Overview of NiCrAIY Powder

NiCrAIY powder is a key material in the world of thermal coatings, known for its outstanding resistance to oxidation and corrosion at elevated temperatures. This powder, composed mainly of Nickel (Ni), Chromium (Cr), Aluminum (Al), and Yttrium (Y), plays a critical role in advanced manufacturing processes, particularly in the aerospace, power generation, and automotive industries. These powders are essential for protective coatings on turbine blades, exhaust systems, and other high-performance components, ensuring longer lifespans under extreme conditions.

What makes NiCrAIY powder so special? It’s all in the combination of materials. Each element brings unique properties: Nickel for toughness, Chromium for corrosion resistance, Aluminum for oxidation resistance, and Yttrium to improve adhesion of the protective oxide layer. Together, they form a high-performance alloy that withstands harsh environments. Now, let’s dive deeper into the specific types, compositions, and applications of NiCrAIY powder.

Composition of NiCrAIY Powder

The composition of NiCrAIY powder varies depending on the specific model or grade. Typically, it involves a balanced mix of Nickel, Chromium, Aluminum, and Yttrium, but some formulations add trace elements to enhance certain properties, such as improved thermal stability or better adhesion.

| Model | Nickel (Ni) % | Chromium (Cr) % | Aluminum (Al) % | Yttrium (Y) % | Other Elements |

|---|---|---|---|---|---|

| NiCrAIY-001 | 65% | 22% | 8% | 0.5% | Cobalt (Co), Iron (Fe) |

| NiCrAIY-002 | 60% | 25% | 10% | 1% | Silicon (Si) |

| NiCrAIY-003 | 70% | 20% | 7% | 1% | Vanadium (V), Molybdenum (Mo) |

| NiCrAIY-004 | 68% | 21% | 9% | 0.3% | Copper (Cu), Zirconium (Zr) |

| NiCrAIY-005 | 62% | 24% | 10% | 0.8% | Tungsten (W) |

| NiCrAIY-006 | 65% | 22% | 8.5% | 0.5% | Boron (B), Hafnium (Hf) |

| NiCrAIY-007 | 63% | 23% | 9% | 1% | Titanium (Ti), Nitrogen (N) |

| NiCrAIY-008 | 66% | 21% | 8% | 1% | Cobalt (Co), Manganese (Mn) |

| NiCrAIY-009 | 61% | 26% | 10% | 0.5% | Phosphorus (P), Carbon (C) |

| NiCrAIY-010 | 64% | 22% | 9% | 0.7% | Silicon (Si), Tin (Sn) |

These percentages can be fine-tuned to meet specific performance requirements, offering versatility in engineering applications.

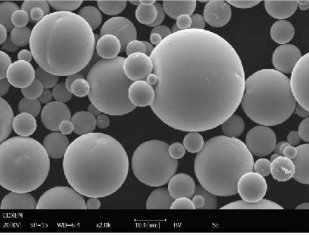

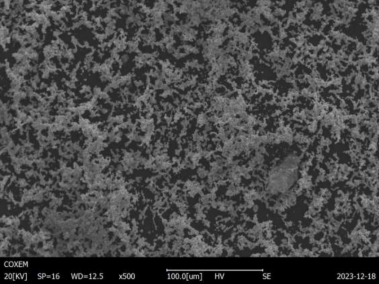

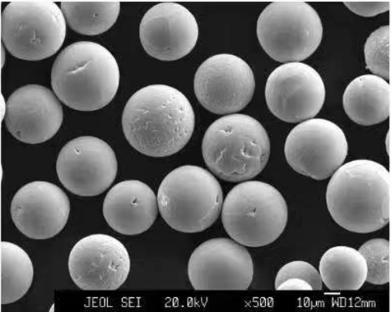

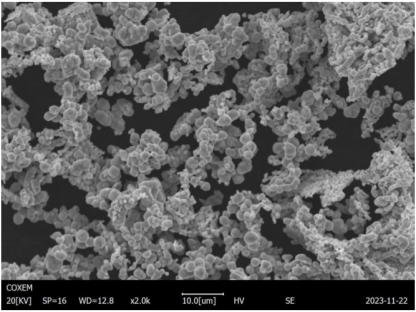

Characteristics of NiCrAIY Powder

NiCrAIY powder is prized for several important characteristics that make it ideal for high-temperature environments. These attributes are critical in applications where material degradation due to oxidation and corrosion could lead to failure.

- High Oxidation Resistance: Thanks to the aluminum and chromium content, a stable oxide layer forms on the surface of the material, protecting it from further degradation.

- Thermal Stability: NiCrAIY powders maintain their properties even at temperatures exceeding 1000°C, ensuring components don’t break down in extreme conditions.

- Corrosion Resistance: The addition of chromium enhances the material’s ability to resist corrosive environments, including those with sulfur or salt content.

- Adhesion Strength: The yttrium plays a crucial role in improving the adhesion of oxide layers, ensuring long-lasting protection.

- Versatility: NiCrAIY powders can be used in a variety of application methods, such as thermal spraying or additive manufacturing.

Applications of NiCrAIY Powder

NiCrAIY powders are employed in a range of industries where heat resistance and durability are vital. From aerospace turbines to gas turbines and even automotive exhausts, these powders ensure parts withstand extreme thermal and corrosive conditions.

| Industry | Applications | Why NiCrAIY is Used |

|---|---|---|

| Aerospace | Turbine blades, engine components | High temperature resistance, extends component life |

| Power Generation | Gas turbine coatings, steam turbines | Excellent oxidation and corrosion resistance, suitable for power plants |

| Automotive | Exhaust manifolds, turbochargers | Thermal stability in high-heat environments, resists oxidation |

| Industrial Gas | Hot gas filtration systems | Durability under high temperature and chemical attack |

| Marine | Ship engine components, exhaust systems | Corrosion resistance in saltwater environments, maintains strength in harsh conditions |

| Additive Manufacturing | Production of complex geometries in high-temperature materials | High strength and oxidation resistance, easily processed in additive manufacturing systems |

| Oil & Gas | Downhole tools, high-pressure valve components | Resistance to corrosive fluids, high mechanical strength in extreme environments |

| Energy Storage | Fuel cells, batteries | Improved thermal and chemical stability for long-term energy storage applications |

These varied applications highlight NiCrAIY’s versatility in multiple industries, particularly where long-term exposure to heat and corrosive elements is a concern.

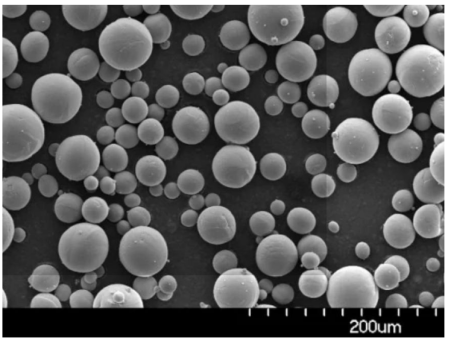

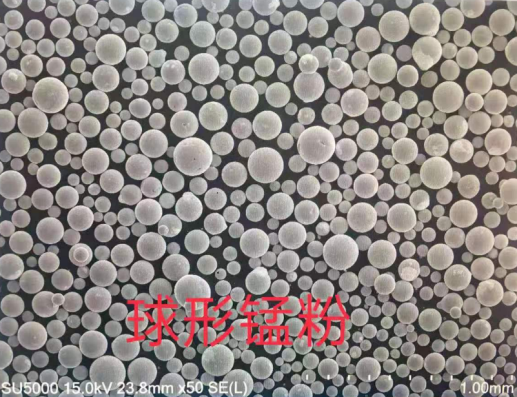

Specifications, Sizes, Grades, and Standards

NiCrAIY powders are available in a range of sizes and specifications, catering to different application methods and performance needs.

| Grade | Powder Size (µm) | Purity Level | Typical Applications | Industry Standards |

|---|---|---|---|---|

| NiCrAIY-001 | 15-45 | 99.5% | High-temperature coatings for turbines | ASTM B213, ISO 14175 |

| NiCrAIY-002 | 10-53 | 99.7% | Thermal barrier coatings, exhaust components | AMS 5597, SAE J 227 |

| NiCrAIY-003 | 20-63 | 99.6% | Additive manufacturing in aerospace | ISO 8064, ASTM E96 |

| NiCrAIY-004 | 15-50 | 99.8% | Marine applications, corrosive environments | EN 10204, DIN 17175 |

| NiCrAIY-005 | 30-90 | 99.4% | Automotive exhausts, turbochargers | AMS 4887, BS EN 10088 |

| NiCrAIY-006 | 45-125 | 99.6% | Gas turbine components, heat exchangers | ASTM E1409, ISO 4501 |

| NiCrAIY-007 | 10-45 | 99.9% | Fuel cells, energy storage systems | ASTM B964, SAE AMS 2437 |

| NiCrAIY-008 | 25-75 | 99.3% | Hot gas filtration systems | ISO 9327-2, DIN EN 14992 |

| NiCrAIY-009 | 35-85 | 99.5% | Additive manufacturing, aerospace applications | ISO 6362-2, ASTM B834 |

| NiCrAIY-010 | 45-125 | 99.7% | Marine applications, corrosion-prone areas | SAE AMS 5709, ISO 9584 |

The grade and size of the powder you choose will depend largely on the application method and the specific performance characteristics required for the final product.

Suppliers and Pricing of NiCrAIY Powder

Pricing for NiCrAIY powders can vary based on factors such as purity, particle size, and supply chain conditions. Below is a rough guide for typical suppliers and their pricing for bulk purchases.

| Supplier | Location | Price per Kg (USD) | Minimum Order Quantity (Kg) | Lead Time (Weeks) |

|---|---|---|---|---|

| ABC Powders | USA | $350 | 10 | 4 |

| Global Metalworks | Germany | $325 | 20 | 5 |

| ThermoMetals Ltd | UK | $375 | 5 | 3 |

| Mega Alloys | China | $300 | 50 | 6 |

| Nickel World | Japan | $400 | 10 | 8 |

Keep in mind that these prices are indicative and can fluctuate depending on market trends, demand, and availability of raw materials.

Advantages and Disadvantages of NiCrAIY Powder

Like any material, NiCrAIY has its pros and cons, which must be weighed when considering its use for a specific application.

| Advantages | Disadvantages |

|---|---|

| Excellent high-temperature oxidation resistance | Higher cost compared to standard coatings |

| Superior adhesion of oxide layers | Requires precise manufacturing processes |

| Suitable for multiple industrial applications | Limited availability of high-purity variants |

| Long service life in harsh environments | Complex thermal spraying methods needed |

| Enhances the performance of critical components | Potential for material contamination during processing |

FAQs

| Question | Answer |

|---|---|

| What is NiCrAIY powder used for? | NiCrAIY powder is primarily used in high-temperature environments like aerospace, power generation, and automotive sectors. |

| What does Yttrium do in NiCrAIY? | Yttrium improves the adhesion of oxide layers, enhancing the longevity of protective coatings. |

| Can NiCrAIY powder be used in 3D printing? | Yes, it’s commonly used in additive manufacturing for creating parts that withstand extreme heat and oxidation. |

| How is NiCrAIY powder applied? | It’s often applied via thermal spraying techniques like High-Velocity Oxy-Fuel (HVOF) or Plasma Spray. |

| What industries benefit most from NiCrAIY? | Aerospace, power generation, automotive, and marine industries benefit from the powder’s heat and corrosion resistance. |

| How does NiCrAIY compare to stainless steel? | NiCrAIY offers superior oxidation resistance at high temperatures compared to stainless steel, making it better for high-heat applications. |

| Is NiCrAIY powder expensive? | It can be more costly than other materials due to its composition and high-performance characteristics. |

| Can it be customized for specific needs? | Yes, the composition of NiCrAIY powder can be tailored to meet specific performance requirements. |

In conclusion, NiCrAIY powder is an indispensable material for industries that demand exceptional high-temperature performance and corrosion resistance. Its unique composition of Nickel, Chromium, Aluminum, and Yttrium provides unmatched durability, making it the go-to choice for critical applications across various industries. Whether you’re in aerospace, automotive, or energy, NiCrAIY offers the reliability and longevity needed to push the boundaries of performance.