1. Introduction: What Is CuCrZr Powder and Why It Matters

CuCrZr powder is a copper-based alloy consisting primarily of copper (Cu) with small additions of chromium (Cr) and zirconium (Zr). It is prized for its excellent thermal and electrical conductivity, high strength, and superior wear resistance after heat treatment. These characteristics make it an ideal material for additive manufacturing and powder metallurgy (PM) applications, especially where thermal and mechanical performance are equally important.

This alloy is particularly useful in industries requiring materials that can withstand high stress and temperatures without sacrificing conductivity. Some of the standout features of CuCrZr powder include:

- High conductivity: Near-pure copper conductivity with added strength.

- Excellent wear resistance: Especially when heat treated.

- Good machinability: Makes it suitable for complex near-net-shape parts.

- Outstanding strength-to-conductivity ratio: Ideal for high-performance industrial parts.

CuCrZr has become increasingly popular in the B2B manufacturing world, especially for companies seeking reliable copper alloys for demanding environments.

2. Industrial Applications of CuCrZr Powder

CuCrZr powder is widely used in several high-performance applications across industries such as aerospace, automotive, electronics, and heavy machinery. Here’s a breakdown of the key industrial applications:

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | 3D printed rocket nozzles, heat sinks | High thermal conductivity, strength under stress |

| Automotive | Resistance welding electrodes, heat exchangers | Durability, thermal fatigue resistance |

| Electronics | Connectors, contact pins, semiconductor packaging | High electrical conductivity |

| Tooling | Injection mold cores, dies | Wear resistance, thermal performance |

| Energy | Fusion reactors, power transmission systems | Radiation resistance, heat management |

Key B2B Use Cases for Wholesale Buyers

- 3D Printing Service Bureaus: For producing customized, high-strength thermal parts.

- Powder Metallurgy Manufacturers: For sintered parts requiring conductivity.

- Distributors of AM Materials: High-margin material for industrial clients.

- OEMs in Electronics: Reliable base for high-volume connector production.

3. Properties and Performance of CuCrZr Alloys

CuCrZr achieves its performance through a unique microstructure that combines the excellent conductivity of copper with the strengthening effects of chromium and zirconium. These elements precipitate during aging, forming fine particles that enhance mechanical properties without drastically reducing conductivity.

Typical Chemical Composition (%)

| Element | Weight % |

|---|---|

| Cu | Balance |

| Cr | 0.5 – 1.2 |

| Zr | 0.03 – 0.3 |

| Others | < 0.1 |

Mechanical and Physical Properties

| Property | Value (Heat Treated) |

|---|---|

| Electrical Conductivity | ≥ 75% IACS |

| Tensile Strength | 450–550 MPa |

| Hardness | 120–150 HV |

| Density | 8.89 g/cm³ |

| Thermal Conductivity | ~300–330 W/m·K |

Performance Advantages for Industrial Buyers

- Stable microstructure: Withstands thermal cycling.

- Scalable properties: Can be tailored via aging and heat treatment.

- Corrosion resistance: Suitable for harsh industrial environments.

📌 For more details on how CuCrZr compares with other PM powders and to explore material grades, visit the PM powder product page.

4. Market Trends and Demand in Powder Metallurgy

The market demand for CuCrZr powder has grown significantly over the past decade due to the increasing adoption of additive manufacturing and powder metallurgy (PM) in high-performance industries. CuCrZr’s unique balance of strength, conductivity, and wear resistance makes it a top choice for manufacturers seeking advanced materials for mission-critical components.

Key Market Drivers

- Growth in Additive Manufacturing (AM): CuCrZr is commonly used in laser powder bed fusion (LPBF) and directed energy deposition (DED).

- Electrification of the Automotive Industry: EV components require high conductivity and strength, making CuCrZr a preferred alloy.

- Aerospace Advancements: Reusable spacecraft and rocket nozzles demand heat-resistant materials.

- Miniaturization in Electronics: As devices shrink, the need for efficient, small-scale heat dissipation increases.

Global CuCrZr Powder Market Forecast (2024–2030)

| Year | Estimated Global Market Size (USD Million) | CAGR |

|---|---|---|

| 2024 | $110M | — |

| 2025 | $125M | 13.6% |

| 2026 | $143M | 14.4% |

| 2027 | $165M | 15.4% |

| 2028 | $190M | 15.2% |

| 2029 | $220M | 15.8% |

| 2030 | $255M | 16.1% |

Emerging Trends

- Hybrid Manufacturing: Combining traditional PM with 3D printing processes.

- Environmentally Friendly Production: Demand for low-carbon, recyclable copper alloys.

- Localized Sourcing: Distributors and OEMs seeking regional suppliers for better logistics.

📌 Learn more about our company’s mission and how we support the PM industry on our About Us page.

5. Key Factors to Consider When Choosing a CuCrZr Supplier

Selecting a reliable CuCrZr powder supplier is critical to ensuring product consistency, reliable lead times, and cost-efficiency. Here are essential factors B2B buyers, wholesalers, and distributors should evaluate:

1. Purity and Consistency of Alloy Composition

- Suppliers should offer guaranteed composition tolerances.

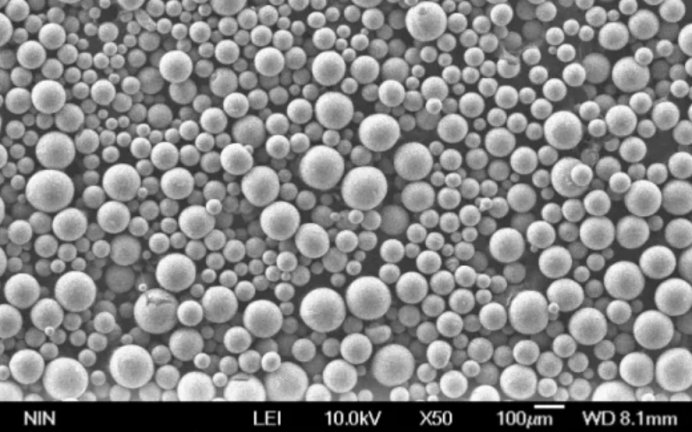

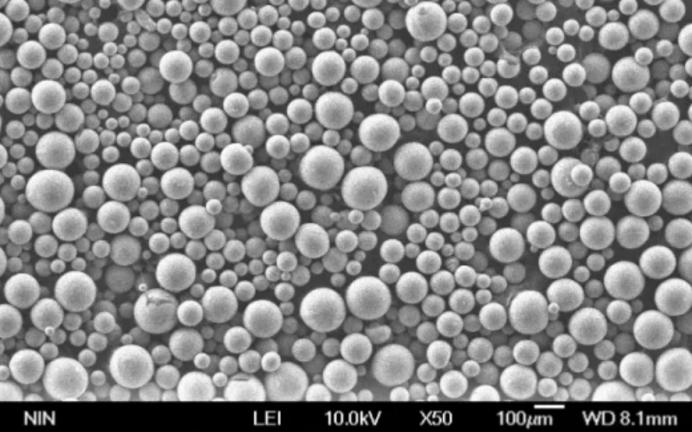

- Consistent particle morphology and size distribution.

2. Production Method Used

| Method | Description | Typical Use |

|---|---|---|

| Gas Atomization | Produces spherical particles, ideal for AM | 3D printing, LPBF |

| Water Atomization | More economical, irregular particles | Traditional PM |

| Combined Atomization | Tailored morphology | Hybrid processes |

3. Certification and Quality Control

- ISO 9001 or equivalent

- In-house lab testing (SEM, XRD, PSD analysis)

- Lot-to-lot traceability

4. Packaging and Logistics

- Vacuum-sealed packaging to prevent oxidation

- Anti-static drums or double sealed bags

- Global shipping capabilities

5. Technical Support

- Pre-sales consultation

- Post-sales metallurgical support

- Custom powder blends for proprietary applications

6. Top Global Suppliers of CuCrZr Powder

When sourcing CuCrZr powder, identifying reputable global suppliers ensures quality assurance, scalability, and regulatory compliance. Below is a list of leading CuCrZr powder manufacturers for B2B procurement:

| Supplier | Region | Key Strengths | Website |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Full-range PM materials, AM powders, custom blends | Visit Truer |

| Höganäs AB | Sweden | Global leader in PM powders, high R&D focus | hoganas.com |

| Sandvik Osprey | UK | High-quality gas atomized powders | materials.sandvik |

| Carpenter Additive | USA | Aerospace-grade CuCrZr powders | carpenteradditive.com |

| GKN Additive | Germany | Strong automotive and aerospace presence | gknpm.com |

Why Shanghai Truer Stands Out:

- Over 15 years in PM materials.

- Full in-house production of CuCrZr via gas, water, and combined atomization.

- Extensive inventory of standard and custom PM powder grades.

- Deep understanding of both additive and conventional PM applications.

📌 To browse Truer’s full PM powder catalog, including CuCrZr and other copper alloys, check out the PM powder product page.

7. Why More Buyers Are Sourcing CuCrZr from China

In recent years, China has emerged as a leading production hub for high-performance powder metallurgy materials, including CuCrZr. B2B buyers across the globe—especially in North America, Europe, and Southeast Asia—are increasingly turning to Chinese suppliers for cost-effective, high-quality copper alloy powders.

Key Reasons B2B Buyers Source CuCrZr from China

1. Competitive Pricing

- Localized raw material sourcing reduces base costs.

- Economies of scale from large-scale manufacturing.

- Lower labor costs compared to Western markets.

2. Technological Advancements

- Adoption of advanced atomization technologies (gas, water, and hybrid).

- Integrated R&D facilities for material customization.

- Enhanced quality control with modern SEM, PSD, and XRD testing.

3. Supply Chain Resilience

- Shorter lead times due to regional warehousing.

- Flexible MOQs (Minimum Order Quantities) for distributors.

- Partner networks for global logistics and customs compliance.

4. Government Support for Advanced Manufacturing

- National policies supporting additive manufacturing and new materials.

- Export incentives for high-tech powder metallurgy products.

Top Chinese Regions for CuCrZr Production

| Region | Strengths |

|---|---|

| Jiangsu | Advanced metallurgy infrastructure |

| Shanghai | R&D and export-focused companies like Truer |

| Guangdong | Strong logistics and export channels |

📌 Want to learn more about our capabilities and how we support global clients in sourcing high-quality powders? Visit our Contact Page to connect with our team.

8. Why Choose Shanghai Truer as Your CuCrZr Supplier

Shanghai Truer Technology Co., Ltd stands as one of China’s most trusted names in powder metallurgy and additive manufacturing. Since launching its AM business in 2019, Truer has quickly become a go-to solution provider for engineering-grade metallic powders, including CuCrZr.

Highlights of Shanghai Truer

| Feature | Benefit to B2B Buyers |

|---|---|

| 15+ Years in PM | Proven track record and industry expertise |

| In-House Atomization | Control over powder morphology and quality |

| Broad Alloy Portfolio | One-stop sourcing for copper, iron, steel, and custom blends |

| Technical Consultation | Application-specific recommendations |

| Global Export Experience | Customs, documentation, and logistics support |

CuCrZr Powder Capabilities

- Production Methods: Gas atomized, water atomized, or hybrid.

- Particle Sizes Offered: D10–D90 ranges available (15–53 µm, 45–105 µm, etc.).

- Purity & Composition: Strict compositional controls, aging treatment available.

- Customization: Tailored particle sizes, blends, and packaging.

- Packaging: Vacuum-sealed, nitrogen-flushed, anti-static drums.

Supporting Your Business Growth

Whether you’re a distributor, OEM, or additive manufacturing specialist, Shanghai Truer offers:

- Fast quotation and sampling services.

- Stable lead times and inventory stocking.

- Technical documentation and certificates (COA, MSDS, RoHS).

📌 Curious about our company’s mission, product range, and value proposition? Learn more on our About Us page.

9. FAQs: Buying Wholesale CuCrZr Powder

Q1: What particle size ranges does Shanghai Truer offer for CuCrZr powder?

We provide a wide range of particle sizes tailored for different applications. Common sizes include 15–45 µm for LPBF, 45–105 µm for DED, and custom ranges for PM.

Q2: Can I request custom alloy compositions or blends?

Yes. We offer custom CuCrZr blends and can adjust Cr/Zr content to meet your specific performance requirements. Contact us for technical consultation.

Q3: What is the MOQ for wholesale CuCrZr orders?

Our standard MOQ is 25 kg, but we can accommodate smaller volumes for R&D or sampling purposes.

Q4: How is the powder packaged and shipped?

Powders are vacuum-sealed in nitrogen-flushed anti-static bags and packed in drums or cartons. Global shipping is available with full documentation support.

Q5: Which industries commonly use your CuCrZr powder?

We supply CuCrZr to clients in aerospace, automotive, electronics, and tooling industries.

Q6: How do I place a wholesale order?

You can request a quote and place an order directly through our Contact Page. Our sales engineers will guide you through the process.

Internal Anchor Text Links Summary (5)

| Anchor Text | Linked Page |

|---|---|

| PM powder product page | https://am-material.com/pm-powder/ |

| About Us page | https://am-material.com/about/ |

| Contact Page | https://am-material.com/contact-us/ |

| Visit Truer | https://am-material.com/ |

| Browse Truer’s full PM powder catalog | https://am-material.com/pm-powder/ |

This concludes our comprehensive guide to CuCrZr powder for industrial and wholesale buyers. For sampling, technical consultation, or large-scale procurement, Shanghai Truer is your trusted supplier for high-performance PM and AM materials.