1. Introduction to 304 Powder and Its Industrial Significance

304 stainless steel powder is one of the most widely used metal powders in additive manufacturing (AM), powder metallurgy (PM), and various sintering processes due to its excellent corrosion resistance, mechanical strength, and weldability. In B2B markets, it plays a vital role in the production of industrial parts, components, and machinery.

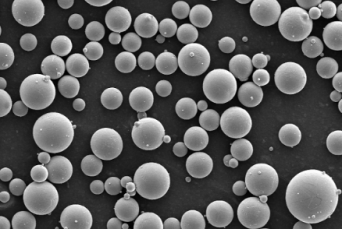

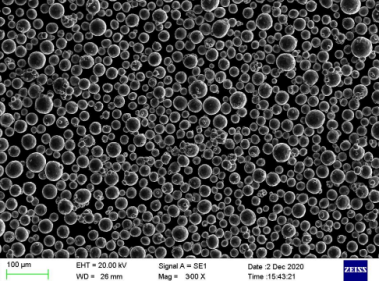

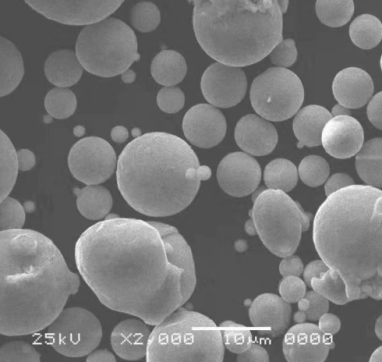

304 powder is typically atomized using gas atomization, water atomization, or combined atomization methods to achieve the desired particle morphology and purity for manufacturing applications. It is especially popular among:

- OEMs (Original Equipment Manufacturers)

- Automobile part manufacturers

- Aerospace component suppliers

- Medical device fabricators

- Metal injection molding (MIM) producers

Key reasons why 304 powder is favored in industrial use:

- High corrosion resistance in a wide range of environments

- Excellent mechanical properties

- Good weldability and formability

- Compatibility with AM and PM technologies

2. Applications of 304 Powder in Manufacturing and Engineering

304 stainless steel powder is utilized across a diverse set of industries for its versatility and reliability. Below are major applications where 304 powder plays a critical role:

✔️ Industrial Applications of 304 Powder

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Exhaust systems, engine components | High-temperature resistance, corrosion protection |

| Aerospace | Structural and non-structural engine parts | Lightweight, high-strength, fatigue resistance |

| Medical | Surgical tools, implants, diagnostics | Biocompatibility, hygiene, sterilization capability |

| Electronics | Housings, connectors, EMI shieldings | Conductivity, non-magnetic versions available |

| Construction | Fasteners, brackets, cladding | Durability, aesthetics, long life |

| Food Processing | Equipment components | FDA-compliant, rust-resistant, easy to clean |

✔️ Additive Manufacturing (3D Printing)

304 powder is suitable for several 3D printing technologies, including:

- Selective Laser Melting (SLM)

- Electron Beam Melting (EBM)

- Binder Jetting

- Direct Metal Laser Sintering (DMLS)

It enables rapid prototyping and production of complex geometries with minimal waste, making it ideal for custom industrial parts.

✔️ Powder Metallurgy (PM)

In PM processes, 304 powder is compacted and sintered to create dense, strong parts for:

- Bearings

- Gears

- Pumps

- Valves

These are widely used in automotive and machinery manufacturing.

3. Chemical Composition and Properties of 304 Stainless Steel Powder

304 stainless steel is an austenitic grade known for its balance of strength and corrosion resistance. Below is its typical chemical composition:

📊 Chemical Composition of 304 Stainless Steel Powder

| Element | Typical Content (%) |

|---|---|

| Chromium (Cr) | 18 – 20 |

| Nickel (Ni) | 8 – 10.5 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

🔧 Key Physical & Mechanical Properties

| Property | Value |

|---|---|

| Density | 7.9 g/cm³ |

| Melting Point | 1400–1450 °C |

| Hardness (HV) | 150–200 |

| Tensile Strength | 505 MPa |

| Yield Strength | 215 MPa |

| Elongation | ≥ 40% |

| Corrosion Resistance | Excellent in neutral & oxidizing environments |

These properties make 304 powder ideal for high-performance and corrosion-resistant parts in demanding environments.

For businesses looking to integrate high-quality stainless steel powders into their manufacturing pipeline, working with a trusted supplier is critical. Shanghai Truer Technology Co., Ltd offers a range of stainless steel powders, including water and gas atomized 304 stainless steel powder tailored for additive manufacturing and powder metallurgy customers. Their commitment to quality control, technical guidance, and material consistency makes them a reliable partner for B2B buyers and distributors.

4. Global Market Trends and Demand Forecast for 304 Powder

With the rapid expansion of additive manufacturing (AM), metal injection molding (MIM), and precision engineering, the demand for 304 stainless steel powder is experiencing sustained growth. According to market research, the global metal powder market is projected to reach USD 6.5 billion by 2027, with stainless steel powders taking a significant share due to their versatility and cost efficiency in industrial production.

📈 Market Drivers for 304 Powder:

- Rising adoption of 3D printing in aerospace and medical industries

- Growing automotive demand for lightweight, corrosion-resistant components

- Increased focus on energy-efficient manufacturing using PM and AM

- Expansion of the electronics and semiconductor sectors

- Sustainability initiatives encouraging recyclable and reusable materials

🌍 Regional Demand Overview

| Region | Key Industries Driving Demand | Growth Rate (CAGR) |

|---|---|---|

| Asia-Pacific | Automotive, Machinery, Electronics | 7.8% |

| North America | Aerospace, Medical, Defense | 6.1% |

| Europe | Industrial Equipment, Renewable Energy | 5.9% |

The Asia-Pacific region, particularly China, is emerging as the global hub for stainless steel powder production due to its scalable manufacturing capabilities, skilled labor, and competitive pricing.

5. How to Evaluate and Choose a Reliable 304 Powder Supplier

Selecting the right supplier is critical for ensuring consistent quality, technical support, and compliance with international standards. B2B buyers, distributors, and OEMs should consider the following factors when vetting a wholesale 304 powder supplier:

✅ Evaluation Criteria Checklist

- Production Method: Gas atomization, water atomization, or a hybrid method? Gas atomized powders generally offer better sphericity and flowability for AM.

- Powder Certifications: ISO, ASTM, or other local certifications for powder metallurgy standards.

- Particle Size Distribution: Suitable PSD for your specific application (e.g., SLM, MIM, PM).

- Supply Chain Reliability: Can the supplier meet your volume and lead time requirements?

- Technical Support: Do they provide in-depth technical data sheets, application advice, and post-sales service?

- Customization Options: Ability to tailor compositions or blends based on specific industrial needs.

- Pricing and Payment Terms: Transparent pricing and flexible payment options for bulk buyers.

🛠️ Recommended Due Diligence Steps

- Request technical data sheets (TDS) and material safety data sheets (MSDS).

- Ask for a sample batch for testing before confirming bulk orders.

- Ensure traceability and batch consistency in long-term supply contracts.

- Visit the production site or conduct virtual audits if possible.

Shanghai Truer Technology Co., Ltd provides full documentation and support for their 304 stainless steel powder products, ensuring that clients receive consistent, application-ready materials.

6. Top 5 Wholesale Suppliers of 304 Powder in Asia

Asia is home to several quality-driven manufacturers of 304 powder. Below are five leading companies offering competitive B2B solutions:

| Supplier | Country | Key Offerings | Strengths |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Water/gas atomized 304 powder, PM additives | Full-service OEM support, custom blends, strong R&D |

| Sandvik Osprey | India | Gas-atomized stainless steel powders | Aerospace-grade quality, global distribution |

| Hoganas AB | China/Sweden | Water atomized stainless and alloy powders | Global presence, high-volume capacity |

| CNPC Powder | China | Metal powders for AM and MIM | Competitive pricing, rapid delivery |

| POSCO Powder | South Korea | Stainless steel and low alloy powders | High-purity products, strong steelmaking background |

Shanghai Truer stands out for its ability to provide both standard and tailored PM solutions, supported by a dedicated R&D team and advanced atomization technologies.

- Customizable grades: Including 304, 316L, and 420 stainless steel powders

- Flexible atomization techniques: Gas, water, or combined methods

- OEM and distributor-friendly: Scalable supply and technical collaboration

👉 Learn more about Truer’s powder metallurgy solutions on their main website.

7. Why More B2B Buyers Are Choosing Chinese Manufacturers for 304 Powder

In recent years, Chinese manufacturers have become the go-to source for high-quality, cost-effective 304 stainless steel powder. Here’s why:

🌟 Competitive Advantages of Chinese Suppliers

- Lower Production Costs: Reduced raw material and labor costs allow for better pricing on bulk orders.

- Advanced Manufacturing Technologies: Use of gas and hybrid atomization techniques for high-performance powders.

- Scalability: Ability to fulfill high-volume orders with short lead times.

- R&D Capacity: Many suppliers offer customized formulations and technical support.

- Global Logistics Networks: Efficient international shipping and customs handling.

🔍 Case Example: Truer Technology’s Value Proposition

Shanghai Truer Technology Co., Ltd, founded in 2009, has quickly risen as a key player in the global powder metallurgy market. Since launching its additive manufacturing business in 2019, Truer has invested heavily in 3D printing powder production and application services. Their dedication to quality and innovation makes them a preferred supplier for:

- E-commerce metal part sellers

- Distributors of PM materials

- Industrial equipment manufacturers

- Automotive and aerospace OEMs

Truer offers a variety of stainless steel powders—like 304 and 316L—produced through gas, water, or combined atomization methods. Their R&D-backed production process ensures consistency, purity, and application-specific performance.

8. Why Choose Shanghai Truer Technology Co., Ltd for 304 Powder

Shanghai Truer Technology Co., Ltd is one of the most trusted and professional suppliers of 304 stainless steel powder in China, with a strong reputation in the additive manufacturing (AM) and powder metallurgy (PM) sectors. Since entering the AM materials segment in 2019, Truer has delivered tailored solutions to a wide variety of B2B clients including OEMs, industrial manufacturers, and material distributors.

🏆 Key Reasons to Choose Truer

| Feature | Benefit to B2B Buyers |

|---|---|

| In-house Atomization Lines (Gas, Water, Hybrid) | Control over powder morphology, flowability, and consistency |

| Diverse Stainless Steel Grades | 304, 316L, 420, custom compositions for PM & AM |

| Custom Particle Size Distribution | Tailored PSDs for SLM, DMLS, or MIM applications |

| Technical Support & R&D | Application engineering, test samples, and material optimization |

| Scalable Production | Supports both small-batch prototyping and bulk industrial orders |

| International Shipping | Global logistics and documentation for export compliance |

Truer also offers a comprehensive range of powder metallurgy additives like lubricants (Lube-W, SUW-5000B), cutting agents, and graphite-based materials to enhance sintering performance and part quality—making them a one-stop shop for PM and AM buyers.

⭐ Example Grades Offered by Truer:

| Product Code | Description | Process |

|---|---|---|

| SBF2218 | Gas atomized 304 stainless steel powder | AM, SLM |

| FX-2008 | Water atomized stainless & alloy blend | PM, MIM |

| FD-0208 | Hybrid diffusion alloyed steel powder | High-density structural parts |

👉 You can explore the full list of available powders on Truer’s product page here.

9. How to Order Wholesale 304 Powder from Truer

Purchasing 304 stainless steel powder in bulk from Truer is a streamlined process designed to cater to global B2B buyers, distributors, and OEM manufacturers.

🛒 Step-by-Step Ordering Process:

- Product Inquiry

Contact Truer’s sales team with your requirements:- Grade & composition (e.g., 304, 316L)

- Quantity (kg or tons)

- Preferred atomization method (gas, water, hybrid)

- Application (3D printing, PM, MIM)

- Quote & Technical Consultation

Truer provides:- Technical Data Sheets (TDS)

- Particle size distribution

- Compliance certifications (ISO, ROHS, etc.)

- Pricing and lead times

- Sample Request (Optional)

For new customers, Truer can provide small test samples for application testing. - Order Confirmation

Confirm your order with:- Purchase Order (PO)

- Payment terms (T/T, LC, etc.)

- Delivery schedule

- Production & Quality Control

Every batch undergoes:- Sphericity inspection

- Flow rate and tap density analysis

- Chemical composition verification

- Packaging & Logistics

Powders are packed in sealed, moisture-resistant containers and shipped via air, sea, or express. - After-Sales Support

Truer offers technical support, reordering assistance, and long-term supply agreements.

👉 Ready to start? You can contact Truer here to request a quote or speak with a technical expert.

10. FAQs: Everything You Need to Know About Buying Wholesale 304 Powder

❓ What is the minimum order quantity (MOQ) for 304 powder?

Truer typically accepts MOQs starting from 50 kg for standard grades. For custom compositions or particle sizes, MOQs may vary.

❓ Can I get customized particle size distribution (PSD)?

Yes. Truer offers tailored PSDs for specific applications such as:

- <15 μm for binder jetting

- 15–45 μm for SLM, DMLS

- 45–106 μm for MIM and PM

❓ What’s the difference between gas and water atomized 304 powder?

| Feature | Gas Atomized | Water Atomized |

|---|---|---|

| Shape | Spherical | Irregular |

| Flowability | Excellent | Average |

| Application | AM, SLM | MIM, PM |

| Cost | Higher | Lower |

Truer provides both options based on your application requirements.

❓ Does Truer provide export documentation and compliance certificates?

Yes. All exports include:

- Material certificates

- ISO 9001 compliance

- Country of origin

- MSDS and TDS documentation

❓ Can I order a trial batch before placing a bulk order?

Absolutely. Truer encourages new clients to test a small sample batch before committing to a full production order.

Internal Anchor Links Summary

To enhance navigation and SEO optimization, here are the internal anchor links embedded in this article:

- About Shanghai Truer Technology Co., Ltd

- Main website for AM and PM solutions

- Product catalog of PM powders

- Contact Truer for wholesale inquiries

Conclusion & Call to Action

304 stainless steel powder is an essential material for manufacturers in automotive, aerospace, medical, and industrial sectors. Whether you’re producing parts via powder metallurgy or additive manufacturing, sourcing high-purity, application-specific 304 powder is critical to your production success.

Shanghai Truer Technology Co., Ltd offers a full range of stainless steel powders—crafted with precision, backed by R&D, and supported by outstanding customer service. Whether you’re a B2B buyer, distributor, or OEM, Truer is your reliable partner for premium 304 powder and custom metal powder solutions.

👉 Get a quote or speak to an expert today by visiting Truer’s contact page.

Let Truer help you build better—one powder particle at a time.