1. Introduction: Why CZ-3000 Powder Matters in Powder Metallurgy

CZ-3000 is a high-performance copper-zinc alloy powder engineered specifically for powder metallurgy (PM) applications. Known for its exceptional machinability, thermal conductivity, and corrosion resistance, CZ-3000 is widely used in manufacturing electrical contacts, bushings, structural parts, and fittings.

In the competitive world of metal part production, B2B buyers — including manufacturers, wholesalers, and industrial engineers — are looking for reliable, high-performance powders that offer:

- Consistent particle size distribution

- Excellent green strength and sinterability

- Low impurity levels

- Competitive cost for bulk purchasing

CZ-3000 meets all these requirements, making it a favored choice in the PM industry. Whether you’re a distributor seeking large-volume orders or an OEM sourcing materials for precision components, CZ-3000 offers the right mix of performance and value.

2. Industrial Applications of CZ-3000 Powder

CZ-3000, a specialized PM-grade brass powder (Cu-Zn), finds applications across multiple high-demand industries. Below are the sectors where CZ-3000 is gaining traction:

| Industry | Application | Benefits of CZ-3000 |

|---|---|---|

| Automotive | Bushings, Bearings, Gears | Low friction, wear resistance |

| Electronics | Electrical contacts, terminals | Conductivity, corrosion resistance |

| Industrial Machinery | Fittings, couplings, gear components | Dimensional accuracy, machinability |

| Consumer Appliances | Structural parts, handles, knobs | Aesthetic finish, anti-corrosive properties |

| Aerospace | Lightweight connectors, fastening systems | Strength-to-weight ratio, reliability |

Key Use-Case Highlights:

- Bushings & Bearings: Due to its superior wear resistance and self-lubricating potential when combined with oil impregnation, CZ-3000 is widely used in the production of PM bushings.

- Electrical Terminals: The powder’s excellent conductivity and corrosion resistance make it ideal for small electrical components.

- Structural Components: Its mechanical strength and ability to be sintered into complex shapes make CZ-3000 suitable for load-bearing parts.

These applications underline the critical role of CZ-3000 in precision engineering and high-volume manufacturing.

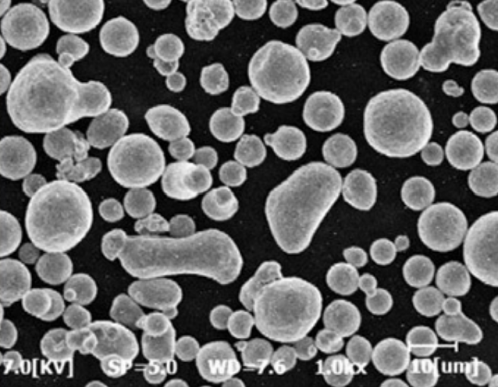

3. Key Properties and Use Cases of CZ-3000

CZ-3000 powder is specifically engineered to deliver superior performance in powder metallurgy processes. Below are its key technical properties:

Physical & Chemical Properties

| Property | Value Range |

|---|---|

| Composition | Cu: 70-85%, Zn: 15-30% |

| Particle Size Distribution | 25–150 μm (typical) |

| Apparent Density | 2.5–3.2 g/cm³ |

| Flow Rate (Hall Flow) | 20–30 s/50g |

| Sintering Temperature | 750–850°C |

| Green Strength | High |

| Compressibility | Excellent |

Powder Processing Benefits

- High Sintering Yield: Ensures better density and mechanical strength in final components.

- Machinability: Enables complex part designs with lower tool wear.

- Corrosion Resistance: Ideal for parts exposed to moisture or chemicals.

- Dimensional Accuracy: Suitable for high-precision engineering needs.

Common Use Cases by Industry

- OEM Manufacturers: Use CZ-3000 for producing high-volume mechanical parts with tight tolerances.

- Distributors: Sell CZ-3000 to regional PM part producers and automotive suppliers.

- E-commerce Sellers: Offer CZ-3000 in smaller packages for prototyping and R&D purposes.

- Industrial Wholesalers: Support contract manufacturers with bulk deliveries.

For a complete list of available PM powders for various applications, explore our Powder Metallurgy Powder Inventory.

4. Global Market Trends and Growth for PM Copper-Zinc Alloy Powders

The global demand for copper-zinc alloy powders like CZ-3000 is rapidly growing, driven by their increased use in automotive, electronics, and machinery manufacturing. According to recent market research, the powder metallurgy (PM) industry is projected to grow at a CAGR of 7.5% from 2024 to 2030, with copper-base alloy powders contributing a significant share.

Key Market Drivers

- Increased Automotive Production: As vehicle production rebounds globally, demand for PM parts like bushings and gears made from CZ-3000 is increasing.

- Miniaturization in Electronics: The need for compact, high-performance components drives demand for precision PM parts.

- Sustainability Push: CZ-3000 offers recyclability and energy-saving production benefits, aligning with green manufacturing initiatives.

- Cost Efficiency: PM processes using CZ-3000 reduce material waste and machining time, appealing to OEMs and Tier 1 suppliers.

Global Demand by Region

| Region | CAGR (2024–2030) | Key Applications |

|---|---|---|

| Asia-Pacific | 8.2% | Automotive, electronics, machinery |

| Europe | 6.9% | Aerospace, green energy, EVs |

| North America | 6.5% | Automotive, industrial tooling |

| Latin America | 5.8% | Electrical, mining equipment |

| Middle East | 4.9% | Oil & gas, infrastructure |

Industry Trends Impacting CZ-3000 Usage

- Custom Alloy Development: Growing preference for tailored PM alloys for specific end-use applications.

- Hybrid Manufacturing: Integration of PM parts with 3D printing components in high-precision industries.

- Localized Supply Chains: Demand for regional sourcing to reduce lead times and tariffs.

CZ-3000 stands out as a cost-effective, high-performance solution that aligns with these global trends. As more manufacturers shift to PM technologies, the relevance of CZ-3000 in bulk procurement and OEM production continues to rise.

5. Top Factors to Evaluate When Selecting a CZ-3000 Powder Supplier

Selecting the right CZ-3000 supplier is critical for product consistency, manufacturing efficiency, and cost control. Below are the key factors that B2B buyers should evaluate before entering into supply contracts:

1. Product Quality & Consistency

- Is the CZ-3000 powder within standard Cu-Zn content tolerances?

- Does the supplier provide a certificate of analysis (COA) for each lot?

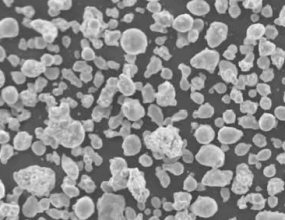

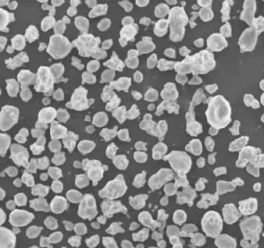

- Are the powders produced using water atomized, gas atomized, or reduction methods?

2. Manufacturing Capabilities

- Does the supplier have in-house atomization and blending facilities?

- Are they capable of tailoring particle size distribution and flow rate?

3. Logistics and Lead Time

- Can the supplier meet your delivery timelines across international markets?

- Do they have warehousing/distribution hubs in your region?

4. Technical Support

- Does the supplier offer post-sales technical consultation?

- Can they assist with powder selection based on your part geometry and sintering needs?

5. Pricing and MOQ (Minimum Order Quantity)

- Are bulk discounts available for high-volume contracts?

- What are the MOQs for repeat and custom orders?

6. Compliance and Certifications

- ISO 9001 certification or equivalent?

- REACH, RoHS, and other regional compliance for electronics or automotive applications?

A reliable supplier like Shanghai Truer Technology Co., Ltd. offers detailed technical support, consistent quality, and customized solutions — making it an ideal partner for industrial buyers and distributors.

6. Leading CZ-3000 Powder Suppliers in Asia and Europe

To help buyers make informed sourcing decisions, below is a list of some of the top CZ-3000 powder suppliers globally, with a focus on Asia and Europe — the two leading regions for PM powder production.

Top Asian Suppliers

| Company | Location | Key Advantages |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Full-spectrum PM powders, custom blends |

| Fukuda Metal Foil & Powder | Japan | High-purity copper alloys |

| CNPC Powder Material Co., Ltd. | China | Large-scale production, R&D capabilities |

Top European Suppliers

| Company | Location | Key Advantages |

|---|---|---|

| Höganäs AB | Sweden | Global PM leader, extensive R&D |

| GKN Hoeganaes Corporation | Germany | Automotive-grade materials |

| ECKA Granules | Germany | Wide range of non-ferrous PM powders |

Why Shanghai Truer Stands Out

While global suppliers offer CZ-3000, Shanghai Truer Technology differentiates itself through:

- Diverse production methods: water atomized, gas atomized, carbonyl

- Customization: tailored particle size and blends for specific applications

- Additive expertise: PM additives, lubricants, and cutting agents

With a strong track record in the Chinese and international PM industry, Truer is trusted by manufacturers seeking long-term, cost-efficient powder sourcing solutions. Learn more about their full capabilities on the Shanghai Truer homepage.

7. Why More B2B Buyers Are Switching to Chinese Manufacturers

In recent years, B2B buyers around the globe—especially from Europe, North America, and Southeast Asia—have increasingly turned to Chinese manufacturers for sourcing metal powders like CZ-3000. This shift is not merely about cost savings; it’s about finding high-quality, scalable, and technologically advanced partners.

Key Reasons for the Shift

1. Competitive Pricing at Scale

- Chinese suppliers like Shanghai Truer Technology offer significant cost advantages due to efficient production processes and local raw material access.

- Lower overhead and labor costs contribute to reduced per-kilogram pricing for CZ-3000 powder without compromising quality.

2. Advanced Manufacturing Capabilities

- China has heavily invested in PM and additive manufacturing technologies.

- Suppliers provide options such as gas atomization, water atomization, and hybrid methods to suit diverse industrial needs.

3. Customization and Flexibility

- Chinese suppliers offer greater flexibility in particle size distribution, packaging formats, and additive ratios.

- Custom alloy development is faster and more cost-effective, making it ideal for OEMs testing new product lines.

4. Shorter Lead Times to Asia-Pacific and Emerging Markets

- Proximity to Southeast Asia and India allows faster delivery via major ports such as Shanghai and Shenzhen.

- Regional distributors benefit from reduced freight costs and shorter inventory cycles.

5. Strong Export Experience

- Leading Chinese exporters, such as Truer, have extensive experience with international shipping, documentation (COO, MSDS, COA), and regulatory compliance.

| Feature | Traditional Western Supplier | Leading Chinese Supplier (e.g., Truer) |

|---|---|---|

| Price per kg (bulk order) | $15–$20 | $10–$14 |

| MOQ | 1 ton | 500 kg |

| Delivery Time | 3–5 weeks | 2–3 weeks |

| Custom Alloy Options | Limited | Extensive |

| Technical Support | Standard | Dedicated English-speaking engineers |

When cost, speed, and customization matter, Chinese manufacturers have become the go-to choice for many global B2B buyers. It’s not just a trend—it’s a supply chain evolution.

8. Why Choose Shanghai Truer Technology as Your CZ-3000 Powder Supplier

Shanghai Truer Technology Co., Ltd., founded in 2009, is one of the most recognized names in China’s powder metallurgy (PM) industry. Since expanding into additive manufacturing in 2019, Truer has solidified its position as a full-spectrum PM powder solution provider for global B2B clients.

What Sets Truer Apart?

✔ Comprehensive Product Portfolio

- CZ-1000 and CZ-3000 brass powder (Cu-Zn alloy)

- PM bronze, PM nickel silver, PM iron and steel powders

- Hybrid low-alloy and prealloyed powders (FD-0208, FL-4605, FX-2008, etc.)

✔ Flexible Production Techniques

- Water atomized, gas atomized, and carbonyl powders

- Combined atomization methods for precise particle control

- Tailored solutions for particle size, flow rate, and apparent density

✔ Additive Expertise

- Industry-leading PM additives: lubricants (Lube-W, SUW-8000), cutting agents (TD-8, SME-100), and soft magnetic additives (QH-150)

- Compatible with CZ-3000 to enhance green strength, machinability, and sinterability

✔ Global Supply Chain and Support

- Export-ready with ISO certifications and compliance documentation

- Technical teams fluent in English, offering pre-sales and post-sales assistance

- Fast delivery across Asia, EU, and North America

Success Cases

- Automotive Tier 1 Supplier in Germany: Reduced manufacturing waste by 12% using Truer’s CZ-3000 with customized additives

- Consumer Electronics OEM in Malaysia: Improved production speed by 25% through optimized powder flow rate and sintering profile

- Industrial Machinery Exporter in Brazil: Switched from European supplier to Truer, saving $60,000 annually on powder procurement

To learn more about Truer’s company background and R&D capabilities, visit their About Us page.

9. FAQs: Everything Buyers Need to Know About CZ-3000 Powder Wholesale

Q1: What is the typical composition of CZ-3000 powder?

A: CZ-3000 is a copper-zinc alloy powder typically composed of 70–85% copper and 15–30% zinc. It is optimized for PM processes.

Q2: What PM methods is CZ-3000 compatible with?

A: CZ-3000 is suitable for cold compaction, sintering, and warm compaction. It can also be used in hybrid manufacturing environments combining PM with 3D printing.

Q3: What packaging options are available for bulk buyers?

A: Standard packaging is 25 kg vacuum-sealed bags or 1-ton jumbo bags. Custom packaging is available upon request.

Q4: Can CZ-3000 be customized for different particle sizes?

A: Yes. Shanghai Truer offers customization between 25–150 μm, based on your application needs (e.g., bushings, terminals, gears).

Q5: What is the minimum order quantity (MOQ)?

A: MOQ starts at 500 kg for standard grades. For custom alloys or special blends, MOQ may vary.

Q6: How can I request a sample or technical data sheet?

A: Contact Truer directly through their contact page for samples, COAs, or technical documents.

Q7: Is CZ-3000 RoHS and REACH compliant?

A: Yes. CZ-3000 powders from Truer meet RoHS and REACH standards for use in electronic and automotive applications.

Q8: Do you offer additives to improve CZ-3000 performance?

A: Absolutely. Additives such as SUW-8000 (lubricant) and QHP-330 (graphite) are recommended to enhance green strength and machining efficiency.

How to Order Wholesale CZ-3000 Powder from China

For B2B buyers looking to source CZ-3000 powder in bulk, Shanghai Truer Technology offers a streamlined ordering process:

Step-by-Step Ordering Workflow

- Inquiry — Submit your application specs and volume via the contact form.

- Consultation — Receive technical advice and recommendations from Truer’s engineers.

- Quotation — Get transparent pricing based on quantity, delivery time, and customization.

- Sample Approval — Request a 1–5 kg sample for internal testing (optional).

- Contract & Payment — Confirm your order and payment terms (e.g., T/T, L/C).

- Production & Quality Control — Your powder is produced under ISO9001-certified processes.

- Shipping — Global delivery via sea or air freight, complete with customs documentation.

- Post-Sales Support — Ongoing technical and logistical assistance from Truer’s support team.

Payment Terms & Logistics Options

| Option | Details |

|---|---|

| Payment Methods | T/T, L/C, Alibaba Secure Pay |

| Delivery Time | 15–20 days (bulk order), 5–7 days (sample) |

| Shipping Ports | Shanghai, Ningbo, Shenzhen |

| Documentation Provided | COA, SDS, COO, RoHS/REACH certification |

To browse all available PM powders and additives, check out the full product catalog.

Final Note: Whether you’re an OEM, distributor, or contract manufacturer, CZ-3000 powder from Shanghai Truer combines technical performance, cost-efficiency, and global support — making it the smart choice for your next procurement cycle.

For inquiries, technical discussions, or custom orders, visit our Contact Page.