1. Introduction: Why Pre-Alloyed Powders Are Transforming Powder Metallurgy

Pre-alloyed powders are revolutionizing modern powder metallurgy (PM) and additive manufacturing (AM) by offering consistent chemical compositions, improved mechanical properties, and better sintering behavior compared to blended elemental powders. These powders are engineered through atomization or chemical methods where all alloying elements are integrated into the base metal before the powder is formed.

For B2B buyers, especially enterprises in automotive, aerospace, and industrial machinery sectors, pre-alloyed powders offer:

- Superior homogeneity

- Enhanced part performance

- Reduced batch-to-batch variation

- Streamlined production workflows

With the rapid growth of additive manufacturing and advanced PM techniques, sourcing high-quality pre-alloyed powders has become critical for manufacturers, distributors, and contract manufacturing facilities.

Key B2B Benefits:

| Benefit | Description |

|---|---|

| Consistent Quality | Uniform chemical composition ensures reliable performance |

| Improved Mechanical Properties | Higher strength, hardness, and wear resistance |

| Compatibility with AM Technologies | Ideal for 3D printing processes like SLM, EBM, and DMLS |

| Efficient Supply Chain | Less need for in-house blending, reducing operational complexity |

Shanghai Truer Technology Co., Ltd has been a pioneer in supplying pre-alloyed powder for PM and AM, offering solutions that support high-performance applications across industries.

2. Industrial Applications of Pre-Alloyed Powders

Pre-alloyed powders are used in a wide range of industries where precision, strength, and thermal stability are non-negotiable. Here are some of the most common industrial applications:

Automotive Industry

- Transmission gears

- Camshafts

- Connecting rods

- Engine brackets

Aerospace & Defense

- Turbine blades

- Structural components

- Heat-resistant parts

Medical Devices

- Orthopedic implants

- Surgical instruments

Consumer Electronics

- Heat sinks

- Structural frames

- Connectors

Tool Manufacturing

- Cutting tools

- Abrasive tools

- Wear-resistant coatings

Application Matrix by Industry and Alloy Type:

| Industry | Common Alloys Used | Key Properties Required |

|---|---|---|

| Automotive | FL-4605, FD-0208 | Strength, fatigue resistance |

| Aerospace | Pre-alloyed stainless steel | Heat resistance, corrosion resistance |

| Medical Devices | Stainless steel, Ti alloys | Biocompatibility, corrosion resistance |

| Tooling | CuSn, Ni-steel | Hardness, wear resistance |

The versatility of pre-alloyed powders makes them a preferred choice for OEMs and Tier-1 suppliers who require reliable materials for high-performance parts.

3. Types of Pre-Alloyed Powders and Their Unique Properties

Pre-alloyed powders are categorized primarily based on the base metal (iron, copper, stainless steel, etc.) and the alloying elements involved. Each type has unique characteristics tailored for specific applications.

Common Pre-Alloyed Powders Offered by Shanghai Truer:

| Powder Type | Grade | Base Material | Characteristics |

|---|---|---|---|

| PM4600 Steel | FL-4605 | Iron | Excellent hardenability, wear resistance |

| Hybrid Low-Alloy Steel | PM4200 | Iron | Good strength and machinability |

| Diffusion Alloyed Steel | FD-0208 | Iron | Improved compressibility |

| Infiltrated Iron | FN-0205 | Iron-Copper | Enhanced density and strength |

| Pre-alloyed Stainless Steel | SBF2218 | Stainless Steel | Corrosion resistance, high strength |

| Pre-alloyed Bronze/Nickel | Various | Copper/Nickel | High conductivity, wear resistance |

Powder Manufacturing Methods:

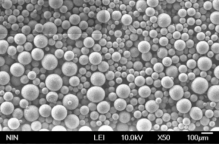

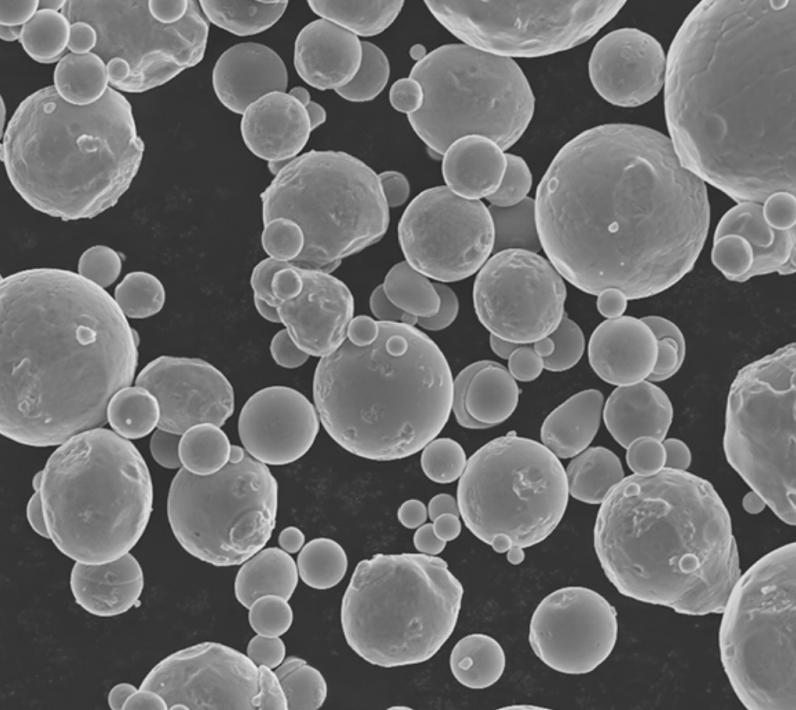

- Water Atomization – Cost-effective, suitable for high-volume applications.

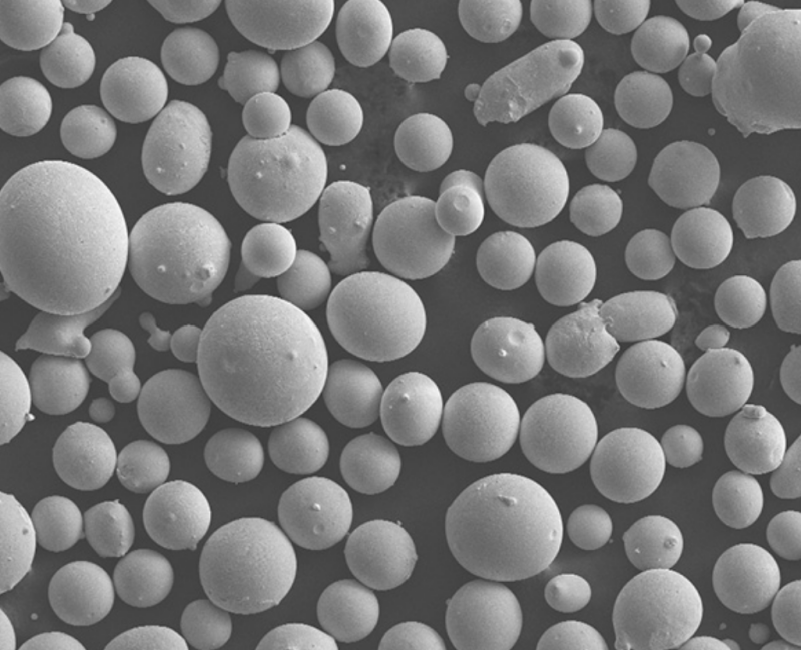

- Gas Atomization – Produces spherical particles ideal for AM.

- Carbonyl Process – Ultra-fine powders for precision parts.

- Combined Atomization – Hybrid of water and gas atomization for custom needs.

Selection Guidelines for B2B Buyers:

When choosing a pre-alloyed powder, consider:

- End-use mechanical requirements

- Compatibility with sintering or AM process

- Density and compressibility

- Cost per kilogram vs performance gains

Example Use Case:

A distributor supplying to electric vehicle (EV) manufacturers may select FL-4605 steel for drivetrain components due to its high strength-to-weight ratio and wear resistance, ensuring long-term performance under stress.

For a deeper understanding of how these powders are produced and customized, visit the Truer Company Overview page to explore their production capabilities and R&D focus.

4. Market Overview: Trends and Growth Potential in Pre-Alloyed Powder Sales

The global powder metallurgy market is undergoing a significant transformation, driven by the rise of pre-alloyed powders. These advanced materials are increasingly preferred across industries due to their enhanced mechanical properties and superior metallurgical uniformity.

Global Market Insights

- Market Size (2023): USD 2.5 Billion (Pre-Alloyed Segment)

- CAGR (2024–2030): Estimated at 7.8%

- Key Drivers:

- Rapid adoption in 3D printing and additive manufacturing (AM)

- Demand from electric vehicles (EVs) and aerospace

- Shift toward high-performance, low-waste manufacturing

Regional Demand Outlook

| Region | Market Share | Key Industries Driving Demand |

|---|---|---|

| North America | 32% | Aerospace, Automotive, Defense |

| Europe | 28% | Industrial Automation, Electronics |

| Asia-Pacific | 35% | EVs, General Manufacturing, Construction |

Industry Trends

- Increased use of gas-atomized pre-alloyed powders for metal 3D printing

- Growth in customized alloy formulations for specific applications

- Rising interest in hybrid manufacturing (PM + AM processes)

- Supply chain partnerships between powder manufacturers and OEMs

For B2B buyers, understanding these trends helps in making procurement decisions that align with long-term technology and market shifts. Suppliers like Shanghai Truer Technology Co., Ltd are investing heavily in R&D to stay ahead of these trends and offer tailored solutions.

5. Key Factors to Consider When Choosing a Pre-Alloyed Powder Supplier

Selecting the right supplier is critical to ensuring consistent product quality, regulatory compliance, and long-term production efficiency. Here are the top factors that wholesale buyers, distributors, and procurement managers should evaluate:

1. Manufacturing Capabilities

- Does the supplier offer multiple atomization methods (gas, water, carbonyl)?

- Are powders available in standard and custom grades?

2. Product Range and Customization

- Can the supplier blend or tailor alloy compositions to meet your specific needs?

- Do they offer hybrid, diffusion, and pre-alloyed options?

3. Quality Certifications

- ISO 9001, ISO 14001, and other certifications ensure compliance and traceability

4. Technical Support

- In-house metallurgical experts and application engineers available?

- Assistance with process optimization and troubleshooting

5. Delivery and Logistics

- Timely delivery and stable inventory management

- Global shipping capabilities or local warehousing options

6. Pricing and MOQ Flexibility

- Competitive B2B pricing tiers

- Low minimum order quantity (MOQ) for prototypes or small-batch production

Supplier Evaluation Checklist

| Evaluation Criteria | Shanghai Truer Technology Co., Ltd |

|---|---|

| Atomization Methods | Water, Gas, Carbonyl, Hybrid |

| Custom Alloy Formulations | ✔ Yes |

| ISO Certifications | ✔ Available |

| MOQ Flexibility | ✔ Yes |

| Technical Support | ✔ Dedicated Engineering Team |

| Global Delivery | ✔ International Shipping |

For more information on the powder options and services available, explore our PM Powder Product Catalog.

6. Top 5 Pre-Alloyed Powder Suppliers in Asia

Asia is home to several world-class suppliers of pre-alloyed powders. For B2B buyers seeking reliable partners, here are five leading companies that stand out in quality, capacity, and innovation.

1. Shanghai Truer Technology Co., Ltd (China)

- Founded: 2009, Additive Division launched in 2019

- Focus: Integrated powder production and additive manufacturing solutions

- Strengths:

- Wide range of PM and AM powders

- Custom alloy development

- Complete additive solutions including lubricants and cutting agents

2. Hoganas AB (Japan Subsidiary)

- Global PM giant with extensive operations in Asia

- Known for high-volume PM steel powders

- Limited customization compared to local manufacturers

3. GKN Powder Metallurgy (China)

- Strong in automotive and industrial metal powders

- Offers pre-alloyed grades, but limited AM-specific options

4. CNPC Powder Material Co., Ltd (China)

- Specializes in gas-atomized stainless steel and aluminum alloy powders

- Popular among 3D printing service bureaus

5. Daido Steel (Japan)

- Known for high-performance tool steels and metal powders

- Offers niche solutions for aerospace and medical industries

| Supplier | Key Strengths | Limitations |

|---|---|---|

| Shanghai Truer | Customization, full PM & AM portfolio | Newer brand globally |

| Hoganas AB (Japan) | Volume production, global brand | Less flexible for custom grades |

| GKN Powder Metallurgy | Automotive OEM relationships | Limited range of AM-specific powders |

| CNPC Powder | Precision atomization, stainless steel focus | Less support for hybrid alloys |

| Daido Steel | Aerospace-grade alloys, high purity | Higher price point |

Shanghai Truer’s position as a comprehensive and flexible supplier makes it an ideal partner for B2B buyers looking for scalability and innovation.

7. Why More Distributors Are Sourcing Pre-Alloyed Powders from China

China is fast becoming the global hub for powder metallurgy, particularly in the production of pre-alloyed powders. Here’s why more global distributors and OEMs are sourcing from Chinese manufacturers:

Cost-Effective Manufacturing

- Lower production costs due to economies of scale

- Competitive pricing without compromising quality

Advanced Production Technologies

- Adoption of modern atomization systems

- Strong investment in R&D and process automation

Diverse Alloy Portfolio

- Ability to produce a wide range of alloys including:

- Iron-copper, iron-nickel, stainless steel, bronze, and brass

- Custom pre-alloyed and hybrid powders

Shorter Lead Times

- Strong domestic logistics networks

- Expedited international shipping

Government Support and Certification

- Chinese manufacturers are increasingly aligning with international standards

- Export-oriented policies and incentives

| Advantage | How It Benefits B2B Buyers |

|---|---|

| Lower Costs | Better margins for resellers and OEMs |

| Custom Alloy Development | Tailored solutions for specialized industries |

| Faster Turnaround | Supports agile manufacturing operations |

| Full-Service Partnerships | From powder to process support |

For B2B buyers considering China as a sourcing destination, Shanghai Truer offers all these advantages in one platform, with a strong reputation for reliability and technical excellence.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Pre-Alloyed Powder Partner

Shanghai Truer Technology Co., Ltd stands out as one of the most professional and reliable additive and PM powder suppliers in China. With over a decade of experience and a dedicated Additive Manufacturing Division launched in 2019, Truer offers complete solutions for OEMs, distributors, and industrial-scale manufacturers.

What Sets Us Apart

✅ Integrated manufacturing capabilities

✅ Full range of PM and AM pre-alloyed powders

✅ Custom alloy development and technical support

✅ ISO-certified quality control

✅ International shipping and supply chain flexibility

Product Range Highlights

| Powder Type | Manufacturing Method | Applications |

|---|---|---|

| PM4600, FL-4605, FD-0208 | Water Atomized, Diffusion Alloy | Automotive parts, structural components |

| FN-0205, FN-5000 | Iron-Copper Infiltration | High-density parts, sintered bearings |

| SBF2218, FX-2008 | Gas Atomized Stainless Steel | Aerospace, medical, corrosive environments |

| CuSn Bronze, Brass, Nickel Silver | Reduction and Atomized Methods | Diamond tools, electrical connectors |

Value-Added Services

- Lubricants & Additives: Lube-W, SUW-5000B, SUW-8000

- Cutting Agents: SME-100 (sulfur-free), TD-8

- Soft Magnetic Additives: QH-150, QHP-330

- Graphite Blends: TBC-400, TBC-1000

These complementary products make Truer a one-stop supplier for all powder metallurgy needs. Whether you’re optimizing part density, improving machinability, or enhancing magnetic properties, Truer has a tailored solution.

For more details about our full additive solutions, visit the official Truer PM Additive Division page.

9. How to Order Wholesale Pre-Alloyed Powder from Shanghai Truer

We’ve designed a streamlined and efficient B2B ordering process to ensure smooth transactions for international and domestic clients. Here’s how you can work with us:

Step-by-Step Ordering Process

- Product Inquiry

- Visit our Contact Page or email our sales team.

- Provide your required powder type, grade, quantity, and application.

- Technical Consultation

- Our engineers will advise on the best alloy and formulation for your needs.

- Customization options available for particle size distribution, flowability, etc.

- Quotation & Sample Delivery

- Competitive B2B pricing with clear lead times.

- Samples can be shipped for testing and validation.

- Bulk Order Confirmation

- Once approved, a purchase agreement is signed.

- MOQ flexibility available depending on powder type.

- Production & Quality Assurance

- Powders are manufactured under strict ISO standards.

- Batch testing certificates are provided with each order.

- Packaging & Shipping

- Export-grade packaging ensures powder integrity.

- Global express or bulk freight shipping options.

- After-Sales Support

- Ongoing technical assistance and reordering support.

- Custom inventory management available for repeat buyers.

Accepted Order Volumes

| Order Type | MOQ | Lead Time (Avg.) | Use Case |

|---|---|---|---|

| Sample Orders | 5–10 kg | 5–10 days | R&D, prototyping |

| Pilot Production | 100–500 kg | 10–15 days | Limited production, testing |

| Bulk Orders | 1 ton+ | 20–30 days | Full-scale manufacturing |

We frequently work with buyers in automotive, aerospace, medical, and electronics industries who require consistent delivery for long-term contracts. For a tailored quote, please reach out via our contact portal.

10. FAQs: Common Questions About Buying Wholesale Pre-Alloyed Powder

Q1: What is the minimum order quantity (MOQ) for pre-alloyed powders?

We offer flexible MOQs starting from 5 kg for samples to several tons for bulk contracts. This helps both small and large enterprises to scale according to their project size.

Q2: Can Shanghai Truer customize alloy compositions?

Yes. Our metallurgical experts work closely with clients to develop custom alloy formulations tailored for specific parts, sintering conditions, and AM processes.

Q3: Do you ship internationally?

Absolutely. We serve clients in North America, Europe, Southeast Asia, and beyond. All export documentation and customs support are provided.

Q4: What testing and certifications do you provide?

Each batch includes a Certificate of Analysis (COA) and may include PSD (particle size distribution), flow rate, apparent density, and chemical composition test results. We comply with ISO 9001 and other global standards.

Q5: What is the difference between pre-alloyed and diffusion alloyed powders?

- Pre-Alloyed Powder: All elements are melted together before atomization, ensuring uniform composition in each particle.

- Diffusion Alloyed Powder: Elements are bonded onto the surface of base powder particles, offering cost savings but with less uniformity.

Q6: How can I get technical support?

Our in-house engineering and metallurgical teams are available for consultation before and after ordering. We also support powder selection, processing optimization, and troubleshooting.

Q7: Where can I learn more about your company?

You can visit our About Us page to learn more about our history, production capabilities, certifications, and R&D focus.

Ready to Order or Need More Information?

Shanghai Truer Technology Co., Ltd is your trusted partner for advanced pre-alloyed powders and powder metallurgy solutions. Whether you are a distributor, OEM, or contract manufacturer, we offer the products, expertise, and support to power your next innovation.

📩 Contact us today for a free consultation or sample request via our Contact Page.