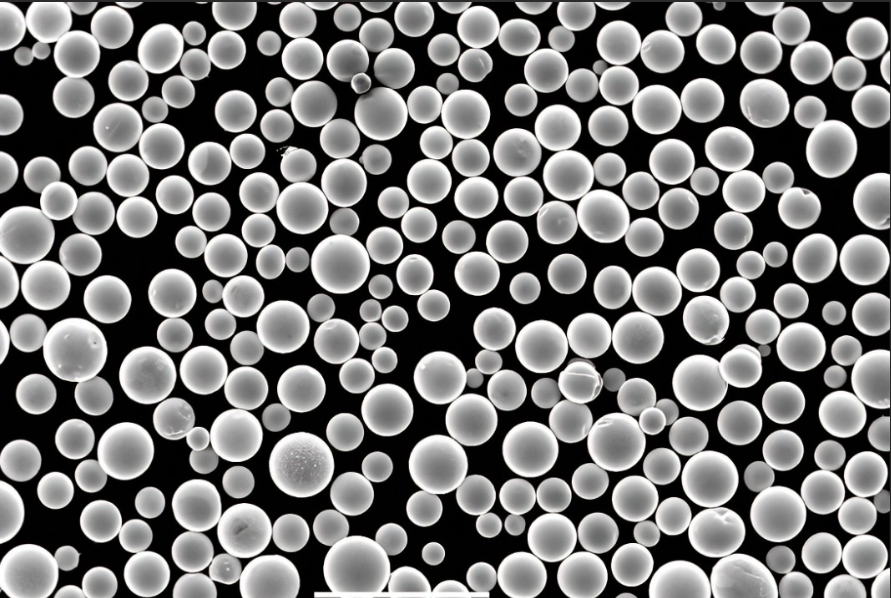

Tungsten is a rare and refractory metal with a melting point of 3,655 K. Tungsten and its alloys have excellent properties such as high density, high temperature strength, high melting point, good heat and corrosion resistance and high hardness, and are widely used in many fields such as atomic energy, medical, defence, military and aerospace. In manufacturing, tungsten and its alloys are often prepared using traditional powder metallurgy processes, i.e. through the forming, sintering and post-treatment of tungsten powder. The morphology, particle size and size distribution, fluidity and bulk density of the tungsten powder have a significant impact on the performance of the pressed billet and therefore the performance of the final tungsten product. Spherical tungsten powders are spherical or nearly spherical in shape and are characterised by good flowability and high bulk density. This makes it easy to uniformly fill the mould cavity, and the size of the billet can be easily controlled under pressure, resulting in a uniform density distribution and low elastic after-effects.

With the rapid development of 3D printing technology, porous materials, high-density powder coating and injection moulding, the demand for high quality spherical tungsten powder is increasing. High-quality spherical tungsten powder not only has good flowability, good sphericity, high loose packing density and vibrational density, but also low oxygen content.

Plasma Spheroidisation of Tungsten Powder

Plasma, with its high temperature, high enthalpy and high chemical reactivity, meets the demand for a heat source for tungsten powder spheroidisation in the tungsten powder spheroidisation process. Plasma spheroidisation technology involves the spraying of irregularly shaped particles by a carrier gas through a charging gun into a plasma arc. Under the action of heat transfer mechanisms such as radiation, convection and conduction, the powder is rapidly heated to whole or partial melting, and the molten particles rapidly solidify and shrink under surface tension to form a dense spherical powder. The advantages of plasma spheroidised tungsten powder are the high concentration of energy, the large temperature gradient, the ability to precisely control the energy input by controlling the process parameters and the thermal energy utilisation of up to 75%. After plasma spheroidisation, the fluidity of the tungsten powder is improved and the loose packing density and vibrational density of the powder are increased. The most commonly used method for the preparation of spherical tungsten powder is RF plasma, which uses the induction of the RF electromagnetic field to produce plasma by induction heating of various gases, with a significant increase in electrical conductivity and high energy Joule heating under the action of the alternating induction electric field. It is a good way to prepare high quality spherical tungsten powders as it not only has the characteristics of a normal plasma, but also has low RF plasma speed, long arc area, long plasma torch life, no electrode discharge, low pollution, and a power range from 0.5 kW to 1.0 MW.

As the most important consumable for 3D printed tungsten products, spherical tungsten powder has its unique advantages to replace conventional tungsten powder. Halogenation, tungsten powder reoxidation- reduction methods have low spherification rate, low yield and The microwave single cavity method of spheroidizing tungsten powder is not sufficient as a heat source, and the powder can be made into a spherical powder. The microwave single cavity method of spheroidizing tungsten powder has insufficient heat source, and the performance of the tungsten powder produced is unstable and poorly consistent.

At present, the spherical tungsten powder prepared in China still suffers from a wide particle size distribution, low yield, poor uniformity, and a high degree of stability. The research and development of spherical tungsten powder is still in the development stage. The research and development of spherical tungsten powder is still in the development stage, and the preparation process, technology and procedure still need to be further studied. The research and development of spherical tungsten powder is still in the development stage, and the preparation process, technology and procedure still need further study.

The plasma spheroidization technology is characterized by high energy consumption, gas consumption high energy consumption, gas consumption, large investment in equipment, high operating costs, immature technology development and other problems. However, the high energy of the plasma and the controllable reaction atmosphere enable the preparation of other The plasma spheroidisation technique has the problems of high energy consumption, high equipment investment, high operating costs and mature technology development. The prepared The prepared spherical tungsten powder has good sphericity, uniform particle size distribution, high densities and good fluidity. The whole preparation process is fast and continuous. Therefore, plasma spheroidization will be an alternative for the preparation of spherical tungsten powder. Therefore, plasma spheroidization is an alternative for the preparation of spherical tungsten powder. In combination with numerical simulations, the process parameters can be The process parameters can be optimised quickly by combining numerical simulations. With the continuous improvement of plasma spheroidisation technology, the reduction of production costs and the optimization of powder parameters With the continuous improvement of plasma spheronization technology, the reduction of production cost and the increase of powder yield, plasma spheronization technology will play an important role in the production of tungsten powder. The plasma spheroidisation technology will have a bright future in the industrial production of tungsten powder spheroidisation.

Frequently Asked Questions (FAQ)

1) Why choose spherical tungsten powder over irregular tungsten powder?

- Spherical tungsten powder offers superior flowability, higher apparent/tap density, and more uniform packing—key for LPBF, DED, MIM, and thermal spraying. It improves layer quality, reduces lack‑of‑fusion defects, and enables tighter dimensional control.

2) What particle-size distribution (PSD) works best for AM with tungsten?

- LPBF commonly uses 15–45 μm (or 20–53 μm) cuts; DED prefers 45–90 μm or 75–150 μm. Narrow PSDs improve flow and packing; ultra-fines increase oxygen pickup and spatter.

3) How does RF plasma spheroidization compare to other routes?

- RF plasma yields highly spherical, dense tungsten powder with low contamination and controllable PSD, but at higher energy/gas cost. Alternatives (halogenation, re‑oxidation/reduction, microwave) have lower yields or poorer consistency for AM-grade needs.

4) How critical is oxygen content in tungsten powder?

- Very. Elevated oxygen increases brittleness and can cause porosity and cracking in sintering/AM. For AM-grade tungsten powder, aim for O < 0.05–0.10 wt% depending on application; verify via ASTM E1019.

5) Can spherical tungsten powder be reused in LPBF?

- Yes, with inert handling, sieving, and cycle-by-cycle QA (PSD, flow, O/N/H, density). Many workflows allow 4–8 reuse cycles before blending with virgin powder; establish limits based on oxygen drift and PSD changes.

2025 Industry Trends: Spherical Tungsten Powder

- Cost and energy optimization: Argon/nitrogen recovery systems and torch efficiency mapping cut RF plasma gas/energy use by 20–35% vs 2023 benchmarks.

- Quality stabilization: Inline optical/AI detection of satellites/hollows improves lot consistency; more suppliers publish digital material passports tied to ISO/ASTM 52907.

- Application growth: Higher demand for radiation shielding lattices, high‑heat flux components, and directed energy system parts drives AM-grade tungsten powder adoption.

- Hybrid processing: Water‑atomized W pre-cursor upgraded via RF plasma spheroidization balances cost with AM flow performance.

- Safer operations: Wider adoption of ATEX/DSEAR-compliant powder stations and closed-loop inert handling for dense, high‑Z powders.

2025 KPI Snapshot for Tungsten Powder Routes (indicative AM-grade ranges)

| Metric | RF Plasma Spheroidized W | Gas Atomized W (where applicable) | Re-oxidation/Reduction + Spheroidize | Microwave Spheroidization |

|---|---|---|---|---|

| Sphericity (aspect ratio) | 0.95–0.98 | 0.90–0.94 | 0.92–0.96 | 0.88–0.93 |

| Oxygen (wt%) | 0.03–0.08 | 0.05–0.12 | 0.05–0.10 | 0.08–0.15 |

| Hall flow (s/50 g) | 15–19 | 18–24 | 17–22 | 20–28 |

| Fine fraction yield (<53 μm) | Moderate | Moderate | Low–Moderate | Low |

| Relative cost | High | Medium–High | Medium | Medium |

| AM suitability (LPBF/DED) | Excellent | Good (limited suppliers) | Good after tight QA | Variable/lot‑dependent |

References: ISO/ASTM 52907:2023; ASTM B212/B213/B703; ASTM E1019; NIST AM‑Bench datasets; HSE ATEX/DSEAR guidance

Latest Research Cases

Case Study 1: RF Plasma Spheroidization of WA Tungsten for LPBF Heat-Flux Panels (2025)

Background: An aerospace thermal systems supplier needed LPBF-grade tungsten with improved flow and low oxygen for thin-wall, high‑density panels.

Solution: Upgraded water‑atomized W via RF plasma; optimized torch power and carrier gas; tight classification to 20–45 μm; closed-loop inert handling; ISO/ASTM 52907 QA.

Results: Sphericity 0.97; O reduced from 0.11→0.06 wt%; Hall flow 16.8 s/50 g; LPBF density ≥99.5%; leak-tight thin walls achieved with 18% fewer recoater defects; first‑pass yield +15%.

Case Study 2: DED of Spherical W for Radiation Shielding with Binder‑Jet Hybrid Cores (2024)

Background: A med‑tech OEM sought complex tungsten shielding geometries with dense outer skins.

Solution: Produced spherical W (45–90 μm) by RF plasma; printed binder‑jet cores, then DED over‑clad for dense outer layers; stress relief and HIP performed.

Results: Final density 99.6% (outer layer); dimensional shrink variation −30% vs BJ-only; shielding performance +12% vs spec; cycle time −22% relative to full DED builds.

Expert Opinions

- Prof. Rajiv Asthana, Professor of Materials Science, University of Wisconsin–Stout

Viewpoint: “For tungsten powder in AM, oxygen and satellite control are decisive—flow and densification hinge on both, not just PSD.” Source: Academic publications and conference proceedings. - Dr. John Slotwinski, Materials Research Engineer, NIST

Viewpoint: “Digital material passports tied to ISO/ASTM 52907 characterization are improving cross‑site reproducibility for high‑Z powders like tungsten.” Source: NIST AM workshops https://www.nist.gov/ - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Viewpoint: “2025 round‑robin efforts are connecting powder metrics to LPBF defect maps in refractory systems, accelerating qualification of spherical tungsten powder.” Source: ASTM AM CoE https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Powder characterization for AM

https://www.iso.org/standard/78974.html - ASTM B212/B213/B703 (density/flow) and ASTM E1019 (O/N/H)

https://www.astm.org/ - NIST AM‑Bench: Public datasets for validating AM processes

https://www.nist.gov/ambench - HSE ATEX/DSEAR: Safe handling of reactive/dense metal powders

https://www.hse.gov.uk/fireandexplosion/atex.htm - Senvol Database: Compare machines/materials, including tungsten powders

https://senvol.com/database - Open-source/engineering tools: Thermo‑Calc (phase predictions), pySLM (scan strategy), AdditiveFOAM (thermal/porosity modeling), ImageJ (morphology analysis)

Last updated: 2025-08-27

Changelog: Added targeted FAQs, 2025 KPI table for tungsten powder routes, two recent case studies, expert viewpoints, and a curated tools/resources list with standards links.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major energy/cost breakthroughs in RF plasma lines, or new LPBF parameter sets for tungsten are released by OEMs.