Molybdenum powder is a versatile material with unique properties that make it ideal for many industrial applications. This guide provides a comprehensive overview of molybdenum powder including its composition, characteristics, production methods, applications, suppliers, and more.

Overview of Molybdenum Powder

Molybdenum powder is a fine granular form of molybdenum metal processed into a powder consistency. It possesses high strength, hardness, thermal conductivity, and resistance to corrosion. The unrivaled thermal and electrical properties of molybdenum make its powder form suitable for usage in diverse manufacturing purposes.

Some key features of molybdenum powder include:

- High melting point of 2623°C

- Strength and hardness retention at high temperatures

- Low thermal expansion coefficient

- Good thermal and electrical conductivity

- Resistance to corrosion

Molybdenum powder’s unique attributes allow it to be alloyed with other metals, used as an additive, formed into solid parts, or applied as a coating. It enhances the properties of steels and performance of components exposed to extreme environments.

The major product forms of molybdenum powder consist of:

- Pure molybdenum powders

- Molybdenum alloys

- Composite powders with molybdenum content

- Coated powders and agglomerates

Molybdenum powder particles are classified into different size distributions or mesh ranges for suitable application needs. Common sizes are -325 mesh, -100 mesh, and -400 mesh. Finer molybdenum powder is also produced in micron and sub-micron sizes.

Composition of Molybdenum Powder

Molybdenum powder can be pure or alloyed with other elements. The composition depends on the desired properties and performance requirements of the finished product.

| Element | Composition Range |

|---|---|

| Molybdenum | 99% min for pure Mo |

| Carbon | 0.005% max |

| Oxygen | 0.025% max |

| Nitrogen | 0.005% max |

| Iron | 0.15% max |

| Copper | 0.01% max |

| Nickel | 0.01% max |

| Chromium | 0.01% max |

| Tungsten | 0.50% max |

Molybdenum alloys provide enhanced properties by combining molybdenum with alloying elements like nickel, chromium, copper, titanium, zirconium, carbon, boron, and others.

Common molybdenum alloys include:

- Molybdenum-titanium (MoTi)

- Molybdenum-chromium (MoCr)

- Molybdenum-nickel (MoNi)

- Molybdenum-tungsten (MoW)

The alloying elements must be uniformly distributed to achieve homogenous blending and optimal performance. Controlled manufacturing processes allow tailoring composition precisely as per application needs.

Characteristics and Properties of Molybdenum Powder

Molybdenum powder exhibits unique properties that make it suitable for high performance parts and components. Its key characteristics are:

| Property | Description |

|---|---|

| Melting point | 2623°C, highest among all pure metals |

| Density | 10.22 g/cm3 at 20°C |

| Thermal conductivity | 138 W/m.K at 20°C |

| Electrical resistivity | 5.7 microOhm.cm at 20°C |

| Thermal expansion | 4.8 x 10-6/K at 25-100°C |

| Mohs hardness | 5.5, brass-like hardness |

| Strength | 500 MPa ultimate tensile strength |

| Oxidation resistance | Excellent up to ~650°C in air |

| Corrosion resistance | Resistant to acids, saline solutions |

| Coefficient of friction | 0.35-0.45 dynamic, 0.20-0.30 static |

Key features:

- Retains high strength and hardness at elevated temperatures

- High melting point allows use in very high temperature applications

- Low thermal expansion benefits thermal shock resistance

- Good electrical and thermal conductivity

- Outstanding high temperature oxidation resistance

- Resists attack by molten metals and salts

These special characteristics make molybdenum metal powder ideal for manufacturing high performance parts for extreme environments in industries like aerospace, energy, electronics, and more.

Production Methods for Molybdenum Powder

Molybdenum powder can be produced using various techniques which yield powder particles of different sizes and properties. The common production methods include:

1. Electrolytic Process

Molybdenum powder is electrolytically deposited onto a cathode plate immersed in a molybdate solution bath. The deposited flaky powder is scraped off and annealed into a spherical powder.

Advantages: High purity (99.97%), spherical morphology, controlled particle size

Sizes: Typically -400 mesh

Uses: Small particle size ideal for otherwise sintering, spray coating

2. Hydrogen Reduction

Ammonium molybdate is reduced by hydrogen gas at high temperatures to produce a powder called molybdenum oxide. Further annealing in hydrogen atmosphere yields pure molybdenum powder.

Advantages: Cost effective, high productivity

Sizes: -325 mesh and larger

Uses: Most common method, suitable for pressing and other metallurgy

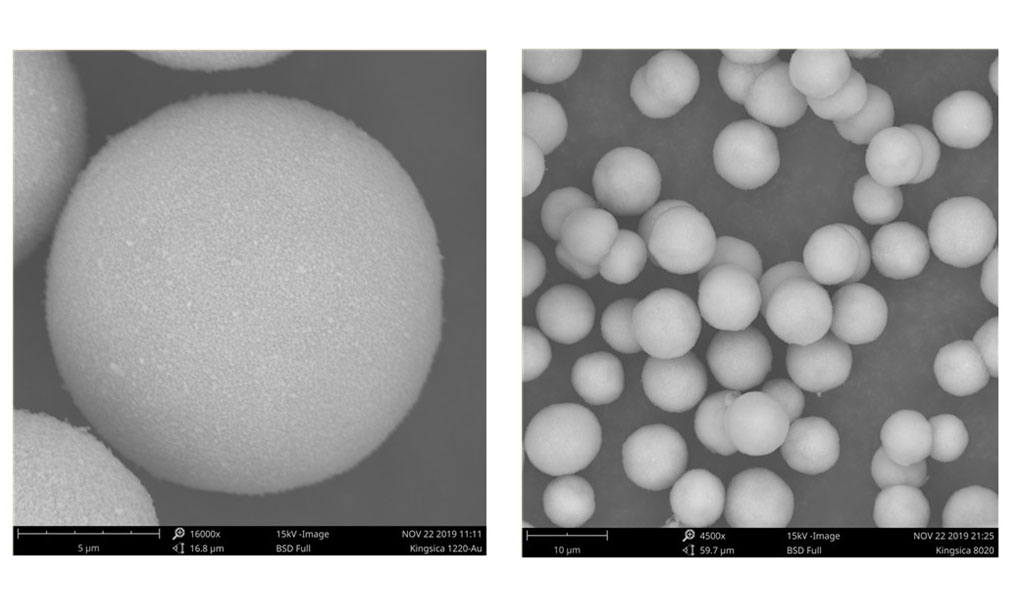

3. Plasma Atomization

Molybdenum electrode is melted by plasma arc and disintegrated by jets of nitrogen or argon gas into fine spherical powder.

Advantages: Small particle size, flowability, highly spherical morphology

Sizes: 10-150 microns

Uses: High performance parts, thermal spray coatings

4. Mechanical Attrition

Molybdenum powder is ground in a ball mill with grinding media into finer sizes through fracturing and cold welding.

Advantages: Wide range of particle sizes

Sizes: From 1 micron to -325 mesh

Uses: Small sizes for sintering, large sizes for other pressing

The particle shape, size range, purity levels, and powder properties can be tailored as per application requirements by selecting suitable production techniques.

Applications of Molybdenum Powder

Thanks to its high temperature strength, thermal properties, and corrosion resistance, molybdenum powder is used across these major sectors:

| Industry | Applications |

|---|---|

| Aerospace | Rocket nozzles, engine parts, heat shields |

| Power Generation | Filaments, electrodes, heating elements |

| Electronics | Cathodes, contacts, metallization pastes |

| Chemical | Catalysts, reactors, piping |

| Metallurgy | Alloying element in tool steels, stainless steels |

| Coatings | Thermal spray coatings on engineering components |

Some specific applications include:

- Furnace windings, heating elements, thermal couples

- High temperature furnace muffles and fixtures

- Cathodes, grids, and lead wires in electronic tubes

- Electromagnets, radio frequency shields

- Additive in special steels like tool, stainless, heat resistant

- Thermal spray coatings on aircraft and land-based turbines

- Sparking electrodes, x-ray targets, glass making equipment

- Crucibles, thermocouple sheaths, nuclear reactors

Molybdenum’s niche high temperature properties allow it to thrive in applications where performance in extreme environments is critical.

Molybdenum Powder Specifications

Molybdenum powder products are available in different purity levels, sizes, morphologies, and compositions tailored to suit various fabrication processes and end-use needs.

| Parameter | Details |

|---|---|

| Purity | Pure (99% min) or alloy grades |

| Particle sizes | -325 mesh, -100 mesh, -400 mesh, micron sizes |

| Morphology | Flaky, spherical, irregular |

| Powder types | Elemental, alloys, composites, coated |

| Chemistry | Mo, MoTi, MoCr, MoW etc. |

| Condition | Annealed, sintered |

Particle size distribution is a critical parameter used to specify molybdenum powder grades based on the mesh size or microns. Common standards followed include:

- ASTM B331 – Mo powder and powder metallurgy products

- ASTM E11 – Wire cloth and sieve standards

- ISO 4497 – Metal powders determination of particle size

Specifying the correct particle size distribution ensures suitability of the molybdenum powder for the target application.

Condition refers to the thermal treatment given to the powder like sintering or annealing to achieve desired characteristics. Annealing makes the powder more suitable for pressing while sintering increases density.

Alloy grades are specified by the percentage composition of alloying elements like MoTi 40/60 indicating 40% molybdenum and 60% titanium.

Molybdenum Powder Handling and Safety

Molybdenum powder can present hazards similar to other dry fine metal powders. Some guidelines for handling molybdenum powder safely are:

- Avoid inhalation by using protective masks

- Prevent contact with skin and eyes

- Ensure adequate ventilation and dust extraction

- Use spark-proof tools and explosion-proof equipment

- Ground equipment and take measures against static buildup

- Store sealed containers in a cool, dry area away from moisture

- Use non-sparking bronze or aluminum containers and handling equipment

Molybdenum powder is not flammable or explosive but its fine size makes it a dust explosion risk under certain conditions. Follow safety standards for handling powders and dusts to ensure a safe work environment.

Inspection and Testing of Molybdenum Powder

Stringent quality control testing ensures molybdenum powder meets the chemical, physical, and dimensional requirements for the target application.

| Test Parameter | Method Used |

|---|---|

| Chemistry | Inductively coupled plasma (ICP) spectrometry |

| Particle size distribution | Laser diffraction, sieving |

| Tap density and flowrate | Hall flowmeter as per ASTM B212 |

| Morphology | Scanning electron microscopy (SEM) |

| Powder microstructure | X-ray diffraction (XRD) |

| Purity | Inert gas fusion analysis |

| Moisture content | Loss on drying |

Documentation with the actual test and analysis results are reported in the certificate of analysis from the manufacturer. Purchasers can request test samples to conduct independent verification testing as well.

Molybdenum Powder Suppliers

There are several reputable manufacturers and suppliers that produce and distribute molybdenum metal powders:

| Company | Location |

|---|---|

| HC Starck Solutions | Germany, United States |

| Plansee Group | Austria |

| China Molybdenum Co. Ltd. | China |

| Anhui Lanjian Powder Metallurgy Co. | China |

| Tritrust Industrial (China) Ltd. | China |

| Buffalo Tungsten Inc. | United States |

| Midwest Tungsten | United States |

When selecting a molybdenum powder supplier, important factors to consider are:

- Ability to consistently produce powders meeting required chemistry, size distribution, morphology, purity levels

- Range of molybdenum powder products and alloys available

- Technical expertise and customer service and support

- Quality certifications and compliance with international standards

- Competitive pricing and minimum order quantity (MOQ)

- Inventory levels and lead times for orders

- Responsible sourcing and supply chain transparency

Cost and Pricing of Molybdenum Powder

Molybdenum powder is more expensive than iron or copper powders but lower in cost compared to cobalt or tantalum powders. Prices fluctuate based on:

- Purity: Higher the molybdenum content, higher the price

- Particle size: Finer powders smaller than 10 microns cost more

- Composition: Alloy grades usually cost more than pure

- Quantity: Prices decrease at higher purchase volumes

- Manufacturing method: Powders made by atomization are priced higher

- Supplier margins: Vary between different powder producers

Some typical price ranges:

| Product | Price Range |

|---|---|

| Pure molybdenum powder, 400 mesh | $20-40 per kg |

| Molybdenum powder, 10 micron | $50-100 per kg |

| Mo-Ti alloy powder | $80-150 per kg |

| Mo-Cr-Cu powder | $100-200 per kg |

Contact trusted molybdenum powder suppliers to request a final price quote per your specific requirements. Negotiate to get the best rates especially for bulk purchases.

FAQs

Q: What is molybdenum powder used for?

A: The main uses of molybdenum powder are in metallurgy as an alloy additive, as coatings on engineering components, as a powder injection molding feedstock, and as cathodes and heating elements in electrical and electronic applications.

Q: Is molybdenum powder toxic?

A: Molybdenum metal and its powder are not inherently toxic. However, certain precautions are needed when handling the fine powder to minimize health risks from exposure. Proper ventilation, protective gear, and safety practices are recommended.

Q: Does molybdenum powder oxidize?

A: While solid molybdenum has excellent oxidation resistance up to 650°C, the high surface area of the powders makes them more prone to oxidation at elevated temperatures and under moisture. Proper storage away from heat, air, and humidity is advised.

Q: What is the difference between molybdenum powder and tungsten powder?

A: The most notable differences are – molybdenum has a lower density than tungsten, melts at a higher temperature, and has better high temperature strength. Molybdenum is more resistant to corrosion while tungsten is more ductile. They also differ in electrical and thermal conductivity.

Q: How is molybdenum powder made?

A: Molybdenum powder can be produced by electrolytic deposition, hydrogen reduction of molybdenum oxide, atomization of molten molybdenum, and mechanical attrition methods. Different techniques yield powders of varying particle sizes, shapes, and properties.

Q: Is molybdenum powder flammable?

A: Like most metal powders, molybdenum powder is not flammable or combustible on its own. However, its finely divided form presents a risk of dust explosions when suspended in air. Precautions for handling powders and dusts safely should be followed.

Conclusion

With its status as the refractory metal with the highest melting point, molybdenum powder offers unique high temperature properties essential for critical applications like rocket engines, power generation, furnace components, and more.

Understanding molybdenum powder’s composition, production methods, characteristics, specifications, pricing, and safe handling allows engineers to select the appropriate grade needed for their specific application requirements.

Combining molybdenum’s strength, thermal conductivity, and corrosion resistance with optimized powder metallurgy processing enables creation of high performance parts cost-effectively. As new technologies emerge in aerospace, energy, transportation, and electronics, molybdenum’s capabilities ensure it remains indispensable.

know more 3D printing processes

Additional FAQs on Molybdenum Powder

1) What particle size ranges are best for different processes?

- Press-and-sinter: -325 mesh (≈ <45 µm) with irregular/sponge morphology for green strength.

- Powder injection molding (PIM/MIM): 1–15 µm with tight PSD for high loading and flow.

- Thermal spray: 10–75 µm spherical or agglomerated-sintered.

- Additive manufacturing (LPBF/DED): LPBF 15–45 µm spherical; DED 45–106 µm.

2) How do oxygen and carbon content impact molybdenum powder performance?

- Elevated O and C raise brittleness and increase oxide/carbide formation, reducing ductility and sinterability. For high-performance PM parts, aim for O ≤ 0.05 wt% and C ≤ 0.01 wt% unless intentionally alloyed.

3) Can molybdenum powder be blended to tailor thermal expansion?

- Yes. Mo can be alloyed/blended with W, Cu, or NiFe to tune CTE and thermal conductivity for heat sinks, RF packages, and tooling. Mo-Cu and Mo-W composites are common for thermal management.

4) What storage practices minimize oxidation and caking?

- Store in sealed, dry, inert atmospheres (argon/nitrogen), <30% RH, 15–25°C. Use desiccants/oxygen scavengers, nitrogen purges after opening, and schedule FIFO to limit air exposure.

5) Is molybdenum powder suitable for hydrogen service components?

- Generally yes due to good hydrogen embrittlement resistance compared to some alloys, but control interstitials (O, N, C) and consider post-sinter HIP/heat treatment to close porosity for pressure-rated parts.

2025 Industry Trends: Molybdenum Powder

- Aerospace/energy rebound: Strong demand for Mo- and Mo-W-based hot-zone hardware, rocket engine components, and thermal spray coatings.

- Electronics packaging: Growth in Mo-Cu and Mo composites for power modules and SiC/GaN devices; tighter flatness and CTE specs.

- Additive manufacturing: Increased availability of spherical Mo and Mo-W powders for LPBF and DED; parameter sets mature, enabling dense (>99.5%) AM parts.

- Sustainability: More producers offer recycled Mo streams with certified impurity controls; lifecycle documentation increasingly requested.

- Safety and compliance: Wider deployment of enclosed conveying, dust monitoring, and ATEX/NFPA-compliant handling for fine Mo powders.

2025 Molybdenum Powder Snapshot (Indicative)

| Metric | 2023 | 2024 | 2025 YTD (Aug) | Notes |

|---|---|---|---|---|

| Global Mo powder demand (kt) | ~48 | ~51 | ~54 | Aerospace/semiconductor recovery |

| Spherical Mo price, 15–45 µm (USD/kg) | 85–130 | 90–140 | 95–150 | Atomized/PA, purity-dependent |

| Irregular Mo, -325 mesh (USD/kg) | 35–55 | 38–60 | 40–65 | Hydrogen-reduced |

| Typical O spec (high-purity PM) | ≤0.06 wt% | ≤0.05 wt% | ≤0.04 wt% | Tighter QC |

| AM adoption (Mo/Mo-W programs) | Emerging | Early pilots | Pilot-to-production | More LPBF/DED parameter sets |

| Mo-Cu use in power modules | Growing | +8% YoY | +10–12% YoY | EV and industrial drives |

Sources:

- USGS Mineral Commodity Summaries (Molybdenum): https://pubs.usgs.gov/periodicals/mcs

- ASTM/ISO powder and PM standards: https://www.astm.org, https://www.iso.org

- Industry analyses (Context/Wohlers-type reports) and supplier technical notes (Plansee, H.C. Starck Solutions)

Latest Research Cases

Case Study 1: LPBF of Fine-Grain Molybdenum for High-Heat Flux Components (2025)

Background: A fusion-energy supplier required complex cooling channels in refractory parts.

Solution: Used spherical Mo powder (D50 ~28 µm, O=0.035 wt%), vacuum LPBF with preheat >600°C, followed by HIP and stress-relief.

Results: 99.6% relative density, thermal conductivity 125–130 W/m·K at RT, no leak paths on helium testing to 1×10^-9 mbar·L/s; build scrap reduced 30% after preheat optimization.

Case Study 2: Mo-Cu Composite Heat Spreaders via PIM + Infiltration (2024)

Background: A power electronics OEM sought CTE-matched spreaders for SiC modules.

Solution: PIM feedstock of fine Mo powder molded to near-net shapes; debind and sinter, then capillary infiltrated with Cu to 20–30 vol% Cu.

Results: Achieved CTE 7.5–8.5 ppm/K (25–200°C), thermal conductivity 200–240 W/m·K; flatness <10 µm over 50 mm; yield improved 12% vs. prior press-and-sinter route.

Expert Opinions

- Dr. Dirk Schwab, Head of R&D, Plansee High Performance Materials

- “Controlling interstitials below 0.05% and using tailored preheats are key to dense, crack-free AM molybdenum—especially for thin walls and lattice structures.”

- Prof. Joachim Banhart, Materials Science, Helmholtz-Zentrum Berlin

- “For thermal management, Mo-Cu remains compelling where high conductivity and mid-range CTE are needed; process route selection (PM vs. infiltration vs. AM) dictates reliability scatter.”

- Dr. Amy J. Clarke, Professor of Metallurgy, Colorado School of Mines

- “Powder genealogy—oxygen pickup and PSD drift—now determines fatigue and thermal shock consistency as much as alloy design in refractory PM systems.”

Practical Tools and Resources

- ASTM B331 (Mo powder), B214/B212 (sieve/flow), B703 (PM refractory metals), B963 (tap density): https://www.astm.org

- ISO 4497 (particle size by sieving), ISO 2739 (Mo products), ISO 13320 (laser diffraction): https://www.iso.org

- USGS Molybdenum Statistics and Information: https://www.usgs.gov

- NIOSH/OSHA metal powder handling and dust explosion guidance: https://www.cdc.gov/niosh, https://www.osha.gov

- MatWeb and Granta MI for Mo/Mo-alloy datasheets: https://www.matweb.com

- Supplier technical libraries: Plansee, H.C. Starck Solutions, Midwest Tungsten

- Senvol Database for AM machine–material compatibility: https://senvol.com

Last updated: 2025-08-25

Changelog: Added 5 new FAQs; included 2025 trend snapshot with data table and sources; provided two recent case studies; compiled expert opinions; listed tools/resources with standards and safety links

Next review date & triggers: 2026-02-01 or earlier if USGS updates indicate >10% demand change, new ASTM/ISO standards publish for Mo powders, or major AM qualification data for Mo/Mo-W is released