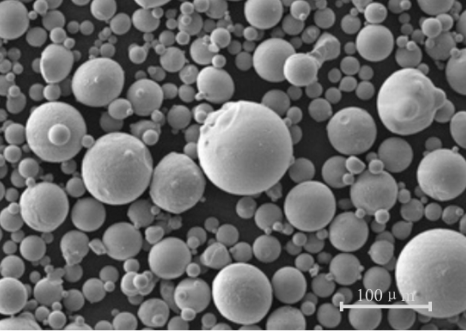

When it comes to cutting-edge materials and advanced manufacturing, fewer satellite particles powder stands out as a crucial component. But what exactly is it, and why should you care? Let’s dive into the fascinating world of fewer satellite particles powder, exploring its composition, characteristics, applications, and more.

Overview

Fewer satellite particles powder is a type of metal powder characterized by a reduced presence of smaller, secondary particles, commonly referred to as satellite particles. This unique feature enhances the powder’s performance in various industrial applications, particularly in additive manufacturing and high-precision coating processes.

Composition and Properties of Fewer Satellite Particles Powder

To fully appreciate the value of fewer satellite particles powder, it’s essential to understand its composition and properties. Here’s a breakdown of some popular models, including their specific compositions and properties.

| Model | Composition | Particle Size (µm) | Purity (%) | Density (g/cm³) | Characteristics |

|---|---|---|---|---|---|

| FSPP-01 | Ni-Cr Alloy | 15-45 | 99.9 | 8.9 | High strength, excellent corrosion resistance |

| FSPP-02 | Ti-6Al-4V | 20-60 | 99.5 | 4.43 | Lightweight, high tensile strength, biocompatible |

| FSPP-03 | Co-Cr Alloy | 10-50 | 99.8 | 8.3 | Superior wear resistance, excellent hardness |

| FSPP-04 | AlSi10Mg | 15-50 | 99.7 | 2.68 | High thermal conductivity, good strength-to-weight ratio |

| FSPP-05 | 316L Stainless Steel | 20-63 | 99.9 | 7.9 | Excellent corrosion resistance, good weldability |

| FSPP-06 | Inconel 718 | 15-53 | 99.6 | 8.19 | High temperature resistance, good mechanical properties |

| FSPP-07 | Copper Alloy | 10-45 | 99.95 | 8.96 | Excellent electrical conductivity, good thermal conductivity |

| FSPP-08 | Hastelloy X | 15-60 | 99.7 | 8.22 | Exceptional oxidation resistance, high strength at elevated temperatures |

| FSPP-09 | Tool Steel H13 | 10-45 | 99.8 | 7.8 | High toughness, good wear resistance |

| FSPP-10 | Tungsten Carbide | 5-25 | 99.9 | 15.6 | Extremely high hardness, good thermal and electrical conductivity |

Applications of Fewer Satellite Particles Powder

The applications of fewer satellite particles powder are diverse and span across various industries. Let’s take a look at how these powders are utilized in different fields.

| Application | Industry | Description |

|---|---|---|

| Additive Manufacturing | Aerospace, Automotive | Enables the production of high-precision, complex parts with enhanced mechanical properties. |

| Coating Processes | Medical, Industrial | Used in thermal spraying and other coating techniques for superior surface properties. |

| Metal Injection Molding | Consumer Goods, Electronics | Allows for the creation of intricate components with high strength and durability. |

| Powder Metallurgy | Engineering, Tooling | Facilitates the production of parts with uniform density and high performance. |

| Conductive Inks | Electronics, Solar Panels | Used in the formulation of conductive inks for electronic circuits and solar cells. |

| Thermal Management | Electronics, Automotive | Provides efficient thermal management solutions for electronic devices and automotive components. |

| High-Performance Alloys | Aerospace, Energy | Essential for manufacturing high-performance alloys with exceptional properties. |

Specifications, Sizes, Grades, and Standards

Understanding the specifications, sizes, grades, and standards of fewer satellite particles powder is crucial for selecting the right material for your application.

| Model | Particle Size (µm) | Grade | Standard |

|---|---|---|---|

| FSPP-01 | 15-45 | Aerospace Grade | ASTM F75 |

| FSPP-02 | 20-60 | Medical Grade | ASTM F2924 |

| FSPP-03 | 10-50 | Industrial Grade | ISO 5832-4 |

| FSPP-04 | 15-50 | Engineering Grade | DIN EN 1706 |

| FSPP-05 | 20-63 | Industrial Grade | ASTM A276 |

| FSPP-06 | 15-53 | Aerospace Grade | AMS 5662 |

| FSPP-07 | 10-45 | Electrical Grade | ASTM B152 |

| FSPP-08 | 15-60 | High-Temp Grade | ASTM B619 |

| FSPP-09 | 10-45 | Tool Grade | ASTM A681 |

| FSPP-10 | 5-25 | Industrial Grade | ISO 9001 |

Suppliers and Pricing Details

Finding reliable suppliers and understanding the pricing details for fewer satellite particles powder can make a significant difference in your project’s success.

| Supplier | Model | Price (per kg) | Contact Information |

|---|---|---|---|

| Metal Powders Inc. | FSPP-01 | $150 | www.metalpowders.com |

| Advanced Materials Co. | FSPP-02 | $200 | www.advancedmaterials.com |

| Precision Alloys Ltd. | FSPP-03 | $250 | www.precisionalloys.com |

| TechMetals Inc. | FSPP-04 | $100 | www.techmetals.com |

| Stainless Solutions | FSPP-05 | $180 | www.stainlesssolutions.com |

| High Temp Materials | FSPP-06 | $220 | www.hightempmaterials.com |

| Copper Specialists | FSPP-07 | $300 | www.copperspecialists.com |

| Heat Resistance Metals | FSPP-08 | $270 | www.heatresistancemetals.com |

| Tool Masters | FSPP-09 | $210 | www.toolmasters.com |

| Carbide Innovations | FSPP-10 | $350 | www.carbideinnovations.com |

Advantages and Limitations

Comparing the advantages and limitations of fewer satellite particles powder helps in making informed decisions for specific applications.

| Model | Advantages | Limitations |

|---|---|---|

| FSPP-01 | High strength, corrosion resistance | Higher cost compared to other alloys |

| FSPP-02 | Lightweight, high tensile strength, biocompatible | Difficult to machine |

| FSPP-03 | Superior wear resistance, excellent hardness | Brittleness under certain conditions |

| FSPP-04 | High thermal conductivity, good strength-to-weight ratio | Lower mechanical strength than some other alloys |

| FSPP-05 | Excellent corrosion resistance, good weldability | Susceptible to pitting in certain environments |

| FSPP-06 | High temperature resistance, good mechanical properties | Expensive and difficult to process |

| FSPP-07 | Excellent electrical conductivity, good thermal conductivity | Prone to oxidation in certain conditions |

| FSPP-08 | Exceptional oxidation resistance, high strength at elevated temperatures | Limited availability and high cost |

| FSPP-09 | High toughness, good wear resistance | Can be prone to cracking under thermal shock |

| FSPP-10 | Extremely high hardness, good thermal and electrical conductivity | Very difficult to machine and costly |

FAQ

What is fewer satellite particles powder?

Fewer satellite particles powder is a type of metal powder with a reduced presence of smaller, secondary particles, enhancing its performance in various applications.

Why is fewer satellite particles powder important in additive manufacturing?

The reduced presence of satellite particles improves the powder’s flowability and packing density, resulting in better mechanical properties and surface finish of the final product.

What are some common applications of fewer satellite particles powder?

It is commonly used in additive manufacturing, coating processes, metal injection molding, powder metallurgy, and the production of conductive inks.

How do I choose the right fewer satellite particles powder for my application?

Consider the composition, particle size, purity, and specific properties required for your application. Refer to the specifications and grades provided by suppliers.