1. Introduction: What is CZ-1000 Powder and Why It Matters in PM Industry

CZ-1000 powder is a copper-zinc based pre-alloyed powder used extensively in powder metallurgy (PM) applications. This material is particularly valued for its excellent compressibility, high green strength, and good sintered mechanical properties. It is a go-to material in automotive, industrial machinery, and electrical component manufacturing.

In the PM industry, where consistency, performance, and cost-efficiency are non-negotiable, CZ-1000 powder stands out as a versatile and high-performing alloy. Manufacturers and component designers appreciate its ability to be compacted into intricate shapes and sintered for reliable, wear-resistant parts.

Key Attributes of CZ-1000 Powder:

- Copper-zinc based alloy

- Excellent green strength

- High compressibility for complex geometries

- Cost-effective for mass production

- Excellent dimensional stability post-sintering

As global demand for precision-engineered components grows, especially in the automotive and electronics sectors, CZ-1000 powder has become an essential material for manufacturers and PM powder suppliers.

2. Industrial Applications of CZ-1000 Powder

CZ-1000 powder is widely used in several industries due to its unique balance of mechanical strength, conductivity, and manufacturability. Below is a breakdown of its most common application areas:

Automotive Industry

- Bushings and bearings

- Synchronous gears and lock rings

- Brake system components

- Transmission hubs

Electrical & Electronics

- Electrical contacts

- Terminal connectors

- Fuse components

Industrial Machinery

- Wear-resistant parts

- Structural components

- Precision spacers

Consumer Goods

- Lock components

- Appliance parts

- Small motor parts

Benefits in Automotive Applications:

| Feature | Benefit |

|---|---|

| High Green Strength | Maintains shape during handling |

| Zinc Content | Enhances corrosion resistance |

| Good Sinterability | Reduces processing defects |

| High Compressibility | Ideal for high-volume production |

CZ-1000’s copper-zinc matrix makes it suitable for parts that require both electrical conductivity and resistance to mechanical wear—an advantage in high-performance industries.

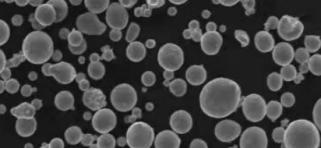

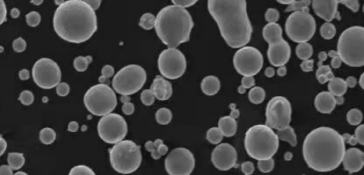

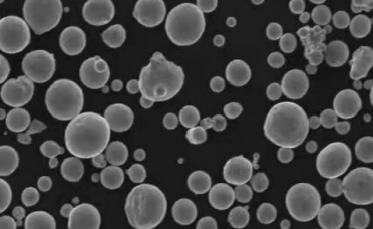

3. Properties and Composition of CZ-1000 Powder

Understanding the physical and chemical properties of CZ-1000 powder is crucial for buyers and engineers evaluating it for specific applications.

Chemical Composition

| Element | Content (%) |

|---|---|

| Cu | 89–91 |

| Zn | 9–11 |

| Fe | ≤ 0.5 |

| Sn | ≤ 0.3 |

| P | ≤ 0.05 |

Physical and Mechanical Properties

| Property | Value Range |

|---|---|

| Particle Size (µm) | 45–150 (typical) |

| Apparent Density | 2.5 – 3.0 g/cm³ |

| Flow Rate | 25–35 s/50g |

| Green Strength | >25 MPa (at 600 MPa) |

| Sintered Density | 6.4 – 6.8 g/cm³ |

Advantages of CZ-1000 Powder:

- Excellent Green Strength: Ensures part integrity during handling prior to sintering.

- Dimensional Precision: Minimal shrinkage and distortion after sintering.

- Corrosion Resistance: Due to alloying with zinc.

- Good Thermal Conductivity: Suitable for electrical and thermal applications.

Engineers favor CZ-1000 for its stability and versatility across various sintering and compaction conditions. It can be used with or without additives, depending on the performance characteristics required.

For further information on CZ-1000 and other PM powders, explore the About Us page of Shanghai Truer Technology Co., Ltd, a leading provider of advanced powder metallurgy materials.

4. Global Market Trends for CZ-1000 Powder

The global demand for CZ-1000 powder has grown significantly in recent years, driven by the expansion of the automotive, electrical, and machinery sectors. Powder metallurgy (PM) continues to gain traction as manufacturers seek cost-effective and sustainable metal forming processes.

Key Market Drivers:

- Automotive Electrification: Increased use of copper-based alloys in EV components.

- Sustainability Trends: PM reduces material waste, aligning with green manufacturing initiatives.

- Miniaturization of Components: CZ-1000 is ideal for compact, high-precision parts.

- Rising Demand in Asia-Pacific: Especially in China and India, where manufacturing bases are expanding.

Global CZ-1000 Powder Market Size Forecast:

| Year | Estimated Market Value (USD Million) |

|---|---|

| 2022 | 310 |

| 2023 | 340 |

| 2024 | 375 |

| 2025 | 415 |

| 2026 | 460 |

Top Consuming Regions:

- Asia-Pacific (China, Japan, India)

- North America (USA, Mexico)

- Europe (Germany, Italy, Czech Republic)

As OEMs look to optimize performance and cost, CZ-1000 continues to gain preference among wholesale buyers and global manufacturers.

5. How to Choose a Reliable CZ-1000 Powder Supplier

For B2B buyers, selecting the right CZ-1000 powder supplier can significantly impact the quality, lead time, and cost-efficiency of production. Here are key factors to keep in mind:

✅ Supplier Evaluation Checklist:

| Criteria | Why It Matters |

|---|---|

| Experience in PM Industry | Proven track record ensures consistency and quality |

| Powder Production Method | Affects uniformity, flowability, and compressibility |

| Certifications (ISO, RoHS) | Compliance with global standards |

| Customization Capabilities | Adapts to specific application needs |

| Logistics & Lead Time | Reliable delivery and support for global buyers |

| Customer Support | Essential for technical guidance and troubleshooting |

Questions to Ask a Potential Supplier:

- What is the typical particle size range and density of your CZ-1000 powder?

- Can you provide material test certificates (MTCs) for each lot?

- Do you offer technical support for compaction and sintering optimization?

- How do you ensure batch-to-batch consistency?

Choosing a supplier with comprehensive in-house capabilities ensures better control over quality, cost, and delivery timelines.

6. Top CZ-1000 Powder Manufacturers and Distributors

Here’s a comparative overview of some of the most recognized CZ-1000 powder suppliers globally:

| Company Name | Region | Key Strengths |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Full-spectrum PM solutions, custom alloying, advanced atomization techniques |

| Höganäs AB | Europe | Global presence, extensive R&D, premium powder grades |

| GKN Powder Metallurgy | North America | Integrated PM part manufacturing, proprietary powder tech |

| Rio Tinto Metal Powders | Canada | High-volume production, automotive-grade powders |

| JFE Steel Corporation | Japan | High-quality ferrous and non-ferrous PM powders |

Among these, Shanghai Truer Technology Co., Ltd stands out for its ability to provide both high-quality powders and powder production equipment—a unique advantage for OEMs and component manufacturers looking for an integrated supply chain.

7. Why More OEMs Choose Shanghai Truer Technology Co., Ltd

Shanghai Truer Technology Co., Ltd has emerged as one of the most trusted names in the Chinese powder metallurgy landscape. Established in 2009, with a dedicated additive manufacturing division launched in 2019, Truer is not just a powder supplier—it’s a full-service PM partner.

🔧 What Makes Truer a Preferred Supplier:

- Extensive Product Range: Offers CZ-1000 along with other PM powders like FC-0208, FN-0205, FL-4605, and FD-0208.

- Advanced Atomization Methods: Water, gas, and hybrid atomization ensure optimal powder characteristics.

- Custom Alloying Capabilities: Tailors compositions for specific applications, including wear resistance and conductivity.

- Integrated Solutions: Supplies 3D printing powders, lubricants, cutting agents, and even powder making equipment.

- Strong Technical Support: Engineering support for sintering and compaction optimization.

Notable Product Lines from Truer:

| Product Category | Examples |

|---|---|

| PM Copper-Based Powders | CZ-1000, CT-1000, F0008 |

| PM Steel Powders | FD-0208, FL-4605, FN-5000 |

| Soft Magnetic Additives | QH-150, QHP-330 |

| Lubricants & Additives | Lube-W, SUW-8000, SME-100, TD-8 |

By offering both materials and process support, Truer helps manufacturers reduce defects, improve mechanical performance, and optimize costs.

You can contact Truer directly to request CZ-1000 powder samples, get technical datasheets, or inquire about volume pricing.

8. How to Order Wholesale CZ-1000 Powder from China

For B2B buyers, OEMs, and distributors, ordering CZ-1000 powder in bulk requires a structured, professional approach. Shanghai Truer Technology Co., Ltd simplifies this process by offering streamlined ordering, competitive pricing, and global logistics support.

Step-by-Step Ordering Process with Truer

| Step | Action | Description |

|---|---|---|

| 1 | Product Inquiry | Reach out via Truer’s contact page or email to specify product (CZ-1000), quantity, and specs. |

| 2 | Technical Consultation | Truer’s engineering team reviews your application needs and suggests optimal powder specs. |

| 3 | Sample Request (Optional) | Free or paid samples sent for validation, testing, and pilot production. |

| 4 | Quotation & Terms | Receive formal quotation including CIF/FOB pricing, lead time, and payment terms. |

| 5 | Order Confirmation | Sign PO (Purchase Order) and agree to final specs. |

| 6 | Production & Quality Control | Powder is manufactured and tested to ensure compliance with ISO standards. |

| 7 | Packaging & Shipping | Secure packaging for overseas shipping with SDS and technical documents. |

| 8 | Delivery & After-Sales Support | Truer provides logistics tracking, customs documentation, and technical follow-up. |

Packaging Options Available:

- 25 kg sealed bags

- 500 kg drums

- Custom pallets for bulk orders

- Vacuum packaging for moisture-sensitive powders

Shipping & Logistics:

- Worldwide delivery via air freight and sea freight

- Export experience to over 30 countries

- Support with customs clearance and documentation

For detailed product tech sheets and MOQ (Minimum Order Quantity), visit the CZ-1000 powder product section on Truer’s official site.

9. FAQs: Common Questions About Buying CZ-1000 Powder in Bulk

Q1: What is the minimum order quantity (MOQ) for CZ-1000 powder?

A: Truer typically supplies starting from 100 kg for trial orders. For standard wholesale contracts, MOQ is 500 kg to 1 ton depending on grade and packaging requirements.

Q2: How does CZ-1000 compare to other copper-based PM powders?

A: CZ-1000 offers superior green strength and compressibility compared to pure copper or bronze powders. Its zinc content provides better corrosion resistance and mechanical integrity.

Q3: What atomization method is used to produce CZ-1000 powder?

A: Shanghai Truer uses water atomization for CZ-1000, which provides excellent flowability and particle uniformity. Hybrid atomization is also available for high-spec orders.

Q4: Can Truer customize the CZ-1000 composition for specific applications?

A: Yes. Truer offers custom alloying services to adjust copper/zinc ratios or add elements like tin, nickel, or phosphorus.

Q5: What are the typical lead times for bulk orders?

A: Standard lead time is 2–4 weeks depending on order size and packaging needs. Expedited shipping is available for urgent orders.

Q6: Does Truer provide technical support for compaction and sintering?

A: Absolutely. Truer’s powder metallurgy team works closely with clients to optimize pressing pressures, sintering temperatures, and additive usage.

Final Thoughts

CZ-1000 powder is a premium copper-zinc alloy that delivers high performance across multiple industries—from automotive to electronics. For industrial buyers, the key to successful implementation lies in choosing a reliable supplier who can ensure consistent quality, flexible customization, and global fulfillment.

Shanghai Truer Technology Co., Ltd is not only a trusted CZ-1000 powder supplier, but also a full-solution partner for PM manufacturers. With a strong track record, advanced production capabilities, and dedicated technical support, Truer is positioned as a leading supplier for OEMs, distributors, and PM professionals worldwide.

Internal Links Summary (Anchor Texts Embedded):

- PM powder suppliers

- About Us page of Shanghai Truer Technology Co., Ltd

- Wholesale buyers

- Contact Truer directly

- CZ-1000 powder product section

📩 Ready to source high-quality CZ-1000 powder for your next manufacturing project? Contact Shanghai Truer Technology Co., Ltd now to get a quote, request a sample, or speak with a technical engineer.