1. Introduction: Why AlSi9Cu3 Powder Is Key in Modern Manufacturing

AlSi9Cu3 is a widely used aluminum casting alloy that has found increasing demand in additive manufacturing (AM) and powder metallurgy (PM) due to its excellent castability, mechanical properties, and corrosion resistance. The alloy consists primarily of aluminum with approximately 9% silicon and 3% copper, providing a balanced combination of strength, thermal conductivity, and lightweight characteristics.

Why B2B Buyers Should Pay Attention to AlSi9Cu3:

- 🚗 Automotive OEMs and Tier-1 suppliers use it for engine blocks, cylinder heads, and transmission components.

- 🏭 Industrial equipment manufacturers value its strength-to-weight ratio.

- 🛠️ 3D printing service providers and contract manufacturers require high-quality AlSi9Cu3 powders for precision parts.

As more industries adopt AM and PM solutions, the demand for reliable, high-performance alloy powders like AlSi9Cu3 has surged. Businesses looking to stay competitive in automotive, aerospace, and tooling sectors are increasingly adding this alloy to their procurement scope.

2. Industrial Applications of AlSi9Cu3 Powder

AlSi9Cu3 powder is engineered for use in both traditional manufacturing and emerging technologies like metal 3D printing. Below are the most common industrial use cases:

🔧 Automotive Industry

| Application | Reason for Use |

|---|---|

| Engine blocks | High strength and thermal conductivity |

| Cylinder heads | Excellent pressure tightness |

| Transmission housings | Reduces component weight |

✈️ Aerospace and Aviation

- Structural parts with low weight requirements

- Heat-resistant housings and enclosures

- Complex geometries via additive manufacturing

🛠️ Tooling and Machinery

- Custom jigs and fixtures

- Mold cores and inserts

- High-performance mechanical parts

⚙️ Additive Manufacturing (AM)

AlSi9Cu3 powder is a go-to material for:

- Selective Laser Melting (SLM)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

📦 Packaging Equipment and Robotics

- Lightweight, corrosion-resistant components

- High fatigue resistance parts

3. Properties and Benefits of AlSi9Cu3 Powder

The physical and chemical properties of AlSi9Cu3 make it ideal for high-performance and durable components in a variety of industries. Below is a breakdown of its key attributes:

⚗️ Chemical Composition:

| Element | Typical Weight % |

|---|---|

| Al | Balance |

| Si | 9 – 11% |

| Cu | 2 – 4% |

| Fe | ≤ 1.3% |

| Mn | ≤ 0.55% |

| Zn | ≤ 1% |

🔬 Mechanical Properties (Post Heat Treatment):

| Property | Value |

|---|---|

| Tensile Strength | ~270–320 MPa |

| Yield Strength | ~140–160 MPa |

| Elongation | 1–4% |

| Hardness (Brinell) | 80–100 HB |

| Density | ~2.7 g/cm³ |

🌟 Key Advantages for B2B Buyers:

- High castability and low shrinkage

- Superior thermal conductivity and corrosion resistance

- Excellent surface finish after processing

- Compatible with multiple 3D printing technologies

- Lightweight alternative to steel components

By offering both performance and affordability, AlSi9Cu3 has become a staple in bulk procurement strategies for OEMs and contract manufacturers alike.

👉 Looking for a reliable supplier of AlSi9Cu3 powder? Learn more about our PM powders and materials to explore Shanghai Truer’s full range of high-quality alloy powders.

4. Market Trends and Demand in Global and Regional Sectors

The global demand for AlSi9Cu3 powder is experiencing rapid growth, driven by the expansion of additive manufacturing, the automotive industry’s shift towards lightweight materials, and the increasing need for precision-engineered components.

🌍 Global Market Overview

According to industry research, the global metal powder market is expected to grow at a CAGR of over 6% from 2024 to 2030. Aluminum-based powders, particularly AlSi9Cu3, are among the top contributors due to their versatility and cost-efficiency.

Key Drivers:

- Automotive Lightweighting Initiatives: Increased use of aluminum alloys like AlSi9Cu3 to replace heavier cast iron parts.

- Additive Manufacturing Boom: Rising adoption in 3D printing requires high-quality, flowable powders.

- Sustainability Goals: Recyclability and resource efficiency of aluminum alloys align with ESG strategies.

📈 Regional Demand Snapshot

| Region | Market Dynamics |

|---|---|

| North America | Strong investment in aerospace and automotive AM programs. |

| Europe | High demand in automotive and robotics sectors; focus on emissions reduction. |

| Asia-Pacific | Fastest-growing region; driven by China’s manufacturing base and EV production. |

| Middle East | Emerging market in aerospace and defense components. |

🔍 Industry-Specific Trends

- Automotive: Shift from cast iron to aluminum parts in engines and chassis.

- Aerospace: Increased demand for lightweight, heat-resistant components.

- Industrial Equipment: Custom, low-volume part production drives AM usage.

With these trends, B2B buyers, especially procurement managers, distributors, and OEMs, are increasingly sourcing AlSi9Cu3 powder for high-volume and high-performance applications.

5. Choosing the Right AlSi9Cu3 Powder Supplier: Key Considerations

Selecting a reliable AlSi9Cu3 powder supplier is critical for maintaining quality, consistency, and production efficiency. Here are key criteria to guide B2B buyers:

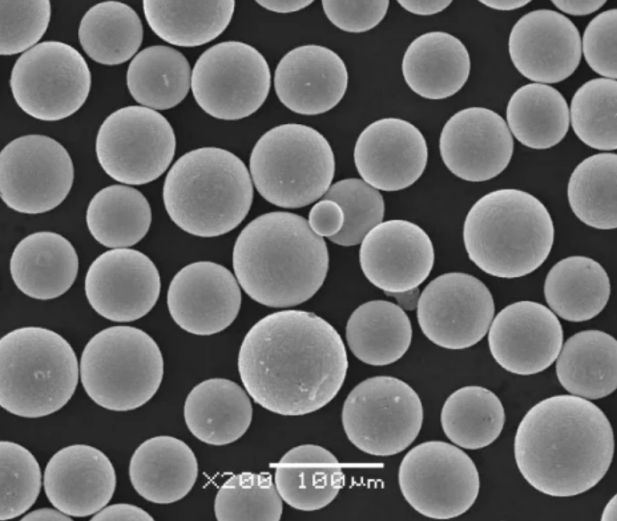

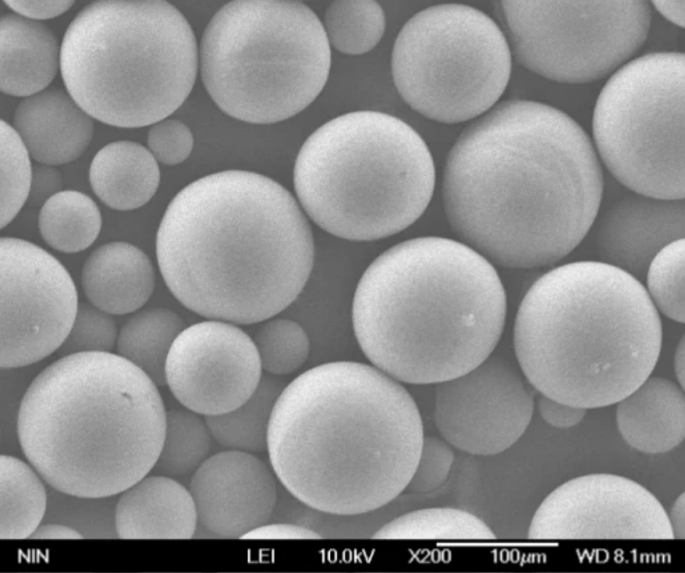

✅ Technical Specifications

- Particle size distribution (PSD) consistency

- Sphericity and flowability (especially for AM)

- Chemical composition verification (certified test reports)

🏭 Production Capability

- Atomization method (gas atomization preferred for AM)

- Batch traceability and quality control

- Custom alloying capacity

📦 Logistics and Supply Chain Support

- Global shipping capabilities

- Lead times and on-time delivery performance

- Packaging options for bulk and specialty orders

🛡️ Certifications and Compliance

- ISO 9001 or IATF 16949 for automotive applications

- RoHS and REACH compliance

- Material Safety Data Sheets (MSDS) availability

🔄 After-Sales Support

- Technical support for material selection and application

- Reorder flexibility and volume discounts

- Return and exchange policies

By thoroughly evaluating these factors, B2B buyers can reduce procurement risks and ensure consistent production output.

6. Top Global and Chinese Suppliers of AlSi9Cu3 Powder

Below is a curated list of trusted manufacturers and suppliers that provide wholesale AlSi9Cu3 powder for industrial use.

🌐 Global Suppliers

| Supplier Name | Region | Features |

|---|---|---|

| ECKA Granules | Germany | High-purity powders, strong R&D support |

| Höganäs AB | Sweden | Global leader in PM and AM powders |

| TLS Technik GmbH | Germany | Specialty gas-atomized aluminum powders |

| Carpenter Additive | USA | Aerospace-grade aluminum alloy powders |

🇨🇳 Leading Chinese Suppliers

| Supplier | Specialty | Website/Link |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | Water/gas atomized AlSi9Cu3 powder, PM additives | Visit our homepage |

| GKN Additive China | Industrial-scale AM metal powder production | – |

| CNPC Powder Group | Broad alloy portfolio, export-ready | – |

Shanghai Truer has emerged as one of China’s most trusted powder metallurgy and additive manufacturing material suppliers, offering consistent quality and excellent technical support.

Why B2B Buyers Trust Shanghai Truer:

- Over a decade of R&D and manufacturing experience

- Advanced atomization technology (gas and water)

- Full control over alloying and powder morphology

- Applications in automotive, tooling, and aerospace

- Custom particle size distribution and packaging options

👉 Want to learn more about our story and capabilities? Read about Shanghai Truer Technology here.

7. Why More Buyers Are Turning to Chinese Manufacturers

In recent years, B2B buyers—especially those in the industrial, automotive, and additive manufacturing sectors—have increasingly turned to Chinese suppliers for sourcing AlSi9Cu3 powder. Here’s why this shift is happening at scale:

💰 Competitive Pricing Without Compromising Quality

Chinese manufacturers offer significant cost advantages due to:

- Economies of scale

- Local sourcing of raw materials

- Advanced automation and production efficiency

This allows B2B buyers to reduce procurement costs while maintaining consistent quality.

🏗️ Massive Production Capacity

China’s manufacturing infrastructure is among the most advanced in the world. Suppliers like Shanghai Truer Technology have invested in state-of-the-art atomization and powder processing equipment, enabling:

- High-volume production

- Custom alloy development

- Rapid turnaround for bulk orders

🔬 Technological Advancements

Chinese powder metallurgy firms are no longer just low-cost producers—they are innovating in:

- Atomization technology (gas, water, hybrid)

- Custom powder blends for additive manufacturing

- Advanced testing and quality control systems

🌐 Global Export Readiness

Leading Chinese suppliers are now fully compliant with international standards such as ISO 9001, and offer:

- Export-friendly documentation

- Logistics support for global delivery

- Multilingual sales and technical teams

📦 End-to-End Service Capabilities

From powder customization to post-sales technical support, Chinese suppliers offer complete solutions that appeal to:

- Automotive OEMs

- Aerospace contractors

- 3D printing service bureaus

- Metal part manufacturers

🔗 Interested in working with a reliable Chinese supplier? Contact Shanghai Truer today to discuss your project needs.

8. Why Choose Shanghai Truer Technology for AlSi9Cu3 Powder Supply

Shanghai Truer Technology Co., Ltd stands out as one of the most professional and technically advanced suppliers of AlSi9Cu3 powder in China. Here’s why international buyers consistently choose Truer for their additive manufacturing and powder metallurgy needs:

🏢 Company Overview

- Founded: 2009

- AM Division Established: 2019

- Specialization: 3D printing powders, powder metallurgy additives, and powder-making equipment

🔍 Key Product Capabilities

| Powder Type | Atomization Method | Use Case |

|---|---|---|

| AlSi9Cu3 | Gas / Water / Hybrid | AM, PM, automotive, aerospace |

| PM Bronze, Nickel Silver | Water atomized | Structural PM parts |

| PM Iron, Steel, Copper Steel | Reduction method | Tools, machinery |

| Stainless Steel PM Powders | Gas / Water atomized | High-corrosion environments |

⚙️ Application-Specific Expertise

Truer’s AlSi9Cu3 powder is engineered for:

- Selective Laser Melting (SLM)

- Direct Metal Laser Sintering (DMLS)

- Binder Jetting

- Traditional PM applications

📊 Quality and Certification

- ISO-certified production lines

- Batch-level traceability

- Advanced QC lab with chemical, morphological, and mechanical testing

🌍 Global Reach

- Export-ready logistics

- Custom packaging for bulk or OEM requirements

- Technical documentation and SDS included with every shipment

🌟 Value-Added Services

- Custom alloy development

- Technical consulting for AM applications

- Additive packages for enhanced performance (e.g., PM lubricants, cutting agents)

🧭 Explore Truer’s full range of powders and additive solutions on the PM Powder Products page.

9. FAQs: Common Questions About Ordering AlSi9Cu3 Powder Wholesale

Q1: What is the minimum order quantity (MOQ) for AlSi9Cu3 powder?

A: The MOQ typically starts at 25 kg, but Shanghai Truer offers flexible order volumes for R&D and prototyping clients.

Q2: What particle size distributions (PSD) are available?

A: Standard PSD options include 15–45 µm, 20–63 µm, and 45–105 µm, customizable upon request depending on your AM system or PM process.

Q3: What atomization methods are used?

A: Truer offers gas atomized, water atomized, and hybrid atomized AlSi9Cu3 powders tailored for different applications.

Q4: Is technical support available for selecting the right powder?

A: Yes, Truer provides application-specific consulting, including material selection, sintering advice, and printing parameter recommendations.

Q5: How long does it take to deliver bulk orders internationally?

A: Delivery timelines typically range from 2 to 4 weeks, depending on order volume and destination. Express shipping is available for urgent needs.

Q6: Is the powder compatible with all types of 3D printers?

A: Yes, Truer’s AlSi9Cu3 powder is compatible with most SLM, DMLS, and EBM metal 3D printers, including EOS, Renishaw, and SLM Solutions.

Q7: Are samples available for testing?

A: Yes, Truer provides free or discounted samples for qualified industrial buyers and research institutions.

✅ Final Internal Anchor Links Summary (5 Total)

| Anchor Text | URL |

|---|---|

| Learn more about our PM powders and materials | https://am-material.com/pm-powder/ |

| Read about Shanghai Truer Technology here | https://am-material.com/about/ |

| Contact Shanghai Truer today | https://am-material.com/contact-us/ |

| Visit our homepage | https://am-material.com/ |

| Explore Truer’s full range of powders | https://am-material.com/pm-powder/ |

By following this structured and SEO-optimized format, you not only attract high-intent B2B buyers and distributors but also position Shanghai Truer Technology as a trusted leader in AlSi9Cu3 powder supply for additive manufacturing and powder metallurgy.

🔗 Ready to start sourcing? Contact us now to get a quote or discuss your custom material requirements.