What is a Metal Atomizer?

Metal atomizers play a crucial role in numerous industries. These devices convert molten metal into fine droplets, allowing for the creation of metal powders or aiding in controlled spray deposition. But how do they work, and why are they so vital?

Working Principle

Metal atomizers function based on the conversion of energy to disintegrate liquid metal into fine particles. This energy can be derived from various sources, including gas, water, or centrifugal forces. Once the metal is atomized, it quickly solidifies to form powders.

Types

There are primarily three types of atomizers:

- Gas Atomization: High-pressure gas, often nitrogen or argon, is used to break up the molten metal stream.

- Water Atomization: Water jets break up the metal stream. This method is often chosen for metals that aren’t reactive with water.

- Centrifugal/Rotary Atomization: Molten metal is forced through a rotating disk, and the centrifugal force disperses the metal.

Applications

Metal atomizers serve diverse sectors:

- Aerospace: Producing high-quality powders for advanced components.

- Medical: Crafting biomedical implants using specialty alloys.

- Automotive: Metal powders in car parts for weight reduction.

Importance

Given the increasing demand for intricate and lightweight components in sectors like aerospace, automotive, and even jewelry, metal atomizers are more important than ever. Their ability to produce fine and homogeneous metal powders makes them indispensable in modern manufacturing.

Innovation

With technology constantly advancing, atomizers are becoming more efficient, with improved yields and finer particle size distributions. Newer designs and computer simulations allow manufacturers to fine-tune atomizer performance, ensuring optimal efficiency.

How Much Does a Metal Atomizer Cost?

Pricing for metal atomizers can vary greatly based on several factors, including the type, size, application, and the manufacturer’s reputation. It’s essential to understand the various pricing tiers to make an informed purchase.

Type-based Pricing

Different types of atomizers come with varied price tags due to the complexity and materials used:

| Type | Price Range (USD) |

|---|---|

| Gas Atomization | $5,000 – $100,000 |

| Water Atomization | $3,000 – $70,000 |

| Centrifugal/Rotary Atomization | $7,000 – $120,000 |

Size Variations

The size of the atomizer often influences its price. Larger atomizers, suitable for industrial-scale operations, will naturally be more expensive than their smaller counterparts:

| Size (Capacity) | Price Range (USD) |

|---|---|

| Small (Up to 5kg) | $3,000 – $15,000 |

| Medium (5kg to 50kg) | $20,000 – $80,000 |

| Large (Above 50kg) | $85,000 – $150,000 |

Brands and Their Offerings

Certain well-established brands in the market offer metal atomizers with advanced features and better warranties, which can influence pricing:

- MetalMakers Inc.: Known for their efficient gas atomizers, prices range from $7,000 to $90,000.

- AtomTech Industries: A prominent name in centrifugal atomization with prices between $8,000 and $115,000.

- AquaSpray Ltd.: They specialize in water atomizers, and their offerings fall in the $4,000 to $65,000 range.

Additional Costs

Apart from the basic cost of the atomizer, potential buyers should also consider:

- Installation Costs: Depending on the size and complexity, installation can add 5% to 15% to the total price.

- Maintenance: Regular maintenance might incur annual costs of around 3% to 7% of the purchase price.

- Replacement Parts: Components like nozzles or rotary disks might need replacement, adding to operational costs.

Choosing Wisely

Given the significant investment, it’s crucial to analyze your requirements and budget. Make sure to seek multiple quotes, consider future operational costs, and prioritize quality over saving a few dollars. After all, a high-quality metal atomizer can be a game-changer for your operations, offering enhanced efficiency and product quality.

Types of Metal Atomizers and Their Price Ranges

Metal atomizers are versatile pieces of equipment, serving a myriad of industries from aerospace to automotive and even jewelry. As such, various types of atomizers have been developed to meet the specific needs of different applications.

Gas Atomization

Gas atomizers use high-pressure gas, typically nitrogen or argon, to disintegrate the molten metal stream into fine droplets. It’s a common method, particularly for producing high-purity metal powders. The absence of any reaction between the gas and metal ensures a high quality of the final product.

Price Range for Gas Atomizers: $5,000 – $100,000

Water Atomization

In water atomization, water jets break up the molten metal stream. It’s a cost-effective method, suitable for metals that don’t react with water. The resulting powder tends to be less spherical than gas atomized powder but is still suitable for many applications.

Price Range for Water Atomizers: $3,000 – $70,000

Centrifugal/Rotary Atomization

This method uses centrifugal force to atomize molten metal. As the metal passes through a rotating disk or a similar mechanism, the force disperses the metal into fine particles. The resulting powders are often used in industries that require high-performance materials, like aerospace.

Price Range for Centrifugal Atomizers: $7,000 – $120,000

Understanding the Functions of a Metal Atomizer

Metal atomizers play an indispensable role in modern manufacturing and have carved a niche in many industries. They primarily convert liquid metals into fine droplets or powders, but how exactly do they achieve this, and what other functions do they serve?

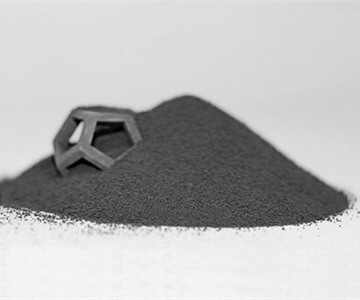

Conversion to Powder

The primary function of a metal atomizer is to take molten metal and disperse it into a mist of fine droplets. These droplets then solidify rapidly, forming fine metal powders. This function is especially crucial for industries that need high-quality metal powders, such as the additive manufacturing sector.

Particle Size Control

Modern atomizers offer control over the size of the particles they produce. Depending on the application, industries might require coarse or fine powders. Metal atomizers can be adjusted to produce the desired particle size, ensuring the powder’s optimal performance in its final use.

Alloy Creation

Atomizers are not just about converting metals into powders. They can also be used to create new alloy compositions. By melting and mixing different metals and then atomizing the resultant mixture, novel alloy powders can be produced. This function is pivotal for sectors like aerospace, where specific alloy compositions are often sought.

Optimized Flow Rates

Advanced metal atomizers come equipped with mechanisms that allow for control over the flow rate of the molten metal. This function is crucial as the flow rate can influence the size and shape of the final particles.

Rapid Solidification

One of the overlooked functions of atomization is the rapid solidification of the metal droplets. This fast cooling can lead to unique microstructures in the metal, often resulting in enhanced material properties. For instance, rapid solidification can prevent unwanted crystalline structures or phase segregations in certain alloys.

Applications of Metal Atomizers in Various Industries

Metal atomizers, with their ability to produce fine and uniform metal powders, are a linchpin in the modern manufacturing landscape. Their applications span several sectors, each benefiting from the unique properties of atomized metals.

Aerospace and Defense

The aerospace industry often requires lightweight and high-strength components. Atomized metal powders, especially those from titanium and superalloys, are extensively used to produce parts through additive manufacturing. This method allows for the creation of components that are not just light and strong, but also intricate, meeting the exacting standards of aerospace applications.

Automotive Industry

As the automotive sector moves towards more fuel-efficient vehicles, there’s a constant push for weight reduction without compromising strength. Metal atomizers provide powders for processes like Metal Injection Molding (MIM) or additive manufacturing, aiding in crafting components that meet these dual requirements.

Medical Field

Implants, dental appliances, and prosthetics often require materials that are both biocompatible and durable. Metal atomizers produce powders of titanium, cobalt-chrome, and other alloys that are extensively used in medical applications. The fine powders enable the fabrication of implants with complex geometries, tailored to individual patient needs.

Jewelry and Art

Atomized precious metals like gold, silver, or platinum find their way into the world of jewelry and art. These powders can be used in various techniques, from traditional casting to modern 3D printing, allowing artisans to craft intricate and unique pieces.

Energy Sector

With the growing push towards renewable energy, there’s an increasing demand for efficient storage solutions, such as batteries. Atomized metal powders, especially those of metals like lithium, play a role in creating efficient battery anodes, facilitating better energy storage.

Electronics and Semiconductors

The electronics industry is always in pursuit of miniaturization while enhancing performance. Metal atomizers provide powders that can be used to create thin-film devices, conductive inks for printed electronics, and solder pastes for chip manufacturing.

Research and Development

As industries evolve, there’s a constant need for novel materials with unique properties. Metal atomizers, especially those that can produce alloy powders, serve the R&D sector by allowing researchers to experiment with new material compositions and study their properties.

Additive Manufacturing

Perhaps one of the most promising applications of metal atomizers is in the field of additive manufacturing or 3D printing. As this technology evolves, there’s a growing demand for high-quality metal powders. Whether it’s for rapid prototyping or final product manufacturing, atomized powders are at the heart of this revolutionary process.

The Benefits of Using a Metal Atomizer

Metal atomizers, through their intricate functioning, hold the potential to revolutionize processes across multiple industries. But how can these benefits translate to advantages for businesses and individuals alike?

High-Quality Metal Powders

One of the primary advantages of metal atomizers is their ability to produce metal powders of exceptional quality. Such powders have uniform particle sizes and fewer impurities, which lead to better performance in their respective applications, be it in aerospace components or medical implants.

Cost-Efficiency

While the upfront cost of metal atomizers might seem significant, their operational efficiency often translates to cost savings in the long run. Atomizers can produce powders in bulk, reducing the per-unit cost. Furthermore, high-quality powders lead to fewer production defects, further amplifying savings.

Tailored Solutions

Modern metal atomizers allow for customizability. Whether a business requires powders of a specific particle size or a unique metal alloy, atomizers can be adjusted to meet these demands. This flexibility is invaluable for industries that constantly innovate and require tailored material solutions.

Environmentally Friendly

Metal atomizers, especially when compared to some traditional powder production methods, are more environmentally friendly. They often use less energy, have fewer emissions, and lead to less waste, aligning with the global shift towards sustainable manufacturing practices.

Safety and Health

The production of metal powders using atomizers can be safer than other methods. Since atomizers typically operate in closed systems, they minimize the exposure of workers to potentially harmful metal fumes or dust.

Enhanced Product Performance

For businesses producing final products, the benefits of atomized metal powders are undeniable. Such powders, given their quality, can enhance the performance of the product. For instance, a battery made using high-quality atomized lithium powder might offer better energy storage and longer lifespan.

Navigating the Selection of a Metal Atomizer

With a plethora of metal atomizers available in the market, making the right choice can seem overwhelming. However, by considering a few critical parameters, one can ensure they select an atomizer that aligns with their needs and offers the best value.

Understand Your Requirements

Before diving into the market, it’s crucial to have a clear understanding of what you expect from the atomizer. Consider factors like:

- The type of metal or alloy you plan to atomize.

- The desired particle size and distribution.

- The quantity of powder you’ll be producing regularly.

Technical Specifications

Different atomizers come with varying technical capabilities. Some might offer higher flow rates, while others might excel in producing ultra-fine powders. Always check the technical specifications and ensure they align with your needs.

Type of Atomization Process

As mentioned earlier, there are primarily three types of atomization processes: gas, water, and centrifugal. Each has its pros and cons. For instance:

- Gas Atomization: Best for high-purity powders, especially reactive metals.

- Water Atomization: Cost-effective but might not suit metals that react with water.

- Centrifugal Atomization: Suitable for high-performance materials with unique microstructures.

Cost Implications

Price is always a consideration. However, it’s essential to view it in terms of long-term value. A cheaper atomizer might have higher operational costs or might produce lower quality powders, leading to more significant expenses in the long run.

Manufacturer Reputation

Given the complexity of metal atomizers, choosing a reliable manufacturer becomes paramount. Look for companies with:

- A strong track record in the industry.

- Positive customer reviews.

- Certifications that attest to their quality.

Maintenance and After-sales Service

A metal atomizer is a significant investment, and its maintenance is crucial for optimal performance. Ensure the manufacturer offers good after-sales service, availability of replacement parts, and possibly training sessions for your staff.

Leading Metal Atomizer Manufacturers in the Industry

The metal atomizer manufacturing landscape is vast, with numerous players offering a range of products. However, a select few stand out, not just in terms of scale but also in quality, innovation, and customer trust. Here’s a look at the top 10 manufacturers in the domain.

1. AtomTech Industries

Renowned for its precision-engineered atomizers, AtomTech has been a market leader for decades. They offer a range of atomizers, from gas to centrifugal, catering to various industries.

2. MetalMakers Inc.

MetalMakers Inc. specializes in high-purity powder production atomizers. Their gas atomizers, in particular, are considered among the best in the industry.

3. AquaSpray Ltd.

A prominent name when it comes to water atomization, AquaSpray has consistently delivered cost-effective and efficient solutions, especially for non-reactive metals.

4. SpinTech Atomizers

SpinTech focuses exclusively on centrifugal atomizers. Their products are known for producing unique alloy powders with intricate microstructures, making them a favorite in the aerospace sector.

5. UltraFine Powders Co.

While not as large as some of the other players, UltraFine is known for its atomizers that produce exceptionally fine metal powders, catering to niche applications.

6. GreenAtom Manufacturing

A relatively new entrant, GreenAtom emphasizes sustainable and environmentally-friendly atomization processes, aligning with the industry’s green shift.

7. RobustMelt Systems

Known for their durable and long-lasting atomizers, RobustMelt is the go-to choice for many industries that require bulk powder production.

8. AlloyCrafters Ltd.

AlloyCrafters specializes in atomizers that cater to alloy powder production. Their products are celebrated for creating novel and high-performance alloy compositions.

9. PreciseAtom Solutions

Focused on precision and control, PreciseAtom’s atomizers offer unparalleled control over particle size and distribution, making them a favorite in research and high-tech industries.

10. GlobalAtom Corp.

With a presence in multiple countries, GlobalAtom Corp. offers a range of atomizers and is known for its exceptional after-sales service and customer support.

Selecting a manufacturer is not just about the product but also the value-added services, customer support, and the trust they have built over the years. The above list offers a starting point, but always delve deeper, seeking customer reviews and conducting trials to ensure the atomizer aligns with your specific needs.

A Guide to Purchasing Metal Atomizers

In today’s world, the search for a reliable source to purchase metal atomizers can be daunting, given the myriad of options available. Whether you’re a business looking for bulk purchases or an individual researching for specific applications, here’s a guide to aid your purchasing journey.

1. Manufacturer Direct Purchases

One of the most reliable ways to buy a metal atomizer is to purchase directly from reputable manufacturers. This ensures that you receive a genuine product, often with warranties and after-sales support. Companies like AtomTech Industries and MetalMakers Inc., for instance, offer direct sales options to businesses and individuals.

2. Online Marketplaces

With the advent of e-commerce, platforms like Alibaba, Amazon Business, and Global Sources have become hubs for sourcing industrial equipment, including metal atomizers. While purchasing, ensure to check:

- Seller ratings and reviews.

- Product specifications against your requirements.

- Return and warranty policies.

3. Trade Shows and Expos

Trade shows dedicated to metal processing, 3D printing, and similar industries often feature stalls from atomizer manufacturers. These events offer an opportunity to see the products firsthand, interact with manufacturers, and even secure deals.

4. Local Distributors and Resellers

Many manufacturers have authorized distributors or resellers in various regions. They can provide local support, faster delivery, and even maintenance services. Always ensure that the distributor is officially recognized by the atomizer manufacturer.

5. Referrals and Recommendations

Sometimes, the best way to find a reliable product is through word of mouth. Reach out to industry peers, colleagues, or online forums related to metal processing for recommendations.

Unveiling the Strengths of Chinese Metal Atomizers

China, known as the world’s factory, has been at the forefront of manufacturing advancements for decades. When it comes to metal atomizers, Chinese manufacturers have carved out a niche for themselves. Here’s an insight into the advantages offered by Chinese metal atomizers.

1. Technological Advancements

Chinese manufacturers have been quick to adopt and integrate the latest technologies into their products. Advanced control systems, precision engineering, and innovative atomization techniques are some of the highlights.

2. Competitive Pricing

Due to the scale of production and efficient manufacturing processes, Chinese atomizers often come with a competitive price tag, offering excellent value for money without compromising on quality.

3. Customization Capabilities

Chinese manufacturers are known for their flexibility in catering to unique customer requirements. Be it a specific alloy composition, particle size, or production capacity; they can often tailor-make atomizers to suit your needs.

4. Robust Supply Chain

China’s well-established industrial supply chain ensures that atomizer components are sourced efficiently, leading to quicker production times and timely deliveries.

5. Global Outreach

Many Chinese atomizer manufacturers have a global presence, with sales and support networks spanning continents. This ensures that customers around the world can access their products and services with ease.

6. Pioneers in Innovation

Companies like Shanghai Truer technology Co., Ltd exemplify the innovative spirit of Chinese manufacturers. Shanghai Truer’s professional team continues to provide customers with personalized additive manufacturing solutions to promote industry technology development and expand the application areas of 3D printing. From testing to finished products, from professional customization to scale manufacturing, they continue to create value to industry through technological innovation.

7. Rigorous Quality Control

Quality assurance is paramount for Chinese manufacturers. Rigorous testing, international certifications, and quality control processes ensure that the metal atomizers produced are of top-notch quality.

8. Comprehensive After-sales Services

Chinese manufacturers emphasize customer satisfaction, and this extends to post-purchase services. Many offer extensive warranties, maintenance services, and round-the-clock customer support.

Spotlight on China’s Elite Metal Atomizer Supplier

China’s manufacturing landscape is vast, with numerous entities competing to be the top choice for customers. In the realm of metal atomizers, while many contenders make the list, a name that consistently emerges at the forefront is Shanghai Truer technology Co., Ltd.

Innovation at its Core

Shanghai Truer technology Co., Ltd is not just another manufacturer. They are innovators, consistently pushing the boundaries of what’s possible in the world of additive manufacturing. Their team’s dedication to providing personalized solutions to customers sets them apart in a competitive market.

Comprehensive Solutions

From the initial testing phase to delivering finished products, Shanghai Truer’s holistic approach ensures that client needs are addressed at every step. Whether it’s professional customization or large-scale manufacturing, they have the infrastructure and expertise to handle varied demands.

Technological Prowess

Shanghai Truer’s emphasis on technological innovation is evident in their products. Their metal atomizers are built using the latest advancements in the field, ensuring efficient performance and high-quality output.

Expanding the Horizons of 3D Printing

One of Shanghai Truer’s standout features is their commitment to expanding the application areas of 3D printing. Through their continuous efforts, they aim to elevate industry standards and create unparalleled value.

A Partner in Progress

Choosing Shanghai Truer technology Co., Ltd is not just about procuring a product; it’s about forging a partnership. A partnership built on trust, innovation, and a shared vision for the future of metal atomization and additive manufacturing.

FAQ

1. What is a metal atomizer?

A metal atomizer is a device that transforms molten metal into fine droplets, which solidify into powders. This process is crucial for several applications, including additive manufacturing and metallurgy.

2. How does the atomization process work?

The atomization process typically involves forcing molten metal through a nozzle and breaking it into tiny droplets using either high-pressure gas, water, or mechanical methods. As these droplets cool, they solidify into metal powders.

3. Why are metal atomizers important in 3D printing?

Metal atomizers produce metal powders that serve as the feedstock for many 3D metal printing processes. The quality and consistency of these powders directly impact the final product’s properties and integrity in 3D printing.

4. Are all metal atomizers the same?

No, metal atomizers can vary based on their atomization method (gas-based, water-based, or rotary), production capacity, and the specific metal or alloy they are designed to process.

5. How long does a metal atomizer typically last?

The lifespan of a metal atomizer depends on its construction, usage frequency, maintenance, and the type of metal being processed. With regular maintenance, industrial atomizers can last several years.

6. Can metal atomizers process multiple types of metals?

While some atomizers are designed for specific metals or alloys, many modern atomizers are versatile and can handle a range of metals with minor adjustments.

7. Are Chinese metal atomizers comparable in quality to those from other countries?

Absolutely. Chinese metal atomizers, especially from reputed manufacturers like Shanghai Truer technology Co., Ltd, meet and often exceed global standards in terms of quality, performance, and innovation.

know more 3D printing processes

Additional FAQs on Metal Atomizers

1) How do I choose between gas, water, and centrifugal atomization?

- Gas atomization (N2/Ar) yields high-purity, spherical powders for AM/MIM; water atomization is lower cost with irregular shapes suited to PM steels; centrifugal/rotary excels for specialty alloys and rapid solidification microstructures.

2) What parameters most affect particle size distribution (PSD) and sphericity?

- Melt superheat, nozzle/orifice geometry, gas type and pressure, melt flow rate, atomization angle, and chamber pressure. Higher gas-to-metal ratios and optimized nozzles improve sphericity and narrow PSD.

3) How do I control oxygen and nitrogen pickup during atomization?

- Use inert gases (Ar or high-purity N2 where compatible), low-leak vacuum/inert chambers, dried gas with <3 ppm H2O, melt deoxidation, ceramic-free EIGA routes for reactive alloys, and rapid powder quench/collection.

4) Can a metal atomizer switch alloys frequently?

- Yes, with strict changeover: drain and purge, crucible/ladle cleanup, nozzle replacement, chamber vacuum bake, and first-off “purge lots” quarantined. Keep alloy families in dedicated lines to minimize cross-contamination.

5) What safety standards apply to operating metal atomizers?

- NFPA 484 for combustible metals, IEC/ATEX for electrical classification, EN ISO 12100 and ISO 13577 for furnace safety, plus local gas handling codes. Implement dust collection, explosion isolation, and inerting interlocks.

2025 Industry Trends in Metal Atomizers

- AM-grade focus: Higher sphericity, lower satellites, and tighter O/N/H specs for LPBF/binder-jet powders.

- Blue/green laser compatibility drives premium Cu/Al powders via gas/EIGA plus post plasma spheroidization.

- Sustainability: Energy‑efficient melt delivery, heat recovery, and powder genealogy “passports” demanded by aerospace/medical OEMs.

- Digital twins: CFD/DEM co-simulation used to tune nozzle jets and predict PSD before production runs.

- Regionalization: New atomization lines in NA/EU/APAC to derisk supply of strategic alloys.

| 2025 Metric (Metal Atomizer/Output) | Typical Range/Value | Why it matters | Source |

|---|---|---|---|

| Gas-to-metal ratio (GMR) in GA | 0.8–2.5 (kg gas/kg metal) | Controls PSD/sphericity and yield | OEM app notes; ASM Handbook |

| LPBF powder PSD target | D10–D90 ≈ 15–45 μm | Recoating stability, density | ISO/ASTM 52907 |

| Satellite content after PS reconditioning | <3–5% (by count) | Flowability, surface finish | Supplier QC data |

| Oxygen spec, Ti‑6Al‑4V AM powder | ≤0.13 wt% (ELI) | Fatigue/ductility | ASTM F136/F3001 |

| Median yield to target cut (AM lots) | 55–75% post‑classification | Cost and availability | Vendor benchmarks |

| Energy use (modern GA line) | ~2–4 kWh/kg powder (alloy/process dependent) | Sustainability KPI | Industry audits/LCA studies |

Authoritative references and further reading:

- ISO/ASTM 52907 (AM feedstock): https://www.iso.org

- ASM Handbook: Powder Metallurgy; Atomization: https://www.asminternational.org

- NFPA 484 (combustible metals): https://www.nfpa.org

- NIST AM Bench datasets: https://www.nist.gov

Latest Research Cases

Case Study 1: CFD‑Optimized Gas Atomizer Nozzle Reduces Satellites (2025)

Background: A powder producer supplying LPBF IN718 faced flow issues from high satellite content in peak demand months.

Solution: Implemented CFD/DEM digital twin to redesign multi-jet nozzle and adjusted GMR; added inline plasma spheroidization for off‑spec lots.

Results: D50 shift from 38 μm to 33 μm with narrower span; satellite count fell from ~11% to 3%; LPBF porosity dropped from 0.42% to 0.12% without changing build parameters.

Case Study 2: EIGA Line for Reactive Titanium Alloys in Medical AM (2024)

Background: A medical OEM needed low‑oxygen Ti‑6Al‑4V ELI powder with consistent PSD for implants.

Solution: Installed electrode induction gas atomization (EIGA) with ceramic‑free melt path, argon ≤10 ppm O2, and automated sieve/classification.

Results: Powder oxygen 0.10–0.12 wt%, PSD D10–D90 = 18–42 μm; tap density +8% vs. legacy GA; downstream hip’d parts met ASTM F3001 tensile/fatigue targets with reduced lot‑to‑lot scatter.

Expert Opinions

- Prof. Peter W. Lee, Chair in Materials Imaging, Imperial College London

Key viewpoint: “Rapid solidification in optimized atomizers suppresses segregation and forms finer carbides/intermetallics, improving AM microstructural homogeneity.” - Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

Key viewpoint: “Pairing atomization with plasma spheroidization closes the quality gap by trimming satellites and tightening tails without a full melt rerun.” - Dr. Brent Stucker, AM standards contributor and industry executive

Key viewpoint: “Powder passports linking atomizer parameters, PSD, and interstitials to part acceptance are accelerating serial qualification.”

Citations for expert profiles:

- Imperial College London: https://www.imperial.ac.uk

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

- ASTM AM CoE: https://amcoe.org

Practical Tools and Resources

- Simulation and design

- Ansys Fluent/CFD, EDEM/ROCKY DEM for nozzle and particle predictions

- OpenFOAM (CFD) for research-scale atomizer modeling

- Standards and safety

- ISO/ASTM 52907; ASTM B214/B822 (PSD); ASTM B212/B329 (density)

- NFPA 484 combustible metals safety guidelines

- QC and analytics

- LECO O/N/H analyzers: https://www.leco.com

- SEM for morphology; ICP‑OES for contamination; inline O2/H2O monitors

- Market/data

- Senvol Database (materials/machines): https://senvol.com/database

- NIST AM Bench datasets: https://www.nist.gov

Last updated: 2025-08-21

Changelog: Added 5 targeted FAQs, 2025 trends with data table and sources, two recent atomizer case studies, expert viewpoints with citations, and practical tools/resources relevant to metal atomizers.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM feedstock standards update, major OEMs tighten O/N/H specs, or significant changes occur in atomizer energy efficiency or yield benchmarks.