Laser powder bed fusion process and mechanical properties of Haynes 188 (GH5188)

Haynes 188 (GH5188) is used in heavy-duty gas turbine combustors due to its balanced high-temperature performance (maximum service temperature 980°C). The mechanical properties of Haynes 188 produced by laser powder bed fusion (LPBF) have not been thoroughly studied. In this study, our engineers systematically explored the LPBF process development and mechanical properties of Haynes 188 at both room and high temperatures.

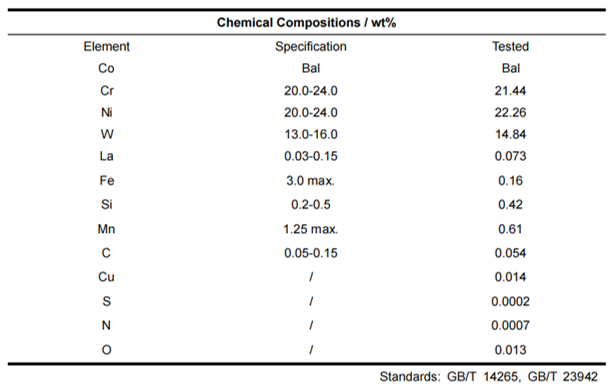

Chemical Composition of Truer Haynes 188 powder:

Samples were printed in two groups:

Group 1 consisted of 16pcs specimens with dimension 20 × 12 × 10 mm³ for densification characterization evaluation and tensile testing. The pass spacing (d) and layer thickness (h) were fixed at 70 μm and 30 μm, respectively, while the laser power (P) and scanning speed (v) were varied from 150 to 300 W and 600 to 1200 mm/s, respectively.

After determining the optimal parameters, group 2 included 90×25×14 mm³ and 35×12×18 mm³ specimens for high-temperature creep and tensile tests, respectively.

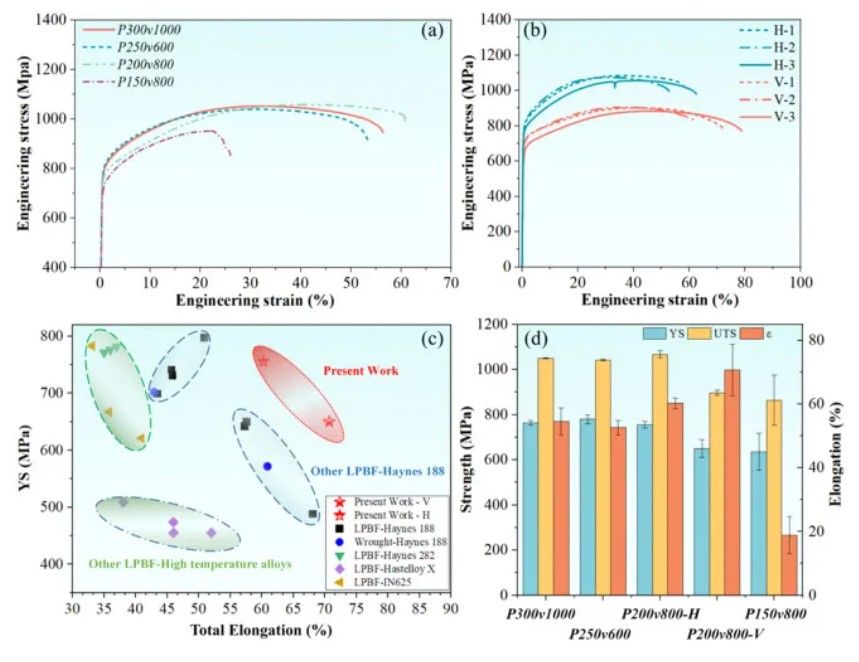

Mechanical properties at room temperature:

Anisotropy evaluation was performed on samples which exhibits excellent overall performance. Significant mechanical anisotropy was observed in the LPBF-H (horizontal) and LPBF-V (vertical) directions: the LPBF-V direction exhibited higher plasticity (elongation 70.7%) but lower strength (YS: 650 MPa, UTS: 897 MPa).

Microstructure:

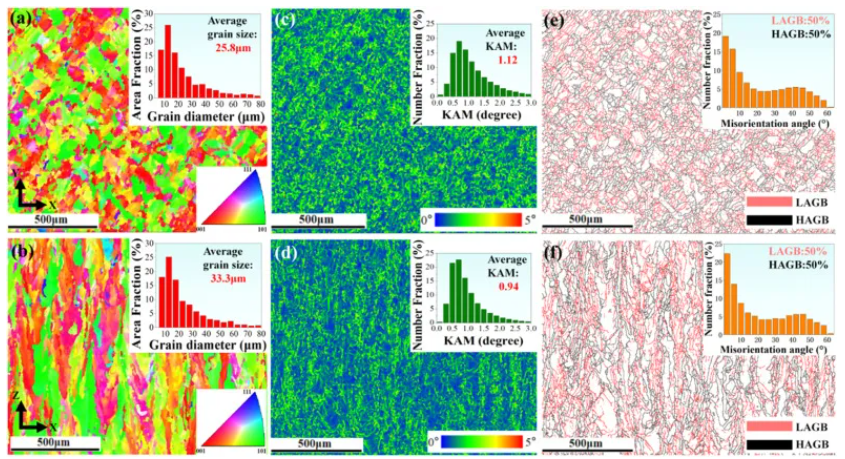

Rapid solidification during the LPBF process causes grain growth along the direction of heat flow, forming a columnar dendrite structure and leading to directional differences in material properties.

This figure reveals distinct grain morphologies at the optimal LPBF parameters. The region parallel to the build direction (BD) exhibits a mixed microstructure dominated by columnar morphology, with a moderate <001> and <101> texture. This texture arises from epitaxial growth along the melt pool boundary under high temperature gradients, with grains from the previously solidified layer acting as nucleation sites for subsequent layers.

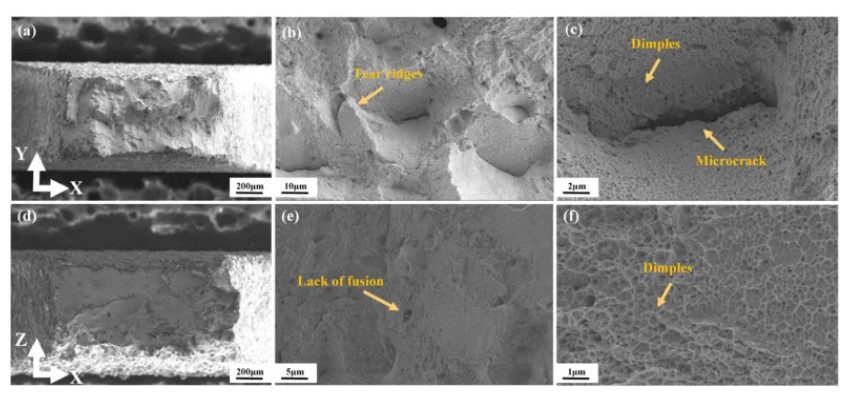

Fracture Morphology:

The fracture morphology confirms a ductile fracture mechanism, characterized by dimples and tear ridges, with occasional unfused porosity. Vertically constructed specimens exhibit larger tear ridges and irregular topography, corresponding to lower strength but higher elongation. Horizontally constructed specimens display finer, more evenly distributed dimples, indicating enhanced strength.

Mechanical properties at high temperature:

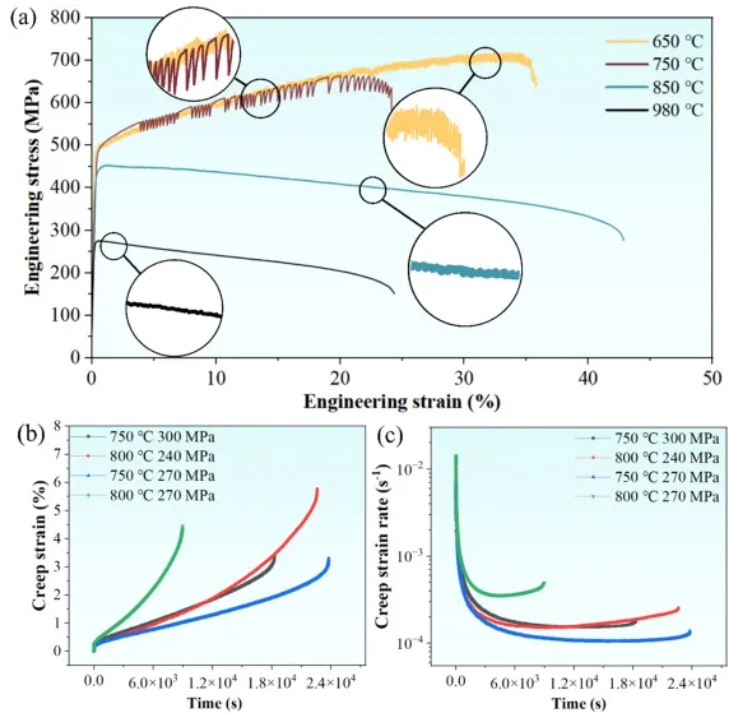

High-temperature mechanical properties were evaluated on samples prepared with optimized parameters. It was observed at 650°C exhibits type B flow behavior, characterized by rapid, small fluctuations around the mean flow stress. This behavior is attributed to repeated pinning and depinning of dislocations by solute atoms (Cr, Co, and W) via diffusion, with local bands propagating in a hopping manner along the tensile axis.

The significant improvement in elongation (75.9% at 850°C) is associated with the coarsening/dissolution of precipitates and enhanced dislocation-solute co-migration.

Although the material softens further at 980°C, it still maintains a significant yield strength of 276 MPa, indicating excellent high-temperature strength retention.

Compared to Haynes 188 prepared by conventional casting and forging processes, the LPBF-prepared Haynes 188 alloy exhibits superior mechanical properties across the entire temperature range. The as-deposited alloy maintains a yield strength of 438 MPa at 850°C, significantly higher than the 281 MPa reported in the literature, attributed to the fine microstructural control.

Conclusion:

LPBF parts of Haynes 188 achieved high room-temperature properties with a yield strength of 756 MPa, a tensile strength of 1067 MPa, and an elongation of 60.2%.

LPBF samples of Haynes 188 maintained remarkable mechanical stability at high-temperature (steady-state creep rate of 1.04×10-4 s⁻¹ at 750°C) and strength (yield strength of 276 MPa at 980°C).