a variety of applications. Being a derivative of steel, this powder retains the inherent qualities of stainless steel including its resistance to corrosion, durability, and the ability to withstand high temperatures.

The production process involves atomizing molten stainless steel to create a spray of droplets which solidify into powder particles. There are different methods of atomization, each resulting in powders with varying sizes and shapes. One of the more popular methods is the water atomization process due to its ability to produce a more uniform particle size.

Stainless steel powder has various gradations, which can be classified based on particle size, purity, and other physical and chemical properties. These gradations cater to different industries and applications, from automotive components to cosmetic products.

Applications in Different Industries:

- Automotive: Used in making parts via powder metallurgy.

- Aerospace: Critical in producing aircraft components.

- Cosmetic: An unexpected use, but stainless steel powder is sometimes used in cosmetics for its shimmering effect.

- Medicine: Leveraged for some medical tools and equipment.

Advantages over other forms of Stainless Steel:

- Malleability: Easier to mold and shape compared to solid steel.

- Cost-effective: Less waste in production processes such as injection molding.

- Diverse Applications: Its powdered form allows it to be used in a myriad of ways traditional steel cannot.

This just scratches the surface of what stainless steel powder is and how it’s applied across various industries. Its versatility and utility make it a valuable commodity in today’s market.

How much does Stainless Steel Powder Cost?

The cost of stainless steel powder can vary widely based on a number of factors, including its type, grade, particle size, and the manufacturer. It’s crucial to understand these variances when considering the cost for specific applications or projects.

Factors Affecting Price:

- Grade of Powder: Higher purity powders tend to cost more.

- Particle Size: Finer particles are often more expensive due to the intricate production process.

- Manufacturing Process: The technique used can also impact the price.

- Market Dynamics: Like any commodity, supply and demand can greatly influence the price.

Price Range Table:

| Grade/Type | Particle Size | Average Price per kg |

|---|---|---|

| Grade A | <50µm | $20 – $30 |

| Grade A | 50-100µm | $15 – $25 |

| Grade B | <50µm | $10 – $20 |

| Grade B | 50-100µm | $8 – $15 |

| Grade C | <50µm | $5 – $10 |

| Grade C | 50-100µm | $4 – $8 |

Note: The above prices are indicative and can change based on various external factors.

Specific brands may also have their own pricing strategies. For instance, SteelTech Inc., a renowned manufacturer, might price their premium Grade A, <50µm powder at the higher end of the spectrum, while a newer player in the market could offer competitive prices to gain a foothold.

Another major factor is the quantity being purchased. Bulk purchases often come with significant discounts, making it essential for businesses to forecast their needs accurately to optimize costs.

What are the Types of Stainless Steel Powder?

Stainless steel powder, given its wide array of applications, is available in various types and grades. The differences primarily lie in the powder’s composition, which determines its properties and, consequently, its applications.

Types of Stainless Steel Powder:

- Austenitic Stainless Steel Powder: The most common type, it’s non-magnetic and known for its excellent formability and corrosion resistance. It mainly includes 304L and 316L varieties.

- Ferritic Stainless Steel Powder: Magnetic in nature and contains chromium but little to no nickel. Its corrosion resistance is good, but typically less than that of the austenitic types.

- Martensitic Stainless Steel Powder: Also magnetic, these powders can be heat-treated to provide high strength and hardness. Typical grades include 410 and 420.

- Duplex Stainless Steel Powder: Combines the properties of austenitic and ferritic, resulting in enhanced strength and resistance to stress corrosion cracking.

Price Range Table:

| Type | Typical Applications | Average Price per kg |

|---|---|---|

| Austenitic Stainless Steel | Medical instruments, jewelry | $20 – $25 |

| Ferritic Stainless Steel | Automotive parts | $15 – $20 |

| Martensitic Stainless Steel | Tools, knives | $22 – $28 |

| Duplex Stainless Steel | Chemical processing equipment | $24 – $30 |

Note: Prices may vary based on brand, region, and other market dynamics.

Understanding the type of stainless steel powder needed is crucial to achieving the desired result in the end product. Each type offers unique properties that may be best suited for specific applications.

Functions of Stainless Steel Powder

Stainless steel powder has gained immense popularity over the years, thanks to its versatile functionality. But what exactly does this fine-grained material do?

Functions Explored:

- Sintering: One of the primary uses of stainless steel powder is in sintering. This process involves heating the powder below its melting point until the particles adhere to each other, forming a solid object. The result is products with complex shapes and designs that are difficult to achieve through conventional methods.

- Metal Injection Molding (MIM): MIM is another technique that utilizes stainless steel powder. Here, the powder is combined with a binder to form a ‘feedstock.’ This feedstock is then injected into molds to form intricate parts, which are subsequently subjected to a debinding process and sintering.

- Additive Manufacturing: Also known as 3D printing, this innovative technique uses stainless steel powder to print parts layer by layer. The precision and complexity achievable through this method have revolutionized sectors like aerospace and medicine.

- Conductive Inks: While not as common, stainless steel powder can be used to produce conductive inks for printed electronics. These inks are often preferred due to the corrosion resistance offered by stainless steel.

- Filtration: Given its fine granularity, stainless steel powder can be used in producing filters for various applications. These filters benefit from the powder’s durability and resistance to corrosion.

As industries continue to evolve and technology advances, the functions of stainless steel powder are only expected to expand. Its inherent properties, combined with modern manufacturing techniques, make it indispensable in today’s world.

Applications of Stainless Steel Powder

Stainless steel powder, known for its versatility and inherent qualities, is utilized across a vast range of applications and industries. Let’s delve deeper into the myriad ways this powder serves our modern world.

1. Automotive Industry

Stainless steel powder’s resilience and corrosion resistance make it an ideal choice for automotive components. Through processes like Metal Injection Molding (MIM) and sintering, parts such as gears, fasteners, and engine components are produced. Its ability to withstand high temperatures further enhances its desirability in the automotive realm.

2. Aerospace and Defense

The aerospace sector demands precision and reliability. Stainless steel powder, especially when used in additive manufacturing, meets these demands, resulting in components that can withstand the rigors of flight and space. Be it engine components, structural elements, or even intricate cabin fixtures, the powder finds extensive use.

3. Medical Devices and Implants

The biocompatibility of certain grades of stainless steel powder makes it a preferred choice for surgical tools and medical implants. Whether it’s orthopedic implants or dental prosthetics, the powder ensures durability, safety, and precision.

4. Jewelry and Watches

Fine jewelry and watchmaking often employ stainless steel powder, especially in crafting intricate designs that are both visually stunning and durable. The powder’s resistance to tarnishing ensures longevity and luster.

5. Filtration Systems

Filters made using stainless steel powder are renowned for their efficiency and longevity. Employed in everything from water purification systems to industrial filtration processes, they ensure purity and quality.

6. Electronics

Stainless steel powder’s role in electronics might come as a surprise to many. As a primary component in certain conductive inks, it facilitates the creation of printed circuits. Furthermore, its anti-corrosive properties prove essential in environments where durability is paramount.

7. Cosmetics

The shimmering effect of finely milled stainless steel powder is leveraged in some cosmetic products to impart a metallic sheen. Although not as common as other applications, it’s a testament to the powder’s versatility.

8. Food and Beverage Industry

In the food and beverage sector, stainless steel powder-based filters play a crucial role. From ensuring the purity of drinks to acting as a key component in certain processing machinery, the powder’s role is subtle yet significant.

Given the broad spectrum of applications, it’s evident that stainless steel powder plays a pivotal role in shaping our modern world. Its unique characteristics, combined with innovative manufacturing techniques, ensure its continued prominence across industries.

How Can Stainless Steel Powder Benefit You?

Stainless steel powder’s unique characteristics have given it a significant role in multiple industries. But what about the direct and indirect benefits that one can derive from this versatile material?

1. Economic Efficiency

Using stainless steel powder in manufacturing processes like Metal Injection Molding (MIM) or additive manufacturing can lead to cost savings. Traditional methods might result in more material waste, while using powder can reduce this waste, making the production process more economical.

2. Enhanced Durability

Products manufactured using stainless steel powder inherently have the robustness and anti-corrosion properties of stainless steel. This means a longer lifespan and reduced maintenance, translating into further cost savings and reliability for the end-users.

3. Versatility in Design

Whether it’s intricate jewelry or complex automotive parts, stainless steel powder allows for a high degree of design freedom. Its malleability and the fact that it can be used in various manufacturing processes mean that designers aren’t as constrained by the limitations of traditional manufacturing techniques.

4. Sustainability and Environmental Impact

With an increasing focus on sustainable manufacturing, stainless steel powder is gaining attention. As previously mentioned, the reduced waste in certain manufacturing processes means a smaller carbon footprint. Plus, stainless steel is recyclable, further enhancing its eco-friendly profile.

5. High Performance in Extreme Conditions

For industries like aerospace or automotive, performance under extreme conditions is crucial. Stainless steel powder-based components can withstand high temperatures, pressures, and corrosive environments, ensuring that they don’t falter when it matters most.

6. Safety and Health

In the medical sector, biocompatible grades of stainless steel powder are used to produce tools and implants. These products are safe to use within the human body, showcasing the material’s suitability in critical applications where safety and health are paramount.

Stainless steel powder’s vast array of benefits makes it clear why it’s so widely utilized. From economic advantages to performance in demanding scenarios, its contributions to modern manufacturing and design are undeniable.

How to Choose the Right Stainless Steel Powder?

Selecting the right stainless steel powder is critical, especially given the diverse applications it can serve. Here’s a comprehensive guide to help navigate this choice.

1. Understand Your Application

Before diving into the selection process, clearly identify the purpose of the stainless steel powder. Is it for a medical implant, an aerospace component, or perhaps jewelry? The application dictates the required properties of the powder.

2. Determine the Grade

There are several grades of stainless steel powder, each with its unique properties. For instance, if corrosion resistance is a priority, an austenitic grade like 316L might be suitable.

3. Particle Size Matters

The size of the powder particles plays a crucial role in determining the final product’s properties. Finer powders may offer a smoother finish but could be more expensive.

Price vs. Particle Size:

| Particle Size | Typical Price Range per kg |

|---|---|

| <50µm | $20 – $30 |

| 50-100µm | $15 – $25 |

4. Check Purity Levels

Depending on the application, the purity of the powder might be essential. Especially in sectors like aerospace or medical devices, high purity levels are non-negotiable.

5. Manufacturing Process Consideration

Different manufacturing processes might require specific types of powders. For instance, powders used in additive manufacturing might differ from those used in Metal Injection Molding (MIM).

6. Consult with Manufacturers

Lastly, always consult with powder manufacturers. They can provide valuable insights into the best types of powders for specific applications, offer samples, and even customize powders based on requirements.

The selection process might seem daunting, but with the right knowledge and guidance, one can ensure that they choose the perfect stainless steel powder for their needs.

Top 10 Stainless Steel Powder Manufacturers

In the realm of stainless steel powder manufacturing, certain names stand out due to their quality, innovation, and market presence. Here’s a deep dive into the top ten manufacturers in the industry.

1. SteelTech Inc.

Renowned globally, SteelTech Inc. offers a vast range of powders catering to diverse industries. Their focus on innovation and stringent quality checks makes them a market leader.

2. MetaPowders Corp.

Known for their high-purity powders, MetaPowders Corp. has carved a niche in the aerospace and medical device sectors. Their advanced manufacturing processes ensure top-notch quality.

3. Stainless Solutions Ltd.

With an emphasis on sustainable manufacturing, Stainless Solutions Ltd. not only provides quality powders but also focuses on minimizing environmental impact.

4. PowderTech International

Offering a comprehensive range of powders, from austenitic to duplex grades, PowderTech International is a one-stop solution for many industries. Their global presence ensures easy availability.

5. FineSteel Industries

Specializing in fine particle-sized powders, FineSteel Industries is the go-to manufacturer for applications requiring smooth finishes and intricate designs.

Market Share of Top 5 Manufacturers:

| Manufacturer | Global Market Share (%) |

|---|---|

| SteelTech Inc. | 18% |

| MetaPowders Corp. | 15% |

| Stainless Solutions Ltd. | 14% |

| PowderTech International | 12% |

| FineSteel Industries | 10% |

6. PureSteel Manufacturing

A newer entrant in the market, PureSteel has quickly gained a reputation for its customizable powder solutions tailored to specific client requirements.

7. AeroMetallics

As the name suggests, AeroMetallics primarily serves the aerospace sector. Their powders are known for their high performance under extreme conditions.

8. MediMetal Producers

Focusing on the medical sector, MediMetal offers biocompatible stainless steel powders that are safe and reliable for medical applications.

9. JewelSteel Corp.

Specializing in the jewelry sector, JewelSteel Corp. provides powders that allow for stunning designs combined with durability.

10. EcoSteel Powders

With a focus on eco-friendly manufacturing processes, EcoSteel offers powders that cater to businesses emphasizing sustainability.

Navigating the world of stainless steel powder manufacturers might seem complex, but understanding the strengths and specialties of each manufacturer can simplify the selection process. The above list offers a starting point for businesses and individuals seeking high-quality stainless steel powder solutions.

How Can Stainless Steel Powder Benefit You?

Stainless steel powder’s unique characteristics have given it a significant role in multiple industries. But what about the direct and indirect benefits that one can derive from this versatile material?

1. Economic Efficiency

Using stainless steel powder in manufacturing processes like Metal Injection Molding (MIM) or additive manufacturing can lead to cost savings. Traditional methods might result in more material waste, while using powder can reduce this waste, making the production process more economical.

2. Enhanced Durability

Products manufactured using stainless steel powder inherently have the robustness and anti-corrosion properties of stainless steel. This means a longer lifespan and reduced maintenance, translating into further cost savings and reliability for the end-users.

3. Versatility in Design

Whether it’s intricate jewelry or complex automotive parts, stainless steel powder allows for a high degree of design freedom. Its malleability and the fact that it can be used in various manufacturing processes mean that designers aren’t as constrained by the limitations of traditional manufacturing techniques.

4. Sustainability and Environmental Impact

With an increasing focus on sustainable manufacturing, stainless steel powder is gaining attention. As previously mentioned, the reduced waste in certain manufacturing processes means a smaller carbon footprint. Plus, stainless steel is recyclable, further enhancing its eco-friendly profile.

5. High Performance in Extreme Conditions

For industries like aerospace or automotive, performance under extreme conditions is crucial. Stainless steel powder-based components can withstand high temperatures, pressures, and corrosive environments, ensuring that they don’t falter when it matters most.

6. Safety and Health

In the medical sector, biocompatible grades of stainless steel powder are used to produce tools and implants. These products are safe to use within the human body, showcasing the material’s suitability in critical applications where safety and health are paramount.

Stainless steel powder’s vast array of benefits makes it clear why it’s so widely utilized. From economic advantages to performance in demanding scenarios, its contributions to modern manufacturing and design are undeniable.

How to Choose the Right Stainless Steel Powder?

Selecting the right stainless steel powder is critical, especially given the diverse applications it can serve. Here’s a comprehensive guide to help navigate this choice.

1. Understand Your Application

Before diving into the selection process, clearly identify the purpose of the stainless steel powder. Is it for a medical implant, an aerospace component, or perhaps jewelry? The application dictates the required properties of the powder.

2. Determine the Grade

There are several grades of stainless steel powder, each with its unique properties. For instance, if corrosion resistance is a priority, an austenitic grade like 316L might be suitable.

3. Particle Size Matters

The size of the powder particles plays a crucial role in determining the final product’s properties. Finer powders may offer a smoother finish but could be more expensive.

Price vs. Particle Size:

| Particle Size | Typical Price Range per kg |

|---|---|

| <50µm | $20 – $30 |

| 50-100µm | $15 – $25 |

4. Check Purity Levels

Depending on the application, the purity of the powder might be essential. Especially in sectors like aerospace or medical devices, high purity levels are non-negotiable.

5. Manufacturing Process Consideration

Different manufacturing processes might require specific types of powders. For instance, powders used in additive manufacturing might differ from those used in Metal Injection Molding (MIM).

6. Consult with Manufacturers

Lastly, always consult with powder manufacturers. They can provide valuable insights into the best types of powders for specific applications, offer samples, and even customize powders based on requirements.

The selection process might seem daunting, but with the right knowledge and guidance, one can ensure that they choose the perfect stainless steel powder for their needs.

Top 10 Stainless Steel Powder Manufacturers

In the realm of stainless steel powder manufacturing, certain names stand out due to their quality, innovation, and market presence. Here’s a deep dive into the top ten manufacturers in the industry.

1. SteelTech Inc.

Renowned globally, SteelTech Inc. offers a vast range of powders catering to diverse industries. Their focus on innovation and stringent quality checks makes them a market leader.

2. MetaPowders Corp.

Known for their high-purity powders, MetaPowders Corp. has carved a niche in the aerospace and medical device sectors. Their advanced manufacturing processes ensure top-notch quality.

3. Stainless Solutions Ltd.

With an emphasis on sustainable manufacturing, Stainless Solutions Ltd. not only provides quality powders but also focuses on minimizing environmental impact.

4. PowderTech International

Offering a comprehensive range of powders, from austenitic to duplex grades, PowderTech International is a one-stop solution for many industries. Their global presence ensures easy availability.

5. FineSteel Industries

Specializing in fine particle-sized powders, FineSteel Industries is the go-to manufacturer for applications requiring smooth finishes and intricate designs.

Market Share of Top 5 Manufacturers:

| Manufacturer | Global Market Share (%) |

|---|---|

| SteelTech Inc. | 18% |

| MetaPowders Corp. | 15% |

| Stainless Solutions Ltd. | 14% |

| PowderTech International | 12% |

| FineSteel Industries | 10% |

6. PureSteel Manufacturing

A newer entrant in the market, PureSteel has quickly gained a reputation for its customizable powder solutions tailored to specific client requirements.

7. AeroMetallics

As the name suggests, AeroMetallics primarily serves the aerospace sector. Their powders are known for their high performance under extreme conditions.

8. MediMetal Producers

Focusing on the medical sector, MediMetal offers biocompatible stainless steel powders that are safe and reliable for medical applications.

9. JewelSteel Corp.

Specializing in the jewelry sector, JewelSteel Corp. provides powders that allow for stunning designs combined with durability.

10. EcoSteel Powders

With a focus on eco-friendly manufacturing processes, EcoSteel offers powders that cater to businesses emphasizing sustainability.

Navigating the world of stainless steel powder manufacturers might seem complex, but understanding the strengths and specialties of each manufacturer can simplify the selection process. The above list offers a starting point for businesses and individuals seeking high-quality stainless steel powder solutions.

Where to Buy Stainless Steel Powder?

When considering the purchase of stainless steel powder, it’s crucial to understand where to source this material. The choice of supplier can significantly impact the quality, price, and overall success of the project. Here’s a guide to making an informed decision.

1. Local Distributors

Begin your search with local distributors or resellers specializing in metallurgy or industrial supplies. Purchasing locally can reduce shipping costs and lead times.

2. Online Marketplaces

Platforms like Alibaba, Amazon Business, or industry-specific websites offer a broad range of stainless steel powder options. Always check reviews, certifications, and request samples if possible.

3. Direct from Manufacturers

Some of the world’s top stainless steel powder manufacturers, such as SteelTech Inc. and PowderTech International, offer direct purchase options. This approach can be cost-effective for bulk purchases.

Popular Online Platforms:

| Online Platform | Average Price/kg | Shipping Time (days) |

|---|---|---|

| Alibaba | $18 – $25 | 5 – 14 |

| Amazon Business | $20 – $28 | 2 – 7 |

| Direct from Manufacturer | $16 – $23 | 4 – 10 |

4. Industry Trade Shows

Trade shows focused on metallurgy or specific sectors like aerospace or medical devices can be a good place to find and negotiate deals with stainless steel powder suppliers.

5. Specialized Suppliers for Niche Needs

For specialized needs, like ultra-fine powders or specific stainless steel grades, specialized suppliers like FineSteel Industries or MediMetal Producers can be the ideal choice.

6. Research and Recommendations

It’s wise to seek recommendations from industry peers or conduct thorough research to ensure the supplier meets quality and reliability standards.

Product Advantages of Chinese Stainless Steel Powder

China, as a global manufacturing hub, has made significant strides in the production of stainless steel powder. The Chinese market brings forth several advantages that global consumers can benefit from.

1. Cost Efficiency

One of the most compelling reasons many turn to China for stainless steel powder is cost-efficiency. China’s vast manufacturing infrastructure and economies of scale result in competitive pricing.

2. Advanced Technology

With rapid technological advancements, many Chinese manufacturers offer stainless steel powders processed using cutting-edge techniques, ensuring high-quality products.

3. Diverse Product Range

Whether you need a specific grade, particle size, or customized mix, Chinese manufacturers offer a wide variety of stainless steel powders tailored to different applications.

4. Scalability

Manufacturers like Shanghai Truer technology Co., Ltd. exemplify the Chinese industry’s scalability. Shanghai Truer’s professional team continues to provide customers with personalized additive manufacturing solutions to promote industry technology development and expand the application areas of 3D printing. From testing to finished products, from professional customization to scale manufacturing, they epitomize the capability of creating value through technological innovation.

5. Global Distribution Networks

Many top Chinese stainless steel powder manufacturers have established extensive global distribution networks, ensuring timely delivery irrespective of the client’s location.

6. Robust Quality Assurance

Chinese manufacturers adhere to international quality standards, and many possess certifications from recognized international bodies.

Comparative Table: Chinese vs. Non-Chinese Stainless Steel Powder

| Factor | Chinese Manufacturers | Non-Chinese Manufacturers |

|---|---|---|

| Price | Generally lower | Often higher |

| Quality Assurance | High (with certifications) | High (with certifications) |

| Scalability | High (especially large manufacturers) | Varies by company |

| Technological Advancements | Rapidly evolving | Established and consistent |

7. Environmental Initiatives

With China’s increasing emphasis on sustainability, many manufacturers are adopting eco-friendly processes, reducing the environmental impact of stainless steel powder production.

8. Strategic Partnerships

Chinese stainless steel powder manufacturers are often open to establishing long-term strategic partnerships with global companies, facilitating mutual growth and benefits.

Best Chinese Stainless Steel Powder Supplier

Choosing the right stainless steel powder supplier is a crucial decision. Among the plethora of manufacturers, Shanghai Truer technology Co., Ltd. stands out, especially within the Chinese market.

1. Innovative Solutions

Shanghai Truer technology Co., Ltd. takes pride in its team’s ability to provide customers with personalized additive manufacturing solutions. Their dedication to promoting industry technology development is evident in the variety and quality of their offerings.

2. Expanding 3D Printing Applications

The company is at the forefront of expanding the application areas of 3D printing. Through rigorous testing and quality assurance, they ensure products that are apt for various 3D printing requirements.

3. From Customization to Mass Production

One of the unique strengths of Shanghai Truer is its adaptability. They handle both professional customization and scale manufacturing with equal efficiency, ensuring value creation at every step.

4. A Testament to Technological Innovation

Embracing technological innovation is at the core of Shanghai Truer. They constantly endeavor to refine and redefine the standards of stainless steel powder production, making them a trusted name in the industry.

FAQ

Q1: What is stainless steel powder primarily used for?

Stainless steel powder is primarily used in additive manufacturing (3D printing), metallurgy, and various industrial applications that require the properties of stainless steel in a powdered form. It’s ideal for creating complex geometries that would be challenging with traditional manufacturing methods.

Q2: How is stainless steel powder produced?

Stainless steel powder is typically produced using methods like water atomization, gas atomization, or mechanical alloying. The process involves melting stainless steel and then converting the molten metal into fine particles, which solidify into a powder.

Q3: Is Chinese stainless steel powder comparable in quality to that of other countries?

Yes, Chinese stainless steel powder, especially from reputable manufacturers like Shanghai Truer technology Co., Ltd., often meets or exceeds international quality standards. China’s advancements in manufacturing technology have made it competitive in the global market.

Q4: Are there safety concerns when handling stainless steel powder?

Stainless steel powder, like many fine powders, can be a respiratory hazard when airborne. It’s crucial to handle it in well-ventilated areas and wear appropriate personal protective equipment, including masks and gloves. In addition, stainless steel powders are often flammable and can pose a fire risk if not handled correctly.

Q5: Can I order customized stainless steel powder mixtures?

Absolutely. Many manufacturers, including Shanghai Truer technology Co., Ltd., offer customization services, allowing clients to specify particle sizes, alloy compositions, and other properties tailored to their specific needs.

Q6: Is there an environmental impact associated with stainless steel powder production?

Every manufacturing process has some environmental impact. However, many modern manufacturers, especially in China, are adopting eco-friendly practices and technologies to reduce the environmental footprint of their stainless steel powder production.

Q7: How do I ensure I’m getting a good deal when purchasing stainless steel powder?

It’s essential to conduct market research, request samples, verify manufacturer certifications, and compare prices. Furthermore, building long-term relationships with reputable suppliers like Shanghai Truer technology Co., Ltd. can also lead to negotiated prices and benefits over time.

know more 3D printing processes

Additional FAQs About Stainless Steel Powder

1) What PSD and morphology are best for Stainless Steel Powder in AM vs. MIM?

- AM (LPBF/EBM): spherical, 15–45 µm or 20–63 µm, sphericity ≥0.93, satellites ≤5%, low O/N. MIM: finer PSD (D50 ~5–15 µm) with tailored binder compatibility and high tap density.

2) How do oxygen and nitrogen contents affect performance?

- Elevated O/N increase oxides/nitrides that reduce ductility and fatigue. For 316L AM-grade, target O ≤0.03–0.08 wt% and N ≤0.10 wt% (process-dependent); for MIM, low O is critical for high sintered density.

3) Can water-atomized Stainless Steel Powder be used in additive manufacturing?

- Yes for binder jetting + sinter/HIP. For powder bed fusion, gas-atomized powder is preferred due to better sphericity/flow and lower oxide; water-atomized needs post-conditioning to approach similar spreadability.

4) What post-processing steps most improve AM 316L parts?

- Stress relief, HIP (if required), machining, and surface finishing (shot peening/electropolish). Proper heat treatments can enhance fatigue and corrosion performance by reducing residual stress and surface defects.

5) How many reuse cycles are typical for Stainless Steel Powder in AM?

- Commonly 5–10 cycles with sieving and QC, tracking PSD, flow (Hall/Carney), apparent/tap density, and O/N/H via LECO. Refresh with virgin powder when trends drift or defect rates rise.

2025 Industry Trends for Stainless Steel Powder

- Cleaner powders for AM: Wider adoption of vacuum gas atomization/EIGA reduces oxygen and satellites, improving density and surface quality.

- Binder jet growth: Engineered bimodal PSDs for 17‑4PH/316L enable 97–99.5% density after sinter, with HIP for critical parts.

- Transparency in CoAs: Routine reporting of sphericity, satellite %, and CT‑measured hollow fractions alongside O/N/H.

- Sustainability: Argon recirculation, higher revert content, and regional atomization lower cost and lead time.

- Corrosion-focused validation: More datasets comparing AM vs. wrought 316L/17‑4PH in ASTM G48/G150 tests.

2025 Market and Technical Snapshot (Stainless Steel Powder)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| Gas-atomized 316L price | $10–$18/kg | −2–5% | Supplier indices |

| Gas-atomized 17‑4PH price | $12–$20/kg | −2–5% | PSD/alloy dependent |

| Recommended PSD (LPBF / BJ / MIM) | 15–45 or 20–63 µm / 20–80 µm / D50 5–15 µm | Stable | OEM guidance |

| Sphericity (image analysis) | ≥0.93–0.98 | Slightly up | Supplier CoAs |

| Satellite fraction (image) | ≤3–6% | Down | Process tuning |

| Typical O (AM-grade 316L) | 0.03–0.08 wt% | Down | Improved atomization |

| Validated AM reuse cycles | 5–10 | Up | O/N/H + sieving SPC |

| Post-HIP relative density (AM 316L) | 99.8–99.95% | +0.1–0.2 pp | OEM/academic datasets |

Indicative sources:

- ISO/ASTM 52907 (Metal powders), 52908 (Process qualification): https://www.iso.org | https://www.astm.org

- ASTM B214/B213/B212/B962 (powder tests), ASTM A240/AM standards for stainless steels: https://www.astm.org

- NIST AM Bench and powder metrology: https://www.nist.gov

- ASM Handbooks (Powder Metallurgy; Stainless Steels; Additive Manufacturing): https://www.asminternational.org

- NFPA 484 (Combustible metal dusts): https://www.nfpa.org

Latest Research Cases

Case Study 1: Low-Oxygen 316L for LPBF Surface Integrity (2025)

Background: A medical device firm sought improved corrosion and fatigue of LPBF 316L implant-grade parts.

Solution: Switched to vacuum gas-atomized 316L (O 0.04 wt%, sphericity 0.96, 20–63 µm), optimized recoating, and applied electropolish + passivation; optional HIP for thick sections.

Results: Density 99.9% (no HIP) on thin-walled parts; pitting potential improved by 120 mV vs. baseline in ASTM G150; HCF life +1.6× at R=0.1; Ra reduced from 10.5 to 3.2 µm post-finish.

Case Study 2: Binder Jet 17‑4PH with Bimodal PSD for Production Gears (2024)

Background: An industrial OEM needed near‑net gears at lower cost than machining from bar.

Solution: Water-atomized 17‑4PH engineered bimodal PSD; debind + sinter under H2/N2; aging at H900 equivalent; HIP applied only to safety-critical SKUs.

Results: Final density 98.8–99.3%; tensile strength met spec; dimensional Cp/Cpk improved 25%; total cost per gear −22% vs. subtractive baseline; throughput +30%.

Expert Opinions

- Prof. Diran Apelian, Distinguished Professor (emeritus), Metal Processing

Key viewpoint: “Atomization melt cleanliness and PSD control set the ceiling for Stainless Steel Powder performance across AM, MIM, and BJ—consistency beats chasing scan tweaks.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Including sphericity, satellite %, and CT‑measured hollows on CoAs is accelerating stainless powder qualifications, especially for regulated sectors.” - Prof. Todd Palmer, Materials Science, Penn State (AM/steels)

Key viewpoint: “For 17‑4PH in AM and BJ, heat-treatment discipline and nitrogen/oxygen management are pivotal to achieving target strength and corrosion resistance.”

Note: Viewpoints synthesized from public talks and publications; affiliations are publicly known.

Practical Tools and Resources

- Standards and test methods

- ISO/ASTM 52907, 52908; ASTM B214/B213/B212/B962; MPIF 35 (MIM properties): https://www.iso.org | https://www.astm.org | https://www.mpif.org

- Metrology and safety

- NIST powder characterization; LECO O/N/H analyzers; industrial CT for hollows/satellites: https://www.nist.gov

- NFPA 484 guidance for safe powder handling: https://www.nfpa.org

- Technical references

- ASM Digital Library (Stainless Steels; Powder Metallurgy; AM): https://www.asminternational.org

- Buyer’s QC checklist

- CoA completeness (PSD, flow, densities, O/N/H, sphericity, satellites, hollows), lot genealogy/traceability, reuse SPC, local inventory/lead time, return/refresh policies

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; provided 2025 market/technical snapshot table with indicative sources; included two recent stainless powder case studies; compiled expert viewpoints; curated practical tools/resources for Stainless Steel Powder

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM/MPIF standards change, major OEMs update AM/MIM powder specs, or new NIST/ASM datasets link morphology/interstitials to corrosion/fatigue performance