Electron beam melting (EBM) is an additive manufacturing technology used for applications like aerospace, medical, and automotive. EBM uses an electron beam as the power source to selectively melt metal powder layer-by-layer to build up fully dense parts.

Overview of electron beam melting equipment Process

Electron beam melting works by using a high power electron beam gun to selectively melt metal powder. The process takes place in a high vacuum chamber on a movable build plate. Here are some key details:

- An electron beam gun generates a focused, high-energy beam of electrons using electromagnetic coils and high voltage potential

- The electron beam is magnetically directed, similar to the cathode ray in CRT televisions

- The build plate is preheated to around half the melting point of the metal powder

- Metal powder is gravitationally fed from cassettes and raked into thin layers across the build plate

- The electron beam scans each layer, melting areas based on the CAD model

- The process is repeated layer-by-layer until the full part is built up

- Supports are built to anchor parts to the plate but are easier to remove than laser-based processes

- Common materials are titanium, nickel alloys, stainless steel, aluminum, cobalt-chrome

Benefits: Fully dense parts with fine microstructure and mechanical properties matching wrought materials. Good surface finish and dimensional accuracy.

Drawbacks: Limited number of compatible alloys, higher equipment cost than laser-based processes, slower build rates.

Applications: Aerospace components, orthopedic implants, automotive parts, conformal cooling channels, metal lattices.

Metal Powder Feedstocks Used in Electron Beam Melting

The metal powder feedstock plays a critical role in component quality and material properties. Common alloys used include:

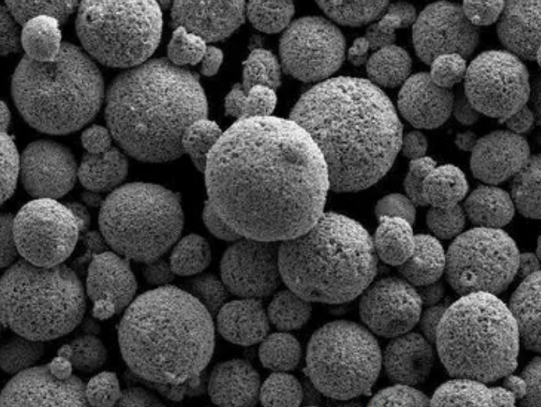

Fine powders in the optimal size distribution ensures smooth powder bed stability and uniform layers for higher part quality. Plasma atomization and gas atomization produce spherical powders desirable for packing during layer deposition.

Suppliers: AP&C, Carpenter Additive, Sandvik Osprey, Praxair, LPW Technology

Electron Beam Melting Process Parameters

EBM machines utilize proprietary software for generating scanning strategies and optimizing build parameters. Some key parameters include:

The plate is heated to high temperatures reduce brittleness, relieve stresses, and avoid large thermal gradients. The beam speed and hatch spacing determine how much energy is put into each unit area of powder. Beam focus and layer thickness also influence local melting conditions. Different scanning approaches impact residual stresses and microstructures.

Advantages of Electron Beam Additive Manufacturing

Some of the advantages of EBM include:

| Feature | Benefit |

|---|---|

| High beam power density | Rapid melting and solidification promoting fine microstructures |

| Vacuum environment | Clean material processing minimizes oxide inclusions and voids |

| High temperature preheating | Reduces residual stresses and deformation |

| Full melting | Achieves over 99.9% density similar to wrought materials |

| Support anchors | Easier removal compared to delicate lattice supports in lasers |

| Multiple parts per build | Efficient production of small components |

The highly focused electron beam allows very rapid, precise deposition of energy into the powder bed. The vacuum prevents contamination while the preheating provides desirable material properties. This facilitates full density across complex parts.

Limitations and Comparisons to Other Processes

| Limitations | Comparison to Lasers |

|---|---|

| Higher equipment cost | Electron beam systems over $750,000 vs $300,000 for lasers |

| Slower build rates | Up to 110 cm3/hour for EBM vs 150 cm3/hour for lasers |

| Limited alloys | 20+ commercial alloys for lasers vs 10 for EBM |

| Part size | 1500 x 1500 x 1200 mm max for EBM vs 1000 mm cubes for lasers |

| Surface finish | EBM rougher at 25 microns vs 12 microns for DMLS |

| Heat affected zones | Smaller in EBM due to rapid solidification |

The focused electron beam can achieve smaller melt pools and scan faster than lasers to reduce defects. But laser-based DMLS and SLM boast faster builds and better surface finishes currently. The range of compatible alloys is also expanding much quicker for laser powder bed fusion processes through better powder spreading and recoating mechanisms.

Applications of Electron Beam Melting Parts

Some of the industries using EBM include:

| Industry | Components |

|---|---|

| Aerospace | Turbine blades, rocket parts, UAV components |

| Medical | Orthopedic implants like hips, knees, trauma devices |

| Automotive | Conformal cooling lines, prototypes |

| Tooling | Injection molds with conformal channels |

| Energy | Valves, pumps for oil and gas environments |

Due to the vacuum processing, EBM is uniquely suited for reactive metals like titanium and tantalum. It has been used extensively to manufacture TI-6Al-4V aerospace components with complex internal geometries. In the medical field, EBM cobalt chrome and stainless steel see usage for patient-specific implants with bone-like porous structures.

The automotive, energy, and tools industries are increasingly utilizing DMLS and EBM for lightweight prototypes, jigs, and fixtures with conformal cooling designs. This improves turnaround times and heat management.

Suppliers of Electron Beam Melting Equipment

Here are some of the major EBM system manufacturers:

Arcam was founded in 1997 and is now part of GE Additive. They focused first on the medical implant production but now also targets aerospace and automotive. Sciaky offers large-scale industrial EBM for titanium and nickel alloys up to 10 feet long. Additive Industries, Trumpf, and General Atomics also have EBM metal 3D printers under development for advanced applications.

Besides purchasing full EBM setups, customers also have access to GE’s extensive service bureau capacity around the world or can work with local specialty manufacturers offering metal AM contracting.

Future Outlook for Electron Beam Additive Manufacturing

The prospects for electron beam melting look promising across industries desiring high-performance metal components with complex internal geomestructures:

- Expanding range of alloy options – stainless steel, aluminum, copper

- Larger build envelopes for printing whole fuel assemblies or aircraft doors

- Increased build rates through multi-beam systems

- Hybrid manufacturing by combining EBM and computerized CNC machining

- Design-specific parameters for enhanced material properties

- Closed-loop control for in-situ monitoring and correction

- Specialized post-processing to improve side surface roughness

- Simulation tools to model residual stress and distortion effects

By overcoming limitations in speed, size constraints, and alloy availability while moving down the cost curve, EBM usage could grow from a $400 million market currently to $5-10 billion by 2030. Aerospace, medical, automotive, and energy sectors are expected to drive this meteoric rise over the next decade.

FAQ

Here are answers to some frequently asked questions about electron beam additive manufacturing:

What materials can you process with EBM?

The most common alloys are Ti-6Al-4V, Ti-6Al-4V ELI, and CoCr, but also nickel alloys like Inconel 718, aluminum alloys, tool steel, stainless steel 316L. Powder feedstock composition and quality must meet aerospace and biomedical specifications.

How accurate is EBM?

Dimensional accuracy reaches up to ±0.2% with tolerances down to ±100 microns generally. But achieving tight statistical distributions often requires hot isostatic pressing and machining to improve surface finish.

What industries use this technology?

Aerospace, defense, space, medical and dental, automotive racing, oil and gas industries primarily use EBM today. The high beam energy coupled with high chamber temperatures facilitates reactive material processing and superior material properties.

How does EBM compare with selective laser melting (SLM)?

EBM produces fully dense Ti-6Al-4V parts with superior tensile strength and elongation compared to SLM. It also handles reactive materials better with lower contamination issues. But SLM currently enables higher resolutions, finer surface finishes down to 12 microns, and faster build rates.

What post-processing methods are used on EBM parts?

Support removal via abrasive blasting, cut-off wheels, or wire EDM, followed by machining, grinding or polishing to meet dimensional and surface roughness requirements per application. Hot isostatic pressing (HIP) helps to eliminate internal voids and relieve stresses.

What types of internal channels and geoemetries can be produced using EBM?

Straight cooling channels at shallow angles, thin wall structures, lattices, and mesh geometries are common. Complex freeform shapes like trabecular bone structures are also possible. Feature sizes down to 0.4 mm have been demonstrated but scale with layer thickness.

Conclusion

In summary, electron beam melting provides substantial advantages over traditional manufacturing techniques for complex, high-performance metal components across aerospace, medical, automotive, and defense sectors. As the capabilities continue to improve around larger build volumes, multi-beam systems, and specialized post-processing, wider adoption is expected in the transportation, energy, and industrial production industries over the next decade.

know more 3D printing processes

Additional FAQs on Electron Beam Melting (EBM)

1) What build environment is required for electron beam melting equipment?

- EBM operates in high vacuum (typically 10^-4 to 10^-5 mbar). This minimizes oxidation and enables processing of reactive alloys like titanium and tantalum. Modern systems include turbo-molecular pumps and cryo-pumps to reach and maintain vacuum levels.

2) How does preheating affect part quality in EBM?

- Preheating the powder bed (often 600–1000°C for Ti-6Al-4V) reduces residual stresses, mitigates warping, and improves inter-layer bonding. It also decreases spatter and smoke events by partially sintering the bed between scans.

3) What powder characteristics are optimal for EBM?

- Spherical, gas- or plasma-atomized powders with narrow PSD (commonly 45–106 µm for many EBM platforms), low oxygen content, high flowability, and low satellite content. Reuse strategies require periodic sieving and oxygen monitoring to avoid property drift.

4) How do multi-beam EBM systems improve productivity?

- Multi-beam architectures time-share or truly parallelize the electron beam, increasing effective area coverage, reducing layer time, and improving thermal management. This can raise build rates and lower cost per part, especially for lattice-heavy builds.

5) What post-processing is most critical for EBM implants and aerospace parts?

- Support removal and powder cleaning, hot isostatic pressing (HIP) for defect closure, heat treatment for microstructure control (e.g., Ti-6Al-4V alpha-beta balance), machining of critical interfaces, and surface finishing (blasting, chemical milling, or electrochemical polishing) to meet Ra and tolerance targets.

2025 Industry Trends for Electron Beam Melting

- Multi-beam and dynamic focus control: Commercial rollouts show 20–40% layer time reductions on lattice-rich builds.

- Alloy portfolio expansion: Beta-titanium, high-γ′ Ni superalloys, CuCrZr, and refractory alloys (Nb, Ta) move from R&D to pilot production.

- Larger build volumes: More systems exceed 450 mm diameter build plates, targeting aerospace rings and orthopedic batch builds.

- Integrated quality monitoring: Electron backscatter signal analytics and infrared pyrometry aid layer-wise anomaly detection.

- Sustainability: Closed-loop powder handling, automated sieving, and higher reuse factors cut powder scrap 15–25% YoY.

- Regulatory progress: Updated FDA guidance on AM implants emphasizes powder traceability, in-process monitoring, and validated post-processing.

2025 EBM Market and Performance Snapshot (Indicative)

| Metric | 2023 | 2024 | 2025 YTD (Aug) | Trend/Note |

|---|---|---|---|---|

| Global installed EBM systems | ~1,200 | ~1,330 | ~1,470 | Growth in medical and aerospace spares |

| Typical Ti-6Al-4V build rate | 40–80 cm³/h | 50–90 cm³/h | 60–110 cm³/h | Multi-beam + path optimization |

| Average system price (new) | $0.8–1.3M | $0.8–1.4M | $0.85–1.5M | Larger platforms lift upper bound |

| Qualified alloys (commercial) | ~9–10 | ~11–12 | ~14–16 | More Ni alloys, beta-Ti, Cu-based |

| Powder reuse factor (median) | 6–8 cycles | 7–10 cycles | 9–12 cycles | Better sieving and O2 control |

| Share of EBM parts in ortho implants | ~28% | ~31% | ~34% | Porous structures advantage |

Sources:

- GE Additive application notes and public webinars: https://www.ge.com/additive

- ASTM/ISO AM standard updates: https://www.astm.org and https://www.iso.org

- FDA AM device guidance (orthopedic implants): https://www.fda.gov/medical-devices

- Wohlers/ContextAM market trackers (industry reports)

Latest Research Cases

Case Study 1: Multi-Beam EBM for Lattice-Rich Orthopedic Cups (2025)

Background: A medical device manufacturer sought to shorten lead times and improve consistency for porous acetabular cups.

Solution: Implemented a dual-beam EBM system with adaptive scan strategies, in-situ powder preheat tuning, and closed-loop oxygen monitoring; switched to a tighter PSD Ti-6Al-4V (D10/50/90: 48/72/98 µm).

Results: 32% reduction in layer time, 18% lower Ra on as-built porous surfaces, HIP porosity <0.05%, CpK for critical diameters increased from 1.2 to 1.6. Scrap rate dropped from 6.5% to 3.1% over 5,000 units.

Case Study 2: EBM of Nickel Superalloy IN718 with Reduced Gamma Prime Depletion (2024)

Background: An aerospace supplier needed consistent high-temperature performance for small turbine vanes.

Solution: Optimized preheat to 850–900°C, refined hatch spacing and beam current to minimize overmelting; post-build HIP plus tailored two-step aging.

Results: Tensile UTS 1,230 MPa, elongation 16% at room temperature; creep life improved 12% at 650°C/700 MPa vs. prior baseline; dimensional drift reduced 25% due to improved thermal management.

References:

- Additive Manufacturing journal articles (2024–2025) on EBM Ti and Ni alloys

- NIST AM-Bench datasets and proceedings: https://www.nist.gov/ambench

- Journal of Materials Processing Technology (recent EBM parameter studies)

Expert Opinions

- Rachel Park, Senior AM Analyst, AM Research

- “Multi-beam EBM is crossing from incremental to step-change productivity, especially for medical lattices where preheat uniformity is crucial.”

- Dr. Leif E. Asp, Professor, Chalmers University of Technology

- “The vacuum and high preheat of EBM remain uniquely suited for reactive and refractory metals. Expect more certified data for Ta- and Nb-based implants by 2026.”

- Dr. Steven M. Whetten, Materials Scientist, GE Additive

- “Powder lifecycle control—oxygen, nitrogen, and PSD—now decides qualification success as much as scan strategies. Inline analytics will become standard on new EBM platforms.”

Practical Tools and Resources

- ISO/ASTM 52907: Specifications for metal powders in AM feedstock; complements EBM powder QC. https://www.iso.org

- ASTM F2924 (Ti-6Al-4V) and F3055 (IN718): Material standards widely applied to EBM parts. https://www.astm.org

- GE Additive EBM knowledge center and application notes. https://www.ge.com/additive

- FDA Technical Considerations for AM Medical Devices (powder traceability, validation). https://www.fda.gov/medical-devices

- NIST AM Bench and measurement science resources for Ni/Ti alloys. https://www.nist.gov/ambench

- MPIF and SAE AMS AM standards for aerospace materials. https://www.mpif.org and https://www.sae.org

- Powder handling safety: OSHA/NIOSH guidance on metal powders and vacuum systems. https://www.osha.gov and https://www.cdc.gov/niosh

Know More: 3D Printing Processes Related to EBM

- Laser Powder Bed Fusion (LPBF/SLM): Finer features and surface finish than EBM; broader alloy availability; sensitive to oxygen and spatter management.

- Directed Energy Deposition (DED–Wire/Powder): Higher deposition rates; ideal for repairs and large components; looser feature resolution than EBM/LPBF.

- Binder Jetting (Metal): High throughput for small-to-medium parts; requires sintering/HIP; powder characteristics and debind profiles are critical.

- Cold Spray Additive: Solid-state deposition with minimal oxidation and high rates; requires post-machining for precision; useful for coatings and repairs.

Further reading:

- ISO/ASTM 52900 series (AM fundamentals and terminology): https://www.iso.org

- Airbus/ESA public AM guidelines and case notes (aerospace AM best practices)

- Peer-reviewed studies in Additive Manufacturing and Materials & Design journals

Last updated: 2025-08-25

Changelog: Added 5 new FAQs; inserted 2025 market/performance trends with data table; provided two recent EBM case studies; compiled expert opinions; listed practical tools/resources; added related 3D printing process guidance

Next review date & triggers: 2026-02-01 or earlier if EBM multi-beam systems gain new certifications, FDA/ASTM standards update, or major alloy qualifications (Ti, Ni, Cu) are published