1. Introduction: Why 317L Powder Matters in Modern Manufacturing

317L stainless steel powder is a high-performance material known for its exceptional corrosion resistance, high-temperature strength, and weldability. This austenitic stainless steel alloy contains elevated levels of molybdenum and low carbon content, making it particularly suitable for harsh environments such as chemical processing, marine, and food-grade applications.

In powder form, 317L is increasingly used in:

- Additive manufacturing (AM) / 3D printing

- Metal injection molding (MIM)

- Powder metallurgy (PM) sintering

- Laser cladding and thermal spraying

The growing demand for lightweight, corrosion-resistant, and high-strength components in industries such as oil & gas, aerospace, and medical devices is driving the popularity of 317L powder among B2B buyers, including:

- Distributors of specialty metal powders

- OEMs in high-performance sectors

- E-commerce platforms focused on additive manufacturing

- Contract manufacturers and machine shops

With its excellent mechanical and chemical properties, 317L powder is a preferred choice for complex components that require high reliability and longevity.

2. Industrial Applications of 317L Stainless Steel Powder

The versatility of 317L powder makes it essential in several high-demand sectors. Here’s a breakdown of key industries and how they utilize this advanced material:

| Industry | Application | Benefit |

|---|---|---|

| Chemical Processing | Reactor vessels, heat exchangers, piping | Superior corrosion resistance against chlorides and acids |

| Medical Devices | Surgical implants, orthopedic tools | Biocompatibility and high cleanliness |

| Aerospace | Structural components, flow systems | High strength-to-weight ratio and oxidation resistance |

| Food & Beverage | Processing equipment, conveyors | Non-contaminating and easy to sanitize |

| Additive Manufacturing | 3D-printed parts for prototypes and end-use | High precision and material consistency |

Key Use Cases:

- 3D Printing for Prototyping and Production: 317L powder’s uniform particle size and flowability make it ideal for laser powder bed fusion (LPBF) and direct energy deposition (DED).

- Corrosion-Resistant Components: Its high molybdenum content (3.0–4.0%) enhances pitting and crevice corrosion resistance.

- Medical Applications: Low carbon content ensures low carbide precipitation during welding, increasing its appeal for implant-grade applications.

3. Properties and Types of 317L Powder

Understanding the metallurgical and physical properties of 317L powder is essential for choosing the right supplier and process.

Chemical Composition (Typical)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 18.0–20.0 |

| Nickel (Ni) | 11.0–15.0 |

| Molybdenum (Mo) | 3.0–4.0 |

| Carbon (C) | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

Mechanical Properties (As-Built or Sintered)

- Tensile Strength: ≥ 550 MPa

- Yield Strength: ≥ 220 MPa

- Elongation: ≥ 30%

- Hardness: ~180 HB

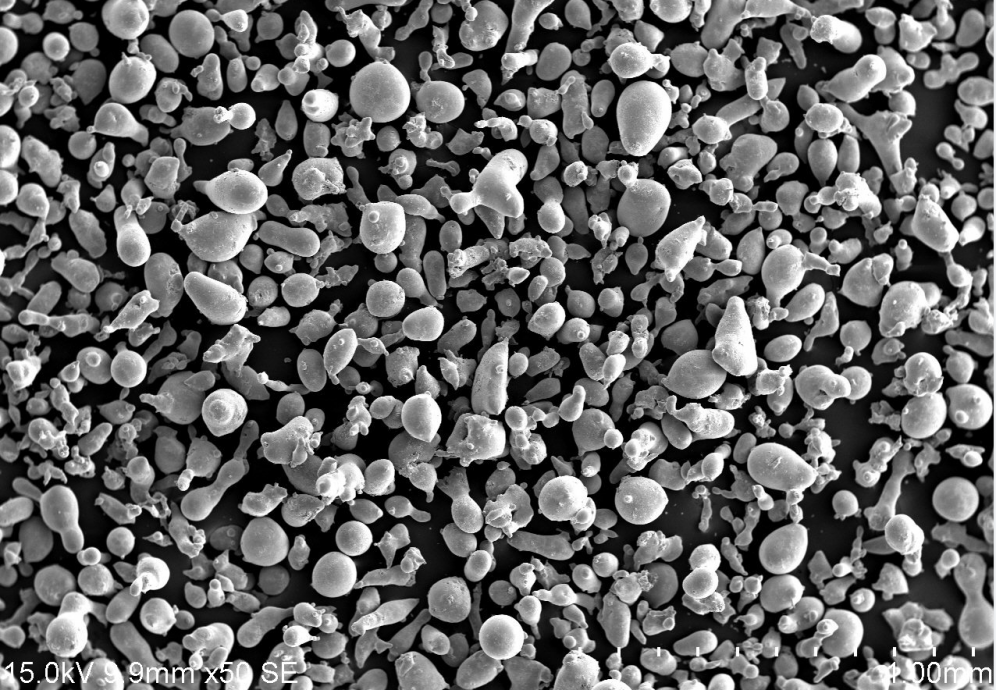

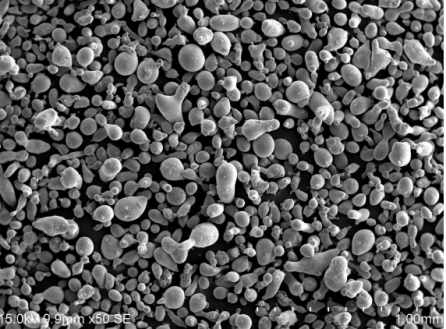

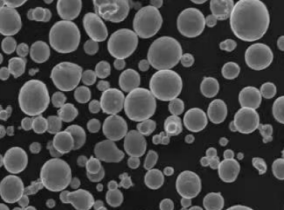

Available Powder Types

| Type | Production Method | Features | Applications |

|---|---|---|---|

| Gas Atomized 317L Powder | Fine spherical particles | Excellent flowability, high purity | AM, MIM |

| Water Atomized 317L Powder | Irregular morphology | Cost-effective, good compressibility | PM sintering |

| Plasma Atomized 317L | Ultra-fine control | High-end aerospace and medical use | LPBF, EBM |

If you’re looking for high-quality PM stainless steel powders, Shanghai Truer offers both water and gas atomized 317L options, meeting stringent B2B requirements for precision manufacturing.

4. Key Factors to Consider When Buying 317L Powder in Bulk

When sourcing 317L stainless steel powder for industrial or additive manufacturing use, it’s critical to assess several technical and commercial factors before making a bulk purchase. These considerations ensure product consistency, compatibility with end-use applications, and long-term supplier reliability.

A. Technical Specifications

Make sure your supplier provides detailed technical documentation, including:

- Particle Size Distribution (PSD): For AM, a common PSD range is 15–45 μm (LPBF) or 45–105 μm (DED).

- Morphology: Spherical powders are preferred for 3D printing due to better flowability.

- Purity: Chemical composition must align with ASTM A276/A240 or customer-specific standards.

- Flow Rate & Apparent Density: Should be optimized for your application process.

B. Production Method

Choose powders based on the manufacturing process compatibility:

| Process | Preferred Powder Type | Notes |

|---|---|---|

| LPBF / SLM | Gas Atomized | Spherical shape, narrow PSD |

| MIM | Fine Water Atomized | Good compressibility |

| PM Sintering | Water Atomized | Cost-effective in volume |

| DED / Laser Cladding | Coarser Gas Atomized | High flow rates needed |

C. Certifications and Quality Assurance

- ISO 9001, ISO 13485 (medical), or AS9100 (aerospace) certifications

- Batch traceability and third-party chemical analysis

- Material Safety Data Sheet (MSDS) and packing/testing protocols

D. Logistics and Bulk Supply Capabilities

- Lead times and shipping reliability

- Inventory availability for large-scale orders

- Packaging for moisture-sensitive or reactive powders

Shanghai Truer, for example, offers various packing formats (airtight drums, vacuum-sealed bags) and provides full documentation with every shipment, ensuring quality from production to delivery.

5. Top 317L Powder Suppliers Globally and in China

To help distributors and B2B buyers make informed sourcing decisions, here is a curated list of established 317L powder suppliers based on technical capabilities, reputation, and regional accessibility.

A. Global 317L Powder Suppliers

| Company | Country | Notable Features |

|---|---|---|

| Sandvik Osprey | UK | High-purity gas atomized alloys; AM-grade powders |

| Höganäs AB | Sweden | Water-atomized powders for PM; wide alloy range |

| Carpenter Additive | USA | Aerospace-compliant stainless powders |

| AMETEK Specialty Metals | USA | Precision powder metallurgy alloys |

| Erasteel | France | High-speed steel and stainless PM powders |

B. Top Chinese 317L Powder Suppliers

| Company | Location | Strengths |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | Shanghai | Wide range of PM and AM stainless powders; hybrid atomization technology |

| CNPC Powder | Sichuan | Gas and water atomized powders; bulk export capabilities |

| Advanced Technology & Materials Co., Ltd. (AT&M) | Beijing | Specializes in high-performance alloy powders |

| Pometon Powder | Suzhou | Joint venture with Italian Pometon; certified quality systems |

Shanghai Truer is particularly notable for offering both water and gas atomized 317L powder, as well as customized additive solutions for PM, MIM, and AM. With over a decade of metallurgy experience, Truer supports OEMs and distributors with scalable production and technical support.

6. Why More Buyers Are Choosing Chinese Suppliers for 317L Powder

Over the last decade, Chinese manufacturers have significantly advanced in the development and production of stainless steel powders, particularly in grades like 317L. Buyers across North America, Europe, and Southeast Asia are increasingly turning to Chinese sources for several reasons:

A. Competitive Pricing

- Lower production and labor costs

- Economies of scale allow for aggressive bulk pricing

- Customizable packaging and logistics solutions

B. Expanded Capabilities

Chinese suppliers now offer:

- Both gas and water atomization lines

- In-house R&D for new alloy development

- ISO, ASTM, and GB standard compliance

C. Rapid Lead Times

- Faster turnaround from inquiry to delivery

- Domestic sourcing of raw materials reduces bottlenecks

- Strong international freight partnerships

D. Proven Quality

Companies like Shanghai Truer Technology have built a reputation for supplying consistent, high-purity 317L powder to clients in over 20 countries. Their hybrid atomization capabilities and comprehensive additive solutions make them a preferred partner for AM and PM industries.

E. End-to-End Service

- Custom powder blends and particle size distributions

- Technical consultation for process optimization

- Post-sales support and application engineering

If you’re a B2B buyer looking for quality, affordability, and responsive service, sourcing from a Chinese supplier like Truer offers a strategic advantage in today’s global market.

7. Why Choose Shanghai Truer as Your 317L Powder Supplier

As the global demand for high-performance stainless steel powders grows, B2B buyers are seeking suppliers who offer more than just raw materials — they need partners who deliver quality, innovation, and reliability. Shanghai Truer Technology Co., Ltd. has emerged as one of the most trusted names in the Chinese powder metallurgy and additive manufacturing industry.

Company Overview

- Founded: 2009

- Additive Manufacturing Division Launched: 2019

- Headquarters: Shanghai, China

- Website: am-material.com

What Sets Shanghai Truer Apart?

| Feature | Benefit |

|---|---|

| In-House Atomization Facilities | Both gas and water atomized powders for optimized performance |

| Broad Alloy Portfolio | PM 317L, 316L, 304L, and custom stainless steel grades available |

| Precision Quality Control | Each batch is tested for particle size, morphology, and chemical composition |

| Customized Solutions | Tailored PSD and blends for MIM, AM, and PM sintering |

| Fast Lead Times | Manufacturing and warehousing ready for bulk orders |

| Comprehensive Support | From material selection to post-sales technical guidance |

Certifications & Standards

- ISO 9001:2015 Certified

- Compliance with ASTM A276, A240, and GB standards

- Material traceability and full documentation per shipment

Truer’s PM and AM Powder Portfolio Includes:

- PM Stainless Steel Powders – 317L, 316L, 304L

- Low-Alloy PM Steels – FD-0208, FL-4605, FX-2008

- Specialty Powders – Diffusion CuSn, soft magnetic materials, and sintered bearing powders

- Lubricants and Additives – Lube-W, SUW-8000, QH-150

Whether you’re a distributor, OEM, or e-commerce seller looking for consistent supply and competitive pricing, Truer offers a complete solution for 3D printing and PM powders. Their advanced R&D and hybrid atomization technology ensure their powders meet the strictest industrial demands.

8. How to Order Wholesale 317L Powder from China

Ordering 317L stainless steel powder in bulk from China can be a streamlined and efficient process if you follow the right steps and work with a reliable supplier.

Step-by-Step B2B Ordering Process

- Define Your Requirements

- Select particle size distribution (e.g., 15–45 µm for LPBF)

- Specify purity level and delivery volume

- Indicate application (AM, PM, MIM)

- Request a Technical Data Sheet (TDS)

- Ensure the chemical and physical properties match your needs

- Request sample for testing if required

- Contact Supplier for Quotation

- Include Incoterms preference (EXW, FOB, CIF)

- Confirm lead time and shipping options

- Negotiate Terms

- Secure volume discounts or long-term agreements

- Discuss payment terms (T/T, L/C, etc.)

- Place the Order

- Provide PO number

- Confirm packaging type (vacuum-sealed, drum, etc.)

- Shipping and Delivery

- Track order with logistics partner

- Ensure documentation is received (MSDS, COA, invoice)

- Post-Sales Support

- Test incoming batch and report feedback

- Reorder or adjust based on performance

Why Work with Shanghai Truer?

Shanghai Truer simplifies this entire process with prompt customer service, multilingual sales support, and flexible order fulfillment options. You can contact their team directly to get a custom quote tailored to your specifications.

Typical Packaging Options

| Packaging Type | Capacity | Features |

|---|---|---|

| Vacuum Bag | 1–5 kg | Moisture-proof, sample orders |

| Sealed Plastic Drum | 20–50 kg | Industrial use, reusable |

| Metal Drum | 100+ kg | Export-ready, anti-static liners |

They offer full export documentation and support customs clearance in most major importing countries.

9. FAQs: Common Questions About Purchasing 317L Powder in Bulk

Q1: What is the minimum order quantity (MOQ) for 317L powder?

A: Shanghai Truer typically offers MOQs starting from 10 kg for sampling and 100 kg for bulk orders.

Q2: Can 317L powder be customized for different applications?

A: Yes. Truer can tailor particle size, flowability, and surface treatment to suit AM, PM, or MIM processes.

Q3: How is 317L powder shipped internationally?

A: It’s packed in airtight containers and shipped via air or sea freight with all necessary export documentation.

Q4: Is 317L powder biocompatible for medical use?

A: Yes, 317L is a low-carbon alloy often used in medical components due to its biocompatibility and corrosion resistance.

Q5: Can I visit the supplier’s facility before placing a bulk order?

A: Absolutely. Shanghai Truer welcomes audits and visits. You can schedule one via their contact page.

Q6: How do I ensure consistent batch quality?

A: Truer provides batch certificates, third-party testing reports, and maintains strict ISO-certified processes.

Q7: What industries typically use 317L powder?

A: Aerospace, chemical processing, food-grade equipment, marine, and medical device industries.

By choosing Shanghai Truer as your 317L stainless steel powder supplier, you gain access to a reliable partner with deep technical expertise, flexible production capabilities, and a customer-first approach. Whether you’re a wholesaler, OEM, or AM specialist, Truer’s product line and service are engineered to help you scale your operations with confidence.

✅ Ready to get started? Request a quote or contact Truer’s sales team today to discuss your 317L powder requirements.