1. Introduction: Why Silicon Powder Matters in Modern Manufacturing

Silicon powder is a vital industrial material used across various manufacturing sectors, including electronics, metallurgy, ceramics, and energy. For B2B buyers—especially those in additive manufacturing, powder metallurgy (PM), and battery production—high-purity silicon powder is critical for enhanced product performance and cost efficiency.

With the rise of Industry 4.0 and precision manufacturing, silicon powder demand has surged, especially in:

- 3D printing

- Semiconductor fabrication

- Lithium-ion battery production

- Metal alloying

For wholesale buyers and distributors, sourcing high-quality silicon powder from reliable suppliers like Shanghai Truer Technology Co., Ltd ensures consistency, competitive pricing, and access to technical support.

Key B2B Keywords:

| Keyword | Search Intent |

|---|---|

| wholesale silicon powder | High-volume purchasing |

| silicon powder supplier | B2B sourcing |

| buy silicon powder bulk | E-commerce & industrial procurement |

| industrial silicon powder | Manufacturing applications |

| silicon powder distributor | Logistics and resale |

2. Industrial Applications of Silicon Powder

Silicon powder is utilized in a wide range of industrial applications due to its unique thermal conductivity, hardness, and reactivity. Below is a breakdown of its primary uses for B2B sectors:

A. Metallurgy Industry

- Alloy Production: Used as a deoxidizer and alloying agent in steelmaking and cast iron.

- Sintered Components: A key additive in powder metallurgy for improving strength and wear resistance.

B. Electronics and Semiconductors

- Semiconductor Wafer Production: Ultra-pure silicon powder is the base material for producing monocrystalline silicon wafers.

- Thermal Interface Materials (TIMs): Enhances heat dissipation in electronic devices.

C. Energy Sector

- Solar Cells: High-purity silicon powder is used in photovoltaic panels.

- Battery Anodes: A silicon-carbon composite is favored in next-generation lithium-ion batteries due to its superior energy capacity.

D. Ceramic and Glass Industries

- Ceramic Materials: Adds thermal resistance and hardness.

- Glass Manufacturing: Enhances durability and chemical resistance.

E. Additive Manufacturing

- 3D Printing Powders: Silicon powder is increasingly used in metal 3D printing for prototyping and functional parts.

Application Table:

| Industry | Application | Benefit |

|---|---|---|

| Metallurgy | Alloying agent in steel & iron | Improves strength & reduces porosity |

| Electronics | Semiconductor base material | Essential for microelectronics |

| Energy | Anode material in batteries | Increases energy density |

| Ceramics & Glass | Heat-resistant ceramics | High durability and thermal control |

| Additive Manufacturing | Metal 3D printing powder | Better part accuracy and density |

3. Types of Silicon Powder and Their Use Cases

B2B buyers must understand the different types of silicon powder to ensure compatibility with their manufacturing processes. Below is an overview of the key categories:

A. Metallurgical Grade Silicon Powder (MG-Si)

- Purity: Typically 98–99%

- Use Case: Steelmaking, aluminum alloys

- Form: Coarse powder or granules

B. Chemical Grade Silicon Powder

- Purity: Typically 99.5–99.9%

- Use Case: Silicones, silicon-based chemicals

- Feature: High reactivity

C. Solar Grade Silicon Powder

- Purity: 99.9999%+

- Use Case: Photovoltaic cells

- Form: Ultra-fine powder

D. Electronic Grade Silicon Powder

- Purity: 99.9999999%+

- Use Case: Semiconductor manufacturing

- Price: Highest among all grades

E. Silicon-Based Composite Powders

- Use Case: Lithium-ion batteries, soft magnetic applications

- Specialty: Often blended with graphite or carbon for improved performance

Comparison Table of Silicon Powder Grades:

| Grade Type | Typical Purity | Primary Applications |

|---|---|---|

| Metallurgical Grade | 98–99% | Steelmaking, casting alloys |

| Chemical Grade | 99.5–99.9% | Silicon chemicals, coatings |

| Solar Grade | 99.9999% | Photovoltaic cells |

| Electronic Grade | 99.9999999% | Integrated circuits, semiconductors |

| Composite Silicon Powder | Varies | Energy storage, 3D printing applications |

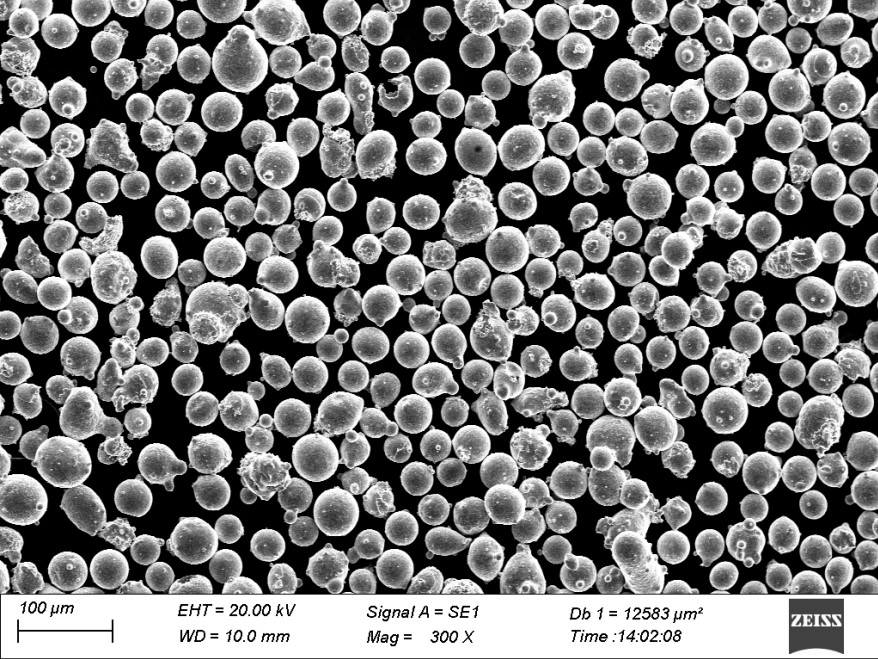

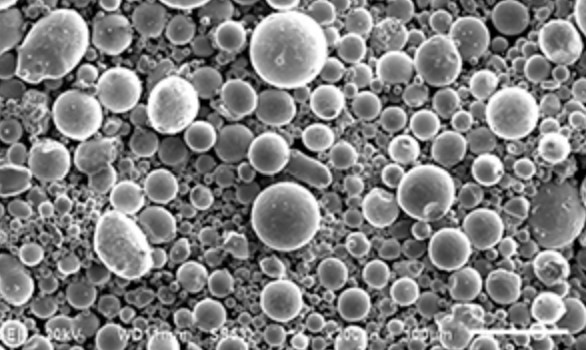

Shanghai Truer Technology Co., Ltd is a trusted supplier offering a wide range of powder metallurgy materials, including composite silicon powders blended for additive manufacturing and battery applications. Their advanced water and gas atomization technologies ensure high-quality, consistent particle size distribution that meets industrial standards.

4. Market Trends in Silicon Powder for B2B Buyers

The global silicon powder market is undergoing a rapid transformation, driven by electrification, green energy, and smart manufacturing. Wholesale buyers, distributors, and OEMs (Original Equipment Manufacturers) are increasingly seeking advanced grades of silicon powder tailored for high-performance applications.

A. Global Market Outlook (2024–2030)

- Market Size: Expected to reach USD 5.8 billion by 2030

- CAGR: Projected CAGR of 6.2%

- Key Growth Drivers:

- Adoption of electric vehicles (EVs)

- Expansion of solar PV installations

- Increased use in 3D printing and powder metallurgy

B. B2B Buyer Trends

- Customization: Buyers demand tailor-made particle sizes and purities.

- Sustainability: Eco-friendly and energy-efficient production methods are a key consideration.

- Supply Chain Stability: Post-COVID disruptions have led buyers to diversify sources.

C. Regional Demand Breakdown

| Region | Key Industries Driving Demand | Notable Trends |

|---|---|---|

| Asia-Pacific | Electronics, metallurgy, batteries | Dominates global production & demand |

| North America | Advanced manufacturing, aerospace | High demand for electronic-grade silicon |

| Europe | Renewable energy, automotive | Strong push for green energy materials |

D. B2B Keyword Insights

| High-Intent Keyword | Use Case |

|---|---|

| silicon powder for batteries | EV and energy storage manufacturers |

| silicon powder suppliers Asia | Regional sourcing for OEMs |

| 3D printing silicon powder | Additive manufacturing applications |

| PM silicon powder bulk | Powder metallurgy buyers and resellers |

5. Key Factors When Choosing a Silicon Powder Supplier

Choosing the right supplier is critical for maintaining quality, price competitiveness, and production efficiency. Here are the top evaluation criteria for B2B buyers:

A. Quality Control and Certifications

- ISO 9001 certification

- In-house lab testing for purity and particle size

- Batch consistency and documentation

B. Production Technology

- Water atomization

- Gas atomization

- Carbonyl and reduction methods

Shanghai Truer Technology Co., Ltd offers both water and gas atomized silicon and metal powders, ensuring flexibility for different manufacturing needs.

C. Product Range and Customization

- Variety of grades available (MG-Si, solar-grade, composite powders)

- Custom particle sizes ranging from microns to nanoscale

- Surface treatments and coating options

D. Logistics and Delivery Lead Time

- Domestic and international shipping capabilities

- Lead times from 7–21 days depending on volume and customization

- Export documentation and compliance

E. Technical Support and After-Sales Service

- Application engineering support

- Material selection consultation

- Ongoing R&D collaboration

Supplier Comparison Checklist:

| Criteria | Importance for Buyers | Shanghai Truer Advantage |

|---|---|---|

| ISO Certification | ✅✅✅ | ✅ ISO9001 Certified |

| Customization Options | ✅✅✅ | ✅ Tailored grades & sizes |

| Atomization Technology | ✅✅✅ | ✅ Water & Gas atomization |

| On-Time Delivery | ✅✅ | ✅ Reliable international shipping |

| Technical Support | ✅✅✅ | ✅ Full engineering assistance |

6. Top 5 Silicon Powder Suppliers in Asia

For B2B buyers sourcing from Asia, these are the most reliable and consistent suppliers in 2024:

| Supplier Name | Country | Specialty | Website |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | PM & 3D printing powders | am-material.com |

| Tokai Carbon Co., Ltd | Japan | High-purity silicon for electronics | tokai.co.jp |

| Elkem ASA | China/Norway | Metallurgical silicon products | elkem.com |

| Yafei Silicon Industry Co., Ltd | China | Solar grade silicon powder | yafeisilicon.com |

| Hanwa Co., Ltd | Japan | Composite and chemical-grade silicon | hanwa.co.jp |

Among these, Shanghai Truer Technology Co., Ltd stands out for its robust range of powder metallurgy materials, exceptional customer service, and flexibility in customization—ideal for wholesale and distributor-level procurement.

7. Why More Buyers Are Choosing Chinese Silicon Powder Sources

China has become the global hub for silicon powder manufacturing due to its cost efficiency, technological advancements, and vertically integrated supply chain. Here’s why B2B buyers are increasingly sourcing from China:

A. Competitive Pricing

- Economies of scale from large domestic production

- Lower labor and energy costs

- Government subsidies in green and tech industries

B. Advanced Manufacturing Capabilities

- State-of-the-art atomization and purification techniques

- Strong investments in R&D and automation

- Capability to produce high-purity and specialized powders

C. Full Supply Chain Integration

- From raw silicon extraction to final powder processing

- Reduced lead times and improved quality control

D. Export-Focused Logistics

- Well-established export protocols

- Partnerships with global freight companies

- English-speaking sales and tech support

E. Strategic Supplier Partnerships

Many OEMs and distributors are establishing long-term partnerships with Chinese manufacturers like Shanghai Truer to maintain stability in pricing and supply.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Supplier

Shanghai Truer Technology Co., Ltd has been a trusted name in the PM and additive manufacturing industry since 2009. As a leading manufacturer of silicon and alloy powders, Truer combines technical expertise with world-class production capabilities.

A. Product Portfolio

- PM silicon powders

- Composite silicon-carbon powders for batteries

- High-purity silicon for 3D printing

Explore their full powder product range here →

B. Production Capabilities

- Advanced atomization lines (water, gas, hybrid)

- Custom particle size distribution (D50 from 5μm to 100μm)

- In-house R&D and testing lab

C. Trusted by Global Buyers

- Exporting to 20+ countries

- Clients in automotive, aerospace, energy storage, and electronics

- OEM and ODM support for large-scale procurement

D. Additive Solutions & Technical Support

Truer is not just a powder supplier—they are a solution provider. Their Powder Metallurgy Additives Division offers:

- Lubricants (e.g., Lube-W, SUW-8000)

- Graphite (TBC-400, QHP-330)

- Cutting agents and soft magnetic additives

Want to learn more about Shanghai Truer’s additive solutions? Contact their expert team today.

9. How to Order Wholesale Silicon Powder from China

For B2B buyers, sourcing silicon powder from a reputable Chinese supplier like Shanghai Truer Technology Co., Ltd is a strategic move that offers cost advantages, material quality, and reliable delivery. Here’s a step-by-step guide to streamline your wholesale procurement process.

Step 1: Define Your Technical Requirements

Before placing an order, clearly define the following:

- Desired powder grade (e.g., metallurgical, solar, composite)

- Purity level required (e.g., 98%, 99.9%, 99.999%)

- Particle size distribution (e.g., D50 = 45 μm)

- Quantity (kg or tons)

- Packaging preferences (drums, vacuum-sealed bags, etc.)

Step 2: Request a Quotation (RFQ)

Send a detailed RFQ to the supplier. When working with Shanghai Truer, you can initiate this process directly through their Contact Page.

⚠️ Include the following in your RFQ:

- Company name and business type (OEM, distributor, etc.)

- Intended application (e.g., metallurgy, batteries)

- Annual consumption estimates

- Delivery location and preferred Incoterms (FOB, CIF, EXW)

Step 3: Technical Approval & Sampling

Once you receive the technical data sheet (TDS) and quotation:

- Review the specifications with your engineering team

- Request a sample (typically 1–5 kg) for internal testing

- Evaluate particle size, purity, flowability, and compatibility

Step 4: Finalize the Purchase Order

After confirming sample approval:

- Sign a purchase agreement and confirm lead time

- Arrange payment (TT, LC, or other terms)

- Receive pro forma invoice and confirm shipping details

Step 5: Quality Inspection & Shipment

Shanghai Truer ensures that every bulk order undergoes:

- Pre-shipment inspection

- Sealed packaging for moisture protection

- Export documentation (COO, MSDS, packing list, invoice)

| Ordering Step | Action Needed from Buyer | Supplier Responsibility |

|---|---|---|

| Define Requirements | Specify grade, size, quantity, packaging | Provide technical specs and samples |

| Request Quotation | Submit RFQ with business info and delivery terms | Send TDS, pricing, and lead time |

| Approve Sample | Test and confirm product suitability | Ship sample with COA and test report |

| Issue PO | Confirm payment and agreement | Start production and confirm delivery timeline |

| Shipment & Delivery | Track and receive goods | Handle logistics, documentation, and quality check |

✅ Tip: Shanghai Truer’s multi-lingual sales team ensures seamless communication for overseas buyers.

10. FAQs: Common Questions About Buying Wholesale Silicon Powder

Q1: What purity levels are available for silicon powder?

Shanghai Truer offers a wide range of purities, including:

- 98% (Metallurgical grade)

- 99.5%–99.9% (Chemical grade)

- 99.999%+ (Solar and electronic grade)

Each is suitable for different industrial applications like casting, battery production, or electronics.

Q2: What particle sizes can I order?

Particle sizes range from sub-micron to 100 microns. Standard distributions include:

- D50 = 10, 20, 45, or 75 μm

- Custom sieving available upon request

Q3: Can I request custom silicon powder composites?

Absolutely. Truer specializes in custom powder blends, including:

- Silicon-carbon composite for lithium batteries

- Silicon-graphite mix for thermal applications

- Silicon alloy powders for PM and 3D printing

Q4: What is the minimum order quantity (MOQ)?

Typically:

- 25 kg for trial orders

- 500 kg for regular wholesale orders

- OEM/ODM available for large-scale buyers

Q5: What are the payment and shipping terms?

- Payment: T/T, L/C, and PayPal for small batches

- Shipping: By air, sea, or express (EXW, FOB, CIF available)

- Delivery Time: 7–21 days depending on volume and customization

Q6: Is technical support available for overseas buyers?

Yes. Shanghai Truer provides:

- Pre-sales material consultation

- Post-sales technical assistance

- Long-term R&D collaboration opportunities

Visit their About Us page to learn more about their mission and capabilities.

11. Conclusion: Your Trusted Partner in Silicon Powder Supply

Silicon powder continues to be a foundational material in modern manufacturing—from metallurgy and energy to electronics and 3D printing. For B2B buyers, sourcing from a high-quality, reliable supplier is essential to maintain product integrity and meet production targets.

Shanghai Truer Technology Co., Ltd stands out as a leading manufacturer and exporter of silicon and alloy powders. With over a decade of experience, advanced atomization technology, and a full product portfolio, Truer is well-positioned to serve global distributors, OEMs, and industrial buyers.

Why Truer?

- ✅ ISO-certified production

- ✅ Custom grades and sizes

- ✅ Technical support for PM, AM, and battery industries

- ✅ Short lead times and global logistics

- ✅ Exceptional product consistency

🔗 Ready to get started? Contact Shanghai Truer’s sales team now for a free quote or sample.