Overview of Iron-based alloy powder 410

Iron-based alloy powder 410 is a versatile material renowned for its excellent mechanical properties and resistance to wear and corrosion. This material is predominantly used in various industrial applications, including manufacturing, automotive, and aerospace sectors. The unique characteristics of iron-based alloy powder 410 make it an essential component in producing high-strength parts and components.

Types of Iron Based Alloy Powder 410

Let’s dive into the specifics. There are various types of iron-based alloy powder 410, each with unique properties and applications. Here’s a detailed table showcasing different models of iron-based alloy powder 410, along with their composition and characteristics.

| Model | Composition | Properties | Characteristics |

|---|---|---|---|

| 410L | Fe-11.5Cr-0.2Mn-0.05C | Excellent corrosion resistance, moderate strength | High weldability, good formability |

| 410HC | Fe-12.5Cr-0.3Mn-0.06C | High hardness, good tensile strength | Suitable for high wear applications |

| 410S | Fe-11.5Cr-0.1Mn-0.03C | Superior toughness, moderate corrosion resistance | Ideal for structural components |

| 410C | Fe-12.0Cr-0.2Mn-0.08C | Balanced properties, moderate wear resistance | Versatile, suitable for various applications |

| 410N | Fe-13.0Cr-0.3Mn-0.05C-0.2N | Enhanced strength, good fatigue resistance | Suitable for high-stress applications |

| 410B | Fe-11.0Cr-0.2Mn-0.05C-0.3B | Excellent wear resistance, high hardness | Ideal for abrasive environments |

| 410F | Fe-11.5Cr-0.1Mn-0.03C-0.2Mo | Improved toughness, good corrosion resistance | Suitable for automotive parts |

| 410M | Fe-12.5Cr-0.2Mn-0.05C-0.5Mo | High strength, good machinability | Ideal for precision components |

| 410A | Fe-11.0Cr-0.2Mn-0.08C-0.1Al | Enhanced oxidation resistance, moderate strength | Suitable for high-temperature applications |

| 410D | Fe-12.0Cr-0.3Mn-0.06C-0.2V | High durability, good mechanical properties | Versatile for various industrial applications |

Applications of Iron Based Alloy Powder 410

The unique properties of iron-based alloy powder 410 make it suitable for a wide range of applications. Here are some common uses for this versatile material:

| Application | Description |

|---|---|

| Automotive Components | Used in manufacturing gears, shafts, and engine parts due to its high strength and wear resistance. |

| Aerospace Parts | Essential for producing high-strength, lightweight components for aircraft and spacecraft. |

| Industrial Machinery | Ideal for making durable parts like bearings, valves, and pumps that require excellent wear resistance. |

| Medical Devices | Used in surgical instruments and implants due to its biocompatibility and corrosion resistance. |

| Construction Equipment | Suitable for structural components and fasteners that need to withstand harsh environments. |

| Oil and Gas Industry | Utilized in drilling equipment and pipelines due to its high corrosion resistance and mechanical strength. |

| Consumer Electronics | Employed in making durable and corrosion-resistant components for electronic devices. |

| Tool and Die Making | Ideal for creating high-strength, wear-resistant tools and dies. |

| Marine Equipment | Used in components exposed to marine environments, offering excellent resistance to saltwater corrosion. |

| Renewable Energy | Essential in manufacturing parts for wind turbines and solar panels, providing durability and longevity. |

Specifications, Sizes, Grades, Standards of Iron Based Alloy Powder 410

Here’s a detailed table outlining the specifications, sizes, grades, and standards of iron-based alloy powder 410, ensuring you find the right fit for your needs:

| Specification | Details |

|---|---|

| Grades | 410L, 410HC, 410S, 410C, 410N, 410B, 410F, 410M, 410A, 410D |

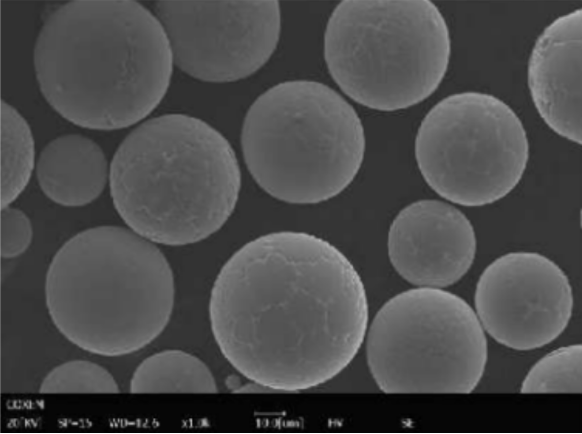

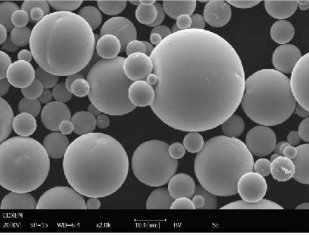

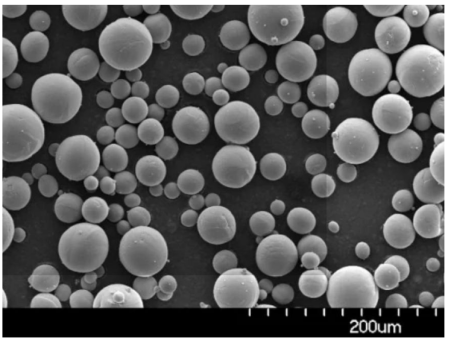

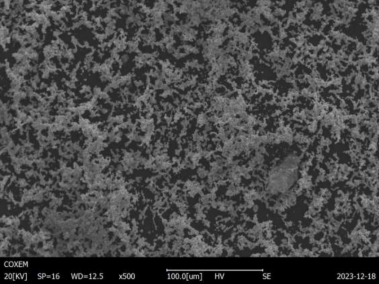

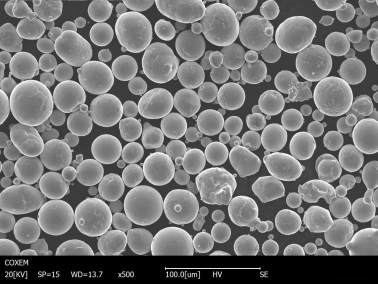

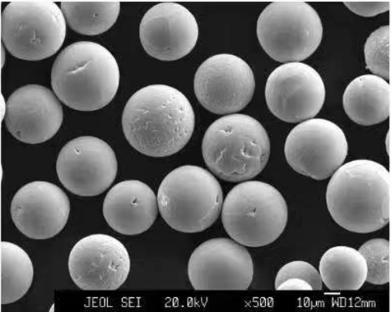

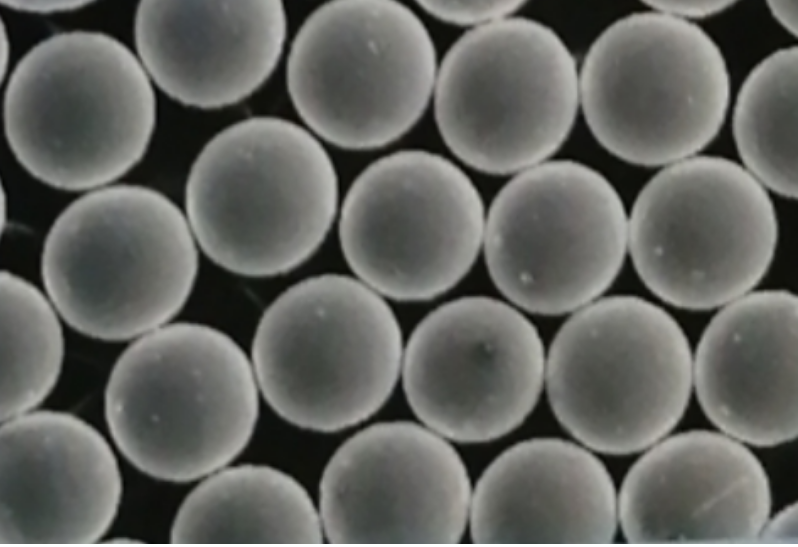

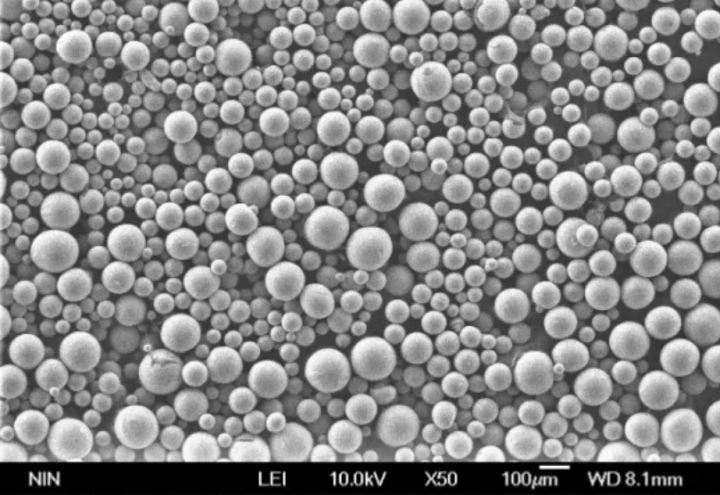

| Particle Size | Available in various sizes from 20 microns to 150 microns |

| Standards | ASTM A276, ASTM A479, ISO 9001 |

| Density | Typically ranges from 7.75 g/cm³ to 7.80 g/cm³ |

| Hardness | Varies between 180 HV and 400 HV depending on the specific grade and heat treatment |

| Tensile Strength | Between 450 MPa and 750 MPa based on grade and processing |

| Elongation | Generally between 15% and 30%, indicating good ductility |

| Form Factor | Available in powder form for additive manufacturing, sintering, and other industrial processes |

| Composition | Primarily Iron (Fe) with 11-13% Chromium (Cr), trace amounts of Manganese (Mn), Carbon (C), and other alloying elements specific to each grade |

Suppliers and Pricing Details of Iron Based Alloy Powder 410

When sourcing iron-based alloy powder 410, it’s crucial to consider reputable suppliers and competitive pricing. Here’s a table featuring some leading suppliers and their pricing details:

| Supplier | Location | Grade | Pricing (per kg) | Bulk Discounts |

|---|---|---|---|---|

| Metalloy Inc. | USA | 410L, 410HC | $15 – $25 | Available for orders above 1000 kg |

| Alloy Powders Ltd | UK | 410S, 410C | $20 – $30 | Discounts on orders over 500 kg |

| Euro Metalworks | Germany | 410N, 410B | $18 – $28 | Custom pricing for bulk orders |

| Asian Alloys | China | 410F, 410M | $12 – $22 | Price breaks at 2000 kg |

| Pacific Metals | Japan | 410A, 410D | $14 – $24 | Special rates for long-term contracts |

Comparing Pros and Cons of Iron Based Alloy Powder 410

Understanding the advantages and limitations of iron-based alloy powder 410 is essential for making informed decisions. Here’s a table comparing the pros and cons:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Corrosion Resistance | Excellent, especially in moderately corrosive environments | Not suitable for highly corrosive conditions |

| Mechanical Strength | High tensile and compressive strength | Requires precise heat treatment for optimal properties |

| Wear Resistance | Good wear resistance, ideal for high-friction applications | Limited in extremely abrasive environments |

| Ductility | Good ductility and formability | Can be brittle if not processed correctly |

| Cost | Cost-effective compared to other high-performance alloys | May be more expensive than standard steels |

| Availability | Widely available in various grades and sizes | Some specific grades may have longer lead times |

| Weldability | Generally good, especially in lower carbon grades | Higher carbon grades can be challenging to weld |

Advantages of Iron Based Alloy Powder 410

Iron-based alloy powder 410 offers numerous benefits, making it a popular choice for various industrial applications. Let’s delve into some of these advantages:

1. Excellent Corrosion Resistance

Iron-based alloy powder 410 is renowned for its ability to resist corrosion, particularly in moderately corrosive environments. This property makes it ideal for applications in the marine, oil and gas, and chemical industries, where exposure to corrosive elements is a common challenge.

2. High Mechanical Strength

This material exhibits impressive mechanical strength, ensuring durability and reliability in high-stress applications. Whether it’s in the automotive or aerospace industry, iron-based alloy powder 410 provides the necessary strength to withstand heavy loads and harsh conditions.

3. Good Wear Resistance

The wear resistance of iron-based alloy powder 410 is another significant advantage. This property is particularly beneficial in manufacturing components subjected to constant friction and abrasion, such as gears, bearings, and valves.

4. Versatility in Applications

Thanks to its balanced properties, iron-based alloy powder 410 can be used in a wide range of applications. From medical devices to construction equipment, this material’s versatility is unmatched, making it a go-to choice for many engineers and manufacturers.

5. Cost-Effective Solution

Compared to other high-performance alloys, iron

-based alloy powder 410 offers a cost-effective solution without compromising on quality. This balance of performance and affordability makes it an attractive option for various industries.

Disadvantages of Iron Based Alloy Powder 410

While iron-based alloy powder 410 has many benefits, it’s also important to consider its limitations to make an informed decision:

1. Limited Corrosion Resistance in Harsh Environments

Although iron-based alloy powder 410 performs well in moderately corrosive conditions, it may not be suitable for highly corrosive environments. In such cases, alternative materials with higher corrosion resistance might be required.

2. Potential for Brittleness

If not processed correctly, iron-based alloy powder 410 can become brittle, which could lead to failure in high-stress applications. Ensuring proper heat treatment and processing techniques is crucial to avoid this issue.

3. Higher Cost than Standard Steels

While it is more cost-effective than many high-performance alloys, iron-based alloy powder 410 can still be more expensive than standard steels. This factor should be considered when budget constraints are a concern.

4. Challenges in Welding

Higher carbon grades of iron-based alloy powder 410 can pose challenges in welding. Special techniques and precautions are required to ensure strong and reliable welds, which can add complexity to the manufacturing process.

FAQs

To further assist in understanding iron-based alloy powder 410, here are some frequently asked questions:

| Question | Answer |

|---|---|

| What is iron-based alloy powder 410 primarily used for? | It is used in automotive, aerospace, industrial machinery, medical devices, and construction equipment. |

| What are the key properties of iron-based alloy powder 410? | High mechanical strength, excellent corrosion resistance, good wear resistance, and versatility. |

| Can iron-based alloy powder 410 be welded easily? | Lower carbon grades can be welded easily, while higher carbon grades may require special techniques. |

| Is iron-based alloy powder 410 cost-effective? | Yes, it offers a good balance of performance and affordability compared to other high-performance alloys. |

| What are the limitations of iron-based alloy powder 410? | Limited corrosion resistance in harsh environments, potential for brittleness, and higher cost than standard steels. |

| How can brittleness in iron-based alloy powder 410 be avoided? | Proper heat treatment and processing techniques are crucial to avoid brittleness. |

| What sizes and grades are available for iron-based alloy powder 410? | Various sizes from 20 microns to 150 microns, and grades including 410L, 410HC, 410S, 410C, 410N, and more. |

| What industries benefit the most from iron-based alloy powder 410? | Automotive, aerospace, industrial machinery, medical devices, construction, oil and gas, and renewable energy. |

| Is iron-based alloy powder 410 environmentally friendly? | It can be recycled, making it a more sustainable choice compared to some other materials. |

| Where can I purchase iron-based alloy powder 410? | Leading suppliers include Metalloy Inc., Alloy Powders Ltd, Euro Metalworks, Asian Alloys, and Pacific Metals. |

Conclusion

Iron-based alloy powder 410 is a highly versatile and valuable material with a wide range of applications across various industries. Its excellent mechanical properties, wear resistance, and corrosion resistance make it an ideal choice for producing high-strength components and parts. While there are some limitations to consider, the benefits often outweigh the drawbacks, making it a popular choice for many engineers and manufacturers. By understanding the specific properties and applications of different grades of iron-based alloy powder 410, you can make informed decisions and ensure optimal performance for your projects.