1. Introduction: What is S2 Powder and Why It Matters in PM

S2 powder is a high-performance powder metal (PM) material primarily used for tool manufacturing, especially in high-load, high-wear applications such as impact-grade screwdrivers, cutting tools, and dies. It is a type of alloy steel powder with optimized hardness, toughness, and wear resistance.

In powder metallurgy (PM), S2 powder is prized for its:

- Excellent impact resistance

- High torsional strength

- Superior wear resistance

- Cost-effective performance in mass production

S2 tool steel typically contains chromium, molybdenum, and vanadium, allowing it to be heat-treated to high hardness levels while maintaining toughness. The powdered form of S2 allows manufacturers to produce near-net-shape parts with minimal material waste and high consistency.

Why S2 Powder is Important for B2B Buyers:

| Feature | Benefit for Industrial Buyers |

|---|---|

| High hardness | Ideal for tool-making and high-impact parts |

| Powder form | Enables precision PM manufacturing |

| Cost-efficient | Reduces waste and machining time |

| Scalable | Suitable for mass production |

For wholesale buyers, S2 powder offers excellent ROI when sourcing for tool manufacturing, precision components, and high-performance mechanical parts.

2. Industrial Applications of S2 Powder in Manufacturing

S2 powder is widely used across industrial sectors that demand superior mechanical strength, abrasion resistance, and fatigue properties. The following industries are the most common consumers of S2 powder:

Applications in Key Industries:

- Automotive Industry

- Production of torque tools, impact driver bits, and automotive fasteners

- Aerospace

- Components requiring durability under stress and temperature fluctuations

- Tool Manufacturing

- Hand tools (e.g., screwdrivers)

- Power tool bits

- Cold forming and stamping tools

- Industrial Equipment

- Dies, punches, and wear parts

- Construction

- Drill bits and high-strength fasteners

Example Use Cases:

| Industry | Common Parts Made with S2 Powder |

|---|---|

| Automotive | Torque tools, engine fasteners |

| Tooling | Screwdriver bits, drill bits |

| Machinery | Wear-resistant bushings, dies |

| Aerospace | Structural supports, brackets |

For OEMs and tool manufacturers, purchasing wholesale S2 powder allows them to maintain consistent quality while optimizing production costs. The PM process using S2 powder enables:

- Near-net-shape manufacturing

- Reduced post-processing

- Improved part uniformity

3. Physical & Mechanical Properties of S2 Powder

S2 powder’s appeal lies in its excellent balance of hardness and toughness. After appropriate heat treatment, it can achieve Rockwell hardness levels of 58-64 HRC, making it ideal for impact-grade tools.

Core Physical Properties:

| Property | Typical Value |

|---|---|

| Hardness (HRC) | 58–64 |

| Density | ~7.75 g/cm³ |

| Tensile Strength | >2000 MPa |

| Yield Strength | >1800 MPa |

| Elongation | ~5% |

| Modulus of Elasticity | ~210 GPa |

Chemical Composition (Typical):

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.45–0.55 |

| Chromium (Cr) | 0.8–1.0 |

| Molybdenum (Mo) | 0.15–0.3 |

| Vanadium (V) | 0.2–0.4 |

| Silicon (Si) | 0.2–0.35 |

| Manganese (Mn) | 0.4–0.6 |

| Iron (Fe) | Balance |

Benefits for B2B Manufacturers:

- High Wear Resistance: Extends tool life, reducing replacement frequency

- Heat Treatability: Allows customization of mechanical properties

- Dimensional Stability: Maintains precision during sintering

- Corrosion Resistance: Suitable for outdoor or harsh environments

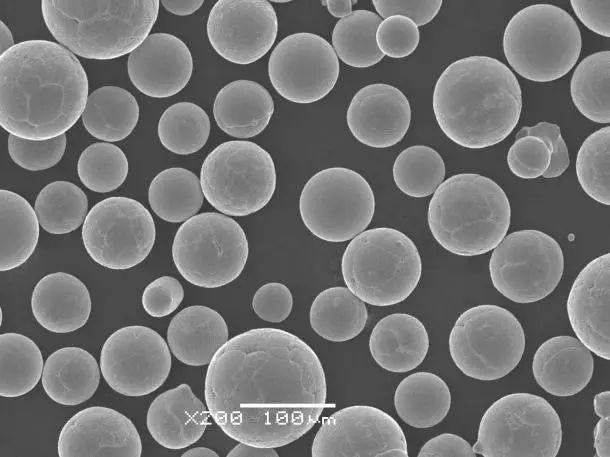

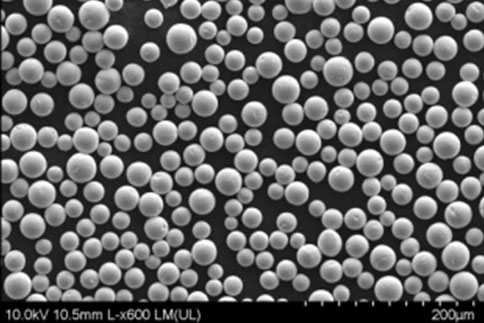

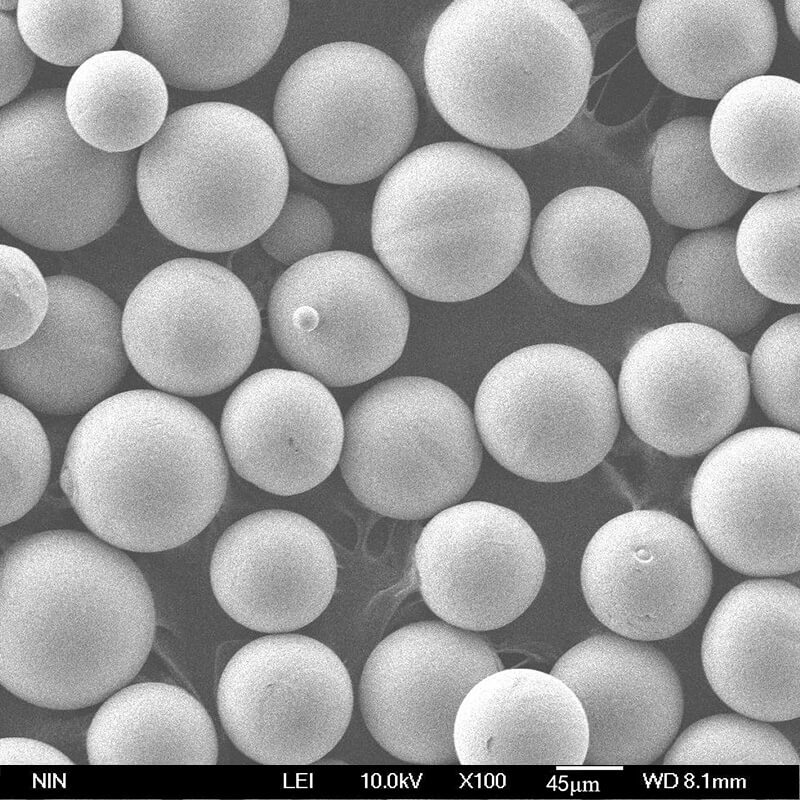

S2 powder can be manufactured via water atomization or gas atomization, depending on the application and desired particle characteristics. For example, Shanghai Truer Technology Co., Ltd offers both water and gas atomized S2 powders tailored for PM applications.

4. S2 Powder Market Trends and Growth Potential

The global market for high-performance tool steels such as S2 powder is experiencing steady growth, driven by increasing demand from automotive, aerospace, and industrial tooling sectors. Powder metallurgy (PM) continues to gain traction as it allows for complex geometries, reduced waste, and cost-effective mass production.

Market Drivers:

- Rising Demand for Lightweight and Durable Tools

OEMs and tool manufacturers are shifting towards high-strength PM materials like S2 to improve product longevity and performance. - Growth in Automotive Aftermarket Tools

Impact-grade screwdriver bits and torque tools made from S2 are in high demand due to their wear resistance and toughness. - Expansion of Precision Manufacturing

Industries such as aerospace and electronics are adopting PM techniques for precision components requiring minimal deviation and high tolerances.

Global S2 Powder Market Forecast (2024–2029):

| Region | CAGR (2024–2029) | Key Market Segments |

|---|---|---|

| North America | 5.2% | Tooling, aerospace, automotive aftermarket |

| Europe | 4.9% | Machinery, automation, power tools |

| Asia-Pacific | 7.1% | Automotive, OEM tools, industrial tooling |

| China | 8.3% | PM components, tool exports, domestic tool use |

Opportunities for Wholesale Buyers:

- Private-label tool production using S2 powder

- OEM partnerships with PM suppliers

- Custom alloy development with PM powder specialists

S2 powder represents a strategic material for manufacturers and distributors aiming to deliver highly durable and cost-effective tools to the global market.

5. Key Factors for Selecting an S2 Powder Supplier

Selecting a reliable S2 powder supplier is critical to maintaining consistent production quality and meeting regulatory and performance standards.

Here are the key factors B2B buyers should evaluate:

1. Powder Quality & Consistency

- Particle size distribution (PSD)

- Flow rate & apparent density

- Purity and composition accuracy

- Sinterability and compressibility

2. Production Capabilities

- Water atomization vs. gas atomization

- Custom alloying capabilities

- Batch traceability and testing

3. Technical Support

- Custom powder formulations

- Application engineering support

- Testing and documentation (COA, MSDS)

4. Logistics & Lead Time

- On-time delivery

- Bulk packaging options (25kg, 500kg, tonnage)

- Export documentation and compliance

5. Certifications & Compliance

- ISO 9001, ISO 14001

- RoHS and REACH compliance

- MSDS and quality assurance documentation

Supplier Comparison Table:

| Criteria | Leading Global Supplier | Shanghai Truer Technology Co., Ltd |

|---|---|---|

| Powder Range | Limited tool steels | Full PM alloy portfolio incl. S2 |

| Customization | Limited | High – tailored S2 alloy blends |

| MOQ Flexibility | High MOQ | Flexible MOQ options |

| Technical Support | Basic | Full R&D, testing, application support |

| Lead Times | 4–6 weeks | Fast turnaround from Shanghai facilities |

| Price Competitiveness | Moderate | High – direct factory pricing |

6. Top Global and Chinese Suppliers of S2 Powder

Identifying a trustworthy supplier is crucial to maintaining quality and delivery timelines. Below are some of the top suppliers globally and in China.

Top Global Suppliers:

| Supplier | Country | Notable Features |

|---|---|---|

| Höganäs AB | Sweden | One of the largest PM powder producers globally |

| GKN Hoeganaes | USA | Strong in automotive PM grades |

| Rio Tinto Metal Powders | Canada | Known for high-purity ferrous powders |

Leading Chinese Suppliers:

| Supplier | Strengths | Website |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | Custom PM powder solutions, including S2 | Visit Website |

| CNPC Powder Group | Mass production, standard grades | |

| Jiande Xinxing | Automotive-grade metal powders |

Shanghai Truer stands out for its wide selection of PM powders, including custom-engineered S2 blends, produced with both water and gas atomization. They offer fast delivery, competitive pricing, and strong technical support.

In fact, their Powder Metallurgy Division is known for delivering reliable additive solutions to tool manufacturers and PM part producers across China and globally.

7. Why More Distributors Are Sourcing S2 Powder from China

China has rapidly become a preferred sourcing destination for high-performance PM powders like S2 due to its advanced production capabilities, competitive pricing, and scalable logistics.

Benefits of Sourcing from China:

- Cost Efficiency

Lower manufacturing and labor costs enable Chinese suppliers to offer better pricing on bulk S2 powder orders. - Advanced Manufacturing Technology

Companies like Shanghai Truer employ both water and gas atomization to meet international quality standards. - Shorter Lead Times

Domestic logistics and port proximity allow suppliers to ship large orders faster than some Western competitors. - Flexible MOQ and Customization

Chinese suppliers are more open to lower minimum order quantities and custom alloy specifications.

Common Misconceptions:

| Misconception | Reality |

|---|---|

| Chinese powders are low quality | Companies like Truer meet ISO and RoHS standards |

| Long lead times | Export-ready inventory and fast production cycles |

| Limited support | English-speaking technical teams and global logistics |

By working with established PM suppliers like Shanghai Truer Technology Co., Ltd, international buyers can source high-quality S2 powder while optimizing costs and supply chain efficiency.

8. Why Choose Shanghai Truer Technology as Your S2 Powder Partner

When it comes to sourcing premium S2 powder for powder metallurgy applications, Shanghai Truer Technology Co., Ltd stands out as a trusted and strategic supplier, especially for B2B buyers, distributors, and OEM tool manufacturers.

About Shanghai Truer Technology Co., Ltd

Established in 2009, with an additive manufacturing division launched in 2019, Shanghai Truer has grown into one of China’s most professional suppliers of PM powders and additive manufacturing materials.

Truer’s Advantages in S2 Powder Supply:

| Feature | Benefit |

|---|---|

| ✅ Full-scale production | Offers both water and gas atomized powders tailored for PM |

| ✅ High-purity S2 powder | Excellent mechanical properties and sinterability |

| ✅ Technical customization | Custom alloy development and particle size control |

| ✅ Fast lead times | Ideal for global distributors and OEM buyers |

| ✅ Competitive pricing | Direct-from-factory cost advantage |

Product Portfolio:

In addition to S2 powder, Truer offers a comprehensive range of PM materials, including:

- PM Steels: FL-4605, FD-0208, FN-0205

- PM Tool Alloys: SBF2218, FX-2008

- Soft Magnetic Additives: QH-150, QHP-330

- Lubricants & Cutting Agents: SUW-5000B, SME-100

Their Powder Metallurgy Additives Division provides complete additive solutions for tool manufacturers, including lubricants and cutting agents that complement S2 powder applications.

Quality Assurance & Certifications:

- ISO 9001-certified production

- Full batch traceability

- COA and MSDS documentation

- RoHS and REACH compliant

For international buyers looking for a reliable long-term partner, Shanghai Truer combines technical expertise with scalable manufacturing—making them an ideal choice for S2 powder procurement.

9. How to Order Wholesale S2 Powder from Truer

Ordering wholesale S2 powder from Shanghai Truer is a streamlined and transparent process tailored to meet the needs of global buyers, OEMs, and tool manufacturers.

Step-by-Step Ordering Process:

- Inquiry Submission

- Contact Truer via their Contact Page or email

- Provide specifications: quantity, particle size, alloy requirements, packaging

- Technical Consultation

- Truer’s engineering team will review your requirements

- Suggest optimal powder type and processing method (e.g., water atomized vs gas atomized)

- Quotation & Sample Approval

- Receive a formal quotation with lead times

- Optional: Request sample batch for initial testing

- Order Confirmation

- Sign purchase agreement

- Arrange payment terms and delivery schedule

- Production & Quality Control

- Powder is produced under strict QA protocols

- COA and MSDS documents are prepared

- Shipping & Delivery

- Export packaging in 25kg bags, 500kg drums, or tonnage-level containers

- Air, sea, or express shipping available worldwide

Minimum Order Quantity (MOQ):

- Flexible MOQs available for new customers

- Bulk discounts for distributors and repeat orders

Payment & Incoterms:

- Accepts T/T, L/C, and other standard B2B payment methods

- EXW, FOB Shanghai, CIF available depending on buyer preference

Support Services:

- Technical support in English and Mandarin

- Post-sales application guidance

- Custom powder development for recurring buyers

For more information or to start your order, visit the Truer Contact Page.

10. FAQs: Buying Wholesale S2 Powder for Manufacturing

Here are some of the most frequently asked questions from our B2B buyers and distributors regarding S2 powder:

Q1: What is the typical particle size range for S2 powder?

A: Truer offers S2 powder in standard PM particle sizes ranging from 45–150 μm. Custom sizing is available upon request.

Q2: Can I request a custom chemical composition of S2 powder?

A: Yes, Truer specializes in custom alloying. You can specify your desired content for elements like Cr, Mo, V, etc., based on your application needs.

Q3: What is the shelf life of S2 powder?

A: When stored in a dry, sealed container under ambient conditions, S2 powder maintains its properties for up to 2 years.

Q4: Is Truer’s S2 powder compatible with all PM equipment?

A: Yes. Their powders are engineered for compatibility with standard PM presses, sintering furnaces, and additive manufacturing systems.

Q5: Can I get technical support for my application?

A: Absolutely. Truer provides pre-sales and post-sales technical consultation to ensure you choose the right powder and processing method.

Q6: Does Truer ship internationally?

A: Yes. Truer exports to North America, Europe, Southeast Asia, and other regions. All shipments are accompanied by necessary export and customs documentation.

Q7: Do you offer volume discounts?

A: Yes, bulk orders receive tiered pricing. Distributors and repeat buyers can also negotiate long-term supply agreements.

⚙️ Start Your S2 Powder Procurement Today

If you’re an OEM, tool manufacturer, or distributor looking for a high-performance, cost-effective S2 powder supplier, Shanghai Truer Technology Co., Ltd is your ideal partner.

- Explore their PM Powder Portfolio

- Learn more About Truer

- Reach out to them on the Contact Page

📞 Contact Truer Now to Request a Custom Quote or Sample

👉 Visit: am-material.com/contact-us

📦 MOQ Flexibility | 🌍 Global Shipping | ⚙️ Technical Support