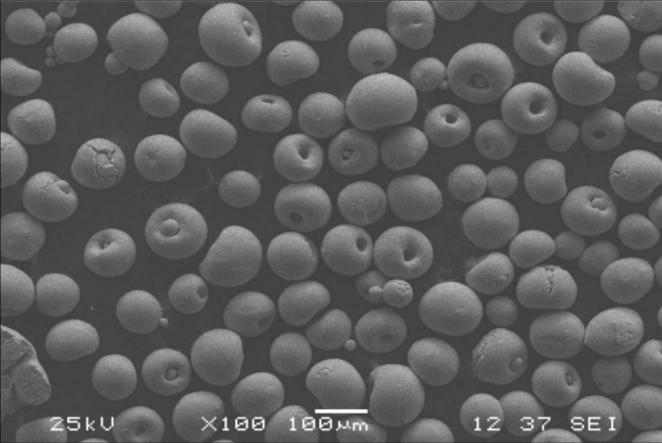

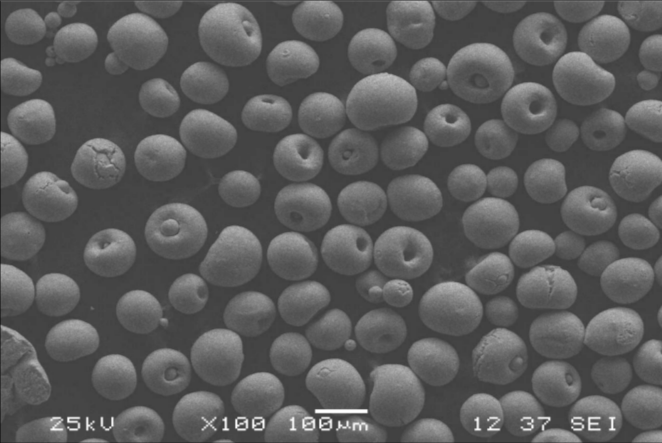

Overview of Pure Ta Powder

Tantalum (Ta) powder, often referred to as Pure Ta Powder, is an indispensable material in various high-tech applications. Renowned for its excellent corrosion resistance, high melting point, and superior strength-to-weight ratio, tantalum plays a critical role in electronics, aerospace, medical devices, and more. But what makes Pure Ta Powder stand out among other metal powders? Let’s dive deep into the details, exploring its properties, grades, uses, and why it’s an essential material for modern industry.

Types of Pure Ta Powder

Tantalum powders come in various grades and specifications to meet the unique needs of different industries. Below is a descriptive list of popular models:

| Model Name | Description | Key Applications |

|---|---|---|

| Ta-200 | High-purity powder (≥99.95%) ideal for capacitor manufacturing. | Electronics, semiconductors |

| Ta-205 | Specialized for high-temperature alloying due to its large particle size. | Aerospace, turbines |

| Ta-CX | Ultra-fine powder for additive manufacturing and 3D printing. | Medical implants, custom parts |

| Ta-NR | Nodular powder with excellent flowability for powder metallurgy. | Automotive, industrial components |

| Ta-F2 | Flaked powder with enhanced surface area, used in chemical applications. | Chemical processing equipment |

| Ta-SM | Super micro-powder tailored for surface coatings. | Thermal sprays, protective layers |

| Ta-H1 | High-density tantalum powder with superior electrical conductivity. | Capacitors, high-performance electronics |

| Ta-Aero | Aerospace-grade powder designed for extreme environments. | Spacecraft, defense applications |

| Ta-Med | Medical-grade tantalum powder, biocompatible and pure. | Medical implants, surgical instruments |

| Ta-AM | Optimized for additive manufacturing with exceptional isotropy properties. | Prototyping, advanced manufacturing |

Composition of Pure Ta Powder

Pure Ta Powder predominantly consists of tantalum, with trace impurities that vary based on grade. Here’s a breakdown:

| Component | Typical Percentage (%) |

|---|---|

| Tantalum (Ta) | ≥99.9 |

| Oxygen (O) | ≤0.05 |

| Nitrogen (N) | ≤0.02 |

| Carbon (C) | ≤0.01 |

| Iron (Fe) | ≤0.005 |

Properties and Characteristics of Pure Ta Powder

Pure Ta Powder exhibits unique properties that make it valuable for specialized applications.

| Property | Details |

|---|---|

| Density | 16.6 g/cm³ |

| Melting Point | 3017°C |

| Electrical Conductivity | Excellent, making it suitable for electronic components. |

| Corrosion Resistance | Highly resistant to acids, particularly hydrofluoric acid. |

| Thermal Stability | Maintains integrity at high temperatures. |

| Workability | Malleable and ductile, enabling diverse processing methods. |

| Biocompatibility | Inert and safe for medical implants. |

Applications of Pure Ta Powder

Pure Ta Powder finds applications in diverse industries due to its versatile properties:

| Industry | Specific Applications |

|---|---|

| Electronics | Capacitors, thin-film resistors, circuit boards. |

| Aerospace | High-temperature alloys, jet engine components, protective coatings. |

| Medical | Bone implants, surgical instruments, biocompatible coatings. |

| Chemical Processing | Corrosion-resistant equipment for chemical plants. |

| 3D Printing | Advanced manufacturing of complex, lightweight structures. |

Specifications, Sizes, and Standards

Pure Ta Powder is available in various sizes and grades to suit industry needs.

| Specification | Details |

|---|---|

| Particle Size | 1–150 µm |

| Purity Levels | ≥99.95% |

| Standards | ASTM B708, ISO 9001:2015 |

| Packaging | 1 kg, 5 kg, 25 kg sealed containers. |

Suppliers and Pricing Details

| Supplier Name | Country | Price Range (USD/kg) | Specialization |

|---|---|---|---|

| H.C. Starck | Germany | $500–$800 | High-purity tantalum powders. |

| Global Advanced Metals | USA | $450–$750 | Electronics-grade powders. |

| JX Nippon Mining | Japan | $600–$900 | Medical and aerospace-grade powders. |

| Zhuzhou Cemented Carbide | China | $300–$600 | Cost-effective industrial powders. |

Advantages and Limitations of Pure Ta Powder

| Aspect | Advantages | Limitations |

|---|---|---|

| Purity | High levels of purity ensure consistent performance. | Higher cost compared to alternative materials. |

| Corrosion Resistance | Unmatched resistance in acidic environments. | Limited availability due to geopolitical factors. |

| Ductility | Easily shaped into complex structures. | Brittle at extremely low temperatures. |

| Applications | Versatile for multiple industries. | Requires specialized handling and processing. |

Why Choose Pure Ta Powder?

If you’re looking for a material that combines strength, flexibility, and corrosion resistance, Pure Ta Powder is a strong contender. Imagine a jet engine turbine operating at blistering temperatures or a pacemaker functioning flawlessly in the human body. Both rely on tantalum for their exceptional performance. Its unique properties make it irreplaceable in critical industries, despite its higher cost and limited supply.

FAQs

| Question | Answer |

|---|---|

| What is the melting point of Pure Ta Powder? | Tantalum melts at 3017°C, making it suitable for high-temperature applications. |

| Can Pure Ta Powder be used in 3D printing? | Yes, specific grades like Ta-AM and Ta-CX are designed for additive manufacturing. |

| Why is tantalum preferred for medical implants? | Its biocompatibility ensures no adverse reactions in the human body. |

| Is Pure Ta Powder recyclable? | Yes, tantalum can be recovered and reused without degrading its properties. |

| What industries benefit most from tantalum? | Electronics, aerospace, medical, and chemical processing industries rely heavily on it. |

Conclusion

Pure Ta Powder stands as a cornerstone in advanced material science. Its ability to perform under extreme conditions while remaining stable and corrosion-resistant makes it invaluable for various industries.