1. Introduction: Why Nickel-Based Brazing Powder Matters in Modern Manufacturing

Nickel-based brazing powders are a cornerstone material in high-performance joining applications, particularly in industries requiring corrosion resistance, high thermal strength, and precise metallurgical bonding. These powders are designed for brazing components at high temperatures, typically in the range of 950°C to 1200°C, offering superior performance compared to traditional welding or mechanical joining methods.

Key Benefits for Industrial Use:

- High Corrosion Resistance: Ideal for harsh environments such as aerospace and chemical processing.

- Thermal Stability: Maintains integrity under extreme temperatures.

- Precision Bonding: Enables uniform and strong metallurgical joints.

- Versatility: Compatible with stainless steels, nickel alloys, and superalloys.

B2B Use Cases:

- OEMs in aerospace and automotive sectors

- Tool manufacturers for cutting and wear-resistant components

- HVAC and heat exchanger panel producers

- Medical equipment and instrumentation manufacturers

For procurement specialists, sourcing managers, and industrial engineers, nickel-based brazing powders offer a reliable, scalable solution that integrates well into automated or manual assembly lines.

2. Industrial Applications Across Sectors

Nickel brazing powders are crucial to high-precision industries where performance and reliability are non-negotiable. Below is a breakdown of the primary industries and how they utilize nickel-based brazing materials.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Turbine blades, jet engine parts | High-temperature strength, oxidation resistance |

| Automotive | Exhaust systems, heat exchangers | Vibration resistance, longevity |

| HVAC | Aluminum coil bonding, finned tubes | Leak-proof joints, corrosion resistance |

| Medical Devices | Surgical tools, implants | Biocompatibility, precision |

| Oil & Gas | Downhole tools, valves | Wear resistance, high-pressure capabilities |

Common Joint Configurations:

- Tube-to-tube bonding

- Tube-to-plate bonding

- Honeycomb structures

- Filter assemblies

These applications often require tight tolerances and void-free joints, making nickel-based brazing powder ideal due to its flowability and capillary action.

3. Types of Nickel-Based Brazing Powders & Their Properties

Nickel brazing powders can be customized or standardized depending on the application. They typically consist of a nickel base alloyed with elements like boron, silicon, chromium, and iron to reduce melting temperature and enhance performance.

Common Alloy Types:

| Alloy Code | Composition | Melting Range (°C) | Notable Features |

|---|---|---|---|

| Ni-Cr-Si-B-Fe | ~80% Ni, 10–15% Cr | 980–1100 | Oxidation resistance, high strength |

| Ni-B-Si | High B, low Cr | 950–1050 | Excellent flow, low melting |

| Ni-Cr-B-Fe | Balanced Cr and B | 1020–1100 | Corrosion-resistant, wear-resistant |

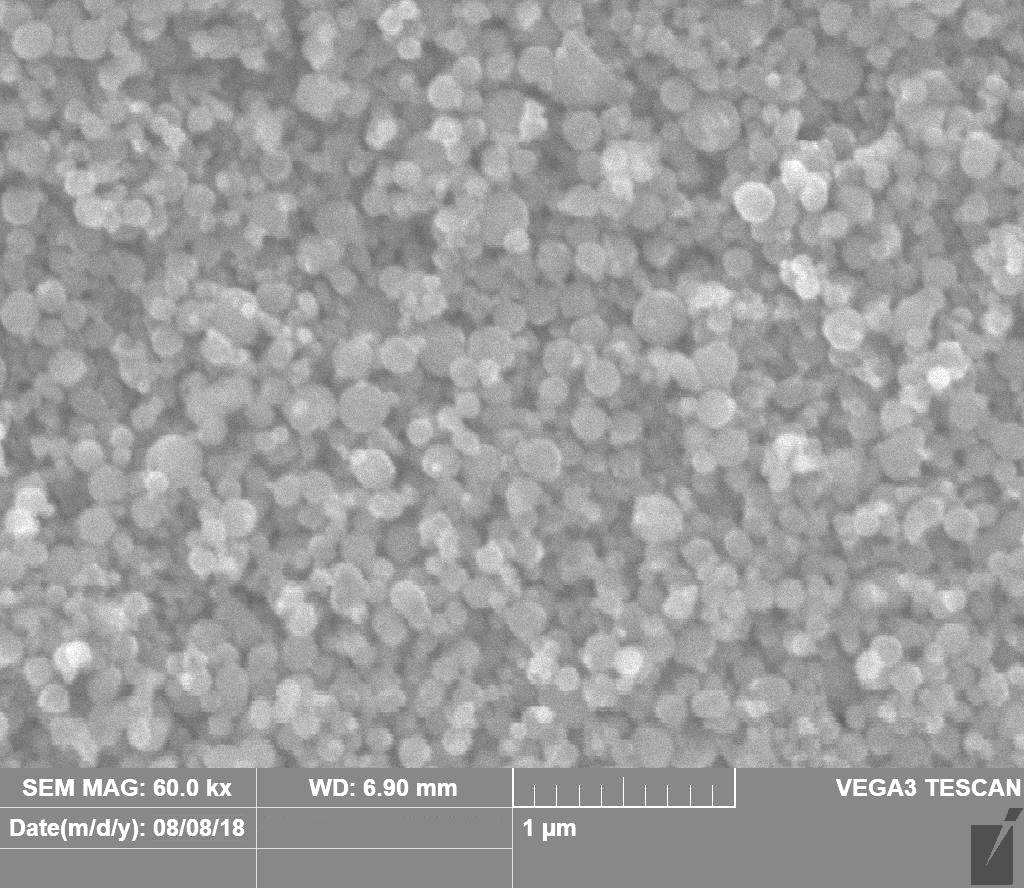

Powder Characteristics:

- Particle Size: Ranges from -100 mesh to -325 mesh depending on application

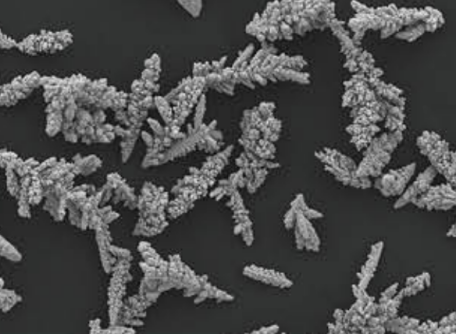

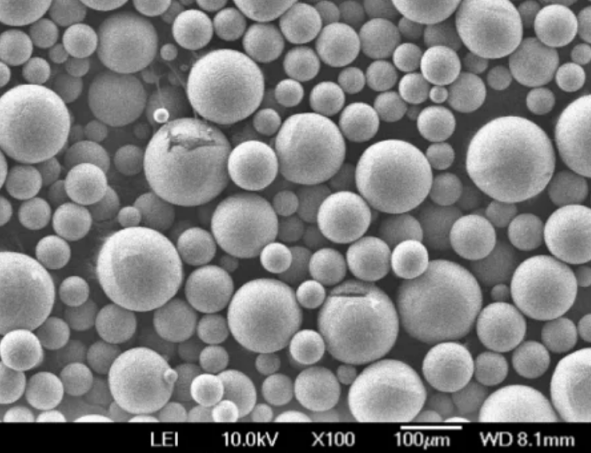

- Morphology: Spherical or angular, with spherical preferred for consistent flow

- Flow Rate: Crucial for gap-filling in capillary joints

- Filler Metal Content: Adjusted for wetting and spread characteristics

Production Methods:

Nickel-based brazing powders are typically produced via:

- Gas Atomization: Produces spherical particles with high purity

- Water Atomization: More economical, but yields irregular shapes

- Crushing of pre-alloyed cast bars: For specialty or custom compositions

4. Global Market Trends & Demand Forecast

The global market for nickel-based brazing powders has seen significant growth, driven by the expansion of high-temperature industries such as aerospace, automotive, and HVAC systems. As manufacturers prioritize strength, corrosion resistance, and lightweight materials, demand for advanced brazing solutions is escalating.

Market Highlights:

- Global Market Value (2023): Estimated at USD 750 million

- CAGR (2023–2030): Projected at 6.2%

- Biggest Growth Sectors: Aerospace, EV batteries, heat exchangers, precision tools

- Key Regions: North America, Europe, and Asia-Pacific, with China as a leading supplier

Key Market Drivers:

- ✔️ Rise in electric vehicles (EVs) and the need for high-efficiency cooling systems

- ✔️ Growth in aerospace components requiring lightweight, high-strength assemblies

- ✔️ Increasing use of brazing automation in manufacturing lines

- ✔️ Shift toward sustainable manufacturing and waste reduction through precision joining

Industry Challenges:

- ❌ Supply chain disruptions (e.g., nickel price volatility)

- ❌ Stringent purity and quality requirements for aerospace and medical-grade powders

- ❌ Need for advanced R&D in low-temperature brazing alloys

Strategic Insight:

Buyers and procurement teams are increasingly sourcing from Asia, especially China, due to:

- Lower production costs

- Advanced powder metallurgy infrastructure

- Availability of gas-atomized and custom alloy powders

5. Key Considerations When Choosing a Nickel Brazing Powder Supplier

For B2B procurement professionals, selecting the right supplier is critical to maintaining product consistency, cost-efficiency, and performance. Here’s what you should evaluate:

📌 Supplier Evaluation Checklist:

| Factor | Why It Matters |

|---|---|

| Production Method | Gas atomized powders offer better flow and consistency |

| Purity & Quality Control | Ensures stable brazing joints, especially in aerospace/medical |

| Customization Options | Custom alloys for specific melting points or applications |

| Certifications | ISO 9001, AS9100, or industry-specific credentials |

| Lead Time & Logistics | Shorter delivery timelines reduce inventory pressure |

| Technical Support | In-house metallurgists improve application success |

| MOQ & Pricing | Competitive pricing for bulk/wholesale buyers |

Technical Questions to Ask Suppliers:

- What is the particle size distribution of your nickel brazing powder?

- Can you provide batch-specific material certificates?

- Do you offer custom alloy formulations?

- What is your process for ensuring powder homogeneity?

These considerations help procurement managers align with suppliers like Shanghai Truer Technology Co., Ltd., who offer rigorous quality control and technical support.

6. Top 5 Nickel-Based Brazing Powder Suppliers in Asia

Asia has become a global powerhouse in powder metallurgy, especially in nickel-based brazing materials. Below are some of the top-performing suppliers catering to industrial clients worldwide.

| Company | Country | Strengths | Certification |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd. | China | Custom nickel-based powders, gas/water atomization, full PM additive solutions | ISO 9001 |

| Nihon Superior Co. Ltd. | Japan | Brazing and soldering materials with high precision | ISO 14001 |

| Hoganas AB (Asia Division) | Sweden (Asia HQ) | Broad PM portfolio, including nickel and stainless steel powders | ISO 9001, ISO/TS 16949 |

| CNPC Powder Group | China | Cost-effective bulk powders, wide alloy range | ISO Certified |

| JFE Steel Corporation | Japan | Advanced R&D in high-purity alloy powders | ISO 9001, ISO 14001 |

Why Shanghai Truer Stands Out:

Shanghai Truer Technology Co., Ltd. not only offers a full range of nickel-based brazing powders but also integrates additive manufacturing equipment, technical consulting, and custom alloy development. Learn more about their capabilities here.

Available Alloys from Truer:

- Ni-B-Si-Cr and Ni-Cr-B-Fe blends

- Custom pre-alloyed and diffusion-bonded powders

- Spherical and angular morphologies for varied applications

7. Why More Buyers Are Sourcing from Chinese Manufacturers

Over the past decade, China has become a global hub for powder metallurgy and brazing materials — and for good reason. B2B buyers, distributors, and OEMs are increasingly shifting their sourcing strategies toward Chinese manufacturers due to a combination of cost-effectiveness, production scalability, and increasingly high-quality standards.

Key Drivers Behind the Shift:

| Reason | How It Benefits B2B Buyers |

|---|---|

| Lower Production Costs | Competitive pricing for bulk/wholesale orders |

| Advanced Manufacturing Tech | Gas atomization, vacuum packaging, and high-purity control |

| Customization Capabilities | Small batch customization and alloy tweaking available |

| High Export Volumes | Well-established logistics and export compliance |

| Government Support | Strategic backing for powder metallurgy R&D and exports |

Specific Advantages for Nickel-Based Brazing Powder:

- Efficient large-scale gas atomization systems

- Availability of pre-alloyed and diffusion alloyed nickel powders

- Flexible MOQ conditions for pilot runs or custom batches

- Responsive technical support teams familiar with Western quality standards

Companies like Shanghai Truer Technology Co., Ltd. exemplify these strengths, offering both standardized and tailored powder solutions to meet the needs of global buyers.

8. Why Choose Shanghai Truer Technology Co., Ltd. as Your Supplier

Founded in 2009, Shanghai Truer Technology Co., Ltd. has evolved into one of China’s most trusted names in powder metallurgy and additive manufacturing. With a dedicated PM Additives Division established in 2019, Truer offers a comprehensive suite of products and services for industrial brazing, sintering, and 3D printing applications.

🔧 What Sets Truer Apart:

| Feature | Description |

|---|---|

| Full Powder Range | Ni-based, Fe-based, Cu-based, Stainless Steel, and hybrid PM alloys |

| Advanced Manufacturing | Gas atomized, water atomized, and reduction methods available |

| Certified Quality | ISO 9001-certified systems + internal QC lab |

| Application Expertise | Support for aerospace, automotive, HVAC, and more |

| Custom Alloy Development | Tailored brazing powder blends based on melting point, flow, and joint design |

| End-to-End Support | From powder to process consulting and logistics |

Powder Grades Available:

- Ni-B-Si-Cr and Ni-Cr-B-Fe custom formulations

- PM stainless steel powders (gas and water atomized)

- PM 4600, FN-5000, FD-0208, SBF2218, and more

- Soft magnetic additives like QH-150

- Advanced lubricants and cutting agents to optimize brazing and sintering processes

📌 For a full product listing and technical data, browse Truer’s PM Powder Catalog.

Industries Served:

- Aerospace & Aviation

- Automotive & EVs

- HVAC & Heat Exchangers

- Medical Devices

- Precision Tooling

By choosing Truer, B2B buyers can ensure material consistency, cost efficiency, and technical compatibility — all from a single, reliable supplier.

9. FAQs: Buying Wholesale Nickel-Based Brazing Powder

Below are some of the most common questions asked by procurement teams and engineering managers when sourcing nickel-based brazing powder in bulk:

❓ What is the Minimum Order Quantity (MOQ) for wholesale orders?

Shanghai Truer offers flexible MOQ options depending on the alloy type and customization needs. Standard orders typically start at 25–50 kg, with discounts for 500+ kg.

❓ Can I request a custom alloy composition?

Yes. Truer specializes in custom pre-alloyed and diffusion alloyed formulations tailored to your melting point, flow, and corrosion resistance requirements.

❓ What quality certifications does Shanghai Truer hold?

Truer is ISO 9001 certified and follows strict quality assurance protocols including batch traceability, sphericity testing, and chemical composition analysis.

❓ Do you ship internationally?

Absolutely. Truer exports to North America, Europe, and Southeast Asia with full documentation and ROHS/REACH-compliance options.

❓ How long is the lead time?

Lead times vary by alloy and volume. Standard powders are typically ready within 7–14 days, while custom batches may require 2–4 weeks.

❓ Are technical data sheets (TDS) and MSDS available?

Yes. All orders include comprehensive documentation including TDS, MSDS, and Certificate of Analysis (COA) upon request.

Embedded Internal Link:

Have more questions or need a custom quote? Contact us today to speak with a metallurgy expert or request a sample.

🔚 Final Notes & Call to Action

Nickel-based brazing powders are a vital component of modern manufacturing, offering strength, precision, and high-temperature performance. As industries evolve and demand tighter tolerances and cleaner joints, the role of advanced brazing materials will only grow.

Shanghai Truer Technology Co., Ltd. is ready to support your production goals with:

- A complete portfolio of nickel-based and hybrid brazing alloys

- Gas and water atomized options for optimal application compatibility

- A team of technical experts to guide material selection and application

- Competitive pricing and global delivery for bulk/wholesale buyers

📩 Don’t wait — request a quote or explore our full product catalog to get started.