1. Introduction to Nimonic 80A Powder in Industrial Manufacturing

Nimonic 80A is a precipitation-hardenable nickel-chromium alloy reinforced with titanium and aluminum. Originally developed for high-temperature aerospace applications, it is now widely used in manufacturing sectors requiring exceptional creep resistance, oxidation resistance, and mechanical strength.

In powder form, Nimonic 80A becomes a vital raw material for:

- Additive manufacturing (3D printing)

- Metal injection molding

- Hot isostatic pressing (HIP)

- Powder metallurgy (PM) applications

The demand for this high-performance alloy powder has grown significantly, particularly among:

- Aerospace component manufacturers

- Gas turbine and engine part suppliers

- Automotive performance part producers

- Industrial furnace and tooling companies

As global industries pivot toward lightweight, high-strength materials, Nimonic 80A powder offers a reliable solution to meet demanding performance requirements.

Key B2B Benefits

| Feature | Benefit for Industrial Buyers |

|---|---|

| High temp resistance | Suitable for turbine blades, exhaust parts |

| Powder form | Ideal for 3D printing and PM applications |

| Creep & oxidation resistance | Long lifecycle in extreme environments |

| Sphericity & flowability | Essential for consistent AM layer deposition |

High-intent B2B keywords: Nimonic 80A powder supplier, wholesale Nimonic alloy powder, Nimonic 80A for additive manufacturing, buy Nimonic powder bulk, Nimonic 80A distributor

2. Key Applications of Nimonic 80A Powder in Aerospace and Engineering

Nimonic 80A powder’s superior mechanical and thermal properties make it a critical material for high-performance applications.

Major Industries Using Nimonic 80A Powder:

- Aerospace Industry

- Turbine blades

- Jet engine combustion chambers

- Exhaust valves

- Afterburners

- Automotive Engineering

- Turbocharger components

- Valves and valve seats

- Performance engine parts

- Power Generation

- Gas turbines

- Heat exchangers

- High-efficiency boilers

- Metal Additive Manufacturing

- Custom aerospace components

- Lightweight structural parts

- Repair parts for jet engines

- Tooling and Mold Making

- Die-casting molds

- Hot forming dies

- High-wear inserts

Application Table

| Industry | Application | Benefit |

|---|---|---|

| Aerospace | Turbine blades, jets | High heat & oxidation resistance |

| Automotive | Turbo parts, valves | Performance under stress and heat |

| Power | Boilers, turbines | Prolonged high-temp operation |

| AM/3D Printing | Custom parts | Precision and design freedom |

| Tooling | Molds and dies | Wear resistance and stability |

3. Material Properties and Metallurgical Advantages of Nimonic 80A

The unique composition of Nimonic 80A gives it exceptional properties that are ideal for high-temperature and high-stress environments.

Chemical Composition (% by weight)

| Element | Typical Content |

|---|---|

| Nickel (Ni) | 69.0 min |

| Chromium (Cr) | 18.0–21.0 |

| Titanium (Ti) | 1.8–2.7 |

| Aluminum (Al) | 1.0–1.8 |

| Carbon (C) | 0.10 max |

| Iron (Fe) | 3.0 max |

| Silicon (Si) | 1.0 max |

| Manganese (Mn) | 1.0 max |

Key Metallurgical Properties

- High creep strength at temperatures up to 815°C

- Excellent fatigue resistance under cyclic loading

- Superior oxidation resistance in high-temperature environments

- Enhanced corrosion resistance in harsh atmospheres

- Good weldability and post-processing compatibility

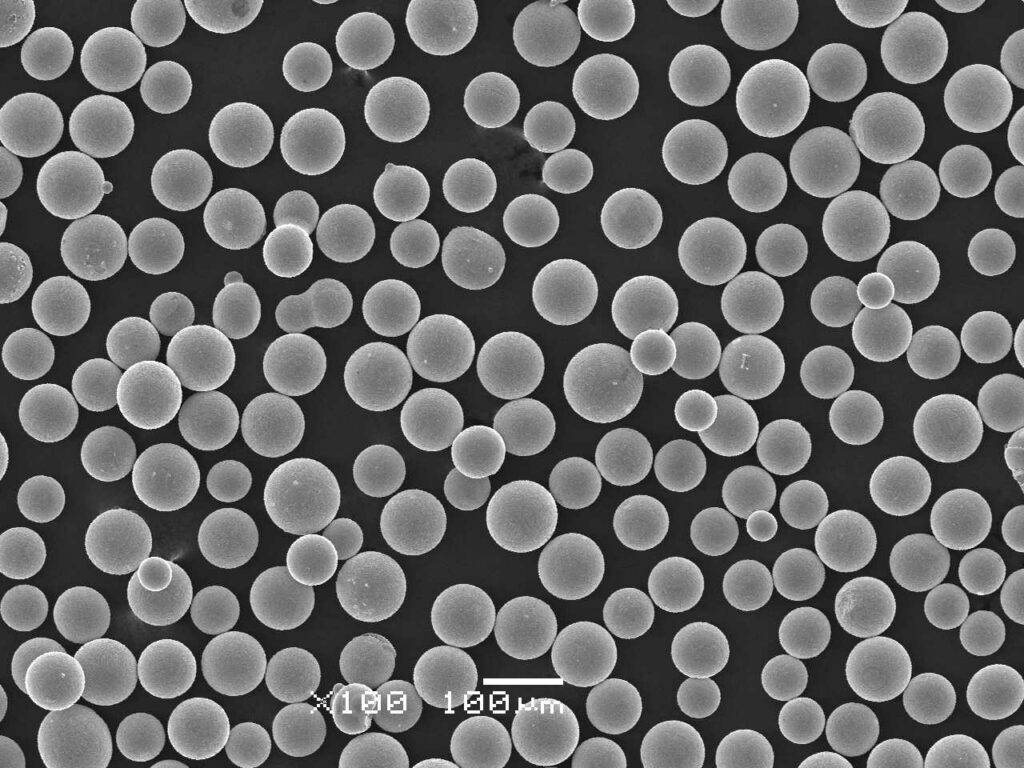

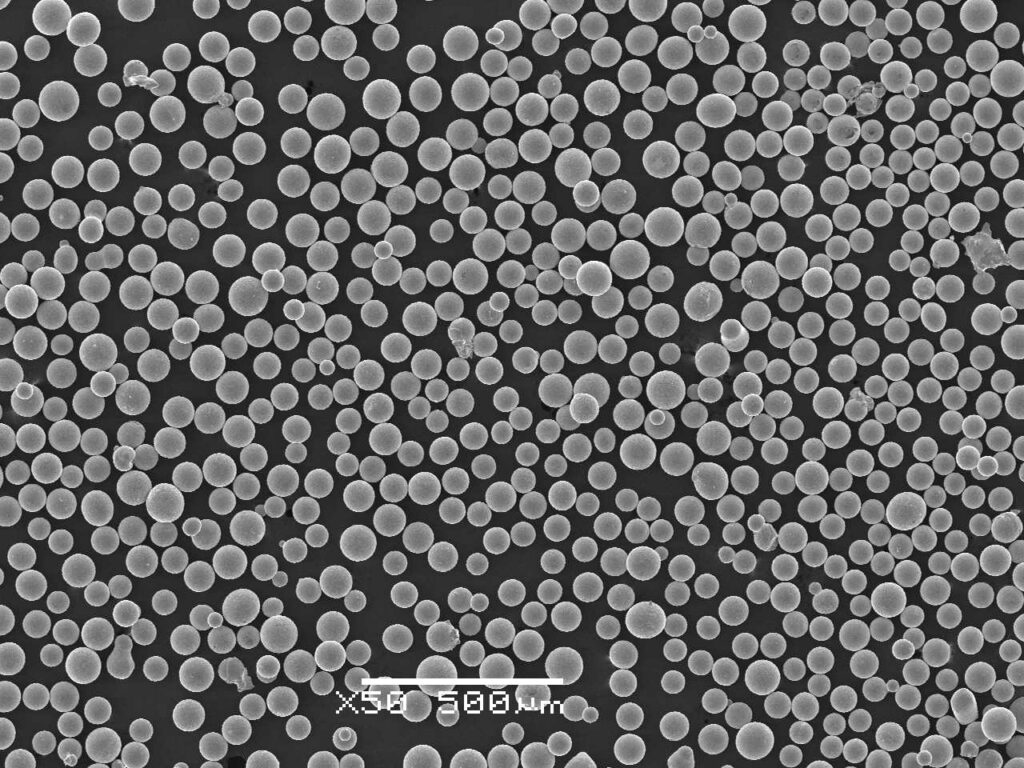

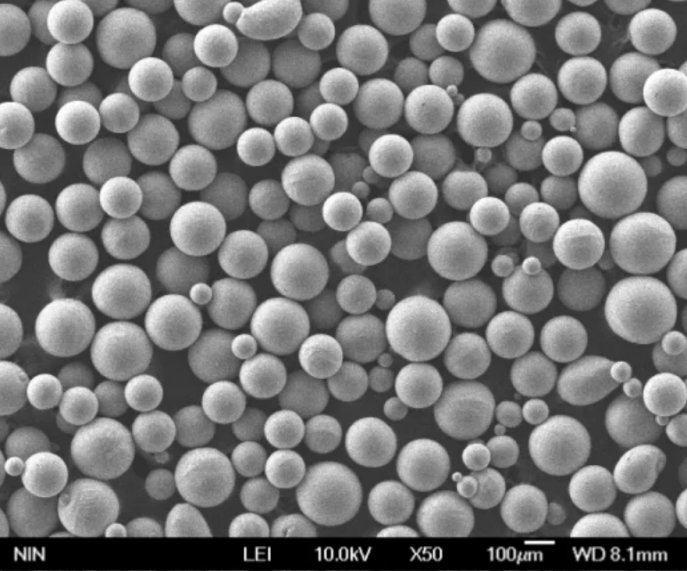

Advantages in Powder Metallurgy

- Uniform particle size distribution

- High purity and low oxygen content

- Excellent flowability for AM and MIM

- Enhanced density and mechanical strength in sintered parts

These properties make Nimonic 80A powder a reliable choice for manufacturers seeking consistent performance in demanding conditions. Especially in additive manufacturing, where powder quality influences final part strength and surface finish, Nimonic 80A stands out.

To learn more about powder metallurgy grades and applications, check out our PM Powder Product Catalog.

4. Current Market Trends and Demand for Nimonic 80A Powder

With the growth of additive manufacturing and the increasing demand for high-performance materials in aerospace and energy sectors, Nimonic 80A powder has gained significant traction in global markets.

Key Market Drivers

- Boom in Aerospace Manufacturing

Post-pandemic recovery and increased defense budgets are fueling demand for heat-resistant materials in aerospace applications. - Shift Toward Additive Manufacturing (AM)

OEMs and engineering firms are adopting metal 3D printing to reduce lead times and cost for complex parts. Nimonic 80A powder, with its excellent flowability and sphericity, is ideal for laser powder bed fusion (LPBF) and electron beam melting (EBM) processes. - Energy Sector Advancements

The global push toward efficient power generation has increased the use of gas turbines, which require high-temperature alloys like Nimonic 80A. - Automotive Lightweighting Initiatives

Performance vehicles and electric cars benefit from parts made with lightweight, high-strength alloys. Nimonic 80A helps manufacturers meet these criteria.

Market Growth Forecast (2024–2030)

| Region | CAGR | Key Industries |

|---|---|---|

| North America | 6.8% | Aerospace, Defense, Energy |

| Europe | 7.1% | Automotive, Industrial Equipment |

| Asia-Pacific | 9.2% | Additive Manufacturing, Tooling |

| Middle East | 5.5% | Power Generation, Oil & Gas |

New Trends to Watch

- Adoption of AI-driven quality control in powder production

- Increased investment in AM-focused alloy powders

- Strategic sourcing from China to reduce cost and increase supply chain resilience

- Custom alloy development for niche engineering applications

5. How to Choose a Reliable Nimonic 80A Powder Supplier

Choosing the right supplier for Nimonic 80A powder is critical for ensuring consistent part performance, regulatory compliance, and supply chain continuity.

Key Factors to Evaluate:

- Powder Morphology and Purity

- Look for spherical particles with minimal satellites

- Ensure oxygen, nitrogen, and carbon levels are within specification

- Production Method

- Gas atomization is preferred for additive manufacturing

- Water atomization or reduced powders may suit PM or MIM applications

- Certifications and Quality Systems

- ISO 9001, AS9100 (aerospace), and other relevant certifications

- Batch traceability and material test reports (MTRs)

- Customization Capabilities

- Ability to tailor particle size distribution (PSD)

- Custom alloying or post-treatment options

- Technical Support and Logistics

- Engineering support for AM or PM process optimization

- Global shipping capabilities and inventory management

Supplier Evaluation Checklist

| Criteria | Description | Importance |

|---|---|---|

| Purity & PSD | Consistent powder quality | ★★★★★ |

| Production Method | Atomization process suitability | ★★★★☆ |

| Certifications | ISO, AS, ASTM compliance | ★★★★★ |

| Tech Support | Application and process guidance | ★★★★☆ |

| Logistics | Lead time, global coverage | ★★★★☆ |

Manufacturers sourcing Nimonic 80A powder for AM, PM, or HIP processes should partner with suppliers who not only deliver material, but also offer technical expertise and customization options.

6. Top Global Suppliers of Nimonic 80A Powder

Here’s a curated list of the leading global suppliers of Nimonic 80A powder, evaluated based on quality, certifications, and B2B service capabilities.

Leading Nimonic 80A Powder Suppliers

| Company | Country | Key Features | Industries Served |

|---|---|---|---|

| Carpenter Additive | USA | Aerospace-grade powders, AM focus | Aerospace, Energy |

| Sandvik Osprey | UK | Gas-atomized powders, ISO certified | AM, Tooling, Automotive |

| LPW Technology (now part of Carpenter) | UK/USA | Powder lifecycle management | AM, Aerospace |

| Shanghai Truer Technology Co., Ltd | China | Custom PM & AM powders, full solution supplier | Automotive, Tooling, AM |

| Erasteel | France | High-speed steel and superalloy powders | PM, HIP, Tooling |

Why Shanghai Truer Technology Stands Out

Shanghai Truer Technology Co., Ltd has been a trusted name in the powder metallurgy industry since 2009 and entered the additive manufacturing segment in 2019. Unlike many suppliers who only offer standard powders, Truer provides:

- Custom atomization techniques (gas, water, hybrid) for optimized powder properties

- Full-spectrum alloy offerings, including Nimonic 80A, PM stainless steels, and diffusion alloys

- Complete additive solutions, from powder supply to technical support

- In-house R&D for new materials like soft magnetic and cutting additives

Truer’s Nimonic 80A powder is ideal for both AM and PM applications, backed by strict quality control, consistent PSD, and industry certifications. Learn more about their capabilities and history on their About Us page.

7. Why More Buyers Are Turning to Chinese Suppliers for Nimonic 80A

Global sourcing trends in the metal powder industry are shifting, with an increasing number of B2B buyers seeking high-quality yet cost-effective alternatives outside of traditional Western suppliers. China, with its rapidly advancing metallurgical capabilities, has emerged as a reliable source for superalloy powders like Nimonic 80A.

Key Advantages of Sourcing from China

- Cost Efficiency Without Compromising Quality

- Chinese suppliers like Shanghai Truer Technology offer competitive pricing due to advanced domestic manufacturing and efficient logistics.

- Quality is maintained through international certifications and rigorous quality assurance protocols.

- Flexible Customization Capabilities

- Chinese manufacturers are more agile in offering tailored particle size distributions (PSD) and custom alloy compositions to meet specific application needs.

- Speed and Scalability

- Shorter lead times and faster order fulfillment help manufacturers meet tight production schedules.

- Scalable production capacity supports both small batch prototyping and large-volume manufacturing.

- Technological Investment

- Leading Chinese producers have invested heavily in additive manufacturing technology and powder atomization processes.

- Hybrid atomization (gas + water) options available for application-specific powder requirements.

- Growing Reputation for Reliability

- Chinese powder metallurgy companies are increasingly recognized for their consistency, innovation, and technical support.

Comparison Table: Western vs. Chinese Suppliers

| Feature | Western Suppliers | Chinese Suppliers |

|---|---|---|

| Cost | High | Competitive |

| Lead Time | 4–8 weeks | 2–4 weeks |

| Customization | Limited | Highly flexible |

| Certifications | ISO, AS9100 | ISO, GB/T, ASTM |

| Technical Support | Moderate | Extensive & responsive |

| MOQ | High | Flexible |

Chinese suppliers like Shanghai Truer Technology are closing the gap with Western competitors while offering additional flexibility and value.

8. Why Choose Shanghai Truer Technology as Your Nimonic 80A Partner

Shanghai Truer Technology Co., Ltd is one of the most trusted powder suppliers in China, known for both its quality products and its deep commitment to customer success. As a leading supplier of PM and AM powders, Truer offers unique advantages for buyers sourcing Nimonic 80A powder.

Core Strengths of Shanghai Truer

- ✅ Established Expertise

Founded in 2009, with a dedicated additive manufacturing division since 2019. - ✅ Extensive Alloy Portfolio

Full range of PM and AM materials including:- PM stainless steels, copper steels, nickel steels

- Custom superalloys like Nimonic 80A

- Specialty powders for diamond tools and sintered bearings

- ✅ Advanced Powder Production Technology

- Water atomized, gas atomized, and hybrid methods

- Controlled particle morphology and high purity

- Custom PSD available for LPBF, MIM, HIP, and PM applications

- ✅ Integrated Additive Solutions

- Additives: cutting agents, lubricants, soft magnetic materials

- One-stop solution for powder metallurgy needs

- Technical consulting and material selection support

- ✅ Global Reach with Local Support

- Responsive export services

- Multilingual customer service

- Fast logistics and global shipping

Key Product: Truer Nimonic 80A Powder

| Specification | Value |

|---|---|

| Purity | ≥99.8% |

| Particle Size | D50: 15–45 μm (customizable) |

| Sphericity | ≥95% |

| Oxygen Content | ≤0.03% |

| Flowability | Optimized for LPBF and EBM |

| Certification | ISO 9001, GB/T 19001, ROHS |

Truer’s Nimonic 80A powder is engineered for optimal performance in high-temperature applications, making it ideal for aerospace, energy, and automotive use cases.

Interested in a custom quote or sample? Reach out via their Contact Page to begin your procurement process.

9. FAQs: Buying Wholesale Nimonic 80A Powder

Q1: What is the minimum order quantity (MOQ) for Nimonic 80A powder from Truer?

A: Truer offers flexible MOQs starting from 5 kg for R&D purposes and prototypes, with scalable options for mass production.

Q2: Can I request custom particle size distribution for Nimonic 80A?

A: Yes, Truer can tailor the PSD based on your specific application—commonly 15–45 µm for LPBF or 45–90 µm for MIM/HIP.

Q3: Is third-party material testing supported?

A: Absolutely. Truer can provide third-party independent lab certifications, including chemical composition and PSD reports.

Q4: What are the shipping options for international buyers?

A: Truer offers global shipping with door-to-door options using DHL, FedEx, or air freight. Export documentation and customs support are included.

Q5: How do I ensure compatibility with my 3D printer or PM process?

A: Truer’s engineering team can assist in powder selection, parameter optimization, and even provide test samples to ensure compatibility.

Q6: Are there technical datasheets and MSDS available?

A: Yes. All powders come with detailed TDS (technical data sheets), MSDS (material safety data sheets), and MTRs (material test reports).

Q7: Where can I see all available PM powders from Truer?

A: You can explore the full catalog of powder metallurgy materials on their PM Powder Product Page.

By working with a trusted supplier like Shanghai Truer Technology, buyers can ensure consistent quality, technical support, and cost-effective sourcing of Nimonic 80A powder for both additive manufacturing and traditional PM applications.

✅ Explore Truer’s full range of engineered powders and services on their official website. Ready to take the next step? Contact their team for a quote or consultation today.