GET 3D Printing Material

Shanghai Truer Industrial Development Co., Ltd

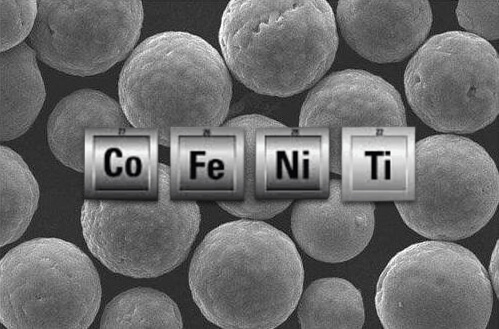

ferrous and high-entroy alloy powder

H13 Alloy Powder

H13 Alloy Powder is a hot work die steel, which is formed by adding alloying elements to carbon steel.

The chemical composition is 4Cr5MoSiV1, with the good overall performance at medium temperature (~600°), high hardenability (can be hardened in the air), low heat treatment deformation rate, its performance and service life is higher than 3Cr2W8V, which can be used in die forging hammer forging die, aluminum alloy dies casting die, hot extrusion dies, high-speed precision forging die and forging press die, etc.

application

Use and 9CRWMN mold steel is basically the same, but because of its high vanadium content, so the medium temperature (600 degrees) performance than 4Cr5MoSiV steel to be good, is a hot work mold steel in a very wide range of uses of representative steel.

H13 Alloy Powder die steel is used for the manufacture of forging dies with high impact loads, hot extrusion dies, fine forging dies; aluminum, copper, and its alloy die casting dies.

Characteristics

- Low pick-up of oxygen and other impurities

- Perfectly spherical and essentially satellite-free

- Narrow particle size distribution.

- high flowability and high packing density

- Low internal porosity

Properties

- High hardenability and high toughness.

- Excellent resistance to thermal cracking and can be water-cooled in the workplace.

- It has a medium resistance to wear and tear, and may also be carburized or nitrided to increase their surface hardness, but with a slightly reduced resistance to thermal cracking.

- Poor secondary hardening ability in tempering due to its low carbon content.

- Resistance to softening at higher temperatures, but the rapid loss of hardness at operating temperatures above 540°C (1000°F) (i.e. a working temperature of 540°C can be tolerated).

- Low heat treatment distortion.

- Medium and high machinability.

- Medium resistance to decarburization.

about us

Truer Industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Our services

Various metal powders

More than 40 grades of high quality spherical metal powders.

Mature application system

More than 1000 customized orthopedic implant materials to more than 20 hospitals.

No risk of stock outage

Perfect supply chain layout and inventory control make no risk of product stock-out.

3D Printing Equipment

SEBM & PREP technology and equipment.

Support customization

We accept OEM/ODM

Fair prices

High quality products at reasonable prices

Send Us A Message

Contact us

sales

Cassiel Ding

+86 – 13611869448

[email protected]

Sales Manager

Lucy Wen

+86 – 15250232891

[email protected]

Quality Control

Mike Wu

+86 – 13862291355

[email protected]

sales

Joan Zhou

+86 – 17316565943

[email protected]

Customer Service

Luke Zhang

+86 – 15250014048

[email protected]