1. Introduction: What Is Silver Coated Copper Powder?

Silver coated copper powder is a high-performance conductive material used extensively in electronics, additive manufacturing, and high-frequency applications. It combines the superior electrical conductivity of silver with the cost-effectiveness and lightweight nature of copper. By coating copper particles with a thin layer of silver, manufacturers can achieve excellent conductivity, oxidation resistance, and thermal stability—making it a preferred material in various B2B industries.

B2B-Relevant Features:

- High conductivity for electronic applications

- Enhanced oxidation resistance compared to pure copper

- Cost-effective alternative to pure silver powder

- Available in various particle sizes for specific industry applications

Common Industrial Buyers:

- PCB and semiconductor manufacturers

- Additive manufacturing companies

- Aerospace and defense equipment suppliers

- Suppliers of EMI shielding materials

Tip: If you’re sourcing high-purity conductive powders for bulk orders, it’s critical to evaluate suppliers that offer consistent particle morphology and proven coating techniques. Learn more about our powder metallurgy capabilities.

2. Applications in Electronics, Aerospace, and 3D Printing

Silver coated copper powder is highly versatile and finds applications across multiple B2B verticals due to its excellent balance of cost and performance.

Key Application Areas:

| Industry | Application Example | Benefits of Silver Coated Copper Powder |

|---|---|---|

| Electronics | EMI shielding, conductive adhesives, PCBs | High conductivity, low cost, reduced oxidation |

| Aerospace | Sensors, radar systems, communication devices | Lightweight, thermal stability |

| 3D Printing | Functional metal parts, conductive components | Printability, sinterability, conductivity |

| Automotive | Electric vehicle components, sensors | Corrosion resistance, high wear tolerance |

| Telecommunications | Microwave and RF shielding materials | Low signal loss, high frequency performance |

Use Case Highlight:

- EMI Shielding – In high-frequency environments such as telecom base stations or military electronics, silver coated copper powder is used in adhesives and coatings to shield against electromagnetic interference.

- 3D Printed Electronics – The powder can be used in sintered layers or conductive inks for printing antennas, circuit interconnects, and RFID tags.

Pro Tip for B2B Buyers: If your application is in high-reliability environments like aerospace or military electronics, verify supplier certifications such as ISO 9001 and RoHS compliance.

3. Properties and Advantages Over Traditional Conductive Powders

Silver coated copper powder offers a unique combination of material properties that make it superior to traditional conductive powders like carbon, nickel, or pure copper.

Comparative Advantages:

| Property | Silver Coated Copper | Pure Copper | Silver Powder | Carbon | Nickel |

|---|---|---|---|---|---|

| Electrical Conductivity | High | High | Very High | Low | Medium |

| Oxidation Resistance | Excellent | Poor | Excellent | Good | Medium |

| Cost Efficiency | High | Very High | Low | High | Medium |

| Thermal Conductivity | High | High | Very High | Low | Medium |

| Weight | Moderate | Moderate | Heavy | Light | Heavy |

Key Technical Properties:

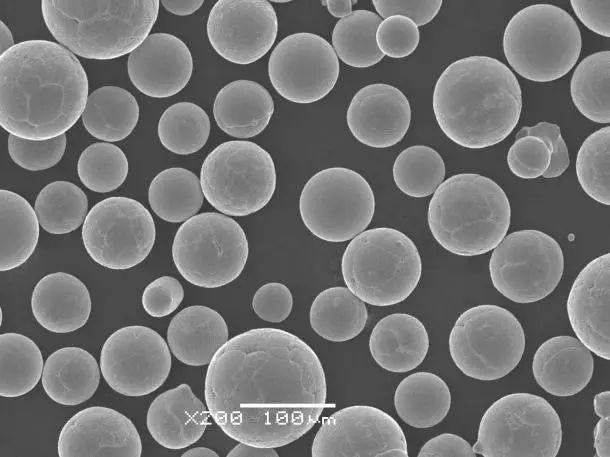

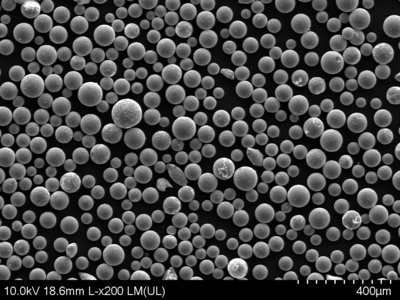

- Particle Size: Customizable (1–50μm typical)

- Silver Layer Thickness: 0.1μm to 2μm

- Purity: >99.9% (combined)

- Bulk Density: 1.2–2.5 g/cm³ depending on particle shape

- Surface Area: 0.5–2.0 m²/g

Performance Benefits:

- Maintains conductivity even in humid or corrosive environments

- Compatible with sintering and paste formulations for electronics

- Reduced risk of galvanic corrosion when used in mixed-metal circuits

Need a Custom Grade? Contact our technical team to discuss custom sizes, coating thicknesses, or dispersion options tailored for your product line.

4. Global Market Trends and Demand Forecast

The global market for silver coated copper powder is expanding rapidly due to the rising demand for high-performance conductive materials across electronics, automotive, 5G, and additive manufacturing sectors. As industries shift toward miniaturization and high-frequency performance, this hybrid metal powder is emerging as a strategic material for B2B manufacturing.

Market Growth Insights:

- CAGR: Estimated at 8.2% (2023–2030)

- Key Growth Drivers:

- 5G infrastructure deployment

- Expansion of electric vehicles and autonomous systems

- Integration of 3D printing in industrial prototyping and end-use parts

- Top Consuming Regions: China, South Korea, Germany, United States, Japan

Demand Segmentation by Industry (2024 forecast):

| Industry Sector | Share of Market Demand (%) |

|---|---|

| Electronics & Semiconductors | 42% |

| Automotive (EV & Sensors) | 21% |

| Aerospace & Defense | 15% |

| 3D Printing & Additive Manufacturing | 12% |

| Others (Medical, Telecom) | 10% |

Strategic B2B Insight:

- OEMs and Tier 1 suppliers are focusing on vertically integrated sourcing for conductive powders to ensure quality, traceability, and supply chain control.

- Smart procurement teams are developing long-term contracts with specialized suppliers like Shanghai Truer Technology Co., Ltd to secure pricing and inventory.

Explore the full range of PM powders available for industrial applications through our powder metallurgy division.

5. Key Considerations When Choosing a B2B Supplier

Choosing the right supplier for silver coated copper powder goes beyond price—it’s about performance consistency, technical support, and supply security. B2B buyers must evaluate several critical factors before committing to a sourcing partner.

Evaluation Checklist for B2B Buyers:

- ✅ Consistent particle size and silver thickness control

- ✅ Proven coating technology for oxidation resistance

- ✅ Batch-to-batch reliability and quality assurance

- ✅ Compliance with RoHS, REACH, ISO9001 standards

- ✅ Logistics efficiency and inventory availability

- ✅ Customization capability for different applications

Must-Ask Questions:

- Can the supplier provide a Certificate of Analysis (CoA) per batch?

- Are technical data sheets (TDS) and material safety data sheets (MSDS) available?

- What is the minimum order quantity (MOQ) for bulk orders?

- Do they offer technical support for formulation integration?

- Are they capable of scaling up production for OEM-level demand?

Pro Tip: Always request a sample batch to test compatibility with your application. Shanghai Truer provides sample shipments on request to qualified B2B buyers.

6. Top 5 Reliable Silver Coated Copper Powder Suppliers in Asia

Asia is home to some of the most innovative and reliable suppliers of silver coated copper powder, offering competitive pricing, high-quality control, and technical expertise.

Top Suppliers to Consider:

| Supplier Name | Country | Highlights |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Advanced coating tech, 3D printing & PM expertise |

| DOWA Electronics Materials | Japan | High-purity electronic powders, ISO-certified |

| Mitsui Kinzoku | Japan | Specialized in conductive materials, global distribution |

| CNPC Powder Material Co., Ltd | China | Bulk powder production, wide variety of metal powders |

| Heraeus | Germany | Premium silver-based materials, global R&D presence |

Why Shanghai Truer Stands Out:

- Offers a wide range of particle sizes and silver coating levels

- In-house R&D for additive manufacturing and powder metallurgy

- Provides powder customization for EMI shielding, sintering, and printing

- Competitive pricing with fast delivery for wholesale orders

- Recognized as a top-tier additive supplier in China’s PM industry

Want to learn more about Shanghai Truer’s background and innovation journey? Visit our About Us page to explore our 15+ years of industry experience.

7. Why More Buyers Are Turning to Domestic Chinese Manufacturers

In recent years, more global B2B buyers have shifted toward sourcing conductive powders from domestic Chinese manufacturers like Shanghai Truer Technology Co., Ltd. This is driven by improvements in quality control, technical capabilities, and cost competitiveness.

Key Drivers Behind the Shift:

- 📈 Rapid advancement in Chinese powder metallurgy technologies

- 🔬 Access to proprietary coating and atomization processes

- 💰 Cost-effective pricing vs. Japanese or European alternatives

- 🚚 Improved international logistics and export experience

- 📋 Compliance with international certifications: ISO, RoHS, REACH

Supplier Comparison Table:

| Feature | Chinese Manufacturers | Overseas Competitors |

|---|---|---|

| Price Competitiveness | ✅ High | ❌ Low |

| Custom Coating Capability | ✅ Available | ✅ Available |

| Lead Times | ✅ Short | ❌ Longer |

| MOQ Flexibility | ✅ Low MOQs | ❌ High MOQs |

| Technical Support | ✅ Multilingual Teams | ✅ Limited |

For B2B distributors and OEMs, this shift presents a strategic opportunity to cut costs without compromising on quality. Shanghai Truer’s domestic innovation and industrial scale make it a preferred choice worldwide.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Supplier

Shanghai Truer Technology Co., Ltd is recognized as one of China’s most professional and complete suppliers of powder metallurgy materials and 3D printing powders. Since launching its additive manufacturing division in 2019, the company has become a trusted partner for global B2B buyers.

What Sets Truer Apart:

- 🧪 Advanced Coating Technology: Superior silver adhesion and uniformity

- 🏭 In-House Manufacturing: Full control over PM and additive production

- ⚙️ Broad Product Range:

- PM Bronze, PM Nickel Silver, PM Infiltrated Iron/Steel

- Gas or water atomized stainless steel and copper alloys

- 📦 Flexible Order Sizes: From R&D samples to industrial bulk orders

- 🤝 Exceptional Technical Support: Custom grades for specific applications

- 🌍 Global Export Experience: Quick turnaround and international logistics

Featured Products for B2B Buyers:

| Product Category | Description |

|---|---|

| Silver Coated Copper Powder | High-purity, low-oxide, customizable grades |

| Additives (Graphite, Lubricants) | QH-150, SUW-8000, TBC-1000, TD-8 |

| Cutting Agents | Sulfur-free SME-100, manganese sulfide |

| Soft Magnetic Additives | QHP-330, QH-150 |

| Diffusion Alloyed Steel Powders | FD-0208, FX-1005, FX-2008, FN-5000 |

Ready to partner with a reliable B2B conductive powder supplier? Reach out to our team via our Contact Page and request your custom quote today.

9. How to Order Wholesale Silver Coated Copper Powder from Truer

When it comes to bulk procurement of silver coated copper powder, Shanghai Truer Technology Co., Ltd offers a seamless and B2B-optimized process. Whether you’re a distributor, OEM, additive manufacturing company, or electronics fabricator, Truer provides flexible ordering options, clear documentation, and reliable international shipping.

Step-by-Step Wholesale Ordering Process:

- Product Consultation

- Contact Truer’s technical team via contact form or email.

- Discuss your application requirements: particle size, silver thickness, purity, packaging format.

- Sample Testing (Optional)

- Request free or paid samples for lab verification or pilot production.

- Quotation & MOQ Confirmation

- Receive a tailored quotation based on volume, delivery terms (FOB, CIF), and certification needs.

- Minimum order quantity (MOQ) is flexible depending on product category.

- Contract Signing & Payment

- Sign a supply agreement or PO contract.

- Payment terms include T/T, L/C, and negotiated credit terms for long-term partners.

- Production & Quality Control

- Each batch undergoes particle size analysis, coating uniformity inspection, and oxidation resistance testing.

- Accompanied with Certificate of Analysis (COA) and Material Safety Data Sheet (MSDS).

- Logistics & Shipping

- Global shipping via air, sea, or express courier.

- Truer supports Incoterms like FOB Shanghai, CIF, and DDP (for certain countries).

- After-Sales Support

- Dedicated customer service and technical support.

- Assistance with custom formulations or reorders.

Required Information for B2B Quotes:

- Target application (e.g., EMI shielding, conductive ink)

- Particle size range

- Silver coating percentage

- Expected annual volume

- Destination country and port

Packaging Options:

| Packaging Size | Material | Typical Use Case |

|---|---|---|

| 1 kg – 5 kg | Vacuum-sealed foil bag | R&D and sampling |

| 10 kg – 25 kg | Double-layer anti-static drum | Pilot production or lab use |

| 100 kg+ | Fiber drum with PE liner | OEM-scale production |

10. FAQs: Everything You Need to Know About Silver Coated Copper Powder

Below are frequently asked questions by purchasing managers, engineers, and procurement teams sourcing silver coated copper powders in bulk.

Q1: What is the silver content in Truer’s coated copper powder?

A: Truer offers customizable silver coating levels ranging from 1% to 20% by weight, depending on your conductivity and cost requirements.

Q2: How does silver coated copper compare to pure silver powder?

A: It offers nearly the same conductivity and corrosion resistance at a significantly lower cost—ideal for high-volume applications like EMI shielding and conductive adhesives.

Q3: Can Truer provide powders suitable for inkjet or screen printing?

A: Yes. Truer’s powders are available in spherical morphology and submicron sizes ideal for printing technologies. Contact our technical team for specific grades.

Q4: Is there a risk of oxidation or performance loss during storage?

A: Truer uses advanced coating methods to ensure long-term oxidation resistance. Powders are vacuum-packed and sealed with desiccants to maintain stability.

Q5: What particle sizes are available?

A: Standard sizes range from 1–50µm. Custom particle distributions can be produced based on your application needs (e.g., <10µm for conductive inks).

Q6: Are Truer’s powders RoHS and REACH compliant?

A: Yes. All materials meet international standards and are accompanied by proper documentation.

Q7: Can I order a small batch or sample before committing to a full order?

A: Absolutely. Sample batches are available for qualification testing and pilot production. Contact us through the website to request a sample.

Internal Links Summary (Anchor Text + URL)

- Learn more about our powder metallurgy capabilities

- Contact our technical team

- About Us page

- Contact Page

- Website

By following this guide, procurement managers, industrial engineers, and wholesale distributors can make informed decisions when sourcing silver coated copper powders. Shanghai Truer Technology Co., Ltd stands out not only for its advanced coating technologies and extensive range of PM and AM powders, but also for its dedication to providing tailored, high-quality solutions to global B2B customers.

👉 For immediate inquiries or to request a product catalog, visit am-material.com or contact our sales engineering team today.