1. Introduction: What is 1.2709 Powder?

1.2709 powder is a high-strength maraging steel powder widely used in additive manufacturing (AM) and powder metallurgy (PM) applications. Known for its excellent mechanical properties, aging hardenability, and weldability, this powder is primarily used in metal 3D printing processes like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS).

Chemical Composition of 1.2709 Powder

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 17–19 |

| Cobalt (Co) | 8–10 |

| Molybdenum (Mo) | 4.5–5.2 |

| Titanium (Ti) | 0.8–1.2 |

| Iron (Fe) | Balance |

Key Features

- High tensile strength (~2000 MPa after aging)

- Excellent dimensional stability during heat treatment

- Superior corrosion resistance

- Excellent machinability before aging

This powder is especially attractive for B2B buyers, including aerospace part manufacturers, mold tool makers, and automotive suppliers who require consistency and high performance in complex geometrical components.

📌 Learn more about Shanghai Truer’s 1.2709 PM powder offerings and how they support high-performance engineering projects.

2. Industrial Applications of 1.2709 Powder

Thanks to its mechanical resilience and excellent processability, 1.2709 maraging steel powder is used in a wide range of industries. Below are the primary sectors utilizing this metal powder in both additive and traditional powder metallurgy manufacturing.

Aerospace & Defense

- High-performance turbine components

- Structural brackets and engine parts

- Lightweight but strong load-bearing components

Tooling & Molding

- Injection molding tools

- Blow mold inserts

- Die-casting molds

- Hot working tools

Automotive

- Lightweight transmission components

- Racing car parts

- High-stress gear assemblies

Medical & Dental

- Surgical instruments

- Dental frameworks

- Orthopedic implants (non-load bearing)

Benefits for Industrial Buyers

- Reduced lead time: Ideal for rapid prototyping and short production runs.

- Cost efficiency: Lower tooling costs compared to traditional forging or casting.

- Customization: Enables design flexibility in complex geometries.

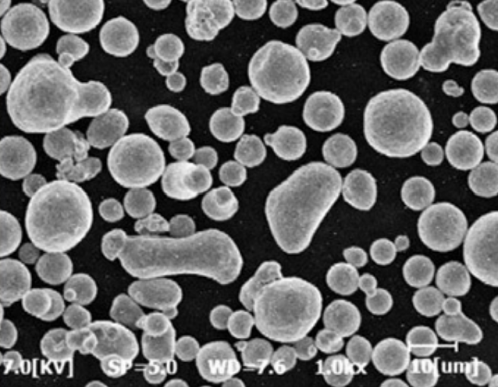

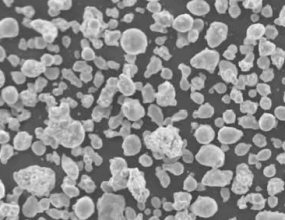

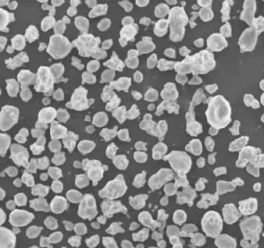

3. Key Properties and Performance Benefits

When sourcing 1.2709 powder for industrial applications, understanding its physical and mechanical properties is vital for selecting a suitable supplier. Shanghai Truer Technology offers gas atomized 1.2709 powders with high sphericity and low oxygen content, optimized for metal 3D printing and sintering applications.

Physical Properties

| Property | Value |

|---|---|

| Particle Size (D50) | 15–45 µm (customizable) |

| Apparent Density | 3.9–4.3 g/cm³ |

| Flowability | 12–18 s/50g |

| Sphericity | ≥ 95% |

| Oxygen Content | ≤ 0.03% |

Mechanical Properties After Aging

| Property | Value |

|---|---|

| Tensile Strength | 1900–2100 MPa |

| Yield Strength | ≥ 1800 MPa |

| Elongation at Break | 4–6% |

| Hardness | 52–54 HRC |

Performance Advantages

- Post-heat treatment hardening allows for excellent wear resistance.

- Low carbon content reduces distortion during sintering or printing.

- Excellent weldability ensures high layer bonding in AM.

Why It’s Ideal for B2B Use

- Reliability: With strict compliance to ASTM and ISO standards, 1.2709 powder ensures consistent quality for large-scale OEM production.

- Efficiency: Helps reduce material waste and machining time.

- Scalability: Suitable for both prototyping and full-scale production runs.

🔗 Curious how these properties translate into better parts? Discover more on our About Us page to see how Shanghai Truer supports engineering innovation.

4. Market Demand and Growth for 1.2709 Powder

With the growing adoption of additive manufacturing (AM) across industries, the demand for high-performance powders like 1.2709 is surging. This maraging steel powder is especially sought after in sectors requiring high strength, dimensional stability, and corrosion resistance.

Global Market Insights

- Market Size (2023): ~$160 million for maraging steel powders

- Projected CAGR (2024–2030): 8–10%

- Primary Growth Drivers:

- Increasing use of metal 3D printing in aerospace and defense

- Shift toward lightweight, high-strength materials in automotive

- Demand for fast prototyping and on-demand manufacturing

- Tooling and mold industries embracing AM for complex geometries

Regional Demand Highlights

| Region | Key Sectors Driving Demand |

|---|---|

| North America | Aerospace, Defense, Automotive |

| Europe | Tooling, Medical, Automotive |

| Asia-Pacific | Manufacturing, Mold Production |

| China | Rapid growth in 3D printing adoption |

B2B Implications

- OEMs look for consistent powder quality to reduce defects in AM parts.

- Distributors seek competitive pricing and reliable supply chains.

- E-commerce resellers demand high-turnover products with stable sourcing.

🔗 For an overview of premium powder offerings, explore our PM powder product catalog.

5. How to Choose a Reliable 1.2709 Powder Supplier

Whether you’re a wholesaler, distributor, or end-user, selecting the right 1.2709 powder supplier ensures consistent performance and cost-effective production. Below are the top factors B2B buyers should consider.

Key Evaluation Criteria

| Factor | Why It Matters |

|---|---|

| Certification & Standards | ISO 9001, ASTM, AMS standards compliance |

| Powder Production Method | Gas atomization for high sphericity and purity |

| Batch Consistency | Reduces risk of AM part failure |

| Packaging & Logistics | Vacuum-sealed, moisture-proof packaging |

| Lead Time & Supply Chain | On-time delivery and stable inventory |

| Technical Support | Post-sale material consultation and customization |

B2B-Focused Tips

- Request batch samples to test powder flowability and morphology.

- Ask for a CoA (Certificate of Analysis) for each powder lot.

- Evaluate the supplier’s AM experience. Not all PM suppliers understand the needs of additive manufacturing.

Red Flags to Avoid

- No in-house testing or quality control lab

- Unclear sourcing of raw materials

- Limited product traceability

6. Top Global Suppliers of 1.2709 Powder

Several companies dominate the global 1.2709 powder supply chain. Here’s a comparison of top players known for reliability in the B2B space:

Leading International Suppliers

| Company Name | Country | Production Method | Notable Clients |

|---|---|---|---|

| Höganäs AB | Sweden | Water/Gas Atomized | Automotive, Tooling |

| Carpenter Additive | USA | Gas Atomized | Aerospace, Medical |

| EOS GmbH | Germany | Gas Atomized | AM OEMs, Prototypers |

| Sandvik Osprey | UK | Gas Atomized | Industrial Tooling |

| Shanghai Truer Technology | China | Water/Gas Atomized | AM, PM, Tooling |

Why Shanghai Truer Stands Out

- Established Expertise: Founded in 2009, with AM powder capabilities since 2019

- Advanced Atomization: Offers both gas and water atomized 1.2709 powders

- Customized Solutions: Can tailor particle size distribution and flowability for SLM, EBM, DMLS, and Binder Jetting

- Comprehensive Product Range: Supplies a wide array of PM grades including CT-1000, FC-0208, FN-5000, SBF2218

🔗 For more about our company’s capabilities and certifications, visit the Shanghai Truer About Page.

7. Why More Buyers Are Turning to Chinese Manufacturers

In recent years, Chinese suppliers have rapidly gained the trust of international B2B buyers in the powder metallurgy and AM space—and for good reasons.

Key Advantages

- Cost Efficiency: Lower production and labor costs allow competitive pricing.

- Faster Innovation Cycles: Rapid prototyping and product development timelines.

- Integrated Supply Chains: Close proximity to raw material sources and logistics hubs.

- Government Support: Strong policy backing for advanced manufacturing and exports.

Value to Distributors & OEMs

- Large-scale orders with stable supply

- Customization for specialized applications

- Technical consulting and post-sale support

- Multilingual service and international logistics

Case Study: Shanghai Truer Technology

With its integrated production of high-quality 1.2709 powder and a full suite of PM additives and lubricants, Truer serves both domestic and global clients with:

- Gas atomized and water atomized powders

- Custom sieving and blending services

- Powder for diamond tools, oil-impregnated bearings, and magnetic materials

- Soft magnetic additives, cutting agents, diffusion CuSn powder

📌 Learn more about our powder metallurgy solutions on the main homepage.

8. Why Choose Shanghai Truer Technology as Your Supplier

Shanghai Truer Technology Co., Ltd. is a leading supplier of premium-grade 1.2709 powder for additive manufacturing and powder metallurgy. Since its founding in 2009 and entry into the 3D printing business in 2019, Truer has built a reputation for providing high-quality powders, tailored services, and technical expertise for B2B customers across various sectors.

Core Advantages for Wholesale Buyers

| Feature | Benefit to B2B Clients |

|---|---|

| In-house Atomization | Guaranteed quality control and consistent output |

| Wide PM Grade Portfolio | Supports diverse applications and production needs |

| Custom Particle Size Options | Tailored for SLM, EBM, DMLS, and Binder Jetting |

| Fast Lead Times | Ideal for high-volume production and urgent projects |

| Technical Support Team | Pre- and post-sale consultation for powder performance |

Product Highlight: 1.2709 Powder by Truer

- Atomization Methods: Gas atomized & water atomized

- Particle Size Range: 15–45 µm (customizable)

- Purity: Low oxygen, high sphericity (>95%)

- Compliance: Meets ASTM and ISO standards

Truer also provides a full suite of complementary PM additives and materials, including:

- Lube-W, SUW-8000 lubricants

- Manganese sulfide and sulfur-free cutting agents

- Soft magnetic additives (QH-150, QHP-330)

- Advanced graphite additives (TBC-400, TBC-1000)

These complete additive solutions make Truer a one-stop partner for powder metallurgy operations.

🔗 Learn more about our full product line by visiting the PM Powder Product Page.

9. How to Order Wholesale 1.2709 Powder from Shanghai Truer

Placing a wholesale order for 1.2709 powder is designed to be simple, efficient, and tailored to your production requirements. Whether you’re ordering for additive manufacturing or component sintering, the Truer team ensures every step aligns with your B2B needs.

Step-by-Step Ordering Process

- Submit Inquiry

Contact the sales team via email or the online contact form with your material specifications, quantity, and use case. - Technical Consultation

Truer’s engineers will help determine the best powder grade, atomization method, and particle size for your process. - Receive Quotation & Sample

A competitive quote is provided, along with optional samples for testing and validation. - Confirm Order & Production

Once approved, production begins with quality control checkpoints at every stage. - Packaging & Shipping

Powders are vacuum-packed in moisture-resistant containers. International shipping options include air freight, sea freight, and express delivery. - After-Sales Support

Receive ongoing technical support, reordering assistance, and application guidance.

B2B Client Services

- MOQ Flexibility: Suitable for both small batches and bulk orders

- OEM Support: White-labeling and custom packaging available

- Documentation: Includes CoA, SDS, and technical datasheets

- Global Shipping: Delivered to over 30 countries

🔗 Ready to request a quote? Visit our Contact Us Page to get started.

10. FAQs: Common Questions About Buying Wholesale 1.2709 Powder

Below are some of the most frequently asked questions from distributors, manufacturers, and e-commerce resellers interested in 1.2709 powder.

❓ What industries benefit the most from 1.2709 powder?

Aerospace, automotive, mold tooling, and medical sectors benefit the most due to the powder’s high strength, excellent aging properties, and dimensional stability during heat treatment.

❓ What is the minimum order quantity (MOQ) for wholesale buyers?

Shanghai Truer offers flexible MOQs, starting from as low as 10 kg for sample orders and scaling up to multiple tons for mass production.

❓ Can I customize the particle size distribution?

Yes. Particle size can be customized to meet the requirements of your specific AM process (e.g., SLM, EBM, DMLS) or traditional PM application.

❓ Does Truer provide technical support for new AM users?

Absolutely. The team includes powder metallurgy and additive manufacturing experts who provide consultation on process optimization, powder selection, and post-processing techniques.

❓ Are there international shipping options?

Yes. Truer ships globally, with logistics partners to ensure safe and timely delivery. Shipping methods include air, sea, and express courier.

Internal Anchor Links Summary

Here are 5 internal anchor text links embedded throughout the article for improved user navigation and SEO:

By following this guide, B2B buyers, distributors, and engineering professionals can make informed decisions when sourcing 1.2709 powder. With its advanced capabilities, competitive pricing, and technical expertise, Shanghai Truer Technology stands out as a trusted supplier in the evolving landscape of additive manufacturing and powder metallurgy.

Want to learn more or get a custom quote? Contact us now and let our experts help you find the right powder solution for your business.