1. Introduction: Why 5052 Aluminum Powder Matters in Modern Manufacturing

5052 aluminum powder is a high-performance, non-heat-treatable alloy known for its excellent corrosion resistance, medium-to-high strength, and superior workability. For industries like aerospace, automotive, electronics, and additive manufacturing, 5052 powder offers a unique combination of mechanical and chemical properties that make it highly suitable for high-volume production environments.

As global manufacturers shift toward lightweight materials and digital manufacturing technologies like 3D printing and powder metallurgy (PM), 5052 aluminum powder has become a go-to material for:

- Laser powder bed fusion (LPBF)

- Metal injection molding (MIM)

- Cold spraying

- Additive manufacturing (AM)

- Sintered components

With the rising demand for sustainable, high-strength, and corrosion-resistant materials, 5052 aluminum powder is becoming an integral part of supply chains for OEMs, distributors, and bulk buyers.

2. Industrial Applications of 5052 Aluminum Powder

5052 aluminum powder is versatile and supports a wide array of industrial applications. Here are several key sectors where its value is maximized:

| Industry | Application | Benefit |

|---|---|---|

| Aerospace | Structural parts, brackets, frames | Lightweight, corrosion-resistant |

| Automotive | Fuel tanks, body panels, chassis parts | Excellent weldability and fatigue strength |

| Electronics | Housings, connectors, cooling components | High thermal conductivity |

| Marine | Boat hulls, underwater fittings | Saltwater corrosion resistance |

| 3D Printing | Custom aluminum parts | Compatibility with LPBF and DMLS |

| Powder Metallurgy | Sintered mechanical components | Strong, ductile, easy to form |

Key Application Notes:

- Sintered Components: 5052 powder is used in PM to create complex shapes with tight tolerances, reducing the need for post-processing.

- Additive Manufacturing: It allows for efficient production of lightweight parts with excellent surface finish.

- Automotive Industry: It’s commonly used in electric vehicle (EV) battery casings and structural supports.

3. Properties and Benefits of 5052 Powder in B2B Use

5052 aluminum alloy is composed mainly of aluminum and magnesium, offering a balance of strength, formability, and corrosion resistance that makes it highly attractive for industrial use.

Chemical Composition (% by weight):

| Element | Content |

|---|---|

| Aluminum (Al) | 95.7 – 97.7% |

| Magnesium (Mg) | 2.2 – 2.8% |

| Chromium (Cr) | 0.15 – 0.35% |

| Iron (Fe), Silicon (Si), Copper (Cu), Zinc (Zn) | ≤ 0.4% (combined trace elements) |

Physical Properties:

- Density: 2.68 g/cm³

- Melting Point: ~607 °C

- Tensile Strength: 210–230 MPa

- Elongation at Break: 12–20%

- Electrical Conductivity: 32–35% IACS

Advantages for Bulk Buyers and Manufacturers:

- Superior Corrosion Resistance: Particularly in marine and industrial environments.

- Excellent Workability: Ideal for complex forming and bending operations.

- Weldability: Suitable for MIG and TIG welding processes.

- Lightweight: Reduces overall part weight, improving fuel efficiency in transportation.

- Cost-Effective: Competitive pricing in the aluminum powder segment for large-scale orders.

Common Mesh Sizes for 5052 Powder:

| Mesh Size | Application |

|---|---|

| -100 to +325 mesh | PM and MIM |

| -200 mesh | Additive manufacturing |

| -325 mesh | LPBF, DMLS, SLM |

For wholesale buyers and B2B procurement teams, selecting a mesh size tailored to your specific forming or sintering process is critical for optimal performance and yield.

📎 For more information on powder metallurgy-grade aluminum powders, visit Shanghai Truer’s PM Powder Division.

4. Key Considerations When Choosing a 5052 Powder Supplier

When selecting a 5052 aluminum powder supplier for industrial or wholesale use, the stakes are high. Poor quality powder can lead to production delays, mechanical failures, and increased costs. Therefore, B2B procurement professionals and distributors must evaluate suppliers based on critical quality, technical, and commercial factors.

Key Criteria to Evaluate Suppliers:

| Criteria | Why It Matters |

|---|---|

| Powder Purity & Composition | Ensures consistent mechanical properties and performance |

| Particle Size Distribution | Impacts flowability, sintering behavior, and print quality |

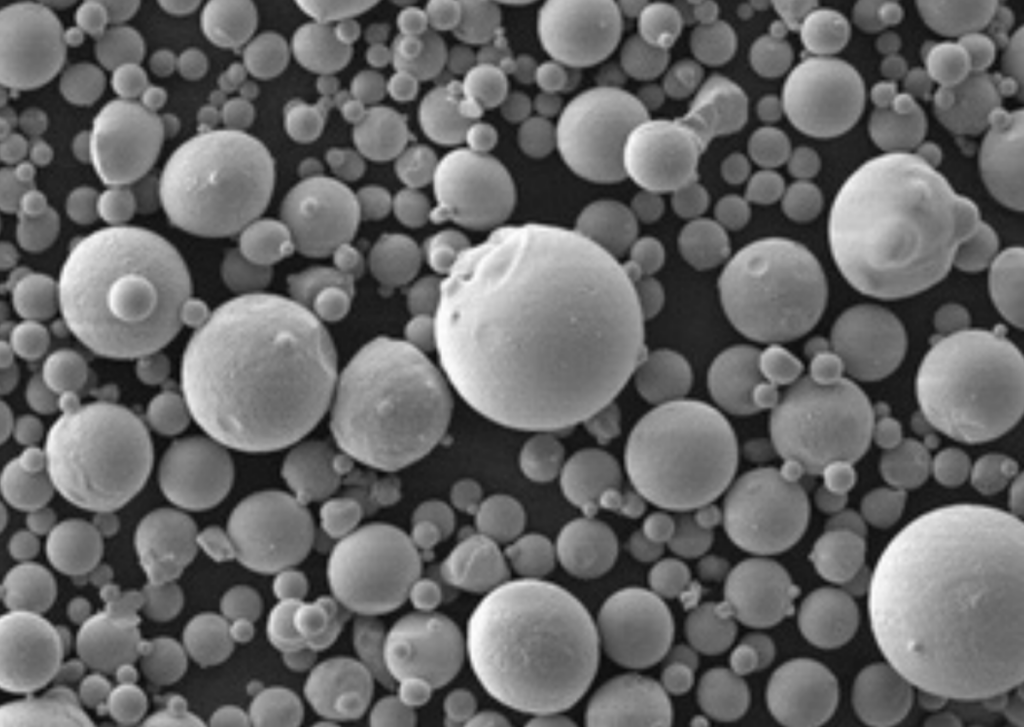

| Production Method | Gas atomized powders often offer better sphericity for AM |

| Certifications | ISO 9001, RoHS, REACH compliance, etc. |

| Logistics & Lead Time | Essential for scaling production and fulfilling orders |

| Technical Support | Helps with troubleshooting and process optimization |

| Customization | Ability to supply custom mesh sizes or blends |

Questions to Ask a Potential Supplier:

- Do you offer gas atomized or water atomized 5052 powders?

- What is your monthly production capacity and delivery time for bulk orders?

- Can I request a Certificate of Analysis (CoA) for each batch?

- What quality assurance processes are in place?

- Do you offer support for AM or PM process optimization?

📌 Tip: Always request a free sample before placing a wholesale order—this helps validate particle morphology, flow rate, and sintering behavior for your application.

5. Top 5052 Aluminum Powder Suppliers in Asia

Asia is a major hub for metal powder production, offering competitive pricing, scalability, and technological innovation. Below are some of the most reliable 5052 aluminum powder suppliers catering to global B2B markets:

Top B2B Suppliers:

| Company Name | Country | Specialization | Key Feature |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Aluminum & PM powders | Full-service from production to application |

| Kymera International | South Korea | Aluminum alloy powders | Global distributor partnerships |

| Fukuda Metal Foil & Powder Co. | Japan | High-purity aluminum powders | Advanced atomization technology |

| CNPC Powder | China | Atomized metal powders | Custom mesh sizes |

| ECKA Granules | Malaysia | Aluminum & non-ferrous powders | REACH & RoHS compliant |

Among these, Shanghai Truer stands out for its dedicated additive manufacturing division, in-house powder production technologies, and wide availability of PM-grade powders for both local and international customers.

🔗 Learn more about Shanghai Truer’s company background and why it’s a trusted name across Asia and beyond.

6. Why More Distributors Source 5052 Powder from China

China has emerged as a global leader in powder metallurgy and additive manufacturing materials. Distributors and OEMs are increasingly choosing Chinese suppliers for several compelling reasons:

Advantages of Sourcing from China:

- Cost Efficiency: Lower raw material and energy costs offer more competitive pricing.

- Large-Scale Production: Chinese suppliers like Truer operate high-capacity facilities that ensure consistent supply even for large-volume orders.

- Technological Advancements: Adoption of advanced atomization methods (e.g., gas, water, hybrid) improves powder quality.

- Customization Options: Ability to tailor mesh size, alloy variants, and packaging to B2B buyer requirements.

- Faster Lead Times: Domestic logistics and international shipping integration reduce delivery times.

Example: Shanghai Truer’s Supply Chain Capabilities

- Offers both water and gas atomized 5052 aluminum powders.

- In-house testing for particle size distribution, morphology, and chemical analysis.

- Flexible MOQ options for distributors and OEM buyers.

- Technical consulting available for AM and PM applications.

📎 To explore sourcing options for 5052 aluminum powder, visit am-material.com and access their full range of powder products and services.

7. Why Choose Shanghai Truer as Your 5052 Powder Partner

Shanghai Truer Technology Co., Ltd, a pioneer in additive manufacturing powders and metallurgy additives in China, offers unparalleled advantages for B2B buyers and distributors seeking to source high-quality 5052 aluminum powder.

What Sets Truer Apart:

| Feature | Benefit to B2B Buyers |

|---|---|

| Founded in 2009 | Over a decade of industry experience |

| Additive Manufacturing since 2019 | Dedicated division for 3D printing powders |

| Full Powder Portfolio | Includes 5052, PM bronze, PM steel, PM stainless, and more |

| Atomization Methods | Water, gas, and hybrid for flexible particle morphology |

| Quality Assurance | Every batch tested for chemical and physical consistency |

| Global Shipping | Export-grade packaging and logistics for international clients |

Customization & Support:

- Mesh sizes: -100/+325, -200, -325 tailored to your sintering or AM process.

- Custom packaging options for OEMs and distributors.

- Application-specific consulting for powder metallurgy, AM, and sintered components.

Powder Grades Available:

In addition to 5052, Truer offers a wide variety of powder metallurgy grades like:

- F-0000, FC-0208, FN-0205

- FL-4605, SBF2218, FX-2008

- Diffusion CuSn powder for diamond tools and sintered bearings

📌 The Truer Powder Metallurgy Additives Division is recognized as one of the most professional suppliers in China, providing complete additive solutions to PM customers.

📎 Ready to discuss sourcing needs? Contact Shanghai Truer’s team today for a tailored quote or technical consultation.

8. How to Order Bulk 5052 Powder from Reliable Sources

For B2B buyers, procurement managers, and distributors, ordering 5052 aluminum powder in large quantities involves several key steps to ensure quality assurance, timely delivery, and cost efficiency. Shanghai Truer Technology Co., Ltd has streamlined this process to support domestic and international clients with scalable fulfillment.

Step-by-Step Ordering Process with Shanghai Truer

| Step | Description | Notes |

|---|---|---|

| 1. Inquiry Submission | Submit an online inquiry or contact sales directly | Click here to contact us |

| 2. Requirement Analysis | Truer’s team reviews specs (mesh size, purity, quantity) | Customization available |

| 3. Quotation & Lead Time | Receive a detailed quote with delivery timeline | Includes Incoterms, MOQ, payment terms |

| 4. Sample Request (Optional) | Request lab-certified sample for testing | Recommended for first-time buyers |

| 5. Purchase Order | Confirm specs and place PO | PO confirmation triggers production |

| 6. Quality Inspection | Each batch tested for chemistry, PSD, and morphology | CoA (Certificate of Analysis) provided |

| 7. Packaging & Logistics | Powders packed per international shipping standards | Export-grade drums or vacuum packs |

| 8. Delivery & Tracking | Orders shipped via air, sea, or courier | Tracked end-to-end with customer support |

| 9. Post-Sales Support | Technical guidance, reordering, feedback loop | Continuous improvement process |

Packaging Options Available:

- 25kg sealed vacuum bags (nitrogen-filled)

- 100kg or 200kg export-grade drums

- Custom labeling for OEM/private label buyers

Payment Terms:

- T/T in advance (bulk discounts for repeat buyers)

- L/C available for large institutional orders

- Flexible terms for long-term B2B partners

📌 Truer works closely with global buyers across Europe, Southeast Asia, North America, and the Middle East, ensuring compliance with international quality and logistics standards.

🔗 Explore more about PM powder options and specifications offered by Truer.

9. FAQs: Buying & Using 5052 Aluminum Powder Wholesale

Below are common questions from procurement teams, engineers, and wholesale buyers when purchasing 5052 aluminum powder:

Q1: What’s the difference between water atomized and gas atomized 5052 powder?

A:

- Gas Atomized: Offers spherical particles, better flowability, ideal for AM.

- Water Atomized: More irregular shapes, cost-effective, used in PM and MIM.

Truer offers both types depending on your process requirements.

Q2: What is the minimum order quantity (MOQ) for 5052 powder?

A:

Typical MOQ starts at 25kg. For customized blends or mesh sizes, MOQ may vary. Discount pricing is available for orders above 500kg.

Q3: Can I request a custom particle size distribution?

A:

Yes. Truer allows clients to specify mesh ranges—for instance, -100/+325 for PM or -325 for LPBF. Custom sieving and blending services are available.

Q4: What certifications does Truer provide?

A:

All powder batches include a Certificate of Analysis (CoA). The company operates under ISO-compliant processes and meets RoHS and REACH standards.

Q5: How does Truer ensure powder quality for international clients?

A:

Each batch is tested for:

- Particle size distribution (PSD)

- Chemical composition

- Flowability

- Tap and apparent density

Truer also ships samples before bulk orders to ensure quality alignment.

Q6: What industries commonly order 5052 aluminum powder?

A:

- Aerospace (lightweight structural parts)

- Automotive (fuel tanks, EV applications)

- Additive manufacturing (custom parts)

- Marine (corrosion-resistant fittings)

Q7: Can I get technical support after purchasing?

A:

Yes. Truer provides ongoing technical support for powder handling, sintering parameters, and additive manufacturing optimization.

Final Thoughts

5052 aluminum powder is a premium-grade material essential to industries seeking lightweight strength, corrosion resistance, and process versatility. Whether you’re a manufacturer, distributor, or procurement officer, sourcing from a reliable supplier like Shanghai Truer ensures not only consistent powder quality but also long-term partnership value.

Shanghai Truer Technology Co., Ltd has built a robust reputation since 2009 by combining material science expertise with global logistics and scalable production. With a wide product portfolio, including PM bronze, steel, nickel alloys, and additive manufacturing powders, Truer is your ideal B2B partner in metal powders.

📎 Ready to scale your production with high-quality 5052 aluminum powder? Visit Shanghai Truer’s official site to explore their full catalog or get in touch with their technical team here.