1. Introduction to FeSiCr Powder and Its Industrial Importance

FeSiCr powder, an alloy composed of Iron (Fe), Silicon (Si), and Chromium (Cr), is a highly valued soft magnetic material in the field of powder metallurgy (PM) and additive manufacturing. With growing demand for energy-efficient motors, transformers, and electronic devices, FeSiCr offers a cost-effective and performance-optimized solution for manufacturers and B2B buyers across various sectors.

Why FeSiCr Powder is in Demand:

- Superior magnetic properties under high-frequency applications

- Excellent corrosion resistance due to chromium content

- Cost-effective alternative to pure iron or other high-end magnetic alloys

- Adaptable to various manufacturing techniques including Powder Metallurgy (PM) and Metal Injection Molding (MIM)

Target B2B Sectors:

- Automotive component manufacturers

- Electrical equipment suppliers

- Industrial motor and transformer OEMs

- Electronic device manufacturers

- Powder metallurgy part producers

B2B buyers are increasingly turning to FeSiCr for the balance it offers between performance, manufacturability, and price. The ability to tailor its composition for specific applications makes it a strategic material for OEMs and distributors alike.

2. Applications of FeSiCr Powder in Various Industries

FeSiCr is not a one-size-fits-all material. Its versatility allows it to be used across multiple sectors, particularly where soft magnetic properties and corrosion resistance are essential.

Key Industrial Applications:

| Industry | Application Area | Benefits of FeSiCr Use |

|---|---|---|

| Automotive | Electric motors, sensors, and actuators | High permeability, minimizes energy loss |

| Electrical Equipment | Transformers, inductors, relays | Enhances magnetic efficiency |

| Consumer Electronics | Magnetic shielding, EMI components | Compact and efficient |

| Aerospace | Navigation systems, sensors | Lightweight and corrosion-resistant |

| Industrial Equipment | Pumps, compressors, motor components | Durability and energy efficiency |

FeSiCr vs. Traditional Materials:

- Compared to pure iron: Better corrosion resistance and lower eddy current loss

- Compared to FeSi: Adds higher thermal stability and performance lifespan

- Compared to ferrites: Easier to form into complex geometries using PM methods

FeSiCr powder is particularly effective in designing compact, efficient magnetic components for next-generation electric and hybrid applications. The growing shift toward electrification in automotive and industrial sectors makes this alloy a top choice for procurement teams and R&D engineers.

3. Physical & Magnetic Properties of FeSiCr for B2B Use

When evaluating FeSiCr powder for industrial applications, understanding its key physical and magnetic properties is crucial for engineers, procurement managers, and wholesale buyers.

Typical Composition (Weight %):

| Element | Range (%) |

|---|---|

| Fe | Balance |

| Si | 3–6 |

| Cr | 5–10 |

Key Physical & Magnetic Properties:

| Property | Value Range | Industrial Benefit |

|---|---|---|

| Relative Permeability | 2000–6000 | Ensures high magnetic efficiency |

| Electrical Resistivity | 40–70 μΩ·cm | Reduces eddy current losses |

| Saturation Magnetization | 1.3–1.6 Tesla | Suitable for compact magnetic components |

| Coercivity | < 100 A/m | Enables rapid magnetization and demagnetization |

| Density | ~7.4 g/cm³ | Offers good mechanical strength |

| Corrosion Resistance | High (due to Cr) | Suitable for harsh or humid environments |

Why These Properties Matter to B2B Buyers:

- High permeability and low coercivity reduce energy losses in electrical systems

- High resistivity improves performance in high-frequency applications

- Corrosion resistance ensures long-term reliability and reduces maintenance costs

For businesses engaged in manufacturing of electric motors and inductive components, these properties translate to better product efficiency, longer lifecycle, and lower total cost of ownership.

🔗 Learn more about premium PM powders including FeSiCr by visiting our PM Powder Solutions Page

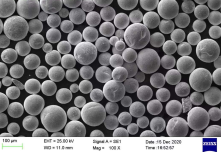

Shanghai Truer Technology Co., Ltd specializes in producing high-purity FeSiCr powder using advanced atomization techniques. Having served the additive manufacturing and PM industry since 2009, their reputation for consistent quality and technical support makes them a preferred supplier among B2B buyers globally.

4. Global Market Trends and Growth Potential of FeSiCr Powder

The FeSiCr powder market is experiencing rapid growth, driven by the global rise in energy-efficient technologies, electrification trends in the automotive industry, and the expansion of the smart grid and industrial automation sectors. For B2B buyers, distributors, and OEMs, understanding these trends is vital for strategic sourcing and long-term supply chain planning.

Key Market Drivers

| Market Driver | Description |

|---|---|

| Electrification of Transportation | Increased use of FeSiCr in EV motors and power electronics |

| Renewable Energy Expansion | Demand for magnetic cores in wind turbines, solar inverters, etc. |

| Growth of Consumer Electronics | Need for compact and efficient magnetic shielding materials |

| Industry 4.0 and Smart Manufacturing | Rise in demand for soft magnetic components in automation and robotics |

| Growth in Metal Additive Manufacturing (AM) | FeSiCr used in 3D-printed functional parts and prototyping |

Market Size and Forecast

According to recent industry reports:

- The global soft magnetic powder market is projected to exceed USD 4.5 billion by 2030, with FeSiCr being one of the fastest-growing segments.

- Asia-Pacific dominates the global market with over 45% market share, led by China, Japan, South Korea, and India.

- The CAGR for FeSiCr powder between 2023 and 2030 is expected to be around 7.8%, largely driven by B2B demand from the automotive and electrical sectors.

Investment Opportunities for Distributors and OEMs

- Bulk procurement programs: Strategic partnerships with PM powder suppliers can reduce costs.

- Private-label production: FeSiCr powder can be customized for OEMs under exclusive agreements.

- Regional distribution rights: Opportunity to act as regional agents or resellers for major Chinese suppliers like Shanghai Truer Technology Co., Ltd.

5. Key Criteria for Choosing a Reliable FeSiCr Powder Supplier

For B2B buyers, choosing the right FeSiCr powder supplier is not just about price—it’s about consistent quality, technical support, logistics efficiency, and long-term reliability. Below are the top criteria procurement professionals should consider:

1. Production Capabilities

- Does the supplier offer customized FeSiCr compositions?

- Are their powders produced using gas atomization, water atomization, or combined methods?

- Can they meet bulk order requirements consistently?

2. Quality Certifications

Ensure the supplier complies with:

- ISO 9001: Quality Management

- ISO 14001: Environmental Management

- RoHS and REACH compliance (especially for EU buyers)

3. R&D and Technical Support

- Does the supplier offer technical guidance for PM or AM applications?

- Can they assist in material selection and process optimization?

4. Logistics and Delivery

- Global shipping capabilities

- On-time delivery records

- Local warehousing or distributor partnerships

5. After-Sales Service

- Batch traceability

- Replacement or refund policies

- Dedicated B2B account management

Supplier Evaluation Checklist

| Criteria | Must-Have | Preferred | Optional |

|---|---|---|---|

| ISO Certification | ✔️ | ||

| Custom Composition | ✔️ | ||

| Technical Support | ✔️ | ||

| Global Shipping | ✔️ | ||

| MOQ Flexibility | ✔️ | ||

| Local Distributor Presence | ✔️ |

6. Top FeSiCr Powder Suppliers in China and Asia-Pacific

China is currently the global leader in the production of powder metallurgy materials, including FeSiCr powders. Here are some of the top suppliers in the region, known for serving B2B buyers, wholesalers, OEMs, and distributors:

1. Shanghai Truer Technology Co., Ltd

- Founded: 2009

- Specialization: Additive manufacturing powders and PM additives

- Strengths:

- Full control over production from powder making to quality testing

- Offers both gas and water atomized FeSiCr powders

- Customizable grades for electric motor, sensor, and transformer applications

- Learn more about Truer on their About Page

2. CNPC Powder Group

- Focus: Iron-based and soft magnetic powders

- Markets: Automotive, electronics, and industrial automation

- Strengths:

- Large-scale production facilities

- Global distribution network

3. Hunan Fushel Technology Ltd.

- Focus: Rare earth elements and magnetic alloy powders

- Strengths:

- Strong R&D partnerships with Chinese universities

- Offers specialty alloys including FeSiCr variants

4. Jinda Powder Metallurgy

- Specialization: Soft magnetic iron-based powders

- Markets: Industrial motors, transformers, and robotics

- Strengths:

- Competitive pricing for bulk orders

- Local warehousing support in South Asia

5. Hoganas (Asia-Pacific Division)

- Global player with regional manufacturing hubs

- Strengths:

- Premium-grade magnetic alloys

- Extensive R&D resources

✅ For detailed specifications, technical data sheets, and bulk pricing, check out Shanghai Truer’s PM Powder Product Page for FeSiCr and related magnetic materials.

Shanghai Truer Technology Co., Ltd stands out as a reliable partner for global B2B buyers. With a strong foundation in additive manufacturing and powder metallurgy, Truer offers highly customizable FeSiCr solutions backed by technical expertise and consistent quality.

7. Why More Buyers Are Switching to Chinese FeSiCr Manufacturers

In recent years, a noticeable shift has occurred in global sourcing behavior—more B2B buyers, especially from Europe, the U.S., and Southeast Asia, are turning to Chinese manufacturers for FeSiCr powder. This trend is driven by several competitive advantages offered by top-tier Chinese producers.

Key Reasons Behind the Shift

| Advantage | Description |

|---|---|

| Competitive Pricing | Chinese suppliers offer significantly lower prices without compromising quality |

| Advanced Manufacturing | Use of modern atomization and refining methods (gas, water, hybrid) |

| Customization Capabilities | Tailored FeSiCr compositions for niche industrial applications |

| Scalable Production | Ability to fulfill both small and large-volume orders |

| Strong Technical Support | In-house R&D teams, application engineers, and material scientists |

| Shorter Lead Times | Optimized logistics and flexible shipping options |

Case Study: Automotive Motor Supplier in Germany

A leading German electric motor manufacturer recently switched to Chinese FeSiCr powder for its new generation of EV motors. After evaluating multiple global suppliers, the company chose Shanghai Truer Technology Co., Ltd due to:

- Fast delivery of over 10 tons/month with consistent quality

- Technical support for sintering, pressing, and coating processes

- Custom composition designed to reduce eddy current loss by 18%

This case exemplifies how Chinese suppliers are not only price leaders but also innovation partners in high-performance applications.

Quality Assurance and Traceability

Modern Chinese FeSiCr manufacturers adhere to international quality standards and offer:

- Batch traceability reports

- COA (Certificate of Analysis) for every shipment

- RoHS and REACH-compliant materials

- Export documentation tailored to local customs regulations

For procurement teams and B2B buyers, these factors reduce risk and ensure compliance with internal and external quality protocols.

8. Why Choose Shanghai Truer Technology Co., Ltd for FeSiCr Supply

Shanghai Truer Technology Co., Ltd has emerged as a premier supplier of FeSiCr powder in the global powder metallurgy and additive manufacturing sectors. Here’s why Truer is the preferred choice for B2B buyers looking for reliable, high-performance FeSiCr products.

Company Overview

- Founded: 2009

- AM Division Established: 2019

- Specialties:

- High-quality 3D printing and PM powders

- Powder making equipment and end-to-end services

- Full range of soft magnetic and alloy powders

🔗 Explore more about Truer’s history and capabilities

FeSiCr Product Advantages

| Feature | Truer’s Offering |

|---|---|

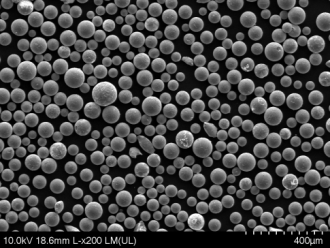

| Powder Grade Options | Customizable FeSiCr compositions for various use cases |

| Atomization Methods | Water, gas, or hybrid atomization based on application |

| Purity Level | High-purity input materials to ensure optimal magnetic performance |

| Granulometry Control | Narrow particle size distribution (PSD) to improve sintering or AM performance |

| Packaging | Anti-static, moisture-proof packaging for global shipping |

| MOQ Flexibility | Supports small R&D batches to full-scale mass production orders |

Technical Support & Additive Solutions

Truer doesn’t just sell powder; they deliver complete solutions. Their in-house R&D and application teams can assist with:

- Material selection for specific magnetic applications

- Optimization of pressing and sintering parameters

- Post-processing techniques including annealing and coating

- Troubleshooting production line integration

Global Reach and OEM Partnerships

Truer currently supplies to over 30 countries with clients in:

- Automotive (Tier 1 and Tier 2 suppliers)

- Consumer electronics

- Electrical and transformer OEMs

- 3D printing service providers

- Powder metallurgy parts manufacturers

Their commitment to long-term OEM partnerships makes Truer an ideal partner for businesses seeking stability, innovation, and scalable supply.

9. FAQs: Common Questions About Sourcing Wholesale FeSiCr Powder

Q1: What is the minimum order quantity (MOQ) for wholesale FeSiCr powder?

A: Shanghai Truer supports flexible MOQs, starting from 5kg for R&D purposes to over 1 ton/month for bulk industrial applications.

Q2: Can I request a custom FeSiCr composition?

A: Yes. Truer offers customizable FeSiCr compositions tailored to your specific magnetic, thermal, or corrosion resistance requirements.

Q3: What is the typical lead time for international orders?

A: Standard lead times range from 7–21 days, depending on quantity and customization. Expedited shipping options are available.

Q4: Is your FeSiCr powder compatible with 3D printing?

A: Yes. Truer provides gas-atomized FeSiCr powders suitable for binder jetting and selective laser sintering (SLS) applications.

Q5: How do I get technical support?

A: You can contact Truer’s technical team directly via their Contact Page. They offer consultation on powder selection, processing, and quality control.

Q6: Do you offer samples?

A: Yes. Sample quantities (100g–1kg) are available for testing and evaluation. Shipping costs may apply depending on location.

Q7: Can I become a distributor or regional agent?

A: Truer is actively seeking distribution partners worldwide. Inquire via their main website for partnership opportunities.

📦 Ready to source high-quality FeSiCr powder? Visit our PM Powder Product Page to request a quote or speak with our experts.

Embedded Internal Links Summary (5 Anchor Texts):

- PM Powder Product Page – linked under product details and ordering section

- About Page – linked under company profile

- Contact Page – linked in FAQs for technical support

- Main Website – linked in partnership and distributor inquiry section

- PM Powder Product Page – repeated as final CTA for sourcing

This comprehensive guide is designed to help B2B buyers, distributors, and OEMs make informed decisions about FeSiCr sourcing. From technical specifications and supplier evaluation to market trends and ordering steps, you now have a complete roadmap.

For direct inquiries or personalized quotes, contact Shanghai Truer Technology Co., Ltd—your trusted partner in FeSiCr and powder metallurgy innovation.