1. Introduction: Why Kovar Powder Is Critical for Precision Industries

Kovar powder, an iron-nickel-cobalt alloy, is a staple material in industries that demand zero thermal expansion mismatch between metals and ceramics. It’s particularly critical in precision applications such as:

- Hermetic sealing of glass-to-metal or ceramic-to-metal components

- Aerospace and defense electronics

- Medical imaging devices and sensors

- Microelectronic packaging

This powder form is especially suited for powder metallurgy (PM) techniques and additive manufacturing (AM), allowing engineers to create high-performance components with tight tolerances and specialized geometries.

Why Kovar powder is in demand:

| Feature | Benefit |

|---|---|

| Controlled thermal expansion | Ideal for glass & ceramic interfaces |

| High dimensional stability | Enables precision manufacturing |

| Excellent mechanical strength | Withstands pressure and thermal cycles |

| Superior oxidation resistance | Enhances product lifespan in harsh environments |

| Compatible with PM and AM | Suited for powder injection molding and 3D printing |

Kovar powder’s popularity in B2B markets stems from its indispensable role in mission-critical applications. As industries increasingly adopt additive manufacturing and microfabrication, the demand for high-purity, consistent Kovar powder is rising globally.

2. Key Applications of Kovar Powder in Industrial Manufacturing

Kovar powder is used across various high-reliability sectors. Below are the main applications where this alloy is irreplaceable:

1. Electronics and Microelectronics

- Hermetic seals for integrated circuits (ICs)

- Headers for transistors and diodes

- Connectors and microelectronic substrates

2. Medical Devices

- MRI-compatible components

- X-ray tube parts

- Precision housings for sensors

3. Aerospace and Defense

- Avionic sensors and optical housings

- Missile guidance assemblies

- Satellite communication components

4. Telecommunications

- Sealed packages for fiber-optic components

- Housings for RF devices

- Transmitter and receiver modules

5. Additive Manufacturing and Powder Metallurgy (PM)

- Binder jetting and selective laser sintering (SLS)

- Injection molding of precision parts

- Complex geometries for thermal management systems

Benefits of Kovar Powder in PM and AM:

- Enhances design freedom for OEMs and system integrators

- Suitable for net-shape fabrication and miniaturization

- Reduces post-processing and machining costs

3. Properties and Performance Benefits of Kovar Alloy Powder

Kovar (ASTM F15) is composed of approximately 29% nickel, 17% cobalt, and the balance iron. Its unique coefficient of thermal expansion (CTE) makes it compatible with borosilicate glass and ceramics, making it indispensable in sealed systems.

Typical Composition of Kovar Powder:

| Element | Weight Percentage |

|---|---|

| Nickel (Ni) | ~29% |

| Cobalt (Co) | ~17% |

| Iron (Fe) | Balance |

| Others | <0.5% (Mn, Si) |

Key Physical and Mechanical Properties:

| Property | Value |

|---|---|

| Density | 8.36 g/cm³ |

| Thermal Expansion (20–400°C) | 4.6×10⁻⁶ /°C |

| Tensile Strength (annealed) | 517 MPa |

| Yield Strength | 276 MPa |

| Modulus of Elasticity | 138 GPa |

| Electrical Resistivity | 49 µΩ·cm |

Advantages in Manufacturing:

- Dimensional Accuracy: Ideal for tight-tolerance parts

- Thermal Matching: Prevents stress fractures in seals

- Oxidation Resistance: Maintains integrity in high-temp environments

- Weldability and Machinability: Easily integrated into complex assemblies

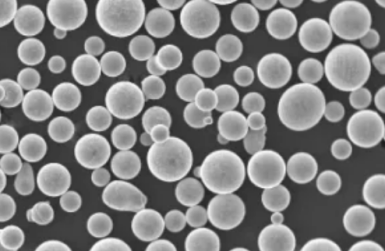

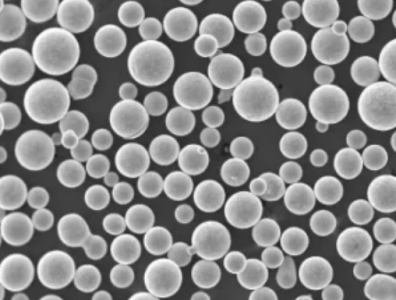

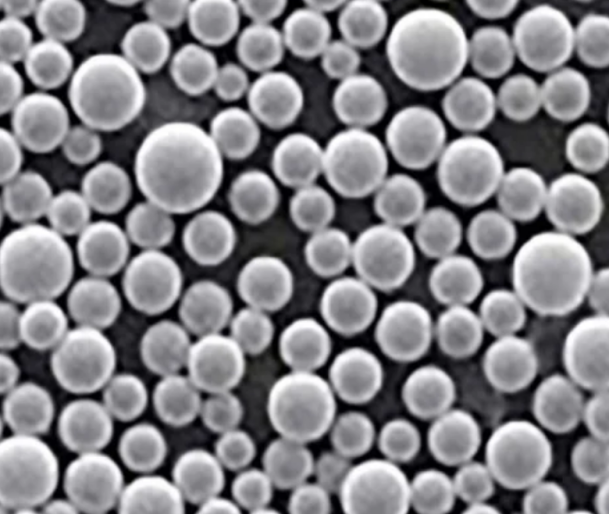

Shanghai Truer Technology Co., Ltd specializes in producing advanced powder metallurgy materials, including Kovar powder, tailored for additive manufacturing and PM. Their powders are offered in varying particle sizes, customized for binder jetting, laser sintering, and cold isostatic pressing.

Explore more about their full PM Powder product range engineered for high-performance applications.

4. Global Market Trends and Demand for Kovar Powder

The global demand for Kovar powder is steadily increasing, driven by the rapid growth in high-reliability electronics, aerospace technologies, and additive manufacturing (AM) applications. As industries push toward lighter, more compact, and thermally stable designs, Kovar’s unique properties make it indispensable.

Key Market Drivers:

- Miniaturization of Electronics: Shrinking device sizes require materials with dimensional stability like Kovar.

- Expansion of Additive Manufacturing: Aerospace and defense sectors are adopting metal 3D printing, boosting Kovar powder demand.

- Medical Imaging Innovation: MRI and X-ray equipment manufacturers require non-magnetic, thermally stable materials like Kovar.

- Telecom Infrastructure: Increased use of sealed fiber optic connectors and RF devices that depend on Kovar.

Kovar Powder Market Forecast (2024–2030):

| Region | CAGR (2024–2030) | Key Industries Driving Demand |

|---|---|---|

| North America | 6.5% | Aerospace, military, medical devices |

| Europe | 5.8% | Industrial electronics, automotive sensors |

| Asia-Pacific | 7.4% | Consumer electronics, telecom, 3D printing |

| Middle East/Africa | 4.9% | Defense electronics, infrastructure development |

Emerging Trend:

The combination of Kovar powder with binder jetting and selective laser sintering (SLS) is enabling OEMs to rapidly prototype and produce mission-critical parts with exceptional reliability.

5. How to Choose a Reliable Kovar Powder Supplier

Selecting a dependable Kovar powder supplier is crucial for manufacturers operating in precision-driven industries. Below are key criteria to evaluate:

1. Purity and Consistency of Powder

- Ensure the supplier offers high-purity Kovar powder with minimal contamination.

- Particle size distribution should meet your process needs (e.g., <45μm for SLS, <15μm for binder jetting).

2. Manufacturing Standards

- Compliance with international standards such as ASTM F15, ISO 9001, and RoHS.

- Availability of technical data sheets (TDS) and material safety data sheets (MSDS).

3. Customization Capabilities

- Can the supplier deliver customized particle sizes or compositions based on specific applications?

- Do they offer prealloyed or diffusion alloyed variants?

4. Logistics and Delivery

- Global shipping capabilities

- Short lead times and strong inventory management

5. Technical Support and Consultation

- Access to in-house metallurgists and engineers

- Post-sales support for process optimization

Checklist to Evaluate Kovar Powder Suppliers:

| Criteria | Truer Technology | Other Suppliers |

|---|---|---|

| High-purity powder available | ✅ | Varies |

| Custom particle sizes | ✅ | Limited |

| PM & AM compatibility | ✅ | Varies |

| In-house technical support | ✅ | Sometimes |

| Global logistics network | ✅ | Varies |

For more insights on how Shanghai Truer meets these standards, check out their About Us page.

6. Top Wholesale Kovar Powder Suppliers Globally

Below are some of the top international and Chinese suppliers of Kovar powder for B2B buyers, OEMs, and distributors.

| Supplier Name | Region | Key Features |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Wide range of PM/AM powders, custom specs, fast delivery |

| Höganäs AB | Sweden | Global metallurgical leader, large-scale production |

| Sandvik Osprey | UK | Gas atomized metal powders for AM |

| AMETEK Powder Metallurgy | USA | Specialty alloy powders for aerospace and electronics |

| CNPC Powder | China | Offers Kovar and other metal powders for AM |

Why Shanghai Truer Stands Out:

- Offers both water atomized and gas atomized Kovar powders

- Supports custom processing and application-specific solutions

- Strong reputation in Chinese powder metallurgy industry

- Comprehensive product portfolio including cutting agents, lubricants, and graphite additives

Shanghai Truer is well-positioned to serve global buyers with competitive pricing, consistent supply, and technical expertise. For a full list of available powders, explore their product catalog.

7. Why More Buyers Are Choosing Chinese Kovar Powder Manufacturers

China has become a leading source of high-performance metal powders, including Kovar, due to its robust manufacturing ecosystem, cost competitiveness, and rapid innovation in advanced materials.

Key Advantages of Sourcing from China:

- Lower Cost per Kilogram: Competitive pricing due to economies of scale

- Strong R&D: Many Chinese suppliers invest in custom alloy development

- Flexible MOQs: Ideal for both small-batch prototyping and large-scale manufacturing

- Speed: Shorter lead times and faster prototyping cycles

Why Shanghai Truer is a Preferred Choice:

- Established in 2009 with a strong foundation in materials engineering

- Began additive manufacturing business in 2019 to meet evolving market demands

- Offers a wide range of prealloyed and hybrid low-alloy powders for PM and AM

- Products include PM Bronze, PM Iron-Copper, PM Stainless Steel, and Kovar powder

Shanghai Truer also provides special additives such as SUW-5000B lubricants, SME-100 sulfur-free cutting agents, and QH-150 soft magnetic additives, making it a one-stop-shop for PM manufacturers.

To get in touch with their sales or technical team, visit the Contact Page and submit your inquiry.

8. How to Order Wholesale Kovar Powder from Shanghai Truer

Whether you’re a distributor, OEM, or precision component manufacturer, ordering Kovar powder in bulk from a trusted supplier like Shanghai Truer is a strategic move. Truer offers an efficient, transparent, and technically supported ordering process tailored for B2B clients.

Step-by-Step Ordering Process

- Initial Inquiry

- Visit the Contact Us page to fill out the inquiry form.

- Provide details such as:

- Required quantity (in kg or metric tons)

- Particle size distribution (e.g., D50 < 15μm, <45μm)

- Application method (e.g., SLS, binder jetting, PM)

- Delivery timeline and location

- Technical Consultation

- Truer’s in-house engineers review your requirements

- Material datasheets and sample specifications are shared

- Custom powder blends or atomization methods are discussed

- Quotation & Sample

- You receive a formal quotation including:

- Unit price per kg/ton

- Shipping options

- Lead time (usually 5–10 working days for standard powders)

- Optional: request a sample batch for testing

- You receive a formal quotation including:

- Purchase Order & Payment

- Confirm the order and submit your official PO

- Payment terms are typically T/T in advance, with options for long-term partners

- Production & Quality Assurance

- Powder is produced under ISO-certified processes

- Each batch is tested for:

- Chemical composition

- Particle size and morphology

- Flowability and apparent density

- COA (Certificate of Analysis) is issued with every shipment

- Shipping & Delivery

- Truer supports global shipping via air, sea, or express courier

- Standard packaging includes sealed drums or anti-static bags

- Custom labeling and export documentation are provided

Ordering Tips for B2B Buyers

- MOQ: Shanghai Truer offers flexible minimum order quantities depending on powder type and processing method

- Lead Time Optimization: For recurring orders, consider an annual supply agreement

- Custom Packaging Available: Anti-moisture, vacuum-sealed, and nitrogen-packed options are available

📌 For more details on available Kovar and other PM powders, browse the product selection page.

9. FAQs: Purchasing Kovar Powder in Bulk for Industrial Use

Q1: What is the minimum order quantity (MOQ) for Kovar powder?

A: MOQs vary depending on the particle size and grade. For standard Kovar powders, the MOQ typically starts from 10 kg.

Q2: Can Truer customize Kovar powder for additive manufacturing?

A: Yes. Shanghai Truer offers custom particle size distributions optimized for SLS, binder jetting, and cold spray processes.

Q3: Is the powder available in both gas and water atomized forms?

A: Yes. Truer manufactures Kovar powder using both gas and water atomization, depending on the required flowability and purity.

Q4: Does Truer provide certificates with each batch?

A: Absolutely. Each shipment includes a Certificate of Analysis (COA) detailing chemical composition, PSD, and density parameters.

Q5: Can I request a sample before placing a large order?

A: Yes, Truer offers sample batches (typically 500g–1kg) for testing and validation.

Q6: What industries commonly order Kovar powder from Truer?

A: Truer serves clients in:

- Aerospace and avionics

- Medical device manufacturing

- Microelectronics and telecom

- Advanced research institutions

Q7: Are there other alloy powders I can order from Truer?

A: Yes. Besides Kovar, Truer supplies:

- PM Bronze, PM Iron, PM Nickel Steel

- PM Stainless Steel (gas and water atomized)

- Diffusion alloyed steels like FD-0208, FL-4605

- Additives for PM such as QHP-330 graphite, SUW-5000B lubricants

📌 For more about Shanghai Truer’s background and technical capabilities, visit their About Us page.

Final Thoughts and Call to Action

Kovar powder is a mission-critical material for industries that demand unmatched thermal stability, strength, and compatibility with ceramics and glass. Whether you’re manufacturing hermetic seals, aerospace connectors, or precision sensors, the quality of your metal powder directly impacts performance and durability.

Why Choose Shanghai Truer Technology Co., Ltd?

✅ Over 15 years in powder metallurgy and additive manufacturing

✅ Full spectrum of PM and AM-compatible metal powders

✅ Custom sizes, atomization methods, and alloy compositions

✅ Fast global delivery and strong technical support

✅ Trusted by enterprises across aerospace, electronics, and medical sectors

If you’re looking to streamline your supply chain, reduce costs, and improve product reliability through premium Kovar powder, Shanghai Truer is your go-to partner.

📩 Ready to get started? Contact Us to request a quote or technical consultation today.