1. Introduction to Nitinol Powder in Modern Manufacturing

Nitinol powder, a nickel-titanium alloy known for its shape memory and superelastic properties, has revolutionized applications across aerospace, medical devices, robotics, and automotive industries. As industries demand more complex, lightweight, and high-performance components, Nitinol powder has become a critical material in additive manufacturing (AM) and powder metallurgy (PM).

What is Nitinol?

Nitinol is an intermetallic compound composed primarily of nickel (Ni) and titanium (Ti), typically in a near-equal atomic ratio. The name “Nitinol” derives from its composition and place of discovery: Nickel Titanium Naval Ordnance Laboratory.

Key Characteristics:

- Shape memory effect (SME)

- Superelasticity

- Biocompatibility

- Corrosion resistance

- High fatigue strength

These qualities make Nitinol powder a sought-after material in precision industries where performance and reliability are paramount.

2. Industrial Applications of Nitinol Powder

Nitinol powder’s versatility allows for widespread use in various B2B sectors. Its compatibility with additive manufacturing techniques such as Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Binder Jetting has opened new frontiers in engineering design and customization.

Common Industrial Use Cases

| Industry | Application Example | Benefits of Nitinol Powder |

|---|---|---|

| Medical Devices | Stents, orthopedic implants, orthodontic wires | Biocompatibility, shape memory |

| Aerospace | Actuators, couplings, fasteners | Lightweight, fatigue resistance |

| Automotive | Fuel systems, engine components | Corrosion resistance, durability |

| Robotics | Artificial muscles, sensors | Precision, superelasticity |

| Consumer Electronics | Temperature-sensitive actuators | Compactness, functional efficiency |

Additive Manufacturing Advantages:

- Complex geometry fabrication

- Minimal material waste

- Customization for patient-specific devices (medical industry)

- Shorter prototyping lead times

3. Properties and Use Cases of Nitinol Powder

When selecting a material for demanding applications, understanding the core properties of Nitinol powder is crucial. Below are the essential physical and mechanical characteristics that make Nitinol a high-performance powder for industrial buyers and engineers.

Key Properties of Nitinol Powder

| Property | Value Range | Industrial Benefit |

|---|---|---|

| Shape Memory Temperature | 70°C to 100°C (customizable) | Thermal actuation applications |

| Superelasticity Strain | Up to 8% | Ideal for dynamic load environments |

| Density | 6.45 g/cm³ | Lightweight component manufacturing |

| Corrosion Resistance | High (especially in biological fluids) | Medical and marine applications |

| Biocompatibility | Excellent | Safe for human body contact |

Use Cases in Powder Metallurgy (PM)

Nitinol powder is increasingly used in PM methods due to its fine particle size distribution and reactivity under sintering conditions. It can be used on its own or blended with other PM powders for hybrid materials.

- PM actuators in aerospace

- Sintered orthodontic archwires

- High-performance bearings with shape memory properties

- Temperature-sensitive control valves

At Shanghai Truer Technology Co., Ltd, we offer custom alloy solutions including Nitinol and other advanced PM powders such as PM Brass, PM Stainless Steel, and hybrid low-alloy powders. Our powders are produced using water atomization, gas atomization, and carbonyl reduction, ensuring high purity and performance consistency.

4. Market Trends and Growth Potential in Nitinol Powder

As advanced manufacturing technologies like 3D printing and precision metallurgy continue to scale across industries, the global demand for Nitinol powder is experiencing exponential growth. Market research indicates that the Nitinol market is poised to grow at a CAGR of 9–12% through 2030, driven largely by the medical, aerospace, and robotics sectors.

Global Nitinol Powder Market Overview

| Metric | Value (2024 estimate) |

|---|---|

| Global Market Size | $860 million |

| CAGR (2024–2030) | 9–12% |

| Key Growth Regions | North America, Europe, Asia-Pacific |

| Leading Segments | Medical Devices, Aerospace, Actuators |

| Primary Production Methods | Gas Atomization, Plasma Rotating Electrode |

Market Drivers

- Rising demand for minimally invasive medical devices

- Adoption of additive manufacturing in aerospace & defense

- Increased R&D in shape memory alloys and smart materials

Wholesale and B2B Buying Trends

In the B2B sector, the wholesale purchase of Nitinol powder is becoming more strategic. Distributors and industrial buyers now prioritize:

- Material traceability & certifications

- Consistent particle morphology

- Custom alloy formulation

- On-time global logistics

These expectations are pushing suppliers to modernize their processing and quality assurance systems.

5. Key Factors When Choosing a Nitinol Powder Supplier

Selecting the right Nitinol powder supplier is vital for manufacturers, OEMs, and industrial R&D teams. Below are critical factors wholesale buyers should evaluate.

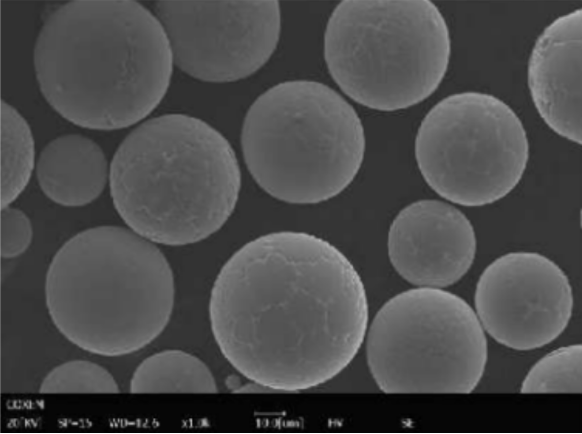

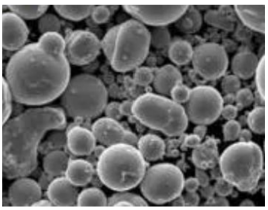

1. Powder Quality & Consistency

- Particle size distribution (PSD) for uniform sintering

- Purity levels (low oxygen and carbon contamination)

- Morphology (spherical vs. irregular particles)

- Lot-to-lot consistency

2. Technical Support & Customization

- Ability to provide application-specific formulations

- Metallurgical consulting services

- Rapid prototyping support

3. Production Capacity & Lead Time

- Scalable manufacturing for bulk orders

- Short turnaround time for urgent projects

- Inventory availability and restocking frequency

4. Certifications & Compliance

- ISO 13485 (Medical)

- AS9100 (Aerospace)

- RoHS, REACH compliance

5. Pricing & Logistics

- Competitive pricing for large-volume purchases

- Transparent Incoterms and delivery schedules

- Global shipping capabilities

6. Top Nitinol Powder Suppliers Globally

Here we list some of the most prominent Nitinol powder suppliers serving B2B sectors, including medical device OEMs, aerospace contractors, and additive manufacturing labs.

| Supplier Name | Region | Specialty | Website |

|---|---|---|---|

| Fort Wayne Metals | USA | Medical-grade Nitinol wires & powders | fortwaynemetals.com |

| Johnson Matthey | UK/Global | Biocompatible alloys and memory materials | matthey.com |

| ATI Specialty Materials | USA | Aerospace-grade nickel titanium products | atimetals.com |

| Shanghai Truer Technology Co., Ltd | China | High-purity, customizable PM and AM powders | am-material.com |

| SAES Getters Group | Italy | Shape memory and actuation materials | saesgetters.com |

Shanghai Truer Technology Co., Ltd stands out in the Asian market for its ability to deliver both standard and customized Nitinol powder solutions to OEMs, R&D institutions, and additive manufacturers. We produce powders using various atomization methods to meet the diverse needs of industrial clients.

📌 Learn more about our company’s mission and technical capabilities.

7. Why More Buyers Are Turning to Alternative Sources

The traditional supply chain for Nitinol powder is dominated by a few Western suppliers, often leading to:

- Extended lead times

- High minimum order quantities (MOQs)

- Region-specific compliance issues

- Limited customization options

Benefits of Alternative Suppliers in Asia

| Benefit | Description |

|---|---|

| Cost-Effectiveness | Lower production and labor costs allow for more competitive pricing |

| Faster Lead Times | Shorter delivery cycles for Asia-Pacific and global buyers |

| Customization Flexibility | Tailored compositions & particle sizes |

| Innovation & R&D Investment | Advanced manufacturing techniques like hybrid atomization |

Shanghai Truer leverages China’s industrial ecosystem and years of experience in powder metallurgy to provide dependable supply with high output capacities. Clients across Europe, North America, and Southeast Asia are increasingly sourcing from Truer due to our balance of quality, speed, and price.

🌐 Explore our full product portfolio of PM powders to see how we support a range of industrial applications with high-performance materials.

8. How to Order Wholesale Nitinol Powder from Shanghai Truer

Ordering Nitinol powder in bulk for your industrial operation requires more than just a purchase—it’s a strategic partnership. At Shanghai Truer Technology Co., Ltd, we simplify the process for B2B clients by offering responsive support, customizable solutions, and global logistics.

Step-by-Step Wholesale Ordering Process

| Step | Action | Details |

|---|---|---|

| 1 | Inquiry | Contact via our contact form or email with specifications |

| 2 | Technical Consultation | Our engineers discuss your application, desired particle size, purity, etc. |

| 3 | Quotation & Sample | We provide a formal quote and can dispatch sample quantities if needed |

| 4 | Order Confirmation | Once terms are agreed, we initiate production or ship from inventory |

| 5 | Production & Quality Control | Powders undergo atomization, screening, and full QC testing |

| 6 | Packaging & Documentation | Products are packed according to export standards with full COA, SDS, etc. |

| 7 | Global Shipping | DHL, FedEx, or freight forwarding based on your location and urgency |

| 8 | After-Sales Support | Ongoing technical consultation and reorder support |

Popular Nitinol Powder Specifications Offered

- Particle size: 15–45 µm / 45–105 µm / Customized

- Morphology: Spherical or semi-spherical (via gas atomization)

- Purity: >99.9%, low oxygen/carbon content

- Packaging: Vacuum sealed, 1kg–25kg containers

- MOQ: 5kg–10kg for custom orders

Customization Capabilities

- Tailored shape memory transition temperature

- Blended powders with PM bronze, stainless steel, or other alloys

- Surface-treated powders for enhanced sintering or flowability

📦 Our logistics team ensures your order arrives safely and on time, with all necessary documentation for customs and regulatory compliance.

Start your project by getting in touch with our team.

9. FAQs: Buying and Using Nitinol Powder in Bulk

Q1: What’s the typical lead time for a bulk order?

A: For standard grades in stock, we can ship within 3–5 business days. Custom alloy production typically takes 2–3 weeks depending on quantity and specifications.

Q2: Can you provide Nitinol powder suitable for medical applications?

A: Yes. We offer high-purity, biocompatible Nitinol powders manufactured under strict QC protocols. Please specify ISO 13485 or other certification requirements during the inquiry.

Q3: How do your powders compare to Western suppliers in terms of quality?

A: Our powders match or exceed international quality standards. We offer competitive pricing, full material traceability, and customization that many Western suppliers don’t.

Q4: What particle size ranges are available?

A: We offer a wide range of particle sizes including 15–45 µm for additive manufacturing (SLM, EBM) and 45–105 µm for conventional PM. Custom sieving is also available.

Q5: What industries do you serve with your Nitinol powder?

A: Our clients span medical device manufacturing, aerospace, automotive R&D, robotics, and precision electronics.

Q6: Do you offer free samples?

A: Yes, we can provide small samples for evaluation, especially for first-time industrial buyers. Shipping costs may apply.

Q7: What is the difference between gas atomized and water atomized powders?

A: Gas atomized powders are typically more spherical and ideal for additive manufacturing. Water atomized powders are more irregular and better suited for conventional PM applications. We offer both types depending on your needs.

Internal Links Summary (Anchor Texts for SEO)

| Anchor Text | URL |

|---|---|

| Shanghai Truer Technology Co., Ltd | https://am-material.com/ |

| company’s mission and technical capabilities | https://am-material.com/about/ |

| product portfolio of PM powders | https://am-material.com/pm-powder/ |

| getting in touch with our team | https://am-material.com/contact-us/ |

| high-quality 3D printing powders | https://am-material.com/pm-powder/ |

✅ If you’re an OEM, distributor, or R&D specialist looking to incorporate Nitinol powder into your manufacturing process, Shanghai Truer Technology Co., Ltd is your trusted partner for quality, speed, and customization.

Let us help you bring your smart material innovations to life.

📞 Contact us today to request a quote or technical consultation.