1. Introduction: What is Atomised SS-430L Powder?

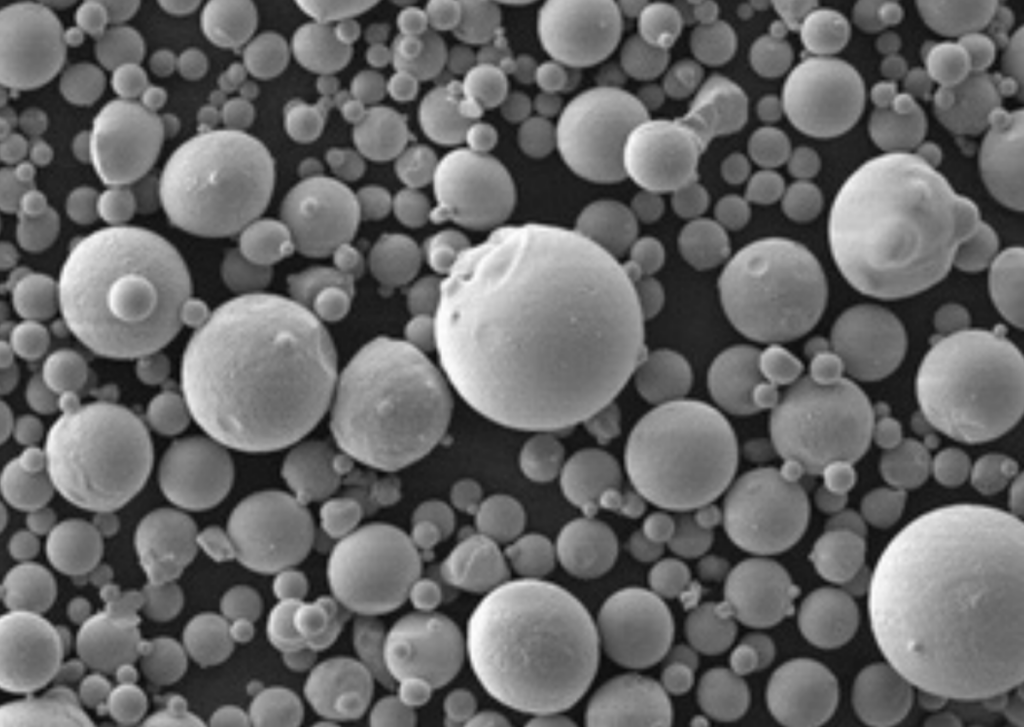

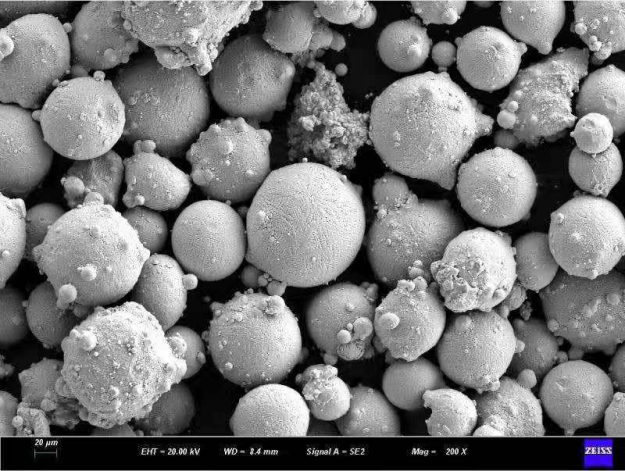

Atomised SS-430L powder is a low-carbon ferritic stainless steel powder produced using atomization techniques such as water or gas atomization. It belongs to the 400 series of stainless steels and is known for its excellent corrosion resistance, high thermal conductivity, and good formability. These characteristics make SS-430L powder especially suitable for powder metallurgy (PM) and additive manufacturing (AM) applications.

In the B2B context, this material is highly sought after in industries such as:

- Automotive

- Home appliances

- Medical devices

- Food processing

- Industrial machinery

Key Features of SS-430L Powder:

| Attribute | Description |

|---|---|

| Composition | Fe-Cr alloy with low carbon (≤0.03% C) |

| Chromium Content | ~16–18% |

| Corrosion Resistance | Excellent in mildly corrosive environments |

| Magnetic Properties | Ferritic (magnetic) |

| Atomization Method | Water or Gas Atomized |

| Applications | PM parts, filters, structural components |

This powder is especially beneficial for parts requiring good corrosion resistance without the cost of austenitic stainless steels like 304L or 316L.

2. Industrial Applications of SS-430L in B2B Manufacturing

Atomised SS-430L powder is used across multiple industries due to its balanced mechanical properties and cost efficiency. Below are the key sectors and their respective B2B use cases:

Automotive Industry

- Exhaust systems

- Sensor housings

- Brake components

- Fuel delivery systems

Food Processing Equipment

- Mixers

- Grinders

- Conveyor parts

Medical Devices

- Surgical instruments

- Orthopedic implants

- Diagnostic equipment casings

Consumer Appliances

- Washing machine parts

- Refrigerator components

- Microwave brackets

Powder Metallurgy Components

| Component Type | Description |

|---|---|

| Structural Parts | For low-load applications |

| Filters | Corrosion-resistant sintered filters |

| Bushings & Bearings | Applications requiring magnetic response |

| Porous Components | For fluid/air flow control |

By offering a reliable balance between performance and cost, SS-430L is often chosen by procurement managers, engineers, and OEM purchasers looking for a durable and cost-effective stainless steel powder.

3. Physical & Metallurgical Properties of SS-430L Powder

Understanding the material properties of SS-430L is essential for any buyer comparing different stainless steel powders. The following table summarizes its key characteristics:

| Property | Value/Range |

|---|---|

| Particle Size Distribution | 15–150 μm (typical) |

| Apparent Density | 2.5–3.0 g/cm³ |

| Flowability | >25 s/50g (Hall Flow) |

| Oxygen Content | ≤0.10% |

| Carbon Content | ≤0.03% |

| Hardness (Sintered) | ~90–120 HRB |

| Magnetic Behavior | Strongly magnetic |

| Sintering Temperature | 1100–1300°C |

Advantages of Using Atomised SS-430L Powder:

- Excellent corrosion resistance in mildly corrosive or oxidizing environments

- Magnetic properties suitable for sensor housings and electronic applications

- Low cost compared to austenitic stainless steels

- High thermal conductivity ideal for heat-exchanger components

Comparison with Other Stainless Powders

| Grade | Magnetic | Corrosion Resistance | Cost Efficiency | Application |

|---|---|---|---|---|

| SS-304L | No | High | Medium | Universal |

| SS-316L | No | Very High | Low | Medical, Marine |

| SS-430L | Yes | Moderate | High | Automotive, Appliances |

For more details on other PM stainless steel grades, visit this page on PM powders.

4. Market Demand and Growth Potential in the Stainless Steel Powder Segment

The stainless steel powder market, including SS-430L, has seen significant growth over the last decade, driven by rapid advancements in powder metallurgy (PM), additive manufacturing (AM), and sintered component production. Particularly in the Asia-Pacific region, the demand from automotive, industrial, and consumer electronics industries has led to a surge in wholesale buying and long-term supply contracts.

Global Market Trends Driving SS-430L Demand

- Rising Adoption of PM Technology

PM enables the production of near-net-shape components with minimal waste, making it an eco-friendly and cost-effective manufacturing method. SS-430L powder is a preferred material for producing cost-sensitive, corrosion-resistant parts. - Increased Use in Consumer Appliances

As the demand for stainless steel components in washing machines, refrigerators, and ovens continues to rise, manufacturers are turning to SS-430L for its affordability and magnetic properties. - Growth in Electric Vehicles (EVs)

The EV industry requires lightweight, corrosion-resistant, and magnetic-compatible components for sensors and actuators, where SS-430L fits ideally.

Market Forecast

| Year | Global Stainless Steel Powder Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2022 | 2.3 | – |

| 2023 | 2.7 | 17.4 |

| 2025 | 3.8 | 18.2 |

| 2028 | 6.1 | 19.0 |

The rise in demand for atomized stainless steel powders like SS-430L is expected to continue, especially in emerging markets like Southeast Asia, India, and Eastern Europe.

5. How to Choose the Right SS-430L Powder Supplier

Selecting a reliable SS-430L stainless steel powder supplier is crucial for supply chain stability, product quality, and compliance with technical requirements. Here are the key factors B2B buyers should consider:

1. Production Method & Consistency

- Ensure the supplier offers both water and gas atomized SS-430L powders.

- Look for consistent particle size distribution and flowability for your process (PM or AM).

2. Technical Support & Documentation

- Request TDS (Technical Data Sheets), MSDS, and Quality Certifications (ISO, RoHS).

- Ask for sintering behavior reports and metallurgical analysis.

3. Customization Options

- Can the supplier customize particle sizes or blends for your specific application?

- Are special packaging or alloy modifications available?

4. Logistics & Lead Time

- Evaluate their delivery timelines and international shipping capabilities.

- Confirm if they maintain inventory for immediate dispatch.

5. Reputation & Industry Experience

- Look for suppliers with over a decade of experience in powder metallurgy.

- Check reviews, case studies, or references in your industry.

Checklist for SS-430L Powder Supplier Selection

| Evaluation Criteria | Must-Have Features |

|---|---|

| Atomization Technique | Water or Gas Atomized |

| Compliance Certifications | ISO 9001, RoHS, REACH |

| Particle Size Control | 15–150 μm with tight PSD control |

| Technical Support | Metallurgists available for consultation |

| Customization Capability | Tailored PSD, packaging, alloy tweaks |

| Lead Time | < 2 weeks for common grades |

| MOQ | Flexible for prototyping and mass production |

You can also learn more about reliable PM powder suppliers by visiting this informational resource.

6. Top 5 Trusted SS-430L Powder Suppliers in Asia

Asia is home to some of the world’s most established and innovative stainless steel powder manufacturers. Below is a curated list of the top 5 SS-430L powder suppliers that serve B2B clients across automotive, electronics, and industrial sectors.

| Supplier Name | Country | Key Strengths | Website |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Full-spectrum PM & AM powder solutions | Visit |

| Hoganas (China) Co., Ltd | China | Global leader in PM powders | hoganas.com |

| CNPC Powder Material Co., Ltd | China | Advanced atomization & export logistics | cnpcpowder.com |

| Pometon S.p.A | Italy (Asia Ops) | Long-standing PM powder expertise | pometon.com |

| Fukuda Metal Foil & Powder Co. | Japan | Specialized in fine stainless steel powders | fukudamm.co.jp |

Spotlight on Shanghai Truer Technology

Shanghai Truer Technology stands out among Asian suppliers due to its:

- Established expertise in PM and AM powders since 2009

- Comprehensive product range including water and gas atomized SS-430L

- In-house testing and customization services for particle size and alloy composition

- Strong export capabilities, serving clients in over 20 countries

Clients can explore their full product line, including SS-430L and other stainless steel powders, by visiting the PM powder page.

7. Why More B2B Buyers Are Turning to Chinese Powder Producers

China has become a global hub for stainless steel powder production, offering cost-efficient, high-quality, and scalable manufacturing solutions for industries worldwide.

Key Benefits of Sourcing from China:

- Cost Advantage

Chinese suppliers offer competitive pricing due to economies of scale and optimized raw material sourcing. - Advanced Atomization Technology

With decades of R&D, Chinese manufacturers now rival Western counterparts in atomization precision and quality consistency. - Custom Production Capabilities

Chinese powder producers often offer more flexibility in customizing blends, particle sizes, and packaging formats. - Robust Export Infrastructure

With established logistics networks, lead times and shipping costs are highly optimized.

Why B2B Buyers Trust Chinese Suppliers:

| Criteria | Advantage from Chinese Suppliers |

|---|---|

| Pricing | 15%–30% lower on average |

| Customization | High flexibility with low MOQ |

| Quality Certifications | ISO, REACH, RoHS compliant |

| Lead Time | Fast production cycles with in-stock items |

| Global Reach | Export to 50+ countries |

One of the most trusted names in the field is Shanghai Truer Technology Co., Ltd, known for its tailored powder solutions and advanced manufacturing capabilities.

8. Why Choose Shanghai Truer Technology for SS-430L Powder

When it comes to sourcing high-quality SS-430L powder for powder metallurgy or additive manufacturing, Shanghai Truer Technology Co., Ltd stands out as a reliable, innovative, and technically advanced partner for global B2B buyers.

Founded in 2009 and entering the additive manufacturing (AM) sector in 2019, Truer has since become one of the most professional powder suppliers in China. Their comprehensive offering and commitment to quality make them a top choice for OEMs, distributors, and industrial buyers.

Key Advantages of Working with Shanghai Truer:

| Feature | Benefit to B2B Buyers |

|---|---|

| 15+ Years Industry Experience | Deep understanding of PM and AM industry requirements |

| In-House Powder Production | Full control of quality, consistency, and customization |

| Dual Atomization Capabilities | Water and gas atomized SS-430L options available |

| Advanced Testing & QC | Full metallurgical lab for quality assurance |

| Technical Support | On-demand consultation and process optimization |

| Global Logistics | Fast international shipping and export documentation |

Truer’s SS-430L powder is offered in various particle size distributions (PSD), tailored for applications in:

- Powder metallurgy (PM) parts

- Sintered filters

- Magnetic components

- Structural parts for automotive and appliances

- Additive manufacturing and binder jetting

Truer’s PM Grade Portfolio Also Includes:

- PM Stainless Steel: SS-430L, SS-304L, SS-316L

- PM Steel Alloys: FL-4605, FD-0208, FD-0200

- Soft Magnetic Alloys: FN-5000, FX-2008

- Infiltrated & Diffusion Alloys: PM CuSn, Iron-copper, Iron-nickel

To view Truer’s full PM powder offerings, visit their dedicated PM powder page.

9. How to Order Wholesale SS-430L Powder from Truer

Placing a wholesale or bulk order with Shanghai Truer Technology is a seamless and transparent process. Whether you’re sourcing for consistent monthly supply or a one-time project-based requirement, Truer’s export team will support you at every step.

Step-by-Step Ordering Process:

- Initial Inquiry

- Contact Truer via the contact page or email with your required specifications (grade, quantity, PSD, atomization type).

- Technical Consultation

- Their engineering team will confirm the technical requirements, recommend suitable grades or blends, and provide detailed TDS/MSDS documents.

- Quotation & Samples

- Receive a formal quotation with lead time, price, and incoterms. Samples for evaluation are available upon request.

- Purchase Order & Payment

- Once the PO is confirmed, Truer begins production or dispatch from inventory. Payment terms vary based on order size and contract.

- Packaging & Shipping

- Powders are packed in sealed, moisture-proof containers. Global shipping with tracking is provided via air or sea freight.

- After-Sales Support

- On-going technical support, reordering assistance, and product performance guidance are available post-delivery.

Packaging Options:

| Package Type | Weight Capacity | Suitable For |

|---|---|---|

| Vacuum Sealed Bag | 5–25 kg | R&D and small batch production |

| Steel Drum | 50–250 kg | Mid-to-large scale manufacturing |

| Custom Pallet | >500 kg | Industrial bulk buyers |

To initiate an order or request a quote, visit Truer’s contact page.

10. FAQs: Buying Wholesale Atomised SS-430L Powder

Q1: What is the difference between gas and water atomized SS-430L powder?

A: Gas atomization produces spherical powders with excellent flowability—ideal for additive manufacturing. Water atomization is more cost-effective and suitable for PM parts where flowability is less critical.

Q2: Can Shanghai Truer customize particle size distribution?

A: Yes. Truer offers customized PSD ranging from 15µm to 150µm depending on your application (e.g., PM compaction, sintering, or AM layering).

Q3: What is the minimum order quantity (MOQ)?

A: The MOQ varies depending on the product and customization needs. For standard SS-430L, MOQ starts as low as 20 kg for evaluation orders.

Q4: How does Truer ensure powder quality and consistency?

A: All powders undergo rigorous testing for flowability, apparent density, chemical composition, and particle morphology in Truer’s in-house lab.

Q5: Is SS-430L powder suitable for magnetic applications?

A: Yes, it is ferritic and magnetic, making it ideal for sensors, actuators, and solenoids.

Q6: Can I request third-party certification for the powder?

A: Yes, Truer can provide third-party lab certifications upon request.

Q7: Does Truer export to Europe and North America?

A: Yes, Truer has active clients in over 20 countries including Germany, USA, India, and Brazil.

Q8: What are Truer’s payment and delivery terms?

A: Standard terms include 30% advance payment and balance before shipment. EXW, FOB, and CIF terms are available.

For more detailed company background, visit Shanghai Truer’s About page.

Embedded Internal Links Summary:

| Anchor Text | URL |

|---|---|

| PM powder page | https://am-material.com/pm-powder/ |

| informational resource | https://am-material.com/about/ |

| Shanghai Truer Technology Co., Ltd | https://am-material.com |

| contact page | https://am-material.com/contact-us/ |

| Shanghai Truer’s About page | https://am-material.com/about/ |

This concludes the comprehensive guide to Atomised SS-430L Powder for B2B buyers. Whether you’re sourcing for powder metallurgy, additive manufacturing, or sintered stainless parts, Shanghai Truer Technology offers a proven, quality-driven, and scalable solution.

Ready to take the next step? Contact us today for a free technical consultation or to request your wholesale quote.