Introduction: Why 430 Stainless Steel Powder Matters in Manufacturing

430 stainless steel powder is a ferritic grade stainless steel known for its excellent corrosion resistance, formability, and moderate mechanical properties. It is widely used in powder metallurgy (PM) and additive manufacturing (AM) applications, especially in automotive, appliance, and industrial sectors that demand magnetic properties and oxidation resistance.

For B2B buyers like manufacturers, wholesalers, and distributors, sourcing high-purity 430 powder is essential for producing parts that meet strict performance and compliance requirements. As global manufacturing shifts toward sustainable and efficient production, powder metallurgy using 430 stainless steel has become a cornerstone in industries like automotive exhaust systems, kitchen equipment, and structural components.

Key Benefits for Industrial Buyers:

- Cost-effective alternative to austenitic stainless steels

- Magnetic properties for specific PM applications

- Good corrosion resistance in mildly corrosive environments

- Easy to process in compaction and sintering

Industrial Applications of 430 Stainless Steel Powder

430 stainless steel powder finds diverse applications across multiple industries due to its balance of corrosion resistance, formability, and magnetic properties. Here’s a breakdown of its most common uses:

| Industry | Application | Advantages |

|---|---|---|

| Automotive | Exhaust system parts, heat shields | Corrosion resistance, cost-effective |

| Appliance | Washing machine drums, kitchen utensils | Formability, aesthetic finish |

| Electronics | Magnetic components, shielding | Ferritic properties |

| Construction | Architectural trim, interior panels | Durability, oxidation resistance |

| Additive Manufacturing | Prototypes, small-batch parts | Consistency and sintering behavior |

Use Cases in Powder Metallurgy:

- Sintered structural parts

- Soft magnetic components

- Metal injection molding (MIM)

- Binder jetting and laser powder bed fusion (LPBF)

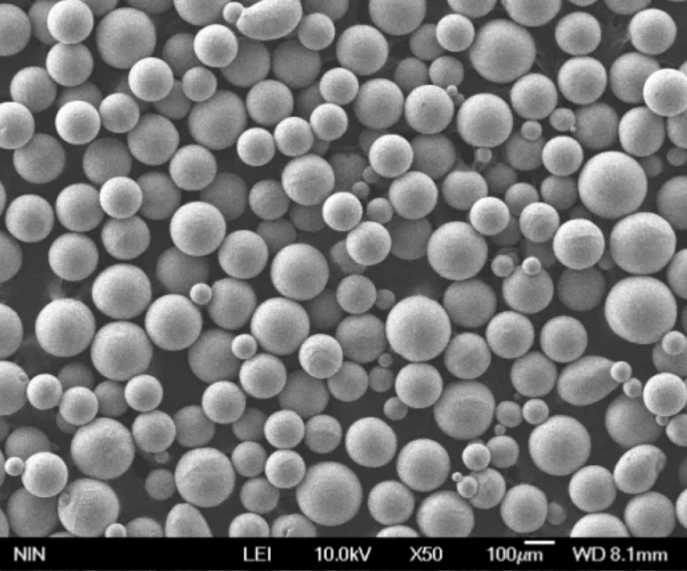

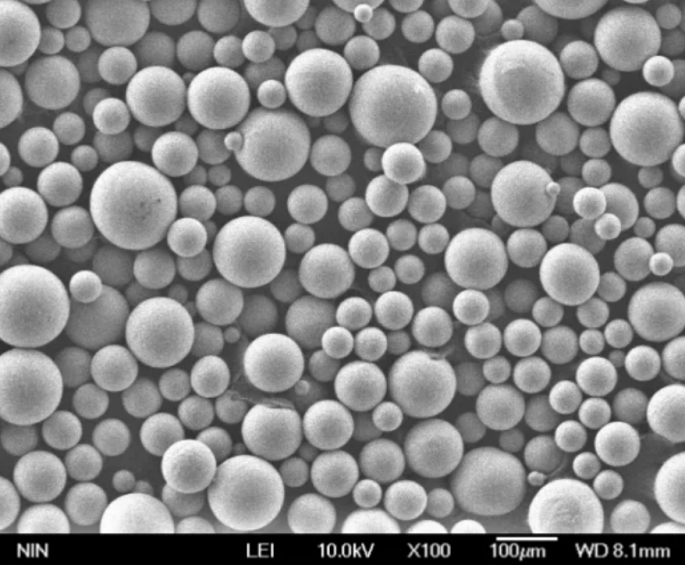

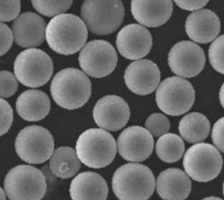

Powder Forms & Production Methods:

- Water Atomized: Suitable for cost-effective PM parts

- Gas Atomized: For high-performance or additive manufacturing needs

- Hybrid Atomization: Combines benefits for specialized applications

Technical Specifications and Properties of 430 Powder

Understanding the technical profile of 430 stainless steel powder is vital for procurement and product development teams. Below is a comprehensive table outlining its key characteristics:

Chemical Composition (Typical)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 16.0 – 18.0 |

| Carbon (C) | ≤ 0.12 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Physical and Mechanical Properties

| Property | Value |

|---|---|

| Density | ~7.8 g/cm³ |

| Melting Point | ~1425°C |

| Magnetic | Yes (ferritic) |

| Corrosion Resistance | Moderate |

| Formability | Good |

| Hardness (HRB) | 65–85 (sintered) |

Particle Size Distribution

| Mesh Size | Application |

|---|---|

| -100/+325 | Binder jetting, MIM |

| -325 | Laser sintering, LPBF |

| Custom sizing | Available upon request |

Shanghai Truer Technology Co., Ltd offers premium-grade 430 stainless steel powders tailored for both powder metallurgy and 3D printing applications. Produced via water or gas atomization, Truer’s 430 powders meet the highest standards of consistency, purity, and performance. Learn more about their full range of PM powders available for wholesale and OEM supply.

Global Market Trends and Demand for 430 Stainless Steel Powder

The global demand for stainless steel powders, particularly ferritic grades like 430, has seen consistent growth due to increasing adoption in automotive, appliance, and additive manufacturing industries. As sustainability and energy efficiency take center stage, powder metallurgy (PM) is being favored for its near-net-shape capabilities and material efficiency — areas where 430 stainless steel excels.

Key Industry Trends Driving 430 Powder Demand:

- Automotive Lightweighting: 430 stainless steel is increasingly used in exhaust components and heat shields, offering cost-effective corrosion resistance and magnetic properties.

- Rise of Metal 3D Printing: Ferritic stainless powders like 430 are being adapted for binder jetting and other AM technologies due to their lower cost and processability.

- Sustainable Manufacturing: PM processes reduce waste by up to 90%, making materials like 430 powder more attractive to eco-conscious manufacturers.

- Asia-Pacific Market Growth: China and India are leading in PM part production, driving regional demand for bulk stainless steel powders.

Market Forecast

| Region | Estimated CAGR (2024–2029) | Key Drivers |

|---|---|---|

| North America | 6.2% | Automotive, aerospace PM |

| Europe | 5.8% | Green manufacturing standards |

| Asia Pacific | 9.1% | Mass production, infrastructure growth |

Buyer Intent Keywords to Track

- “bulk 430 stainless steel powder”

- “wholesale PM stainless steel powder”

- “3D printing grade 430 powder supplier”

- “ferritic stainless steel powder for sintering”

These search terms signal strong purchasing intent from manufacturers, distributors, and e-commerce resellers looking to source 430 powder in volume.

Key Considerations When Choosing a 430 Powder Supplier

Choosing the right supplier of 430 stainless steel powder is critical to ensuring consistent quality, reliable delivery, and technical support. B2B buyers must evaluate both product characteristics and supplier capabilities.

Evaluation Checklist for 430 Powder Suppliers:

1. Powder Consistency & Purity

- Verify particle size distribution (PSD)

- Confirm chemical composition matches ASTM or ISO standards

- Inspect morphology (spherical/irregular) for application suitability

2. Manufacturing Methods

- Water vs. gas atomized — choose based on sintering or AM application

- Check if hybrid atomization options are available

3. Logistics & Lead Time

- Availability of stock for large-volume orders

- Regional warehousing for faster delivery

- Export experience and documentation support

4. Technical Support

- Application consulting for sintering or 3D printing

- Custom powder formulations

- Certifications (ISO 9001, RoHS, REACH)

5. Value-Added Services

- Pre-sintered or pre-alloyed options

- Blending with lubricants or additives

- Custom packaging for automated PM processes

Top 5 Trusted Suppliers of 430 Stainless Steel Powder Worldwide

Here’s a curated list of top global suppliers trusted by OEMs, contract manufacturers, and PM part producers for sourcing high-quality 430 stainless steel powder:

| Supplier | Country | Highlights |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Custom PM & AM powders, full-range additive solutions, hybrid atomization |

| Höganäs AB | Sweden | Global leader in PM powders, strong distribution in EU and Americas |

| Sandvik Osprey | UK | High-purity gas-atomized stainless powders for AM |

| Rio Tinto Metal Powders | Canada | Bulk powder supply, automotive-grade consistency |

| Carpenter Additive | USA | Specialty stainless powders for aerospace and medical industries |

Highlight: Shanghai Truer Technology Co., Ltd

Established in 2009, Shanghai Truer is a specialist in powder metallurgy and additive manufacturing powder solutions. Their 430 stainless steel powder is produced via water or gas atomization and meets stringent requirements for both sintering and 3D printing.

Why Truer Stands Out:

- Offers diffusion alloyed and pre-alloyed stainless grades

- Full technical support and customization

- Domestic and international logistics capabilities

- Integrated additive manufacturing division for AM-grade powders

Truer also provides value-added products like lubricants (Lube-W, SUW-8000), soft magnetic additives (QH-150), and proprietary cutting agents — making it a one-stop partner for PM manufacturers.

For more about Truer’s mission and innovation in powder metallurgy, visit their About Us page.

Why More Distributors Are Sourcing from China for 430 Powder

China has become a central hub for powder metallurgy materials, including 430 stainless steel powder. Distributors and B2B resellers globally are shifting to Chinese suppliers due to a combination of cost-effectiveness, quality improvements, and scalable production.

Reasons B2B Buyers Are Turning to Chinese Suppliers:

- Economies of Scale: Lower production and labor costs

- Advanced Manufacturing: Modern atomization technology and QC systems

- Faster Lead Times: Localized warehouses and export expertise

- Custom Solutions: Willingness to tailor powder formulations

Case Study: Shanghai Truer’s Competitive Edge

Truer’s hybrid atomization technology ensures consistent powder morphology and flowability, critical for both PM and AM applications. Their in-house R&D also allows them to supply specialty powders like PM phosphorus iron and PM infiltrated steel, expanding their relevance beyond just 430 stainless.

Key Support for Distributors:

- OEM and private labeling options

- Technical data sheets and COAs

- MOQ flexibility for emerging markets

- Access to PM additives and lubricants

Looking to streamline your sourcing from China? Reach out to Truer’s sales team for distributor pricing and product catalogs.

How to Order Wholesale 430 Stainless Steel Powder from China

Ordering 430 stainless steel powder in bulk doesn’t have to be a complex process — especially when buying from an experienced supplier like Shanghai Truer Technology Co., Ltd. Whether you’re a distributor, OEM manufacturer, or additive manufacturing company, following a structured procurement process helps ensure smooth international trade and consistent quality.

Step-by-Step Guide to Ordering from Truer

1. Define Technical Requirements

- Specify particle size range (e.g., -100/+325 mesh for PM, -325 mesh for AM)

- Choose atomization method: water, gas, or hybrid

- Indicate required chemical composition standards (e.g., ASTM A276)

2. Request Quotation

- Contact Truer’s sales team with:

- Desired quantity (MOQ: 100 kg to 5,000+ kg)

- Packaging preferences (25 kg drums, 1-ton pallets, vacuum-sealed)

- Delivery location and Incoterms (FOB Shanghai, CIF, DDP, etc.)

3. Review Sample and COA

- Request technical datasheet and sample batch

- Review Certificate of Analysis (COA) for:

- Elemental composition

- PSD (particle size distribution)

- Flow rate and apparent density

4. Confirm Order & Payment Terms

- Payment: T/T, Letter of Credit (L/C), or PayPal for small trials

- Lead time: 7–14 days for most grades

- Bulk discounts for 1-ton+ orders

5. Shipping & Documentation

- Truer handles export documentation:

- MSDS, COA, RoHS/REACH compliance

- Customs clearance support

- Options for sea freight, air freight, or rail (for EU/Asia)

6. After-Sales Support

- Technical consultation for sintering or AM settings

- Reordering and inventory management

- Access to Truer’s full additive solution portfolio

Example Order Flow

| Step | Action | Responsible Party |

|---|---|---|

| 1 | Send RFQ with specs | Buyer |

| 2 | Issue quotation | Truer |

| 3 | Approve sample & COA | Buyer |

| 4 | Finalize PI & payment | Buyer/Truer |

| 5 | Arrange export & shipping | Truer |

| 6 | Delivery & technical support | Truer |

📌 Want to streamline your procurement? Start by visiting Truer’s contact page and submit your specifications.

FAQs: Buying Wholesale 430 Stainless Steel Powder

Q1: What is the minimum order quantity (MOQ) for 430 stainless steel powder?

A: Truer typically supports MOQs starting at 100 kg for trial batches. Large-volume orders (1 ton or more) receive competitive bulk pricing.

Q2: Can I get a customized particle size distribution (PSD)?

A: Yes. Truer can tailor PSD to your application — whether for powder metallurgy, metal injection molding, or binder jetting.

Q3: Is 430 stainless steel powder magnetic?

A: Yes. 430 is a ferritic stainless steel, making it inherently magnetic — ideal for applications requiring soft magnetic properties.

Q4: What are the available atomization methods?

A: Truer offers water atomized, gas atomized, and hybrid atomized options to meet different end-use requirements.

Q5: What packaging options are available?

A: Standard packaging includes 25 kg vacuum-sealed bags, 100 kg drums, or 1-ton super sacks. Custom packaging is available upon request.

Q6: How long does it take to receive an order?

A: Lead time is 7–14 days for most grades. Shipping time varies by region — generally 5–20 days depending on method and destination.

Q7: Does Truer offer technical support for AM or PM processes?

A: Absolutely. Truer’s metallurgists and engineers provide full consultation for sintering temperatures, binder compatibility, and additive blending.

Q8: Are Truer’s powders certified?

A: Yes. Truer provides full documentation, including COA, MSDS, and compliance with ISO, RoHS, and REACH standards.

Why Choose Shanghai Truer Technology for 430 Powder

Shanghai Truer Technology Co., Ltd is not just a supplier — it’s a strategic partner for manufacturers and distributors in the powder metallurgy and additive manufacturing industries. With over a decade of expertise and a commitment to innovation, Truer delivers stainless steel powders that meet the demanding needs of modern production.

Truer’s Competitive Advantages for B2B Buyers:

✅ Wide Alloy Portfolio

From 430 stainless to PM copper steel, Truer offers over 15 powder grades, including PM4600, FD-0208, FX1005, and more.

✅ Custom Atomization Techniques

Water, gas, and hybrid atomization methods allow Truer to produce powders for sintering, MIM, and 3D printing.

✅ Integrated Additive Solutions

Truer’s additives division provides lubricants (SUW-8000), graphite (TBC-1000), and cutting agents compatible with their powder offerings.

✅ High Purity & Consistency

Strict quality control ensures batch-to-batch consistency — critical for mass production and regulatory compliance.

✅ Global Logistics Support

With experience exporting to North America, Europe, and Southeast Asia, Truer ensures smooth delivery and customs handling.

✅ R&D and Technical Support

In-house engineers offer consultation, application development, and powder customization to suit client-specific projects.

Explore Truer’s products and capabilities on their official homepage.

Ready to Source High-Quality 430 Stainless Steel Powder?

If you’re a manufacturer, distributor, or industrial buyer looking for a reliable source of PM-grade or AM-grade 430 stainless steel powder, Shanghai Truer Technology is your trusted partner.

📩 Contact their expert team here to request samples, quotes, or technical consultation.