1. Introduction: Why SiO₂ Powder Is in High Demand Across Industries

Silicon dioxide (SiO₂) powder, also known as silica powder, is a foundational raw material prized for its unique properties such as chemical inertness, high thermal stability, and excellent dielectric characteristics. It is widely used in industries ranging from electronics to construction, ceramics to coatings, and even in the field of additive manufacturing.

For B2B buyers, especially those sourcing materials for industrial-scale production, sourcing high-purity SiO₂ powder is critical to ensuring product quality and cost-efficiency. The growing global demand for advanced ceramics, semiconductor substrates, and precision casting has made SiO₂ powder a high-priority procurement item for suppliers, wholesalers, and manufacturers.

Key Characteristics Driving B2B Demand:

- High surface area

- Low impurities (<99.9% purity available)

- Controlled particle size distribution

- Compatibility with various manufacturing processes

B2B buyers such as electronics manufacturers, additive manufacturing specialists, and refractory product producers must ensure that the SiO₂ powder they purchase meets strict industry-specific specifications.

2. Industrial Applications of High-Purity SiO₂ Powder

Silicon dioxide powder is a multi-functional material with diverse industrial uses. Below is a breakdown of its major applications across B2B industries:

| Industry Sector | Applications | SiO₂ Form Used |

|---|---|---|

| Electronics & Semiconductors | Insulators, dielectric layers, microchip substrates | Ultrafine, high-purity |

| Ceramics & Refractories | Kiln furniture, crucibles, thermal insulation | Fused silica, micronized |

| Additive Manufacturing (3D Printing) | Binder Jetting, SLS additive material | Spherical, nano-sized |

| Coatings & Paints | Thixotropic agent, anti-caking, matting agent | Amorphous silica |

| Precision Casting | Investment casting molds, shell building | Fused silica |

| Rubber & Plastics | Reinforcing filler, anti-blocking, UV protection | Precipitated silica |

| Food & Pharma | Anti-caking agent, tablet flow enhancer | Food-grade silica |

Emerging Application: Additive Manufacturing

In the field of 3D printing and powder metallurgy, high-purity SiO₂ powder is being increasingly used as a binder or shell material. Companies like Shanghai Truer Technology Co., Ltd have developed innovative formulations that integrate silica-based additives in their powder metallurgy solutions, ensuring improved part density, flowability, and sintering performance.

3. Types and Grades of SiO₂ Powder for B2B Buyers

Understanding the different types of SiO₂ powder is crucial for buyers looking to optimize performance in specific industrial processes. Below is a table highlighting the most common variants:

| SiO₂ Powder Type | Particle Size Range | Purity (%) | Applications |

|---|---|---|---|

| Fused Silica Powder | 1–100 µm | 99.8–99.99 | Refractories, electronics, investment casting |

| Colloidal Silica | 5–100 nm | 99.9 | Coatings, polishing, catalysts |

| Precipitated Silica | 10–100 µm | 98–99 | Rubber, plastics, food additives |

| Amorphous Silica | 1–50 µm | 99.5–99.9 | Paints, coatings, sealants |

| Crystalline Quartz Powder | 1–100 µm | 99.5–99.9 | Ceramics, glass, electronics |

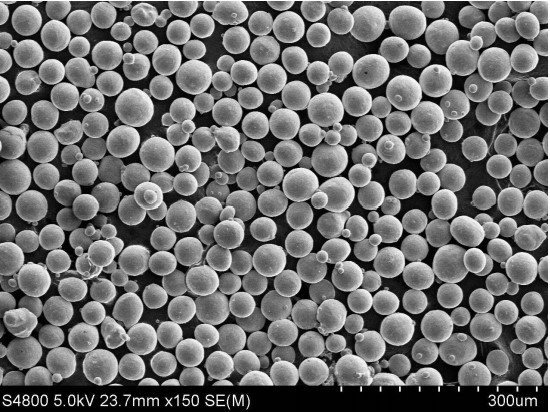

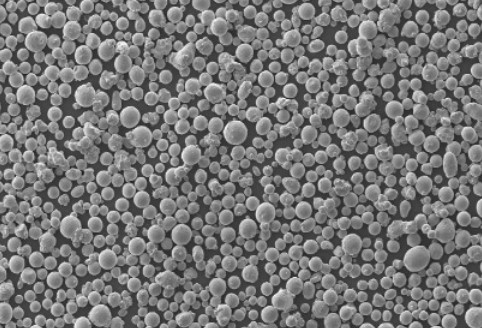

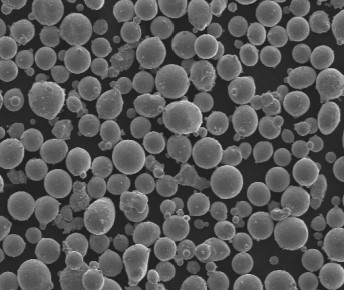

| Spherical SiO₂ (3D Printing) | 10–50 µm | 99.9 | Additive manufacturing, PM applications |

B2B Considerations When Choosing a Grade:

- Desired application (e.g., thermal resistance, insulation, flowability)

- Particle morphology (spherical vs. irregular)

- Bulk and tap density

- Compatibility with other PM powders and binders

Shanghai Truer Technology Co., Ltd offers customized SiO₂ powder solutions tailored for powder metallurgy and additive manufacturing applications. Their PM powder portfolio includes advanced formulations that integrate SiO₂ with metals such as iron, copper, and stainless steel to enhance sintering properties and mechanical performance.

4. Global Market Trends and Growth Opportunities in SiO₂ Powder

The global silicon dioxide (SiO₂) powder market is experiencing steady growth, driven by its increasing use in high-tech industries such as electronics, additive manufacturing, and green energy. According to recent industry reports, the global SiO₂ market is expected to surpass USD 14 billion by 2030, growing at a CAGR of over 6.5% from 2023.

Key Market Drivers:

- Growth in Semiconductor Manufacturing: Demand for ultrafine, high-purity SiO₂ for chip fabrication.

- Expansion of the EV and Battery Sector: Use of SiO₂ in separator coatings and thermal insulation.

- 3D Printing Growth: Increased adoption of silica-based powders in binder jetting and SLS technologies.

- Rising Use in Pharmaceutical Applications: Regulatory-compliant, food/pharma-grade SiO₂ for excipients.

Regional Demand Breakdown:

| Region | Key Industries Driving Demand | Market Share (%) |

|---|---|---|

| Asia-Pacific | Electronics, ceramics, metallurgy | 45% |

| North America | Additive manufacturing, pharmaceuticals | 25% |

| Europe | Refractories, automotive, coatings | 20% |

| Rest of World | Construction, mining, R&D | 10% |

Opportunities for B2B Buyers and Distributors:

- Private labeling opportunities for SiO₂ filler and additives.

- OEM partnerships with 3D printing and ceramic manufacturers.

- Bulk procurement contracts with material R&D companies.

- Value-added distribution for specialty SiO₂ grades.

B2B procurement teams are increasingly sourcing SiO₂ powder from manufacturers that can provide consistent quality, technical support, and global shipping capabilities — all areas where Shanghai Truer Technology Co., Ltd excels.

5. Key Parameters When Selecting a Reliable SiO₂ Powder Supplier

Choosing the right supplier for bulk or specialty SiO₂ powder is critical for manufacturers, resellers, and material scientists. Below are essential parameters B2B buyers should evaluate:

✔️ Purity and Consistency

- Look for 99.5% to 99.99% purity levels.

- Ensure tight control of trace metal impurities.

- Evaluate lot-to-lot and batch consistency.

✔️ Particle Morphology and Size Distribution

- Uniform particle size is crucial for flowability in AM and surface finish in ceramics.

- Spherical morphologies are preferred in additive manufacturing for better packing density.

✔️ Production and Processing Methods

| Method | Benefits |

|---|---|

| Fused Silica | Low thermal expansion, high purity |

| Precipitated Silica | High surface area, cost-effective |

| Gas-phase Synthesis | Ultrafine, highly pure nano-particles |

| Milling & Classification | Custom particle size ranges |

✔️ Packaging and Logistics

- Suppliers should offer custom packaging solutions (e.g., 25 kg bags, 1-ton super sacks).

- Consider export experience, REACH compliance, and MSDS documentation.

✔️ Technical Support and Customization

- On-demand technical support for integration into composite formulations.

- Ability to custom-blend SiO₂ with other PM powders (e.g., Fe-SiO₂, Cu-SiO₂).

Truer’s team offers comprehensive support in selecting the right SiO₂ grade for your specific application, whether you’re in precision casting, 3D printing, or advanced ceramics. Their additive experts can provide guidance on integrating SiO₂ with other PM materials for enhanced sintering and mechanical performance.

6. Top 5 Wholesale SiO₂ Powder Suppliers in Asia

Asia is a powerhouse in the production of technical-grade SiO₂ powders, thanks to its advanced manufacturing infrastructure and cost efficiencies. Below are five leading suppliers catering to international B2B buyers:

| Supplier Name | Country | Specialties | Website/Contact |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | PM-grade SiO₂, AM powders, custom blends | am-material.com |

| Tokuyama Corporation | Japan | Ultrapure SiO₂ for semiconductors | tokuyama.co.jp |

| Evonik Industries | Germany/Asia | Precipitated and colloidal silica | evonik.com |

| Admatechs Co., Ltd. | Japan | Spherical amorphous silica for electronics | admatechs.co.jp |

| OCI Company Ltd. | South Korea | Silica for batteries, coatings | oci.co.kr |

Why Shanghai Truer Stands Out:

- Offers integrated solutions combining SiO₂ with metals for PM applications.

- Supplies custom particle sizes and spherical SiO₂ for AM.

- Advanced production methods including combined water-gas atomization.

- Strong technical background and service capabilities.

As a trusted supplier to industries across Asia, Europe, and the Americas, Truer continues to help B2B buyers streamline their supply chain while boosting R&D innovation.

7. Why Buyers Are Shifting to China-Based SiO₂ Powder Manufacturers

Over the past decade, China has emerged as a dominant force in the global SiO₂ market, offering high-quality materials at competitive prices. Several factors are contributing to this shift:

Key Advantages of Chinese Suppliers:

- Cost Efficiency: Lower production and labor costs.

- Scalability: Ability to handle high-volume bulk orders.

- Advanced Technology: Adoption of gas-phase and fused silica processes.

- Customization: Flexible production lines for tailored specifications.

How Truer Meets International Standards:

Shanghai Truer Technology Co., Ltd, established in 2009, has built a reputation for delivering premium PM and additive manufacturing materials. Since launching its 3D printing powder division in 2019, Truer has expanded rapidly, offering solutions that integrate:

- High-purity SiO₂ powders with custom size distribution.

- Proprietary diffusion alloyed powders and soft magnetic additives.

- Expert support from concept to mass production.

Their wholesale PM powder solutions are designed for global manufacturers and distributors who require consistent quality and technical reliability.

8. How to Order Wholesale SiO₂ Powder from Trusted Sources

For industrial buyers, R&D institutions, and distributors, establishing a streamlined procurement process for silicon dioxide (SiO₂) powder is essential for maintaining production timelines, ensuring consistency, and optimizing cost. Shanghai Truer Technology Co., Ltd simplifies this process through technical consultation, flexible packaging, and global logistics capabilities.

Step-by-Step Guide to Ordering SiO₂ Powder from Truer

| Step | Description |

|---|---|

| 1. Product Inquiry | Visit https://am-material.com/contact-us/ and submit your requirements (purity, particle size, quantity). |

| 2. Technical Consultation | Truer’s R&D team will evaluate your application and recommend the optimal SiO₂ grade or blended solution. |

| 3. Quotation & Sample | Receive a formal quote and request samples for lab testing or pilot runs. |

| 4. Order Confirmation | Once approved, confirm your order and choose packaging and shipping options (e.g., 25 kg bags, 1-ton jumbo bags). |

| 5. Production & QC | Powder is produced in ISO-certified facilities with rigorous QC protocols (including SEM, PSD, ICP-MS analysis). |

| 6. Shipping & Delivery | Truer offers FOB, CIF, and DDP terms with real-time tracking and export documentation. |

Available Packaging Options

- 25kg kraft paper bags (standard)

- 500kg–1000kg jumbo bags (bulk)

- Vacuum-sealed foil bags (for high-purity or nanomaterials)

- Custom labeling for OEM/private label partners

Payment & Delivery Terms

- Lead Time: 7–15 business days for standard orders

- Payment Terms: T/T, L/C, or negotiated terms for long-term contracts

- Shipping Ports: Shanghai, Ningbo, or as per client request

For repeat orders or long-term contracts, Truer also provides contract manufacturing and inventory stockpiling services to help your business scale efficiently.

9. Frequently Asked Questions (FAQs)

Q1: What is the purity range of SiO₂ powder offered by Truer?

A1: Truer offers SiO₂ powders with purities ranging from 99.5% to 99.99%, depending on the application. High-purity fused silica is available for electronics and additive manufacturing industries.

Q2: Can I request a custom particle size distribution?

A2: Yes. Truer specializes in custom particle engineering. Clients can specify D50, D90, and D100 values, and Truer can adjust milling and classification to meet exact requirements.

Q3: Are Truer’s SiO₂ powders suitable for additive manufacturing (3D printing)?

A3: Absolutely. Truer provides spherical and ultra-fine SiO₂ powders optimized for binder jetting and SLS technologies. These powders offer excellent flowability and sinterability.

Q4: What quality control measures are in place?

A4: Truer uses SEM analysis, laser diffraction for PSD, ICP-MS for impurity analysis, and LOI testing to ensure every batch meets strict quality standards.

Q5: Is international shipping available?

A5: Yes. Truer exports globally and provides full documentation (MSDS, COA, REACH registration, customs clearance). Clients can choose preferred incoterms and shipping carriers.

Q6: Can SiO₂ be blended with other PM powders?

A6: Yes. Truer offers pre-blended solutions such as Fe-SiO₂, Cu-SiO₂, and Ni-SiO₂ for sintered parts, diamond tools, and soft magnetic applications.

Q7: Does Truer provide technical assistance for integration into existing processes?

A7: Yes. Truer has a dedicated technical support team to assist with formulation, sintering optimization, and compatibility assessments.

For more technical specifications and offerings, refer to the full PM powder catalog.

Final Recommendations: Why Truer Should Be Your SiO₂ Powder Partner

Shanghai Truer Technology Co., Ltd is more than just a supplier—it is a trusted partner to global manufacturers, additive manufacturing innovators, and powder metallurgy specialists. With over 15 years of experience, Truer has engineered a supply chain built on precision, quality, and customer service.

What Makes Truer Stand Out:

✅ One of China’s most professional additive and PM powder suppliers

✅ Offers a full range of SiO₂ types: fused, amorphous, spherical, precipitated

✅ Customizable solutions for 3D printing, ceramics, and high-tech applications

✅ Advanced production technology: water atomization, gas atomization, and hybrid methods

✅ Fast lead times and global logistics support

✅ Technical expertise in blending SiO₂ with PM materials for optimized performance

✅ Strong reputation in domestic and international powder metallurgy markets

Whether you’re sourcing SiO₂ for precision casting, looking for a high-purity grade for electronics, or planning to integrate it into your additive manufacturing workflow, Truer has the technical capability, product consistency, and customer support to meet your needs.

Start your partnership with a trusted powder supplier today.

👉 Contact Truer’s technical team for a free consultation or sample request.