1. Introduction: Why SS-410L Powder Is Crucial in Modern Manufacturing

In the evolving landscape of additive manufacturing (AM) and powder metallurgy (PM), stainless steel powders like SS-410L are gaining significant traction among OEMs, e-commerce sellers, and industrial component manufacturers. SS-410L, a martensitic stainless steel with low carbon content, offers a balance between corrosion resistance, mechanical strength, and cost-effectiveness—making it highly suitable for structural parts, sintered filters, and automotive components.

Key B2B Search Keywords:

- Wholesale SS-410L stainless steel powder

- Buy SS-410L powder in bulk

- SS-410L powder for additive manufacturing

- SS-410L powder suppliers for 3D printing

- Industrial stainless steel powder distributors

Why Atomised SS-410L Matters:

- Enables high-density sintered parts

- Improved flowability in AM and PM processes

- Suitable for high-throughput production

- Reduces post-processing costs due to better surface finish

Shanghai Truer Technology Co., Ltd, a leading supplier of stainless steel powders in China, has been a key innovator in this space. Since 2019, their additive manufacturing division has developed high-quality powders tailored for AM and PM applications. With advanced water and gas atomization techniques, Truer provides superior-grade SS-410L powder to global B2B clients.

👉 Learn more about Shanghai Truer Technology

2. Applications of SS-410L Powder in Industrial Sectors

SS-410L powder’s versatility makes it ideal for various industrial uses. Its corrosion resistance and mechanical performance under heat and stress are especially valuable in the following sectors:

| Industry | Application Examples | Benefits of Using SS-410L Powder |

|---|---|---|

| Automotive | Brake components, bushings, gear parts | High wear resistance, cost-effective |

| Aerospace | Structural brackets, housings | Dimensional stability, corrosion resistance |

| Oil & Gas | Filters, pump parts | Resistance to corrosive fluids |

| Medical Devices | Orthopedic tools, surgical supports | Biocompatibility, excellent surface finish |

| Consumer Appliances | Heating elements, appliance parts | Heat resistance, formability |

Advantages for Wholesale Buyers:

- Easily scalable for large production volumes

- Compatible with both metal injection molding (MIM) and selective laser melting (SLM)

- Conforms with international PM standards like MPIF and ISO

Shanghai Truer supports bulk buyers with consistent supply, technical support, and customization options for specific applications. Check out their SS-410L powder product range for more details.

3. Physical and Mechanical Properties of Atomised SS-410L Powder

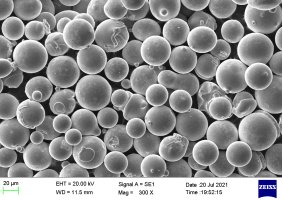

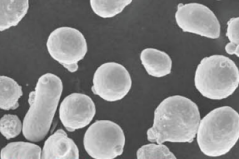

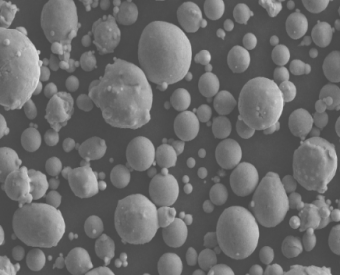

SS-410L stainless steel powder is available in various particle size distributions and can be customized according to the sintering process used by the buyer. Shanghai Truer offers both water-atomized and gas-atomized versions, each suited for different manufacturing needs.

| Property | Typical Values |

|---|---|

| Chemical Composition | Fe: Balance, Cr: 11.5–13.5%, C: <0.03%, Si: <1% |

| Particle Size Distribution | D50: 30–60 µm (customizable) |

| Flow Rate (Hall, s/50g) | 25–35 |

| Apparent Density | 2.5–3.2 g/cm³ |

| Sintered Density | Up to 7.3 g/cm³ |

| Hardness (HRB) | 70–85 |

| Tensile Strength | 480–620 MPa |

Features of Atomised SS-410L Powder:

- Excellent flowability for AM processes

- Low oxygen content for better sintering outcomes

- Consistent morphology ensures uniform performance

- Reduced impurities for increased reliability

Customization Options at Truer:

- Particle size tuning for MIM, SLM, or Binder Jetting

- Alloy blend optimization

- OEM labeling and packaging for distributors

🔍 Explore more stainless steel powder specifications on AM-Material.com

4. Market Trends and Global Demand for Stainless Steel Powders

The global stainless steel powder market is experiencing a significant uptrend, driven by rapid adoption in additive manufacturing (AM), powder metallurgy (PM), and metal injection molding (MIM) industries. Atomised SS-410L powder, in particular, has seen increased demand due to its balance of corrosion resistance, affordability, and mechanical strength.

📊 Key Market Insights:

| Metric | 2023 Estimate | 2028 Forecast |

|---|---|---|

| Global SS Powder Market Size | USD 1.3 Billion | USD 2.1 Billion |

| CAGR (2023–2028) | 9.2% | |

| Major Growth Sectors | Automotive, Aerospace, AM | Energy, Medical Devices |

| Top Regional Markets | China, USA, Germany, Japan | India, South Korea, Brazil |

🔎 B2B Trends Driving Demand:

- Supply Chain Localization: OEMs and Tier 1 suppliers are diversifying sources to reduce dependency on singular markets.

- Shift to Sustainable Manufacturing: SS-410L’s recyclability aligns with sustainability goals.

- Customization Demand: End-users are seeking tailored powder solutions for specific part geometries.

Wholesale Insight: Distributors and bulk buyers are increasingly favoring direct relationships with manufacturers like Shanghai Truer Technology to ensure quality control, faster lead times, and technical support.

👉 Discover more about our powder metallurgy capabilities on our homepage

5. Factors to Consider When Choosing an SS-410L Powder Supplier

Selecting the right atomised SS-410L powder supplier is critical for ensuring product consistency, production efficiency, and regulatory compliance in B2B manufacturing workflows.

✅ Supplier Evaluation Checklist:

| Evaluation Criteria | Why It Matters for B2B Buyers |

|---|---|

| Powder Quality & Composition | Impacts part performance, sintering success |

| Atomization Technology | Determines powder morphology and flowability |

| Batch Consistency | Essential for large-volume production and repeatability |

| Certifications | ISO, RoHS, and REACH compliance for export |

| Customization Capabilities | Ability to modify size distribution or alloy content |

| Lead Time & Logistics | Affects your production planning and inventory control |

| Technical Support | Critical for troubleshooting and application optimization |

| Pricing & MOQ Terms | Impacts your supply chain budgeting and competitiveness |

🌟 Shanghai Truer Technology Advantage:

- Dual atomization (gas + water) processes to meet diverse manufacturing needs

- In-house R&D for tailored powder blends

- ISO-certified production and traceability

- Consistent quality across batches

- Flexible MOQ for distributors and OEMs

🔗 View our complete product offering in PM Stainless Steel Powders

6. Top Global Suppliers of SS-410L Powder

When sourcing SS-410L powder in bulk, companies should evaluate not just the price, but also the supplier’s capacity, technical expertise, and global reach. Here’s a comparison of top-tier suppliers catering to B2B buyers:

| Company Name | Country | Specialty | Atomization Tech | B2B Services Offered |

|---|---|---|---|---|

| Shanghai Truer Technology | China | PM & 3D Printing Powders | Gas & Water | OEM customization, bulk supply, technical consulting |

| Höganäs AB | Sweden | High-purity metal powders | Water | Global distribution, advanced R&D |

| Carpenter Additive | USA | Additive manufacturing powders | Gas | Application engineering, logistics support |

| Sandvik Additive | Sweden | Premium AM & MIM powders | Gas | Ultra-fine powders, in-house printing services |

| Pometon S.p.A. | Italy | Industrial-grade PM powders | Water | Automotive-grade parts supply, technical training |

Why Shanghai Truer Stands Out:

- One of China’s most professional additive suppliers in the PM industry

- Offers a full solution: powder production + equipment + application support

- Strong presence across Asian, European, and North American markets

- Competitive pricing and faster delivery due to localized production

📞 Ready to connect with us? Contact the Truer Team for wholesale inquiries.

7. Why More Buyers Are Choosing Chinese Manufacturers for SS-410L Powder

Over the past decade, China has become a dominant force in the global powder metallurgy (PM) and additive manufacturing (AM) supply chain. More B2B buyers—from OEMs to material distributors—are sourcing stainless steel powders like atomised SS-410L from Chinese suppliers due to several strategic advantages.

📈 Key Reasons Why Buyers Are Sourcing from China:

- Cost Efficiency

- Lower raw material and labor costs reduce the total cost of production.

- Competitive pricing allows for better margins for resellers and OEMs.

- Production Scale & Capacity

- Chinese manufacturers like Shanghai Truer operate large-scale atomization lines.

- Capable of fulfilling high-volume bulk orders with consistent quality.

- Technological Advancements

- Use of hybrid atomization technologies (gas and water) for optimized properties.

- In-house R&D allows for rapid development of custom alloys.

- Shorter Lead Times

- Robust domestic logistics and international shipping networks.

- Reduced time-to-market, especially for East Asia and Pacific buyers.

- Regulatory Compliance

- Leading Chinese suppliers comply with ISO 9001, RoHS, and REACH standards.

- Traceability and documentation support for global distribution.

💡 Pro Tip for Distributors:

When sourcing from China, choose established companies with a proven export track record, like Shanghai Truer Technology, to ensure reliability and technical support.

8. Why Choose Shanghai Truer Technology as Your SS-410L Powder Partner

Shanghai Truer Technology Co., Ltd. has emerged as one of China’s most trusted powder metallurgy suppliers. Since entering the additive manufacturing industry in 2019, Truer has developed a robust portfolio of metal powders, including high-purity atomised SS-410L.

🏆 What Sets Shanghai Truer Apart:

| Feature | Benefits to B2B Buyers |

|---|---|

| Dual Atomization (Gas + Water) | Tailored flowability and density for AM & PM needs |

| Wide Grade Range | From CT-1000 to FD-0208 and customized SS-410L blends |

| In-House R&D | Fast development of custom alloy compositions |

| Production & Equipment Integration | End-to-end AM solution: powder + equipment + support |

| OEM & Distributor Friendly | Flexible MOQ, white-label packaging, and fast shipping |

✔ Product Quality Assurance:

- Consistent Particle Morphology: Ensures predictable sintering behavior.

- Low Oxygen Contamination: Improves mechanical performance in final parts.

- Batch-to-Batch Consistency: Critical for large-scale MIM/SLM production.

🔧 Full-Service Support:

- Technical consulting for application optimization

- Custom particle size distribution

- Export documentation and logistics support

Explore Truer’s full line of metal powders and additives on their product page

9. FAQs: Buying Wholesale Atomised SS-410L Powder

Q1: What is the MOQ for wholesale orders of SS-410L powder from Shanghai Truer?

A: The minimum order quantity is flexible, starting from 100 kg for trial orders. Bulk pricing tiers are available for orders above 500 kg.

Q2: Which industries benefit most from SS-410L powder?

A: Automotive, aerospace, energy, medical, and general manufacturing industries commonly use SS-410L due to its high strength and corrosion resistance.

Q3: Can I request a custom particle size distribution?

A: Yes. Truer offers customization based on your sintering or printing process requirements (SLM, MIM, Binder Jetting, etc.).

Q4: Are Truer powders certified?

A: Absolutely. All powders come with COA and comply with ISO 9001 standards. RoHS and REACH documentation is also available for global exports.

Q5: How do I place a wholesale order?

A: You can reach out directly via the Contact Us page to get a quote, request samples, or begin procurement.

✅ Ready to Source High-Quality SS-410L Powder?

Shanghai Truer Technology is your trusted partner for high-performance atomised SS-410L powder. Whether you’re an OEM, distributor, or e-commerce supplier, Truer delivers consistent quality, technical expertise, and competitive pricing to meet your production demands.

🔗 Visit AM-Material.com to browse our full product portfolio or get in touch with our team today.

📌 Internal Links Used in This Blog:

- https://am-material.com/about/ – “Shanghai Truer Technology”

- https://am-material.com/pm-powder/ – “SS-410L powder product range”

- https://am-material.com/pm-powder/ – “PM Stainless Steel Powders”

- https://am-material.com/contact-us/ – “Contact the Truer Team”

- https://am-material.com/ – “AM-Material.com”

Let us know the next topic you want to explore!